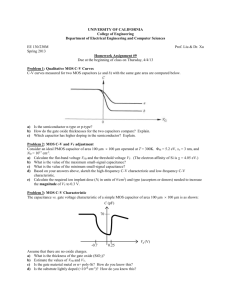

Reliability and Failure Analysis of Electronic Components

advertisement

Reliability and Failure Analysis

of Electronic Components

By

Dr. Charles Surya, ENC

CD 636, ×6220

ensurya@polyu.edu.hk

• For VLSI Circuits to be a useful and growing technology, 2 conditions

must be satisfied:

– Can be produced in large quantities at low cost

– Cats can perform their functions throughout their intended lifetime

• To lower the cost of manufacturing, one must determine the optimal

size of the IC.

• The optimal size is a compromise between several competing

considerations:

–

–

–

–

Partitioning of the system

yield of good circuits

packaging and system assembly cost

reliability of complete system

• Large number of IC’s results in high yield and assembly cost

• To arrive at an optimal division of the system, we must be able to

predict the total system reliability as a function of the number of IC’s of

varying size

2

Mechanism of Yield Loss in VLSI

• Cause for low yield falls into 3 basic categories:

– Parametric processing problems

– CKT design problems

– random point defects in circuits

Processing Effects

• Often a wafer is divided into regions good chips and bad chips (Fig. 1 p.

614, Sze)

• This is most likely due to processing effects such as

– Variations in thickness of oxide or polysilicon layers

– Variations in resistance of implanted layers

– Variations in width of lithographically defined features

3

• Alignment of photomasks

– e.g. PolySi gate lengths are shorter in thinner polySi regions than

in thicker polySi regions. This may cause channel lengths to be

too short and transistors cannot be turned off. This leads to

excessive leakage current

• Variations in thickness of deposited dielectric lead to variations in

contact window size. This may lead to non-operative circuits if the

circuits depend on having a low value of contact resistance.

• Variations in the doping of implanted layers which also leads to

variations in contact resistance

• Also, wafer may vary in size during processing in excess of 20ppm.

Therefore a 125 mm wafer changes in size by 2.5mm. This may cause

significant misalignment.

4

Circuit Sensitivities

• Certain areas of a wafer have low device yield because the design of a ckt

has failed to consider expected variations in device parameters and

correlation between variations in different parameters.

Point Defects

• A 3 m dust can cause a break in a metal conductor

• Si chunks may be knocked out of the wafer during processing

• Isolated oxidation induced stacking fault may cause excessive leakage

current

Modeling of Yield-loss Mechanisms

• We need to model IC yield in terms of fundamental parameters independent

of particular IC and characteristics of the process and processing line

because:

– by accurately modeling the yield we can predict the cost and availability

of future ckts

5

•

•

•

•

•

•

•

•

– once yield-modeling parameters are known one can compare

processing quality of different process lines and indicate where

improvements are required

IC yield is expressed as

Y=Y0Y1(D0,A,i)

1-Y0 = fraction of bad chips due to processing related effects

1-Y1 = remaining fraction of bad chips which is a function of

density of point defects

A is the chip area

i is the parameter unique to different models of the yield

Y = ratio of good chips to total number of chips per wafer

All models predict Y decreases monotonically as A increases

Yield modeling can identify those processes and mechanisms that limit

yield of present IC

The process can then be improved or eliminated as needed

6

Uniform Density of Point Defects

• In those areas where yield not degraded by either processing or ckt

sensitivities, the remaining cause of chip failure is randomly distributed

point defects (see See p. 617, 618)

• A grid of 24 chip sites with 10 defects randomly distributed. In this

example 16 of the 24 sites have 0 defects

• Of the remaining sites 6 have 1 defect no site has more than 2 defects

• The problem of determining the yield is identical to the problem of placing

n balls in N cells and then calculating probability of a given cell containing

k balls

P k = (n!)/[k!(n-k)!] (1)/(Nn)(N-1) n-k

• If N and n are both large n/M = m remains finite and can be approximated

as

Pk =e-mmk /k!

• The probability that a chip contains no defects is Y1 = P0 = e-m

• The probability a chip contains 1 defect is

P1 = me-m

7

• If the area of the chip is A, the total chip area in the useable part of a

wafer is NA

• The density of defects is n/NA = D0

• The average number of defects per chip, m, is m = n/N = D0 NA/N = D0

A

Y1 = P0 = exp(-D0 A)

