Indian Oil Raw Materials for Geotech by Mr. P. Shyam Kumar, PADC

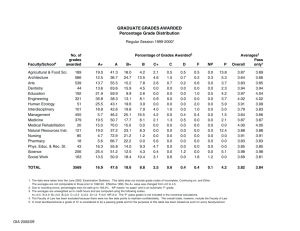

advertisement

PROPEL 1030RG PROPEL 1120YG Raw Materials For Geotech PROPEL 1250YG PROPEL 1350YG By P.SHYAM KUMAR PADC, Panipat Ministry of Textile-FICCI Conference,FICCI ,New Delhi 19th Nov 2010 Content Company Profile IOCL in Petrochemicals Polymer Plants & Technology Geosynthetics & Applications Raw Materials Technical Support Customer’s benefits & Opportunities Company Profile Indian Oil - An Overview Diversified, Transnational, Integrated energy company Fortune 500 Global company, ranked at 105th position in 2009 18th largest petroleum company in the World Sales turnover in 2008 – 09 : 2,85,337 Cr (US $ 63 bn) Indian Oil An Overview 3 overseas subsidiaries in SL, Mauritius & Dubai Refinery Pipelines Owns 10 out of 19 Refineries in India Refining Capacity – 60.20 MMTPA R&D Country’s largest network of nearly 10,000 KM. Marketing 17,600 RO’s, 5000 LPG Distributors, 101 AFSs, 90 Bottling Plants, 200 Bulk storage terminals & depots 2100 Lube formulations 140 Patents Business Development Bio-fuels & Gas Marketing Prod & Marketing : LAB, PTA & Polymers Indian Oil in PETROCHEMICALS Indian Oil in Petrochemicals Linear Alkyl Benzene at Gujarat Refinery Capacity – 120 TMT LAB, UOP Detal Process Project Cost - Rs 1200 crore Commissioned August 2004 Successfully operating at over 100% capacity PX/PTA at Panipat Capacity 553 TMT PTA (Invista T 10 Technology)/ 370 TMT PX, UOP Technology Project Cost – Rs. 5000 crore Commissioned June 2006 Successfully Operating at 100% capacity Naptha Cracker & Downstream Polymer at Panipat Product : LLDPE, HDPE, PP,MEG, Benzene Capex : Rs. 14000 Cr. Commissioned April 2010 Polymer Plants & Technology IOCL Polymer Plants & Technology Sr. No Plant 1 Polypropylene 2 300 Spheripol – Basell 2 Dedicated HDPE 1 300 Hostalen – Basell 3 HDPE / LLDPE Swing 1 350 Sclairtech - Nova Polypropylene Plant Spheripol No. of Lines Capacity per Line (KTA) Dedicated HDPE Plant Technology/ Licensor Swing Plant Hostalen “With 1.25 Million MT capacity, IOCL will be the second largest Polyolefin producer in India” Sclairtech Spheripol Technology : Process Capability Polypropylene • MFR: 0.3 - > 1600 g/10min • Xylene Insoluble: 90 – 99 (wt)% • Flexural Modulus 500 – 2200 MPa • Izod Impact Strength up to 750 J/m • SIT in RACO as low as 115°C • MP 130 - 165 ° C Site Photo : Spheripol Line of IOCL, Panipat Global PP Capacity – 48 MMTA Global PP Consumption – 46.5 MMTA Spheripol Technology Share : 45% (100 lines) Hostalen Technology : Process capability Site Photo : Hostalen Line of IOCL, Panipat Dedicated HDPE • Product Density - 0.94 – 0.965 gm/cc • MFR - 2.2 (I21) to 60.0 (I5) dg/min • Conversion rate up to 99.5 % for Ethylene. • Excellent Quality & Product consistency. • Bimodal grades. Global HDPE Capacity – 33 MMTA Global Consumption – 30.3 MMTA 7 MMTA of HDPE Produced by Hostalen Technology (36 lines) Sclairtech Technology : Process Capability Site Photo : Sclairtech Line of IOCL, Panipat Swing Unit (HD/LLDPE) • Density – 0.905-0.965gm/cc • MFI – 0.3 – 150 gm/10min • High ethylene conversion > 98% • Short residence time in the reactor • Low gel level, lot-to-lot consistency • Capability