Designing with Quartus II

advertisement

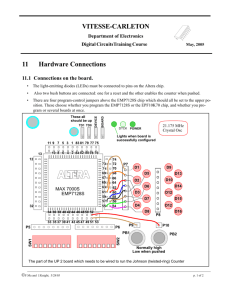

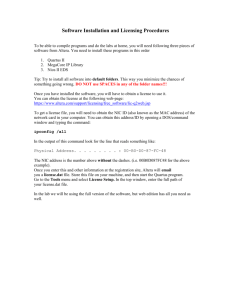

Quartus II Basic Training Copyright © 2005 Altera Corporation Programmable Logic Families Structured ASIC HardCopy® II, HardCopy Stratix High & Medium Density FPGAs Stratix II, Stratix, APEX™ II, APEX 20K, & FLEX 10K® Low-Cost FPGAs Cyclone II & Cyclone FPGAs with Clock Data Recovery Stratix II GX CPLDs MAX II, MAX 7000 & MAX 3000 Embedded Processor Solutions Nios II Configuration Devices Serial (EPCS) & Enhanced (EPC) Copyright © 2005 Altera Corporation 2 MAX 7000A & MAX 3000A Family Overview 5,000 10,000 600 1,250 2,500 EPM7512AE EPM7256AE EPM7128AE EPM7032AE EPM3512A EPM3256A MAX 7000A Useable Gates 600 1,250 2,500 Macrocells 32 64 128 256 512 32 64 128 256 512 Maximum User I/O Pins 34 66 96 158 208 36 68 100 164 212 tPD (ns) 4.5 4.5 5.0 7.5 7.5 4.5 4.5 5.0 5.5 7.5 fCNT (MHz) 227 222 192 127 116 227 222 192 172 116 tSU (ns) 2.9 2.8 3.3 5.2 5.6 2.9 2.8 3.3 3.9 5.6 tCO1 (ns) 3.0 3.1 3.4 4.8 4.7 3.0 3.1 3.4 3.5 4.7 Copyright © 2005 Altera Corporation 3 EPM3128A EPM3064A EPM3032A MAX 3000A EPM7064AE Parameter 5,000 10,000 Complete Voltage Portfolio 5.0 V 3.3 V 2.5 V MAX 7000S MAX 7000AE MAX 7000B Performance Leader Feature Leader Wide Range of Package Offerings Industrial-Grade Offerings High Performance Feature Leader Wide Range of High Performance Feature Leader Wide Range of Package Offerings Package Offerings MAX 3000A Price Leader Feature & Package Subset of MAX 7000AE Copyright © 2005 Altera Corporation 4 MAX Device Block Diagram Copyright © 2005 Altera Corporation 5 MAX Macrocell Global Global Clear Clock Parallel Logic Expanders (from other MCs) 7000 has two Global Clock Programmable Register Register Bypass ProductTerm Select Matrix 36 Programmable Interconnect Signals Shared Logic Expanders 16 Expander Product Terms Copyright © 2005 Altera Corporation 6 PRn D Q VCC Clear Select ENA CLRn Clock/ Enable to PIA Select to I/O Control Block MAX II: The Lowest-Cost CPLD Ever New Logic Architecture 1/2 the Cost 1/10 the Power Consumption 2X the Performance 4X the Density Non-Volatile, Instant-On Supports 3.3-, 2.5- & 1.8-V Supply Voltages Breakthrough Technology to Expand the Market Copyright © 2005 Altera Corporation 7 Flexible Supply Voltage On-Chip Voltage Regulator Accepts 3.3-, 2.5- & 1.8-V Supply Inputs Internally Converted to 1.8-V Core Voltage Convenience of 3.3 V with the Power & Performance of 1.8 V Copyright © 2005 Altera Corporation 8 MAX II Device Family Device Typical Logic Elements Macro(LEs) cells User I/O Pins Speed Grades Fastest tpd1 (ns) User Flash Memory (bits) EPM240 240 192 80 3, 4, 5 4.7 8,192 EPM570 570 440 160 3, 4, 5 5.5 8,192 EPM1270 1,270 980 212 3, 4, 5 6.3 8,192 EPM2210 2,210 1,700 272 3, 4, 5 7.1 8,192 Copyright © 2005 Altera Corporation 9 MAX II Packaging & User I/O Pins Device 100-Pin TQFP1 144-Pin TQFP 256-Pin FBGA2 0.5-mm Pitch 0.5-mm Pitch 1.0-mm Pitch 16 x 16 mm 22 x 22 mm 17 x 17 mm EPM240 80 EPM570 76 EPM1270 EPM2210 Denotes Vertical Migration Notes: 1. TQFP: thin quad flat