• This Poisson estimation was used to predict yield in the early days in the

manufacture process

• The actual yield was found to be much larger than predicted

8

Yield Enhancement using Redundant Circuitry

• Many large MOS memory chips are designed with redundant circuitry,

which can be switched to replace defective circuit elements

• This is usually accomplished using fusible links which can be fused as

needed using laser or other techniques

• The yield will then be modified as shown

•

Y1 = P0 + P1

• P0 = probability of chip containing no defects

• P1 = probability of chip containing 1 defect

• = probability of chip containing 1 defect and can be repaired by using a

single redundant column

Simple Non-uniform Distribution of D

• Discrepancy between measured and predicted yield led to investigation of

non-uniform distribution of D0 across a wafer

9

• The yield can be expressed as

• The yield is expressed as

Y = exp(-DA) f(D) dD

• f(D) is the normalized distribution of defect density

f(D) dD = 1

• 3 different D0 are investigated:

– Delta function Y1 = exp(-D0A)

– Triangular

Y2 = {[1-exp(-D0A)]/D0A}2

– Rectangular Y3 = {1-exp(-2D0A)}/2D0A

• for D0A >> 1 we find that

– Y1 = exp(-D0A)

– Y2 = 1/(D0A)2

– Y3 = 1/(2D0A)

• Y3 is found to be most closely fit to the observed yield of large IC’s

• The above distributions do not have any physical basis, therefore more

physically based distributions need to be investigated

10

Gamma Distribution

• The Gamma distribution is more physical

f(D) = 1/[()() ]D -1 exp(-D/ )

• and are 2 distribution parameters and () is the gamma function

• Average density of defects =

• Variance of D = 2

• Consequently Y4 = 1/(1+SD0A)1/s

• for s 0, Gamma function reduces to delta function and Y4 exp(-D0A)

• Using different values of s, Gamma function is a good approximations of

Y2 and Y3 over a wide range of D0A

• Gamma yield functions can be used to represent a large variations in the

shape of experimental yield vs area curve see Fig. 4 and 5 p. 621 and 622

of Sze.

• Each type of defect is characterized by

– its mean defect density Dn0

– shape factor of its distribution Sn

11

– portion of total chip area An susceptible that defect

– Using Gamma yield function

Yn = 1/{(1+SnAnDn0)}1/Sn

• The overall yield is the product of the yield for each known type of defect

Y = Yn

for n=1,2,….,N

• For a mature process in a well controlled high yield line, all of the major

yield-limiting defects have probably been controlled or eliminated. The

yield is a product of many terms each approximately 1.

• This means SnAnDn0 << 1

ln Y = [-(1/Sn) ln(1+SnAnDn0)]

ln(1+SnAnDn0) SnAnDn0

Thus lnY = -AnDn0

Y = exp(- AnDn0)

D* = (1/A) AnDn0

Y = exp(-AD*)

• Here An is the total chip area susceptible to the particular defect

12

Reliability Requirements for VLSI

• It is instructive to consider examples of the effects of device failure

– Early discrete solid state computer systems typically consisted of 105

transistors per system

– If 1 device failure per month is set as the minimum acceptable

condition then the failure rate

< 1/(105 720 hrs)

= 14 10-9 failure/device-hour

• 1 FIT 1 failure/ 109 device-hour

• The objective for the hypothetical system is for < 14 FIT

Reliability Theory (Sze p. 627)

• Useful mathematical description requires precise definition of the terms

• Definitions:

– Reliability -- probability that an item will perform a required function

under stated conditions for a stated period of time

13

• For an IC the required function is generally defined by a test program for

an automatic test set

• Often initial test programs are not complete and the ckts are not tested

under “all” required conditions

• As new device failure modes are identified, the appropriate tests are

included in later test programs

• Stated Conditions -- comprise of the total physical environments,

including mechanical, thermal, electrical ….

• Stated period of time -- the time during which satisfactory operation is

required

Cumulative Distribution Function

• If the device is operational at t = 0. The probability that the device will

fail at or before t is given by the function F(t)

F(t) = 0

t<0

0 F(t) F(t`)

0 t t`

F(t) 1

t

14

Reliability Function and Probability Density Function

• The probability density function is

f(t) = dF(t)/dt

• The Cumulative distribution function is

t

F(t) = 0 f(x)dx

• The reliability function is

R(t) = t f (x)dx

• Thus f(t) = - dR(t)/dt

15

Failure Rate

• In many applications the quantity of most concern is the instantaneous

failure rate

• This is often referred to as the hazard rate

• Fraction of devices that were good at time t and that fail by t + is

given by

•

F(t + ) - F(t) = R(t) - R(t+ )

• The average failure rate during the time interval, , is

•

(t) = average failure rate

•

= 1/ [R(t) - R(t+ )]/R(t)

•

for 0

•

(t) = - 1/R(t) dR(t)/dt = f(t)/R(t)

•

= f(t)/[1 - F(t)]

•

= - d[ln R(t)]/dt

•

R(t) = exp[- 0t (x) dx]

16

Mean Time to Failure (MTTF)

and Common Distribution Functions (p. 630 Sze)