to produce C4, C8 & terpolymers Global PE Capacity – 77 MMTA Global PE Consumption – 73.1 MMTA Sclairtech Capacity : 3.5 MMTA (11 lines) IOCL Polymer Grade Portfolio Polyethylene • LLDPE – 11 Grades – 0.9 MFI to 50 MFI (Butene & Octene) • HDPE - 22 Grades – 0.1 MFI to 18 MFI (Unimodal & Bimodal) All PE Grades will meet the requirements of IS : 10146-1982 for food contact applications, IS:10141-1982 positive list of constituents & US FDA: CFR Title 21,177.1520 Polypropylene • Homo Polymer – 14 Grades – 2 MFI to 35 MFI • Random Copolymers – 5 Grades - 1.8 MFI to 45 MFI (Clarified & GP) • Impact Copolymers – 8 Grades – 3 MFI to 50 MFI (Medium to Super high Impact) All PP Grades will meet the requirements of IS : 10910 for food contact applications, IS:10909 positive list of constituents & US FDA: CFR Title 21,177.1520 Geosynthetics & Applications Geosynthetics Family Geosynthetics Geogrids (Woven) , Georopes, Geonets, Geocomposites, Geocells, PVDs(PP) etc Geotextiles NonWoven Woven Multi Filament Slit Tape Needle Punched Indian Scenario Potential - 25KTA Imports - 53% Suppliers - 12 Spun Bond Global Trend in Geosynthetics 10 19 USA EU 51 AUS China India 5 Other Asians 14 ~250KTA Applications & Functions Application Areas Roads (NHAI & NRRDA) Railways Ports & Airports Coastal Protection Ground Improvement Functions Separation Reinforcement Filtration & Drainage Containment (barrier) Protection Raw Materials for Geosynthetics Raw Materials for Geosynthetics PP Advantages Polymers Used PP ≈ 85 % Lower density and MP PET ≈ 12 % Low Cost PE ≈ 2 % Availability Nylon ≈ 1 % Polymer yarn used Good balance of properties IOCL PP -Woven Grades for Geotech Grade and Performance Attributes Good processability Good balance of tenacity & elongation. PROPEL 1030RG MFI- 3 (g/10min) Consistency in MFI gives excellent thickness control Tailored additive package for lower water carryover Grades are designed to give tenacity > 5gpd and elongation ~20% Isotactic Index > 95%,with FM >1450MPa IOCL PP – F &F Grades for Geotech Grades and Performance Attributes PROPEL 1120YG Consistent medium to high melt flow MFI- 12 (g/10min) Narrow to medium molecular weight distribution Tailored additive package PROPEL 1250YG High purity MFI- 25 (g/10min) Low oligomer content Tenacity of 2.5 - 4 g/den PROPEL 1350YG % Elongation at break of 70 - 100 MFI- 35 (g/10min) Exhibits higher tenacity on industrial scale Technical Support Product Application & Development Centre - PADC PADC is being set up at Panipat (Haryana) near Panipat Naphtha cracker Project (PNCP). New Grade development New Application Knowledge development Management Marketing PADC Technical Customer Support to Relation Customers Management PADC PLANT Customers State of Art Technology Centre with sophisticated Plastic PADC is an interface between Plant, Processing & Characterisation equipments Marketing & Customers Customer Benefits with IOCL Entry • Ample raw material availability with IOCL entry • Wider PP product portfolio due to 2 Spheripol lines. • Plants incorporating latest developments & most sophisticated control systems for superior lot to lot consistency. • Sizable plant capacities will help in stream-lining supply & pricing fluctuations which are frequently experienced