3. Copolymers (CMS)

advertisement

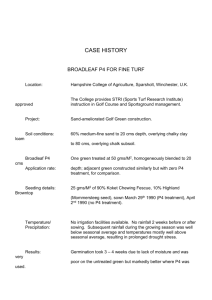

Precision Macromolecular Chemistry group (PMC) Charles Sadron Institute - UPR 22 CNRS European Engineering School of Chemistry, Polymers and Materials Science University of Strasbourg Intensification of NMP and ATRP (co)polymer syntheses by microreaction technologies Prof. Christophe A. Serra Caine Rosenfeld, Florence Bally, Dambarudhar Parida, Dhiraj Garg http://ics-cnrs.unistra.fr/caserra Atelier de Prospective du GFP, Paris, Dec. 4th, 2014 Outline 1. Context 2. Microprocess overview 3. Results Synthesis of linear, block and branched (co)polymers – Influence of micromixing – Influence of microreactor geometry – Influence of pressure CFD Analysis 4. Conclusion 2 Outline 1. Context 2. Microprocess overview 3. Results Synthesis of linear, block and branched (co)polymers – Influence of micromixing – Influence of microreactor geometry – Influence of pressure CFD Analysis 4. Conclusion 3 1. Context Motivation Synthesis of architecture-controlled (co)polymers – Block, linear or branched architectures • low PDI, defined MW – Applications in drug delivery, photoresist Two-fold strategy – Chemistry • Rely on controlled/”Living” polymerization techniques » ATRP, NMP » Intrinsically “slow” reactions – Process • Development of an intensified and integrated continuous-flow microprocess 4 Outline 1. Context 2. Microprocess overview 3. Results Synthesis of linear, block and branched (co)polymers – Influence of micromixing – Influence of microreactor geometry – Influence of pressure CFD Analysis 4. Conclusion 5 2. Overview Polymerization microprocess Synthesis (CMS) Monomer A Solvent Initiator Pump µreactor 1 µmixer Monomer B µreactor 2 Copolymer Pump Rosenfeld et al., React. Eng., 1 (5) (2007) 547-552; Bally et al., React. Eng., 5 (11-12) (2011) 542–547 6 2. Overview Polymerization microprocess Synthesis (CMS) Monomer A Solvent Pump Initiator µreactor 1 µmixer Monomer B µreactor 2 Copolymer Pump Analysis (COA) Solvent Eluate Injection RI GPC Column Viscosimeter UV LSD ELSD Dilution Waste Train of detectors Rosenfeld et al., React. Eng., 1 (5) (2007) 547-552; Bally et al., React. Eng., 5 (11-12) (2011) 542–547 7 2. Overview Polymerization microprocess Synthesis (CMS) Monomer A Solvent Pump Initiator Recovery (IPR) µmixer Monomer B nanoparticles solvent µreactor 1 µreactor 2 µmixer Copolymer µmixer Non solvent Pump Analysis (COA) Solvent Eluate Injection RI GPC Column Viscosimeter UV LSD ELSD Dilution Waste Train of detectors Rosenfeld et al., React. Eng., 1 (5) (2007) 547-552; Bally et al., React. Eng., 5 (11-12) (2011) 542–547 8 2. Synthesis (CMS) Continuous-microflow synthesis unit To COA 9 2. Synthesis (CMS) Microreactors Microtubular reactors (ID 876 µm) – Coiled tube (CT) 10 2. Synthesis (CMS) Microreactors (cont’d) Microtubular reactors (ID 876 µm) – Coiled tube (CT) End of the helix – Coil flow inverter (CFI) • Better mixing • Lower RTD After bend 1st Inlet A.K. Saxena and K.D.P. Nigam, AIChE J., 1984, 30, 363-368 After 2nd bend 11 2. Microprocess features Screening Operating conditions – Flow rate, temperature, pressure, residence time, monomer concentration Polymerization methods – FRP, CRP (NMP, ATRP, RAFT) Rapid measurements Analysis every 12 minutes Libraries Homopolymers Copolymers 12 2. Microprocess features Fully automated Software controlled Over night experiments – Pressure sensors – Temperature probes Modular New reaction blocks New