• MTTF is a common measure of reliability

MTTF = 0 t f(t) dt

• It is desirable to have a single mathematical model that represents the

failure rate of devices over their entire lifetime

• (t) generally varies as a function of time as shown

A. High “early failures” or

“Infant Mortality” due to

manufacturing defects

B. “Midlife” or “Steady state”

period of low and generally

constant failure rate

C. “Final” or “wear out”

period

C

t

17

Exponential Distribution Function

• The simplest distribution function, exponential, is characterized by a

constant failure rate over the lifetime of the device. This is useful for

representing a device in which all early failure mechanisms have been

eliminated

– (t) = 0

– R(t) = exp(- 0t)

– F(t) = 1 - exp(- 0t)

– f(t) = 0exp(- 0t)

– MTTF = 0 t 0exp(- 0t) dt

18

Weibull Distribution

• (t) varies as a power of the age of the device

= (/)t-1

where and are constants

• For < 1 the failure rate decreases with time and can be used to represent

early failure

• For = 1, (t) is constant and can be used to represent steady state

• For > 1, (t) increases with time and can be used represent wearout

condition

• For = 1, the failure rate is constant which is a special case of Weibull

distribution

•

R(t) = exp{-(1/)t}

1

f(t) = (/) t-1exp {-(1/)t}

1 F (t ) exp t

MTTF = 1/ (1+1/) where =1.

which is linear. The

1

ln ln

slope of the line is

ln t ln

1 F (t )

. The MTTF is the

time when F(t) = 0.5

19

In some applications, a better fit can be obtained through the

introduction of a 3rd parameter, , in which X = t - is used to replace

t in the above equations to represent

• a shift by the amount of in the time axis

• Physically this represents a portion of device lifetime is used up during

manufacturing burn-in or device testing

Accelerated Testing

• If the required failure rate is ~ 100 FIT or less, then the time required

to observe one failure in 100 devices is approximately 100,000 hr (11.4

yrs)

• Thus it is impossible to test the required reliability under normal

operating conditions

• This necessitates means to accelerate the mechanisms that cause

devices to fail

20

• 5 common stresses are used to accelerate device failure

– temperature

– voltage

– current

– temperature cycling to accelerate mechanical failure of chips and

assembly package

• In such studies, different failure mechanisms may be accelerated by

different level of stress even for the same type of stress

• A device may fail at normal operating conditions because of 2 completely

different mechanisms

• Under the applied stress, one of these failure modes may be accelerated

much more than the other

• Thus, we only see 1 failure mode in those tests

• After successfully eliminating the mode we may only the failure rate by

small factor under normal operating condition

• Adequate studies must be done under normal operating conditions to

satisfy that no failure mechanism remain that were not accelerated by the

applied stress

21

Temperature Acceleration

• Many failure mechanisms involve chemical or physical processes that can

be accelerated by raising the temperature

R R0 exp( Ea / kBT )

• Ea is the activation energy

• If some parameter of IC changes as a function of time, and if the IC fails

when the parameter exceeds certain value.

• The Rates at two different temperatures are related as

E

t1 R2

exp a

t 2 R1

kB

1 1

T1 T2

• The IC would fail when the destruction reaction proceeds to some value

equal to the failure criterion

• Rtf = constant

t f t f 0 exp( Ea / k BT )

• Thus a plot of ln(MTTF) versus 1/T, the slope will correspond to the

activation energy

22

Voltage and Current Acceleration

• Voltage and current are effective acceleration stresses

• Voltage stress cause failure in devices due to:

– dielectric breakdown

– interface charge accumulation

– charge injection

– corrosion

• Most studies indicate that the reaction rate, Rx, of the failure mechanism is

proportional to a power of the applied voltage

R(T ,V ) R0 (T )V (T )

•

•

•

•

where R0(T) if thermally activated

varies between 1 to 4.5

For dielectric breakdown, a different type of acceleration occurs

For a given field, a certain fraction of devices fail in a very short time, of

the order of seconds

• Very few additional failure occurs as the field is maintained

• If the applied field is increased, additional fraction failures occur

23

• In such cases, operation at an increased voltage is more in the nature of

screening rather than accelerating the failure mechanism

• Increased current level is used to accelerate failures caused by

electromigration in metallic conductors

R R0 J (T )

• 1<<4

Stress-Dependent Activation Energy

• (T) describes the temperature dependence of the reaction rate

• For failure accelerated by voltage or current stressing, the activation

energy is dependent on the applied bias

• The Eyring model states that

a(T ) S

Q

R sinh

exp

k

T

k

T

B

B

• where S = applied stress

a(T ) k BT (T ) k BT ( 0

1

k BT

)

