Resource Solutions Provider - Business Profile Information

advertisement

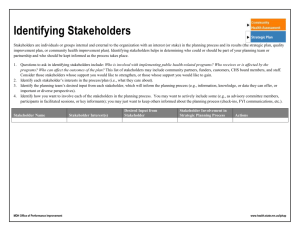

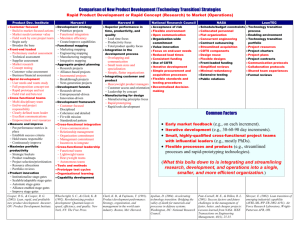

Resource Solutions Provider - Business Profile Information Organizational Name Mergence Systems LLC 641 Grooms Road Suite 110 Clifton Park, NY 12065 http://www.mergencesystems.com main office- 1 (518) 406-6858 fax- 1 (815) 349-2754 (815 IS correct) How many offices or organizational locations 1 location How many employees in your organization 1 employee Please describe your organization’s core competencies and purpose of business We help organizations infuse new technology into critical business processes, and achieve desired results in complex technical system integration environments. Our services capture the value of technology across organizations, reduce endemic system project risks, and present organizational stakeholders with clear options based on traceable and quantifiable business impact. Stakeholder management: We identify technical system boundaries, analyze how different stakeholders interact with systems, and investigate the underlying stakeholder business needs to optimize the entire system to support critical business process execution. Requirements management: We align traceable technical system requirements with stakeholder needs and ensure measurable business impact, identify advantages and disadvantages of multiple system requirement combinations, and facilitate essential coordination between different business, technical, and project participants. Concept management: We effectively expose differentiations between alternative solution concepts, plan and design system prototype testing to ensure measurable performance, and identify real options to minimize system downside and improve success potential. Please describe what your organization can offer to NYS manufacturing companies Our blend of business and technical qualification provides a unique capability to support an underserved boundary in small and medium-sized organizations. We bring to the table both technical fluency and business relevance that provides options and clarity when faced with complex and challenging projects that involve existing and new systems, technologies, and processes. Cross-functional alignment: Complex business systems support critical functional processes. Our systems integration expertise helps clients to understand underlying interactions, coordinate organizational system goals, and achieve cross-functional alignment. We work across existing functional domain experts to move everyone in the same direction. Technical complexity management: Our experience helps clients to conquer the boundary between business and technical complexity. We help to simplify, clarify, and present complex systems options by working with technical experts and business stakeholders. Global perspective: We bring global business to the local upstate New York region. Our services incorporate timeless perspectives, principles, and methods from projects in over 15 countries around the world, and we apply universally applicable global business system lessons and experiences to help local organizations. Please describe/list the number and types of products and/or services your organization sells. Stakeholder system boundary, interaction, control, and dynamics evaluation New and existing system mapping Business impact of technology evaluation System requirements definition and mapping Technical requirements analysis Optimal frontier analysis to select technical solutions Techno-functional requirements mapping System concept and prototype selection System test plan definition End-to-end, stream, and unit test planning and scripting System modeling for decision making: Monte Carlo analyses, decision trees, lattices, system dynamics, project dynamics Please describe your organizational supply chains (describe the major supply chain or supplier types that your organization serves/sells to, and buys from) As a services organization, we work directly with clients as an adjunct resource to help solve their problems, and leverage their existing supply chains and relationships as appropriate for the project. Industry (please describe your organization’s major industry sector(s)/sub-sector(s) classification) – Our organization fits under “Scientific and Technical Consulting Services” (NAICS code 54169). However, we are able to work with any client organizations that are attempting to align technical system complexity with business processes, including small and medium sized manufacturing. Most of our past experience is with electrical, automotive, and industrial manufacturing. Which organizations do you consider as the major organizational competitors? Please list organizational names General and specialized consulting and contracting organizations (Deloitte, KPMG,…) and contracting organizations are competitors. However, with our specialized systems experience and scope, we are able to work alongside or in collaboration with other service providers. How many years has your organization been in business in New York We have recently located in the Albany, NY area. Please describe any notable accomplishments or successes you have achieved or facilitated for your customers Strategy, leadership, and management Led 8-member functional-technical analyst team that implemented improved manufacturing and supply chain processes and technologies at 14 plants, warehouses and sales offices for electrical products manufacturing division in Canada. Mentored and trained business analysts and project managers in centralized IT organization in requirements gathering, needs analysis, scoping, and new technology integration concepts that enhanced the value of shared technology platform investments and increased coordination across large manufacturing