in Indian market. • IT Enablement – E Commerce module – Transparency and ease of transaction • 1st PP plant in Northern region, which is 2nd largest consumption region in India – Northern Region has potential to be largest region • Business opportunity with company trusted by Indians for over 50 years. “Let’s work together for nurturing a long term business relation” Thank you Back - Up Panipat Naphtha Cracker Complex (PNCC) Feedstock 2.3 MMTPA Naphtha • Ethylene- 857 KTA • Propylene – 650 KTA • Butadiene – 130 KTA • Benzene – 130 KTA • MEG 325 KTA Naphtha Cracker Unit Technology : ABB Lummus • 650 KTA PE and 600 KTA PP IOCL PP : Product Attributes Bimodal Grades Lot-to-lot consistency Product benchmarked in over 100 countries Low Ash Content Low Odour Compliance to FDA Excellent Organoleptic Properties High Isotactic Index in PPHP Excellent Processability & High Tenacity High Clarity of PPRCP Grades Low Seal Temp. Grades High Yield High Selectivity Catalyst High Ethylene Content ICPs Excellent Extrusion Coating grades Broad MFR Range Reactor Grades up to 100 MI IOCL PP : Product Envelope HOMO POLYMER CO POLYMER ICP IM (GP/FURNITURE/BATTERY/AUTO) RCP GP EX RCP ISBM RCP EBM RCP GP IM GP IM RCP TWIM TWIM RAFFIA BOPP CPP TQPP F&F EBM 1 NON WOVEN 10 Technology :Spheripol Licensor : Basell 100 MFI (g/10min) Plant capacity : 2 lines of 300 KTA each Product ICP TWIM ICP EC : Polypropylene (Homo/RCP/ICP) IOCL Homo Polymer IOCL RCP IOCL ICP IOCL HDPE (Hostalen Plant) : Product Attributes 0.940 – 0.965 g/cc up to 60 (I5) dg/min Excellent Dart Impact & Sealing Properties in Film Grades High Flow, High Gloss & Low warpage Injection Moulding Grades Good balance of ESCR, Stiffness & impact properties in blow moulding grades Excellent combination of processability & final product performance in bimodal grades Good processability & low water carry over in Raffia Grades Bimodal Pipe grades complying PE63, PE80 & PE100 Requirements IOCL HDPE (Hostalen Plant) : Product Envelope 0.97 LARGE CONTAINERS TAPES & MONOFILAMENT Density (g/cc) 0.96 * INJECTION MOULDING* 0.95 SMALL BOTTLES PIPES HM FILM 0.94 0.93 0.10 0.22 Technology : Hostalen Licensor : Basell Capacity : 300 KTA Product : HDPE 0.28 1.00 1.20 MFI (g/10 min) 2.00 18.0 MFI I5 (g/10 min) * MFI I (g/10 min) 2 IOCL PE (Swing Plant) : Product Envelope 100 MFI (g/10 min) LL IM 10 HD IM EX. COATING ROTO MOLDING LL FILM RAFFIA 1 W&C PIPE COATING 0.1 0.91 0.92 0.93 0.94 Density (g/cc) Technology :Sclairtech Licensor : Nova Chemicals Plant capacity : 350 KTA Product : LLDPE/ HDPE PIPE/ PIPE COATING/ HD FILM/ BM 0.95 0.96 IOCL GRADE 0.97 IOCL HDPE (Swing Plant) : Product Attributes Road Map Objective: To demonstrate Polyolefin Geosynthetics as an essential and important material for roads and infrastructure projects for for long lasting performance and cost benefits. Break up of Activities Interactions with Nodal Agencies – On going • Civil Bodies (MOSRTH,NHAI,NRRDA,FICCI & PWD’s / R&B’s • Testing Bodies (CRRI, IIT’s /IISC,BTRA & ITC) • Accreditation & Approval Bodies (IRC,RDSO & BIS) Interactions with Consultants/Manufactures – On going • Techfab, Garware, Maccaferi &Gayatri • BCH,Terram & Polyfelt Interactions with Turnkey Contractors -Planned • NHAI Approved