24

• Q is related to the Arrhenius activation energy

Q Ea 0 a(T ) S B

• SB is the breakdown stress, the value of the applied stress where failure

of the device occurs essentially instantaneously

• The reaction rate can also be expressed as

E S

R sinh[ (T ) S ] exp a 0 1 B exp( 0 S B )

k BT

• under conditions of low stress, R reduces to

E S

R (T ) S exp a 0 1 B exp( 0 S B )

k BT

• At high stresses

E S S

R exp[ 0 ( S S B )] exp a 0 1 B 1

k BT

• From the above expressions Reaction Rate is a function of the applied

stress, the effective activation energy will decrease with increased rate

25

Humidity-Temperature Acceleration

• Presence of water vapor in the chip environment introduces a new variety

of possible failure mechanism

• Water vapor quickly permeates plastic packaging material

– 1. water vapor transports contaminants from surface of package

through the plastic

– The chip is then exposed to water vapor and various contaminants

– 2. Diffusion of the contaminated water vapor through the passivation

layer of the chip

– This step can be speeded up if the passivation contains defects or

cracks

– The penetration of water vapor through the passivation layer

determined the reaction rate

– 3. Once water reaches the metallization level, electro-chemical

corrosion process can occur

– The ions needed for this corrosion process can arise from the

contaminants which diffused through the passivation layer.

26

– If the intermediate dielectric of the chip is a phosphorous-doped

glass, the water vapor can extract the phosphorus from the

dielectric

– Electrochemical corrosion is a rapid process leading to

metallization failure

– This failure mechanism can be accelerated by increasing the partial

pressure of water vapor in the environment

27

Burn-in

• For mature products, the initial reliability studies would have identified

and eliminated failure processes so that steady-state failure rate meets

or exceeds design goal

• However, the manufactured devices still show existence of continuing

early failure

• Generally, manufacturing defects cause the infant mortality failures

e.g. pinholes, photoresist or etching defects resulting in near-opens or

shorts

• Contamination on the chip of the package, scratches, weak chips or

wire bonds, partially cracked chips or packages

• The purpose of the burn-in procedure is to operate the devices for

some time during which most of the devices that are subject to

• Infant mortality failure actually fail

• The conditions during burn-in presumably accelerate the failure

mechanisms that contribute to infant mortality failure

• Studies of infant mortality under increased T conditions show that

infant mortality have an activation energy of 0.37 to 0.42 eV

28

Properties of Metal-Oxide Silicon (MOS) System

• To understand the MOS system the step is to derive the energy band

diagram

• We note that at thermal equilibrium the Fermi level is constant

• The energy band diagram for a separated system is shown below:

E0

E

C

q

= 4.1 eV

q = 4.1 eV

M

8 eV

E

C

E

Ei

fm

E fs

EV

EV

29

• When connected the Fermi

level will be constant. The

Fermi level in Si depends on

doping level of the Si

• For Ei - Ef = 0.29 eV the band

diagram is shown

Flat-band Condition

Accumulation

E fm

EC

Ei

E

EV fs

E fm

EC

Ei

Efs

EV

30

Weak Inversion

Depletion

EC

EC

Ei

Efs

EV

E fm

Ei

Efs

EV

E fm

Strong Inversion

q p

E fm

q s

EC

Ei

Efs

EV

31

• Strong inversion condition stipulates that qP = qs

• Thus to turn an MOS into strong inversion -- a condition for the

formation of a conduction channel or inversion layer under the gate, a

minimum band bending of 2 qP is required

• The threshold voltage VT is then represented by

1

VT VFB 2 | p |

4 s qN A | p |

Cox

• We can gain further insight into the MOS by realizing that it is

basically a capacitor

• The charges in the Si of the MOS system can be expressed as

Q Cox [(VG VFB ) ( s p )]

• The terms in the square brackets constitute the voltage drop across the

oxide. Since part of the charges are associated with the dopants in the

depletion layer, therefore free carrier concentration in the inversion

layer is

Qn Cox (VG VFB 2 | p |) 4 S N A | P |

32

• The second term is the charge in the depletion layer VG here is the gate

bias required to produce a band bending of 2|P| and is therefore

equivalent to the threshold voltage

• The proof for the expression of charge in Si is

qN A xd

s

33

• Where E is the electric field in Si

• The total band bending in Si is | s | E0 xd

• From Poisson’s equation we have

| s |

qN A xd

2 s

• For xd = xdmax we have s = 2p and xd max

• Charge is the Si layer is qNAxdmax, thus

4 p

qN A

Qd 4qN A p

• The total charging voltage is V Vox Vsi

• where V

si

s

p

VG VFB Vox ( s p )

Vox [(VG VFB ) ( s p )]

Eox

xox

xox

Es

ox Eox

s

Cox'

ox

xox

34

'

• Substituting into the previous equation s Es Cox

[(VG VFB ) ( s p )

'

'

'

• From Poisson’s equation we obtain s E Qs Qn Qd

• Concentration of free carriers in the inversion layer is Qn' Cox (VG VT )

Oxide and Interface Charges

• Charges at Si-SiO2 interface and the oxide may influence the threshold

voltage through the modifications of the flat-band voltage. If the density

of charge at x=x1. It induces an equal and opposite charges divided

between silicon of the metal gate. The closer is x1 to xox (the Si-SiO2

interface), the greater will the fraction of induced charges at Si-SiO2

interface and the oxide may influence the threshold voltage through the

modifications of the flat-band voltage. If the density of charge at x=x1. It

induces an equal and opposite charges divided between silicon of the metal

gate. The closer is x1 to xox (the Si-SiO2 interface), the greater will the

fraction of induced charge within the Si.