and supply chain implementation projects. Designed and deployed enhanced global requirements mapping procedure that reinforced systems solutions and enhanced benefits and risk visibility. Coordinated business stakeholders, process experts, end users, and technical developers towards optimal and achievable future-state manufacturing and supply chain system designs for power quality division in Australia and New Zealand that accounted for regional geographical business challenges. Oversaw functional design, development, and implementation of 150 new and enhancement cross-functional custom technical components during 15-month ERP implementation that resulted in user acceptance testing success. Collaborated with business stakeholders in Central and Eastern European countries to produce functional requirements that resulted in consolidated future-state process and technology system blueprints for customer orders, shipping, inventory, and procurement processes for distributed multi-national manufacturing, warehousing, and drop-shipment organization. Designed strategy for system concept process and technology testing across business stakeholders at 7 Scandinavian sales office locations and oversaw internal and third-party technical development resources that improved unit testing results and that avoided critical milestone interruption. Planned requirements, implementation, development, and testing for emergency invoice redesign project in Poland that avoided legal compliance penalties. Coordinated filtration product line migration activities on-site in Reynosa, Mexico manufacturing plant that reduced project risk and maintained planned milestones. Interfaced with external contractors around system implementation process and technology projects that aligned future state designs with organization strategy and user needs. Presented Customer Relationship Management (CRM) system needs and requirements analysis to senior business leadership at electrical products manufacturer divisional headquarters that effectively communicated the business benefits and risks of a complex technology investment. Hands-on process and technology innovation Designed cross-functional system technical requirements validation process for central IT organization that reduced configuration cycles and established robust future implementation baselines. Analyzed organizational performance data and recommended future process improvements in shipping, logistics, warehousing, and quality that reduced overhead, improved visibility to key information, and eliminated opportunities for repetitive errors in global manufacturing environment. Deployed 18 ERP implementation project data standards that enhanced automation and integration in shipping, logistics and warehouse processes. Established evaluation criteria for approval board that reduced custom technology enhancement review time by 75%. Formalized “delegate and decide” sub-teams for new processes and technology that resulted in a 60% requirement review iteration reduction. Contributed to global baseline design for strategic ERP system roadmap that resulted in 18 successful global implementation projects in five continents. Presented risk analysis and options to senior leadership for strategic technology upgrade plan that influenced development of critical roadmap and timeline. Designed intercompany processes for customer orders, inventory and financials between frontend sales offices and intercompany warehouses on separate ERP systems that resulted in more accurate order processing. Introduced international Available to Promise (ATP) technology between Australia and New Zealand locations that improved customer visibility and reduced international emergency freight costs for intercompany orders. Conducted classroom training in Scandinavian sales offices that aligned users around improved manufacturing, customer order, and supply chain processes. Monitored performance of key metrics during implemented system launches and provided support to users that preserved critical logistics business activities. Defined, tested, and deployed major internal customer-facing information system project as part of large acquisition at a global diversified industrial manufacturer in Central Europe. Architected and implemented automatic transaction flows between separate Oracle and SAP systems for customer orders, shipping, returns, inventory, and field service that reduced overhead between high labor cost sales offices and warehouses. Facilitated “conference room pilot” (CRP) and user acceptance testing (UAT) initiatives that achieved milestones and verified functionality for major technology projects. Designed, implemented, and tested 3 standard EDI transactions between customer order system and third-party warehouse that automated shipment and inventory transactions across 8 countries. Orchestrated cross-functional needs identification activities across 12 business locations that resulted in shared technology improvements for warehouse put-away, customer order entry, intercompany order processing, and third-party shipping carrier integration. Developed model plant assessment tool to compare 6 North American manufacturing locations that identified critical improvement opportunities for major automotive parts supplier. Organized governance board and user groups across North American manufacturing locations that reinforced model plant process improvement initiatives for major automotive parts supplier. Overhauled ERP and financials system in multi-industry manufacturing facility in Reynosa, Mexico. Trained clerks in plant and Pharr, Texas warehouse locations in cross-border shipment processes that improved customer service and inventory management coordination between facilities, and reduced late warehouse arrivals and customs fees. Performed industry