pack 2. FineLine BGA® package (1.0-mm pitch) Copyright © 2005 Altera Corporation 10 116 160 116 212 204 324-Pin FBGA 1.0-mm Pitch 19 x 19 mm 272 New Small Packages T100 0.5mm TQFP 16x16mm New Packages Partial M100 0.5mm MBGA 6x6mm F256 1.0mm FBGA 17x17mm Partial M256 0.5mm MBGA 11x11mm Packages minimize PCB area and optimize ease-of-use Partial arrays allow for 2 layer PCB break out Copyright © 2005 Altera Corporation 11 MAX II Architecture Logic Elements (LEs) Staggered I/O Pads Configuration Flash Memory JTAG & Control Circuitry User Flash Memory Copyright © 2005 Altera Corporation 12 MAX II Logic Element (LE) sload sclear aload Register Chain addnsub Reg data1 data2 data3 cin 4-Input LUT data4 clock ena aclr Row, Column & Direct Link Routing Local Routing LUT Chain Register Chain Copyright © 2005 Altera Corporation 13 User Flash Memory Feature Flash Memory Storage Bank 8,192 Bits Per Device Interface to SPI, I2C, Parallel, or Proprietary Buses Industry First! Applications Store Revision & Serial Number Data Store Boot-Up & Configuration Data Copyright © 2005 Altera Corporation 14 User Flash Memory Block MAX & MAX II Comparison Parameter MAX MAX II 0.3-um EEPROM 0.18-um Flash Product Term Look-Up Table (LUT) 32 to 512 Macrocells 128 to 2210 Macrocells (240 to 2,210 LEs) Global Row & Column None 8 Kbits 212 272 5.0 V, 3.3 V, 2.5 V 3.3 V/2.5 V, 1.8 V 5.0 V, 3.3 V, 2.5 V, 1.8 V 3.3 V, 2.5 V, 1.8 V, 1.5 V Global Clock Networks 2 per Device 4 per Device Output Enables (OEs) 6 to 10 per Device 1 per I/O Pin None 1 per I/O Pin Process Technology Logic Architecture Density Range Routing Architecture On-Chip Flash Memory Maximum User I/O Pins Supply Voltage I/O Voltages Schmitt Triggers Copyright © 2005 Altera Corporation 15 What is Nios II? Altera’s Second Generation Soft-Core 32 Bit RISC Microprocessor Debug On-Chip ROM On-Chip RAM FPGA Copyright © 2005 Altera Corporation 16 Avalon Switch Fabric Nios II CPU Cache - Nios Developed By Altera II Plus Internally All Peripherals Written In HDL - Can Harvard Architecture Be Targeted For All Altera FPGAs - Synthesis Royalty-Free Using Quartus II Integrated Synthesis UART GPIO Timer SPI SDRAM Controller Nios II Processor Architecture Classic Pipelined RISC Machine 32 General Purpose Registers 3 Instruction Formats 32-Bit Instructions 32-Bit Data Path Flat Register File Separate Instruction and Data Cache (configurable sizes) Tightly-Coupled Memory Options Branch Prediction 32 Prioritized Interrupts On-Chip Hardware (Multiply, Shift, Rotate) Custom Instructions JTAG-Based Hardware Debug Unit Copyright © 2005 Altera Corporation 17 Problem: Reduce Cost, Complexity & Power Flash I/O CPU SDRAM I/O I/O I/O I/O I/O FPGA CPU DSP DSP Solution: Replace External Devices with Programmable Logic Copyright © 2005 Altera Corporation 18 Problem: Cost, Complexity & System OnReduce A Programmable Chip (SOPC) Power Flash FPGA SDRAM CPU is a Critical Function Solution: ReplaceControl External Devices Required forProgrammable System-Level Logic Integration with Copyright © 2005 Altera Corporation 19 Licensing Nios II