• The induced charge changes the charge stored in the Si at equilibrium

therefore it alters the flatband voltage.

• The size of VFB can be found using Gauss’ law to obtain the value of the

gate voltage that causes all of the oxide charge Qoxto be mirrored in the

35

gate electrode.

• Under this condition the field is constant between x = 0 and x =x1 and

0 for x > x1.

• For 0 < x < x1 we have the following relationship

Qox'

Eox

, 0 x x1

ox

VFB

x1 Qox'

xox Cox'

• The result can be generalized to account for shift in VFB using an

arbitrary charge distribution

xox

VFB

1

'

Cox

x

0 xox ( x)dx

• where (x) is the volume charge density at x

Origins of Oxide Charges

• There are at least 4 distinct types of charges in the oxide-silicon system

– Qf ’ -- fixed interface charge density

– Qot’ -- oxide trapped charge density

– Qit’ -- interface trapped charge density

– Qm’ -- mobile charge density

36

• Qf ’ is positive and is located within a very thin (1 - 2nm) laryer fo nonstoichiometric silicon oxide (SiOx)

• Qot’ can be both positive and negative, typically predominantly

negative. Located in traps distributed throughout the oxide layer.

Distortion in the C-V curve is due to unstable charges at the interface.

• The trapping sites Nit (cm-2) are located at the Si-SiO2 interface and

have energy levels within the bandgap with density Dit cm-2eV-1

• To relate behavior of these traps to the distorted C-VG, as shown in the

following figure, consider an oxide-Si interface characterized by

interface trapping levels at energy Es. The gate voltage causes the

Fermi level at the surface to cross Es, the charge state of these levels

will change. This introduces a voltage dependent term, Q’it/Cox’, into

the equation for VFB above making both flatband and threshold

voltages vary with VG that led to the distortion the C-V curve.

• For Nit > 1010cm-2 is generally unacceptable for reliable device design.

Using modern MOS technology, Nit is reduced by annealing device in

forming gas (90% N2 and 10% H2)

37

Mobile charge results from alkali-metal ions particularly sodium.

They induce VFB.

• The alkali ions have sufficient mobility when relatively low gate biases

are applied. The mobility increases with temperature and thus

magnifies the problem of VFB instability at high temperatures. The

ions are positively charged, therefore -VG draws the ions to the metalSiO2 intrface where their effect is minimal. +VG pushes them to the

Si-SiO2 interface where their effects are most significant.

• For voltage stability of 0.1V, less than 2x1010cm-2 mobile ions can be

tolerated. Mobile ions can be avoided by careful processing and

oxidation in HCl that immobilizes alkali ions.

Hot Electron Degradation

• The assessment and improvement of reliability on the CKT level

should be based on both failure mode analysis and the basic

understanding of the physical failure mechanisms.

• Processes such as electromigration and electrostatic discharge cause

catastrophic changes in device characteristics

38

• Other mechanisms such as hot-electron effects cause non-catastrophic

failures which develop gradually over time and change CKT

performance

Scattering of Channel Hot-Electrons into the Oxide

• In order for electrons to obtain enough kinetic energy to be injected

into the oxide, it has to

– gain K.E.

– its momentum redirected towards the oxide through a quasi-elastic

collision

– following the collision, the electron must travel to S-SiO2 without

further collision

• These processes are statistically independent, the injection probability

is obtained as the product of the probabilities of each event

• MOSFET gate current is made up of electrons injected into the gate

oxide by quasi-elastic scattering

• It consists of electrons that overcome the image potential well in the

oxide and reach the gate electrode

39

Hot Carrier Effects

• Advances in VLSI is achieved through down scaling of device

dimension such as channel length, junction depth and gate oxide

thickness without proportional scaling of power supply voltage

• Decrease in device dimensions results in significant increase of the

horizontal and vertical electric fields in the channel region

• Electrons or holes with high K.E. may be injected into the gate oxide,

degrading I-V characteristics of MOSFETs.

• This is one of the important factors that limits the maximum

achievable device densities in VLSI circuits

• Hot-carrier damage results in:

– trapping of carriers on defect sites in the oxide

– creation of interface states at Si-SiO2 interface leads to degradation

in transconductance, shifts in threshold voltage and decrease in

drain current capability.