detectors – Raman – NIR Inline polymer recovery Colloidal suspension 13 Outline 1. Context 2. Microprocess overview 3. Results Synthesis of linear, block and branched (co)polymers – Influence of micromixing – Influence of microreactor geometry – Influence of pressure CFD Analysis 4. Conclusion 14 3. Copolymers (CMS) Continuous one-step statistical copolymerization Atom Transfer Radical Polymerization (ATRP) – Librairies of poly(DMAEMA-BzMA) / Influence of micromixer 15 3. Copolymers (CMS) Continuous one-step statistical copolymerization Continuous-flow setup Nitrogen generator Solvent Catalyst Ligand Monomer Comonomer Initiator HPLC Pump HPLC Pump Micromixer P Pressure sensor Microreactor T Temperature Regulator 75°C Online GPC Analysis (CORSEMP) Waste NMR Analysis 16 3. Copolymers (CMS) Continuous one-step statistical copolymerization (cont’d) Micromixers Micromixers Name Principle Number of channels/ Inlet TJunction Bilamination 1 450 micron HPIMM Digital Multilamination 15 45 micron KM CC-2 Impact mixing 5 100 micron Parida et al., Green. Proc. Synt., 6 (1) (2012) 525-532 Channel width 17 3. Copolymers (CMS) Continuous one-step statistical copolymerization (cont’d) 100 Conversion % 90 80 70 60 +35% 50 40 30 20 10 0 0 50 100 150 200 250 Time in minute Batch 20% T-Junc 20% HPIMM 20% Parida et al., Green. Proc. Synt., 6 (1) (2012) 525-532 KM 20% 18 3. Copolymers (CMS) Continuous one-step statistical copolymerization (cont’d) 25000 20000 +6,000 Mn 15000 10000 -50% 5000 0 0 50 100 150 200 250 Time in min. Batch 20% T-Junc. 20% HPIMM 20% Parida et al., Green. Proc. Synt., 6 (1) (2012) 525-532 KM 20% 19 3. Copolymers (CMS) Continuous one-step statistical copolymerization (cont’d) 2.2 a PDI 1.9 1.6 1.3 Batch T-J HPIMM KM 1 0 5000 10000 15000 20000 25000 X100 Mn (g/mol) Parida et al., Green. Proc. Synt., 6 (1) (2012) 525-532 20 3. Copolymers (CMS) Continuous two-step block copolymerization PBA-b-PS Nitroxide-Mediated Polymerization (NMP) – PBA-b-PS with low polydispersity index (PDI) • Mixing between viscous and liquid fluids by means of microstructured mixers 1) Homopolymerization 2) Block copolymerization 1st monomer Pump 1 Solvent Initiator Pump 2 1st block T1 1 Micromixer 2nd monomer (solvent) T2 2 Copolymer Microtube reactor (µR1) Microtube reactor (µR2) 900 µm ID / 2.9 m length 900 µm ID / 5.7 m length 21 3. Copolymers (CMS) Micromixers Fluid B Fluid B Fluid A Fluid A Fluid B Fluid A Mixing by … Bilamination Multilamination Multilamination CF ML45 ML20 ML50 Number of microchannels 1 16 15 10 Film thickness 450µm 45µm 20µm 50µm 22 3. Copolymers (CMS) Sorting by form factor (F) Multilamination Bilamination R Re ρVD h 2 πR Dh ( 2) Re CF h w 2 w h Dh (w h) ρ Q η R π 2 Re ML F ρ 2Q η n w h 2 R (π 2) n(w h) 23 3. Copolymers (CMS) Micromixers Fluid B Fluid B Fluid A Fluid A Fluid B Fluid A Mixing by … Bilamination Multilamination Multilamination CF ML45 ML20 ML50 Number of microchannels 1 16 15 10 Film thickness 450µm 45µm 20µm 50µm F 1 2.8 3.9 4.6 24 3. Copolymers (CMS) Continuous two-step block copolymerization (cont’d) 1st block Microtube Batch T1 = 140°C 1 = 190 min - 3:1 vol. BA/Toluene - "High" [AX]0 Not purified - 5% mol. free TIPNO - 2 equiv. Acetic BA Conversion (%) 91 95 Theoretical Mn (g/mol) 33600 34900 Experimental Mn (g/mol) 26600 29700 PDI 1.44 1.80 Rosenfeld et al., Chem. Eng. Sci., 62 (2007) 5245-5250. anhydride 25 3. Copolymers (CMS) Continuous two-step block copolymerization (cont’d) Copolymer Batch