Contractors • NRRDA ,PWD’s & R&B’s Contractors Promotional Tools & Ways – Under Preparation • Presentations ,Testimonials & Case studies • Provide inputs on Projects, Guide lines & Tenders • CRM with above all agencies IOCL PE (Swing Plant) : Product Envelope Types Denier Functions Tapes 1650 -1700 Reinforcement, Embankment, Separation FDY 840x1200 Reinforcement, Embankment, Separation Staple Fiber 3 Filtration, Separation Typical PP Woven Geotextiles Property Sample 1 Sample 2 Sample 3 Mass per unit area [gsm] 250 220 180 Thickness [mm] 3.0 2.5 1.8 Apparent Opening Size [mm] 0.60 0.60 0.60 Grab tensile strength [kN] 3.0 2.5 2.0 Warp 90 70 55 Weft 85 65 50 Trapezoidal tear strength [kN] 1.5 1.2 0.75 Puncture resistance [kN] 0.90 0.75 0.60 Wide with tensile strength [kN/m] UV resistance [ % 500 hr exposure] 50 - 70 Samples Wide width tensile Mass per strength [kN/m] unit area [gsm] Warp Weft Sample 1 90 85 250 Sample 2 70 65 Sample 3 55 50 50 -70 Thickness [mm] 50 - 70 Thread count [per inch] Warp Weft 3.0 20 18 220 2.5 15 14 180 1.8 12 11 Specifications for Polypropylene Woven Geotextiles for use in Road/ Pavement Reinforcement Sr. No 1 2 3 4 5 6 7 8 9 10 11 12 Particulars Material EOS Sp.gravity Weight in Grms per sq.mtr Thickness in MM Breaking strength (5cm x 20 cm strip) (IS:1969-LATEST ADITION) Warp way (kgs) Weftway (kgs) Elongation (IS:1969-LATEST ADITION) warp way weft way Grab strength (3"x1" strip) (ASTM D1682) warpway (kgs) weftway (kgs) Elongation % (grab test) (ASTM D1682) Warpway Weftway Tear strength (single) (ASTM D1682) warpway (kgs) weftway (kgs) Water permeability(litres/cm/sq mtr) at 10 cm.water head width of fabric Values 100%-polypropylene as per site 0.91 >210 >0.59 >215 >155 <36 <33 >182 >130 <36 <33 >41 >44 >10 >2.0 mtrs Non-Woven Geotextile standards S.No Property Test Method Values 1 Polymer PP/PE/PET/Polyamide 2 Mass/Area IS: 14716 / ASTM D: 3776 250 GSM minimum 3 Thickness at 2 Kpa ASTM: 5199 2 mm (minimum) 4 Roll width 5.0 metre (minimum) 5 Roll Length 50 m (minimum) Mechanical Properties 1 Tensile Strength IS: 13162 / ASTM D 4595 / EN ISO: 10319 40kN/m (Minimum) 2 Elongation at Break IS: 13162 / ASTM D 4595 / EN ISO: 10319 40 % - 70% Hydraulic Properties 1 Apparent opening size O95 IS 14294 / ASTM D: 4751 / EN ISO: 12956 40 – 85 microns 2 Water Flow Rate the Plane IS: 14324/ ASTM D: 4491 20 lit. /m2/s (minimum) Woven Geotextile standards S.N o Property Test Method Values 1 2 Polymer Mass/Area PP/PE/PET/Polyamide IS: 14716 / 100GSM minimum ASTM D: 3776 3 4 Thickness at 2 Kpa Roll width ASTM: 5199 5.0 metre (minimum) 5 Roll Length 50 m (minimum) 1 TS at Warp TS at Weft Mechanical Properties IS: 1969 / 40kN/m (Minimum) ASTM D 4595 / 35kN/m (Minimum) EN ISO: 10319 2 Elongation at Warp Elongation at Warp IS: 1969 / ASTM D 4595 / EN ISO: 10319 3 Puncture Strength Puncture Strength IS: 13162 / ASTM D: 4833 1 Apparent opening size O95 2 Water Flow Rate the Plane 0.65 mm (minimum) 15%-30 % 15%-30 % 600 N (Minimum) Hydraulic Properties IS 14294 / 425 microns ASTM D: 4751 / (maximum) EN ISO: 12956 IS: 14324/ ASTM D: 4491 15 lit. /m2/s (minimum) IOCL PE (Swing Plant) : Product Envelope Needle – Punched Woven monofilament Multifilament Slit Film Calendared (Tape x Tape) Thermal Bonded