literature, benchmark database, and expert research for Customer Relationship Management (CRM) initiative that reduced external consulting costs. Conducted management reporting requirements assessment and component prioritization across global locations that enhanced access to key process information and metrics. Redesigned 30 management reports for customer order process, delivery, warehousing, and quality that improved visibility to emerging trends and alignment across multiple locations. Designed custom platform modules with open-source Content Management System (CMS) software to align mentors with mentees for geoscientist organization, match professional consultants across more than 30 different market sectors, and plan 400 attendee conference. Harnessed powerful technology for small organizations at minimal cost. Please check all of the resource capabilities, services and/or expertise from the following list that your organization can provide: ____Engineering: Contract Services ____Engineering Consulting Services __x_Management Consulting/Strategic Planning ____Production Flexibility/Capacity __x_Product Design & Development/Prototype Development ____Additive Manufacturing/Process Automation __x_Commercialization/Scale Up __x_Regulation/Compliance __x__Supply Chain Management/Supply Chain Development/Supplier Scouting ____Specialized Equipment/Instrumentation ____Specialized Facilities/Labs ____Site Selection/Fit Up ___Import/Export ____Workforce/HR/Training/Recruitment ____Internship __x_Information Technology Services ____Sustainability/Waste Management/Energy Savings ____Marketing/Web/Social Media Services ____SBIR/Grant Application Assistance ____Funding/Capital & Finance Services/Grants/Investment ____Research/R & D ____Business Development/Partner Development/Market Development ____Professional Business Services: Legal/IP ____Professional Business Services: Sales/Sales Training ____Professional Business Services: Accounting/Finance ____Professional Business Services: Administrative/Conference Room/Facility leasing ____Professional Business Services: Executive Recruitment/Executive Advisory/Mentorship ____Start Up/Business Planning ____Other – please describe and list Please provide any additional key words that represent the organization’s capabilities, expertise, application domain and sector focus, target customers or markets, industry(s), etc. Complex systems Technical implementation Concept selection Cross-cultural Cross-functional Requirements analysis Solution design Stakeholder analysis Stakeholder management Large system integration System value System performance Business needs Individual Expertise/Profile Information Form – If Applicable If applicable, please provide information about individual experts within your organization. Individual Name Daniel Adsit Organization Mergence Systems LLC Title Principal Phone 1 (518) 478-6126 Email dan@mergencesystems.com Awards 2011 Eaton Corporation Future Leaders Zone Award Recipient Resume, CV, Bio: EXPERIENCED SYSTEMS AND TECHNOLOGY LEADERSHIP AND MANAGEMENT PROFESSIONAL Customer-focused and relationship-oriented business process innovator, technology leader, and consultant with expertise in identifying, analyzing and optimizing complex systems problems, challenges, and opportunities. Imaginative problem solver with exceptional MIT management and engineering education. Adaptable personality and skillset in broad business and technical concepts. Able to inspire, influence, and collaborate with others in all functional and technical roles. Highly organized self-starter with refined interpersonal, written and verbal communication skills. Additional qualifications and experience include: 9 years of experience with dynamic business information systems, technology programs, strategic projects, manufacturing environments, and complex supply chains On-site project experience in 16 countries, including growth markets in Mexico and Eastern Europe. Mastery of analytical and statistical tools including QFD, profit/loss statement analysis, system dynamics, discount analysis, control diagramming, Monte Carlo simulations, decision trees, real options, and regressions Trained change management professional with practical implementation experience Agile and adaptable ability to manage change across business and technical contexts EDUCATION Massachusetts Institute of Technology (MIT), Cambridge, MA Sloan School of Management & School of Engineering Master of Science in Engineering & Management Cornell University, Ithaca, NY College of Engineering Bachelor of Science in Information Science, Systems & Technology February 2014 2006 RELEVANT EXPERIENCE Mergence Systems LLC, Clifton Park, NY 2014-present Principal Massachusetts Institute of Technology (MIT), Cambridge, MA Fellow, System Design & Management (SDM) Program SDM Leadership Curriculum (2013) Eaton Corporation Project locations in USA, Mexico, Europe, Asia, Australia and New Zealand 2013-2014 Enterprise Common Platform Specialist (2011-2013) Functional Analyst, Distribution and Transportation (2008-2011) Analyst, Strategic Technical Enhancement Program (2006-2008) 2006-2013 PLS Launch Solutions, Inc., Ithaca, NY 2005-2006 Web Systems Designer and Developer Please describe any key words that represent your domain expertise, capabilities, and focus areas (customers, applications, markets, industries, etc.) Business process improvement Complexity management Concept evaluation and selection Cross-functional needs alignment Customer needs focused End-to-end process execution Information systems IT strategy and execution Requirements analysis and alignment with stakeholder needs Risk analysis Solution design Supply chains System integration Systems issue resolution System value delivery Technical communication and presentation Technical contribution Technology