BioHorizons_MidtermPP_Fall06

BioHorizons Fatigue Test System

Corp 3

Midterm Concepts Presentation

Team Members

Jonathan Hill

John Maddox

Allen Lindsay

Crichton Neal

Chris Howell

Felicia Craig

Bradley Johnson

Project Overview

General Specification

ISO Standards

Primary Concept

•

•

• Solid Edge

Advantages/Disadvantages

Water Bath

• Economic Analysis

Secondary Concept

Phase II

Specifications and Constraints

General Constraints

small and light enough to operate on a tabletop

clean and quiet enough to operate indoors at the

BioHorizons offices

Able to perform fatigue tests as well as static load tests

Control system and sensors must measure failure load and cycles to failure and discontinue operation at this point

Entire system must be able to be calibrated accurately enough for continuous operation within ISO 14801 specifications and constraints

Economic Constraints

to produce a fatigue testing machine that can be reproduced and used for less than it currently costs to have the dental implants tested from an outside company

ISO Standards

ISO provides more specific specifications and constraints in ISO

14801 —Dentistry—Fatigue test for endosseous dental implants

Several of the more pertinent specifiations are covered below, obtained from the ISO document:

The testing machine should be capable of applying the specified load with an error not exceeding ± 5% at maximum load.

The endosseous dental implant shall be clamped such that it makes a 30 ° ± 1° angle with the loading direction of the testing machine.

The device shall clamp the specimen at a distance 3.0 mm ±

0.1 mm apically from the nominal bone level as specified in the manufacturer’s instruction for use.

ISO Standards (continued)

More constraints and specifications:

The dimensions of the loading member shall be chosen to define a distance l = 11.0 mm ± 0.1 mm from the centre of the hemisphere to the clamping plane.

For endosseous dental implants that include materials in which corrosion fatigue has been reported or is expected to occur…testing shall be carried out in water of Grade 2 according to ISO 3696, in normal saline [.09%]* or in physiologic medium. The fluid and the test specimen shall be kept at 37 °C ± 2°C during the testing.

Fatigue testing shall be carried out with a unidirectional load.

The load shall vary sinusoidally between a nominal peak value and 10 % of this value . The loading frequency shall be ≤ 15 Hz . Testing in liquid media shall be conducted at frequencies ≤ 2 Hz .

*As specified by BioHorizons

Other Applicable ISO Standards

ISO 1099 : Metallic materials —Fatigue testing—Axial force controlled method

ISO 1942-1 : Dental vocabulary —Part 1: General and clinical terms

ISO 3696 : Water for analytical laboratory use —Specification and test methods

ISO 4965 : Axial load fatigue testing machines —Dynamic force calibration —Strain gauge technique

ISO 7500-1 : Metallic materials —Verification of static uniaxial testing machines —Part 1: Tension/compression testing machines —Verification and calibration of the forcemeasuring system

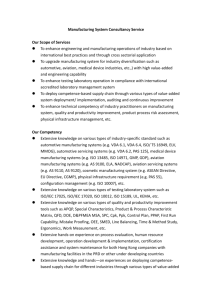

Concept Overview

Different Views

Exploded View

Temperature

Sensor

Exploded View

Liquid Bath

Container

(Pyrex)

Frame (steel)

Washer

(Rubber)

Container Base

Thumb Screw

Insert (will be tapped to hold test piece)

Linear

Motor/Load

Cell

Base (steel)

Mounting Screws

Advantages

Long life

Excellent precision and reliability

Ease in varying load and frequency

Low maintenance

Easy setup

Small number of parts

Conduct static and fatigue tests without changing setup

Disadvantages

Initial costs are high

Replacement parts would be high

Possible motor cooling may need to be addressed

Different inserts need to be tapped for each implant tested

Water Bath

Major Components

Heating element

Small and compact

Low fluid volume rated

Temperature switch

Small and compact

+-2 °C tolerance

Dish

Metal bottom

Glass sides

Water tight

Water level switch

Small and compact

Safely maintain water level

Dish

Metal base

Base for mounting heating components

Able to drain the dish through a ball valve

Glass tube

Forms sides

Able to withstand high temps incase of heating problems

Able to see the test specimen during testing

Washer

Or sealant as of yet to be determined

Seals the base to the glass

Standards

ISO 14801:2003

5.4 Testing Environment

testing shall be carried out in water of Grade 2 according to ISO 3696

fluid and the test specimen shall be kept at 37

°C+2°C or -2 °C

Heating Element

Compact Cartridge-Style Immersion Heater

1 5/8" long type 316 stainless steel element

Maximum temperature of 100 ° C

CSA Certified and UL-Registered

Can be fully immerged in saline solution

Temperature switch

Submersible Cartridge Temperature Switch

Operates as a thermostat

300 series stainless steel outer shell adjusted between -73 ° and +315° C

2” long element

UL-Registered

Search continues to refine this component

Water Level Switch

Vertical-Mount Liquid-Level Switch

Maintain a safe water level for the

Immersion heating element

Over all length of 1 7/8“

Max temperature rating of 105

°C

When the fluid level drops too low

cut power to the heating element

turn on a warning light or trigger a system warning in the testing program letting the tester know to add more fluid

Linear Servo Motor

Handles static loading up to 500 lbf.

Handles a cycling load from 0 to 150 lbf. at a rate up to 15 Hz

Load Cell

Piezoelectric sensing cell

Highly repeatable

Fatigue Rated load cell

Low profile to fit easily within machine

Controls

Load cell sends a signal through a DAQ card to

LabView

LabView takes the data and depending on the load it will send a signal to the Driver which will in turn increase or decrease the current

Economic Analysis

Linear Motor, Cooling Jacket, Controller, and Driver : $19600

Load Cell : $1000

Lab View : $1200 per year

Jig Frame and Base : $2000

Computer : $600

Heating Accessories : $300

Cables and Connectors : $200

Total Costs : $25000

Alternative Design

Advantages

Cheap saline bath container

Rotary motor is cheaper than linear motor

Disadvantages

Bearings

(maintenance)

Expensive to machine

Small error in load cell reading due to the bearing friction

Angle of applied force will be less reliable

Complicated – many possible places for failure

Phase II-Completed by Dec.

Obtain more quotes on linear motors

Dimension Concept

Stress Analysis

Finalize Concept