40

Oxide degradation Mechanism in MOS system

• Cause by injection of high-energy electrons and holes into the gate

oxide near the drain

• The damage is in the form of localized oxide charge-trapping and

interface trap generation

• Recent experimental evidence shows that hot-carrier related

degradation can occur in deep-submicron devices with Leff = 0.15m

at drain voltage as low as 1.8V. Therefore hot electron degradation

may occur even with significant reduction in drain voltage.

• The continuing technology thrust must therefore accompanied by some

limitations to ensure hot-electron reliability

• Hot-carrier injection causes degradation in the transconductance, shift

in threshold and decrease in sub-threshold drain current

• There are many disagreement concerning the physical degradation

mechanisms due to the lack of a reliable and sensitive techniuqe to

evaluate hot-carrier damage at the interface. Moreover, hot-carrier

induced oxide damage is very localized, the interpretation of the

analysis is complex

41

Injection of Hot-Carriers into Gate Oxide

• Hot-carriers are electrons and holes that have a much higher K.E. than

average carrier population

• E’s in S.C. at equilibrium mostly have energy about

kBT above EC. At

equilibrium, K.E. of carriers that encounter large E may gain

significant K.E. in a short distance. Thus E- EC = kBTe where Te is the

effective electron temperature. There are 2 distinct modes of electrons

injection in nMOS

– Substrate hot-electron effect (SHE)

– Channel hot-electron effect (CHE)

• Substrate hot-electrons are derived from leakage current. Electrons

generated in the channel depletion region or diffusing from the bulk

neutral region of the substrate drift toward the Si-SiO2 interface and

gain K.E. from the high field in the surface depletion region

• The energetic electrons may overcome surface energy barrier and

inject into the gate oxide.

• Some of the injected electrons are trapped in the oxide, resulting in a

relatively uniform oxide charge accumulation that shifts the threshold

42

voltage over time.

• The SHE is observed mainly in long-channel MOSFETs. As channel

length decreases, SHE decreases since a large fraction of the hotelectrons generated in the substrate region are swept into the source

and drain regions instead of the device surface

• CHE is more pronounced at large VDS. Electrons reaching Si-SiO2

interface with large K.E. may surmount the energy barrier. Electrons

and holes generated by impact ionization also contribute to charge

injection into the oxide. Hot-electron current and oxide degradation

occurs mainly at the drain end. From the figures, the increased density

of equipotential lines leads to larger horizontal field. Hot-electrons

and hot-holes can be injected into the oxide interface with the aid of

the vertical field or with their K.E. energy alone.

• Injected current density is

J e ( x) n( x, y ) pinj ( x, y )dy

y

• Where n(x,y) is the local electron concentration at (x,y)

• pinj(x,y) is the spatial distribution of injection probability

• pinj(x,y) depends on several events that provide the electron with a

momentum directed towards the oxide interface and with a K.E.

sufficient to overcome interface potential barrier.

43

• Injection of hot carriers occurs mainly in a narrow injection zone at the

drain end of the device where lateral field reaches maximum.

• In log channel MOSFETs, the spatial extent of injection region and

magnitude of electric fields near the drain are largely independent of

the channel length, L.

• For short channel devices, the heavier dopin or shallower junctions

increase the electric fields in the drain region. Due to short channel

effects the channel current entering the drain increases more rapidly

than 1/L.

• Thus, devices with smaller geometries will be more sensitive to hotcarrier related degradation.

• Oxide degradation in the form of charge trapping which occurs in a

short distance of about 0.1 m. However, a large percentage of the

electrons entering the oxide are either scattered in the oxide and/or

returned to Si substrate by the opposing field.

• The charges that do not reach the gate electrode degrades the oxide by

charge trapping and interface trap generation.

44

Impact Ionization

by Hot-Electrons

• In saturation region a high E exists in the channel depletion region.

Electrons will, therefore, be accelerated by the field. Some move

horizontally and creates electron hole pairs (EHP) by impact ionization

near the drain.

• Impact ionization process creates an avalanche plasma consisting of

generated EHP in the pinch-off region

• The holes created are collected by the substrate constituting the drift

component of the substrate current

• The drain current that contributes to impact ionization substrate current

is a function of lateral electric field in pinch off region and VGS and L

Impact

Ionization

45

• Some electrons and holes in the avalanche plasma can gain sufficient

K.E. to surmount Si-SiO2 potential barrier and become injected into

SiO2. Majority of the holes generated constitute substrate current of

MOSFET. Therefore, substrate current is considered a reliable and

convenient monitor of the amount of hot-carrier degradation in nMOSFETs

• To create EHP, hot-electrons

must have K.E. > i (impact ionization

energy). Thus i / qEm is the distance the electrons must travel in E Em

to gain energy i.