process Continuous process T2 = 125°C 2 = 190 min Not purified ML50 BA/S Conversions ML20 CF BR 93% / 44% 96% / 50% 99% / 36% 99% / 50% Th. Mn (g/mol) 37100 40100 37800 43300 Exp. Mn (g/mol) 34700 36600 26600 33600 PDI 1.28 1.40 1.73 1.74 (1H NMR) (PS equiv.) Rosenfeld et al., Chem. Eng. J., 15 (S1) (2008) S242-S246 26 3. Copolymers (CMS) Continuous two-step block copolymerization (cont’d) Influence of the micromixer geometry 2 - Most efficient micromixer tested: wider and fewer microchannels ML20 Mainly controlled by the velocity CF 1.8 PDI Ip Q2=9.3 µL/min ML45 1.6 1.4 ML50 1.2 0.5 1.5 2.5 Re' F 3.5 4.5 Rosenfeld et al., Lab. Chip., 8 (2008) 1682-1687 5.5 27 Outline 1. Context 2. Microprocess overview 3. Results Synthesis of linear, block and branched (co)polymers – Influence of micromixing – Influence of microreactor geometry – Influence of pressure CFD Analysis 4. Conclusion 28 3. Microreactor geometry (CMS) PDI Recall one-step statistical copolymerization in CT 5000 10000 15000 Mn 20000 25000 Microreactor with internal mixing to overcome diffusion limitations 29 3. Microreactor geometry (CMS) Linear polymers Atom Transfer Radical Polymerization (ATRP) – Librairies of poly(DMAEMA) / CT vs. CFI Nitrogen generator Solvent Catalyst Ligand Monomer Comonomer Initiator HPLC Pump HPLC Pump Micromixer P Pressure sensor Microreactor Online GPC Analysis (CORSEMP) T Temperature Regulator Waste NMR Analysis 30 3. Microreactor geometry (CMS) Linear polymers (cont’d) ID= 876 µm Conversion (%) 80 60 CT, 3 m 40 20 CT CFI 0 0 30 60 90 120 CFI, 3 m Time (min.) No significant increase in conversion between CT and CFI Parida et al., Macromolecules, 47 (10) (2014) 3282–3287. 31 3. Microreactor geometry (CMS) 25000 2 20000 1.8 15000 1.6 10000 ID= 876 µm PDI Mn (g/mol) Linear polymers (cont’d) CT, 3 m 1.4 5000 CT 1.2 CFI 0 1 0 20 40 60 80 Conversion (%) CFI, 3 m Mn is higher in case of CFI (avg. +2000 g/mol) Significant reduction in PDI for CFI (-0.13) Parida et al., Macromolecules, 47 (10) (2014) 3282–3287. 32 3. Microreactor geometry (CMS) RTD measurements 1,4E-03 1,2E-03 1,0E-03 E(t) 8,0E-04 6,0E-04 4,0E-04 2,0E-04 0,0E+00 0 50 100 150 200 t(min) Reactor Variance (s²) Pe (-) Dax (m²/s) CT 605 286 2.5 x 10-5 CFI 322 1004 7.14 x 10-6 RTD is narrower in CFI compared to CT High Pe in case of both reactors indicates low axial dispersion Parida et al., Macromolecules, 47 (10) (2014) 3282–3287. 33 3. Microreactor geometry (CMS) Branched polymers Self-Condensing vinyl coPolymerization, adapted to ATRP Inimer = Monomer + Initiator m a- b 2-(2-bromoisobutyryloxy)ethyl methacrylate (BIEM) Matyjaszewskiet al., Macromolecules 1997, 30, 5192 34 3. Microreactor geometry (CMS) Branched polymers (cont’d) 35 3. Microreactor geometry (CMS) Branched polymers (cont’d) DMAEMA and BIEM conversions Inimer Conversion (%) 80 + 7.5% 60 40 Batch 20 CT CFI 0 0 30 60 90 120 Time (min.) Higher BIEM conversion for CFI Parida et al., Macromolecules, 47 (10) (2014) 3282–3287. 36 3. Microreactor geometry (CMS) Branched polymers (cont’d) GPC traces – Batch reactor Presence of BIEM-initiated macromonomers/oligomers Parida et al., Macromolecules, 47 (10) (2014) 3282–3287. 37 3. Microreactor geometry (CMS) Branched polymers (cont’d) GPC traces (2 hrs) 10 % Normalized Intensity (a.u.) Normalised Intensity (a.u.) 5% Batch 6 CT Batch CFI 7 8 Elution time (min.) 9 6 CT 7 8 Elution time (min.) CFI 9 Highest oligomeric units in batch Lowest in CFI Parida et al., Macromolecules, 47 (10) (2014) 3282–3287. 