P-type Doping of Silicon Nanowires

advertisement

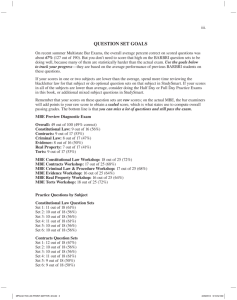

Principles and Applications of Molecular Beam Epitaxy Aaron Vallett EE 518 April 5th, 2007 Instructor: Dr. J. Ruzyllo Outline Introduction Review of epitaxial growth MBE Process Chamber construction Beam sources Characterization MBE Applications Devices R&D/Commercial Summary Introduction Invented in late 1960s at Bell Labs by J. R. Arthur and A. Y. Cho An epitaxial growth process involving one or more molecular beams of atoms or molecules physically arranging themselves on a crystalline surface under ultrahigh-vacuum conditions Growth is tightly controlled – layer compositions and thickness can be adjusted at an atomic scale Epitaxy Review Growth of thin, high quality, single-crystal layers on a similar-type crystal substrate Molecules are adsorbed on the surface Diffuse across the surface until finding a suitable crystal site Image from http://www.phys.ubbcluj.ro/~rote/Zahn/Introduction.pdf MBE Process Overview Very similar to thermal evaporation with one big difference - UHV (10-8 - 10-11 torr) Solid source materials are heated to melting point in effusion cells UHV gives source molecules a large mean free path, forming a straight beam Beam impinges on heated substrate (600°C) Incident molecules diffuse around the surface to the proper crystal sites and form crystalline layers Characterization tools allow growth to be monitored in-situ Image modified from http://projects.ece.utexas.edu/ece/mrc/groups/street_mbe/mbechapter.html MBE Chamber Stainless steel chamber and seals reduce leaks After servicing, chamber must be baked and outgassed at ~200°C for 2-5 days UHV achieved through use of cryo, Ti-sublimation and ion pumps – no oil Cryo-shroud promotes condensation of contaminants and stray particles Image from http://ocw.mit.edu/NR/rdonlyres/Electrical-Engineering-and-Computer-Science/6772Spring2003/B5D923F5-9B4C-4436-A1F1-0343B35E1928/0/lect8_part1.pdf Sample Preparation and Loading Starting substrate must be ultra clean and flat Wafer usually comes “epiready” with a protective oxide Substrate loaded in load-lock and heated for outgassing for several hours Substrate may then move to a buffer chamber and be outgassed again Growth substrate then loaded onto holder in growth chamber Protective oxide desorbed by heating substrate on the chuck in UHV Goal is to keep the chamber and sample as pure as possible Image from http://www.uwo.ca/isw/images/Mbeiiism.gif Effusion Sources and the Molecular Beam Effusion: the process where individual molecules flow through a hole without collisions Source material is heated to vapor phase Ultra-low pressure in UHV leads to molecules with mean free paths of hundreds of meters Opening in effusion cell is small – molecules travel straight out of it with no collisions, forming a beam Images from http://www.mbe-kompo.de/products/effusion/effusioncell_ome.html and http://zumbuhllab.unibas.ch/060929GufeiMBE.pdf Effusion Cell Construction A typical MBE system may feature 8 effusion cells Crucible is constructed of pyrolytic boron nitride (PBN) to withstand temperatures up to 1400°C Thermocouple must accurately measure crucible temperature Change in T of .5°C changes flux by 1% During the day flux variations of <1%, day-to-day <5% T must be controlled within a half-degree at 1000°C Images from http://www.riber.com/en/public/solidcells.htm and http://www.hlphys.jku.at/fkphys/epitaxy/mbe.html Sources seated in a cooling shroud to maintain flux and eliminate thermal crosstalk between cells Mechanical shutters in front of sources control the beam In-situ Characterization Deposition in UHV allows unique in-situ measurements to be taken RHEED – reflection-high-energy-electron-diffraction Electrons from a gun strike the growing surface at a shallow angle The crystal reflects electrons into a diffraction pattern Diffraction pattern and intensity can provide information on the state of the surface Mass spectrometry Used to measure surface and chamber composition Ionization gage Used to measure chamber pressure or molecular beam flux Images from http://www.elettra.trieste.it/experiments/beamlines/lilit/htdocs/people/luca/tesihtml/node25.html and http://www.phys.ubbcluj.ro/~rote/Zahn/Introduction.pdf MBE Abilities Deposition rate is ~ 1 μm/hr or 1 monolayer/sec Computer controlled shutter can be opened or closed in 100 mS Defect free, super abrupt, singleatom layers can be grown – only MBE allows this precision Multiple beams can impinge the surface at once to create III-V materials or dope a layer during growth AlGaAs/GaAs alternating layers 15 monolayers Images from http://www.phys.ubbcluj.ro/~rote/Zahn/Introduction.pdf and http://research.yale.edu/boulder/Boulder-2005/Lectures/Willett/boulder1.pdf Device Applications Traditionally used for very specific, commonly compoundsemiconductor, applications HBTs, MESFETs and HEMTs Quantum wells Semiconductor lasers Silicon-on-sapphire growth Also being considered for use in commercial production of SiGe MOSFETs Images from http://www.micro.uiuc.edu/mbe/laserd.htm and Thompson et. al. IEEE Trans. On Semicon. Manufacturing, Vol. 18, No.1, February 2005 MBE in Industry By nature MBE has a very low throughput If it is needed for future CMOS processing, manufacturers will install clustered MBE chambers to increase throughput Images from http://users.ece.gatech.edu/~alan/ECE6450/Lectures/ECE6450L13and14CVD%20and%20Epitaxy.pdf Summary MBE creates near-perfect crystalline layers MBE is a purely physical process, so blocking the beam can stop layer growth Slow growth time allows atomically thin and super abrupt layers to be grown Mixing of beams permits growth of compound semiconductor and doped layers MBE is a costly and time consuming technique, but its high level of precision may drive it into the commercial CMOS world References Parker, E. “Technology and Physics of Molecular Beam Epitaxy” 1985 Chang, L. and K. Ploog “Molecular Beam Epitaxy and Heterostructures” 1985 Liu, W. “Fundamentals of III-V Devices” 1999 http://www.phys.ubbcluj.ro/~rote/Zahn/Introduction.pdf http://projects.ece.utexas.edu/ece/mrc/groups/street_mbe/mbechapter.html http://www.uwo.ca/isw/images/Mbeiiism.gif http://www.mbe-kompo.de/products/effusion/effusioncell_ome.html http://zumbuhllab.unibas.ch/060929GufeiMBE.pdf http://www.riber.com/en/public/solidcells.htm http://www.hlphys.jku.at/fkphys/epitaxy/mbe.html http://www.elettra.trieste.it/experiments/beamlines/lilit/htdocs/people/luca/tesihtml/node25.html http://www.phys.ubbcluj.ro/~rote/Zahn/Introduction.pdf http://research.yale.edu/boulder/Boulder-2005/Lectures/Willett/boulder1.pdf http://www.micro.uiuc.edu/mbe/laserd.htm R M Sidek et al 2000 Semicond. Sci. Technol. 15 135-138 Thompson et. al. IEEE Trans. On Semicon. Manufacturing, Vol. 18, No.1, February 2005 http://users.ece.gatech.edu/~alan/ECE6450/Lectures/ECE6450L13and14-CVD%20and %20Epitaxy.pdf