• The probability of an electron travelling a distance to gain the required

K.E. or more is

i

Pi exp[

qEm

]

where is hot-electron mean-free path. Since IDS is the total electron

flow in the channel. Rate of supply of hot-electrons with K.E. > i is

I sub C1 I DS exp( i )

qEm

where C1 is a weak function of the max. channel field Em.

46

Oxide Traps and Charge Trapping

• Concentration of oxide trapped charges and interface trapped charges

are changed by capture of excess electrons or holes by existing traps in

the oxide.

• The oxide charge distribution can also be changed by impact release of

the trapped electron or hole by a hot-carrier. The electron or hole traps

in the gate oxide are mainly Si “dangling bonds”. The dangling bonds

give rise to the electron and hole traps.

Interface Trap Concentration

• Interface trapped charge arises from a.) structural, oxidation-induced

defects; b.) metal impurities; c.) defects caused by radiation or hotcarriers

• Unlike other trapped charges, interface trapped charges are in electrical

communication with the underlying Si. Thus, influence of interface

trapped charge on electrical characteristics of MOSFETs depends on

its bias conditions.

• Generation of new interface trap is the primary cause of degradation of

MOSFETs. New traps generated by hot-electrons and hot-holes

through breaking:

47

– Si-Si and Si-O bonds

– breaking of H bonds at interface, releasing H and leaving dangling

Si- or O- bonds

– H released by hot-carrier impact migrates towards Si-SiO2

interface and is then trapped by proton traps.

Bias Dependence of Degradation Mechanism

• Oxide degradation takes place by carrier trapping in oxide due to hotelectron carrier injection and interface trap creation

• These are the two most significant degradation mechanism, but there is

no clear consensus on their relative contribution Hot-carrier related

device degradation reaches maximum when VGS = VDS/2. This

coincides with max. of substrate current, thus it is often linked to

impact ionization.

• When VTH shift is plotted as a function of gate voltage, the

degradation exhibits 2 local maxima:

– First peak: electron injection into SiO2 is max. resulting in charge

trapping

– Second peak: at VGS = VDS/2, corresponds to impact ionization

48

of electrons and holes.

• For VTH = VDS/2, VTH(t) = Atn where 0.5 < n < 0.7

• A depends on ISUB, IDS and processing parameters

Effects of Hot-Carrier Damage on Device Characteristics

• Trapped charges in gate oxide influence surface potential and thus

local flat band voltage

• C-V measurement can be used to measure total amount of trapped

charge in SiO2. Accumulating negative charge shifts the local VFB to

positive direction.

• Influence of interface traps generated by hot-carriers depends on the

instantaneous bias conditions. Since interface traps are in electrical

communication with the underlying Si substrate, occupation of the

traps depends on the Fermi level at the Si-SiO2 intface and energy

distribution of interface traps and the physical nature of NiT (whether

the trap is acceptor or donor type).

• In n-MOS most generated NiT are acceptor type, mostly located at the

drain end. Traps will start to be charged by electrons from substrate as

the surface is biased from accumulation into weak inversion, ant then

into strong inversion

49

• Once all traps are filled, their influence is similar to fixed oxide

charge, which is the case because for all practical purposed the

device are in strong inversion

• Surface mobility is decreased due to increased surface scattering

• Significant reduction in ID in linear region

• Less effect on ID in saturation region because once in saturation ID

is governed by the channel region between the source and pinch off point

• Asymmetry between forward and reverse I-V curves also due to

localization of oxide damage near the drain end

– as n decreases gm decreases

– ID/ID0 decreases

– VT increases

Radiation Induced Interface Traps

• The major effect of ionization radiation on MOS devices is the

generation of positive oxide charge resulting from hole-trapping at SiSiO2 interface.

50

• Radiation consists of high energy particle such as electrons, neutrons,

protons and energetic x-ray and gamma ray

• Photons with E > EG of SiO2 can generate EHP. Some of the generated

carriers recombine. Most are driven toward the electrode by the oxide

field. Electrons rapidly drift toward the positive electrode and flow out

of the circuit. Holes drift much more slowly towards negative

electrode.

• Once holes reach Si-SiO2 interface a fraction becomes trapped

constituting the radiation induced positive oxide charge

51

Latchup in CMOS Circuits

• CMOS (Complementary MOS) is a very important class of circuits in

VLSI technology

• Advantages of CMOS circuits includes low power, high speed logic

circuits

VDD

VDD

PMOS

Vo

Vi

Vo

NMOS

Vib

Via

• In bulk CMOS CKTs both n- and p-channel MOSFETs exist side by

side. This is achieved by starting with a Si wafer of one type and

creating in it regions of the opposite type. In so doing, FETs are not the

only structures fabricated, pnpn devices consisting of parasitic bipolar

transistors are also created.

52

• Under normal operation the circuit performs as an inverter and the

bipolar portion can be ignored. However, if the bipolar circuit

switches from its normally high impedance state to its low impedance

state, the power supply sees a low impedance path to ground.