38 3. Microreactor geometry (CMS) Branched polymers (cont’d) Polymer characteristics (BIEM 5mol% @ 2 hrs) 3 3500 +700 2.5 2500 PDI Mn (g/mol) 3000 2000 -0.28 2 Batch 1500 CT CFI 1000 1.5 0 20 40 60 80 100 120 Time (min.) Mn exhibits the following trend: batch < CT < CFI PDI follows the opposite trend: batch > CT > CFI Parida et al., Macromolecules, 47 (10) (20141)3282–3287 39 3. Microreactor geometry (CMS) Branched polymers (cont’d) Impact of flow inversion on molecular characteristics Highest branching efficiency in CFI and lowest in batch Controlled branched structure in microreactors especially in CFI Parida et al., Macromolecules, 47 (10) (20141)3282–3287 40 Outline 1. Context 2. Microprocess overview 3. Results Synthesis of linear, block and branched (co)polymers – – – – Influence of micromixing Influence of microreactor geometry Influence of pressure Scale-up CFD Analysis 4. Conclusion 41 3. Operating parameters (CMS) Effect of pressure Chemical system 42 3. Pressure (CMS) Effect of pressure Procedure 43 3. Pressure (CMS) Effect of pressure (cont’d) Polymer characteristics 80 25000 20000 40 20 1 Bar 50 Bar 0 0 20 40 60 1.4 15000 1.3 10000 PDI 60 Mn (g/mol) Conversion (%) 1.5 1.2 5000 1.1 1 Bar 50 Bar 0 1 0 20 Time (minute) 40 60 80 Conversion (%) Decrease in activation volume Reduced termination Increased density, thus increased residence time Parida et al., J. Flow Chem., 4 (2) (2014) 92-96. 44 3. Pressure (CMS) Effect of pressure (cont’d) Microreactor dimension 576 µm 876 µm 1753 µm Parida et al., J. Flow Chem., 4 (2) (2014) 92-96. 45 3. Pressure (CMS) Effect of pressure (cont’d) Microreactor dimension Reduced diffusion distance Parida et al., J. Flow Chem., 4 (2) (2014) 92-96. 46 Outline 1. Context 2. Microprocess overview 3. Results Synthesis of linear, block and branched (co)polymers – – – – Influence of micromixing Influence of microreactor geometry Influence of pressure Scale-up CFD Analysis 4. Conclusion 47 Inlet 48 Inlet Outlet 49 Inlet Outlet 50 Inlet Position of two tracer particles 51 Outline 1. Context 2. Microprocess overview 3. Results Synthesis of linear, block and branched (co)polymers – Influence of micromixing – Influence of microreactor geometry – Influence of pressure CFD Analysis 4. Conclusion 52 4. Conclusion NMP and ATRP processes can be intensified Higher monomer conversion Higher MW Narrower MWD (lower PDI) Better controlled architecture (higher branching rates) Microreactors and micromixers Efficient intensification tools New operating windows (Higher P, Higher T) CFI – A chaotic mixer/reactor • Better internal mixing • Narrower RTD – Smaller foot print than ST 53 4. Acknowledgements Faculty Students – – – – – – – – – – – – – – – – N. Sary M. Quentin N. Berton C. Rosenfeld E. Godard B. Reynard A. Filliung J. Quillé C. Zhang S. Trotzier F. Bally C. Kister A. Ali P. Gonzales D.K. Garg D. Parida – – – – Collaborators C. Brochon M. Bouquey R. Muller G. Hadziioannou Staff – – – – – – T. J. C. C. C. C. Djekrif Quillé / S. Gallet Mélart Ngov Sutter Kientz – – – T. Vandamme & N. Anton (CAMB) K. Nigam (IIT Dehli) Y. Hoarau (IMFS) Industrial partners – – S. O’Donohue (PL) V. Hessel (IMM) Financial support EAc 4379 « Ponts Couverts » in Strasbourg 54 Thank you for your attention 55 Increasing throughput Polymer in solution 8 microtube reactors in parallel for the production of to 4 kg per week of PMMA Yoshida and coll., Org. Process Res. Dev., 10 (2006) 1126-1131 56