• If the current from the supply is not limited somehow, there might be

irreversible damages done to the circuit.

• However, even if the circuit is protected, the pnpn’s low impedance

state can still cause the circuit to malfunction.

53

Switching Mechanism (Streetman p. 401)

• The operation of a CMOS

circuit can be understood using

a two-transistor analogy

i

1

E

p

B

n1

C

p

1

J 1 i b 1 = ic 2

J2

2

J2

ic1 = i b 2

J3

n1

C

p

2

B

n2

E

2

• Thus the parasitic bipolar transistors in a CMOS inverter can be

viewed has two interconnected BJTs

• Each BJT can be modeled by Ebers Moll model

S PE

Pn

N S PE

Pn

E

C

ICS PC

Pn

B

CS PC

Pn

54

• The Ebers-Moll model uses the diode equations for the emitter and

collector plus extra terms that provide coupling between the emitter

and collector.

• For a forward biased diode, the excess carriers is

pE pn (e qV / k BT 1)

• Thus the emitter current is

pC I ES

pE

I I CS

(pE N pC )

pn

pn

pn

pC I CS

pE

I C N I ES

I CS

( I pE pC )

pn

pn

pn

I E I ES

• Thus, IC and IE can be expressed as

I C N I E (1 N I ) I CS (e qVCB / k BT 1)

I C N I E I C 0 (e qVCB / k BT 1)

I E I I C (1 N I ) I ES (e qVEB / k BT 1)

I E I I C I E 0 (e qVEB / k BT 1)

55

Two-Transistor Analogy

• The analysis of the 2-transistor analogy is given below:

ic1 1i I C 01 ib 2

ic 2 2i I C 02 ib1

• where 1,2 are the emitter-to-collector current transfer ratios for the

transistors

• However, the sum of ic1 and ic2 is the total current through the device.

Thus, ic1 ic 2 i

i (1 2 ) I C 01 I C 02 i

I C 01 I C 02

i

1 (1 2 )

• As indicated in the above equations, as long as the sum, 1 + 2, is small

compared to unity, the current i is small at approximately the combined

collector saturation currents of the 2 equivalent transistors. As 1 + 2

approaches unity the current i increases rapidly. At this state both

transistors become saturated and will remain in the low resistance state

after the switching.

56

Variation of with Injection

• Since the 2-transistor analogy implies that switching involves an

increase in the 1 and 2 to the point that 1 + 2 becomes unity, it is

important to understand how 1 and 2 depend on injection for a

transistor.

• is the product of the emitter injection efficiency, , and the base

transport factor, B where

I En

I

;

B C

I En I Bp

I En

• At very low currents, is dominated by recombination in the transition

region of the emitter junction

• As the current increases, injection across the junction begins to

dominate over the recombination. This leads to increase in B due to

the saturation of recombination centers as excess carrier concentration

becomes large.

57

Forward Blocking State

• At this state the applied voltage is mainly across the reverse biased

junction j2

• j1 and j3 are forward biased but current remain small because holes are

injected from p1 into n1.

• If a hole recombines with an electron in n1 the electron must be

replenished to maintain space charge neutrality.

• The supply of electrons is very restricted because j2 is reverse biased.

• As a result current through j1 is approximately the same as the reverse

saturation current of j2. Similar arguments hold for current through j3.

58

Conducting State

• As 1 + 2

1, many holes injected at J1 survive to be swept across j2

into p2. Similarly, electrons injected at j3 are collected at j2. This is

regenerative because more electrons injected into n1 induces more holes

injection across j1 to maintain neutrality.

• When this happens depletion at j2 begins to shrink. Finally, j2 becomes

forward biased.

• The overall voltage across the devices approximates the potential drop

across 1 forward biased pn junction.

• The triggering of the junction is often caused by the breakdown of j2

59

Avoiding Latchup

• Latchup can be avoided by incorporating guard structures in the circuits.

• There are two types of guard structures

– minority carrier guards

– majority carrier guards

• The guard structures are used to decouple the parasitic bipolar transistors

from each other

Minority Guard

• Minority carrier guards are used to collect injected minority carriers

before they can cause a problem.

• The minority carriers injected into the substrate could be collected by a

reversed-biased well/substrate junction and flow through the well as

majority carriers.

Majority Guard

• The basic mechanism of a N+ majority guard ring in the well is to steer

current away from the parasitic emitter.

60

Silicon on Insulator (SOI)

• Devices fabricated on SOI substrates are fabricated by dielectric

separation

• At this point the most mature technology for manufacturing SOI

substrates is Separation by IMplantation of OXygen (SIMOX)

• In this technology heavy dosage of oxygen is implanted into Si wafer

to obtain SiO2 with a layer of single crystalline Si on top

• Separation of devices can therefore be accomplished by etching the Si

layer through

• Therefore there will not be any parasitic bipolar transistors

61