Delivered As Encrypted Megacore Licensed Via Feature Line In Existing Quartus II License File Consistent With General Altera Megacore Delivery Mechanism Enables Detection Of Nios II In Customer Designs (Talkback) No Nios II Feature Line (OpenCore Plus Mode) System Runs If Tethered To Host PC System Times Out If Disconnected from PC After ~ 1 hr Nios II Feature Line (Active Subscriber) Subscription and New Dev Kit Customers Obtain Licenses From www.altera.com Nios II CPU RTL Remains Encrypted Nios II Source License Available Upon Request On Case-By-Case Basis Included With Purchase Of Nios II ASIC License Copyright © 2005 Altera Corporation 20 Quartus II Basic Training Quartus II Development System Feature Overview Copyright © 2005 Altera Corporation Software & Development Tools Quartus II All Stratix, Cyclone & Hardcopy Devices APEX II, APEX 20K/E/C, Excalibur, & Mercury Devices FLEX 10K/A/E, ACEX 1K, FLEX 6000 Devices MAX II, MAX 7000S/AE/B, MAX 3000A Devices Quartus II Web Edition Free Version Not All Features & Devices Included See www.altera.com for Feature Comparison MAX+PLUS® II All FLEX, ACEX, & MAX Devices Copyright © 2005 Altera Corporation 22 Quartus II Development System Fully-Integrated Design Tool Multiple Design Entry Methods Logic Synthesis Place & Route Simulation Timing & Power Analysis Device Programming Copyright © 2005 Altera Corporation Typical PLD Design Flow Design Entry/RTL Coding Design Specification - Behavioral or Structural Description of Design RTL Simulation - Functional Simulation (Modelsim®, Quartus II) - Verify Logic Model & Data Flow (No Timing Delays) LE M512 M4K I/O Synthesis - Translate Design into Device Specific Primitives - Optimization to Meet Required Area & Performance Constraints - Precision Synthesis, Synplify/Synplify Pro, Design Compiler FPGA, Quartus II Place & Route - Map Primitives to Specific Locations inside Target Technology with Reference to Area & Performance Constraints - Specify Routing Resources to Be Used Copyright © 2005 Altera Corporation 24 Typical PLD Design Flow tclk Timing Analysis - Verify Performance Specifications Were Met - Static Timing Analysis Gate Level Simulation - Timing Simulation - Verify Design Will Work in Target Technology PC Board Simulation & Test - Simulate Board Design - Program & Test Device on Board - Use SignalTap II for Debugging Copyright © 2005 Altera Corporation 25 Design Entry Methods Quartus II TopLevel File Text Editor Top-level design files can be schematic, HDL or 3rdParty Netlist File AHDL VHDL Verilog Schematic Editor Block Diagram File Graphic Design File .bdf .gdf .bsf .tdf .vhd .v .edf .edif .v, vlg, .vhd, .vhdl, vqm Block File Symbol File Text File Text File Text File Text File Text File Memory Editor HEX MIF Generated within Quartus II 3rd-Party EDA Tools EDIF HDL VQM Mixing & Matching Design Files Allowed Copyright © 2005 Altera Corporation 26 Imported from 3rd-Party EDA tools Quartus II Basic Training Quartus II Quick Start LAB1 Copyright © 2005 Altera Corporation Objectives Create a project using the New Project Wizard Name the project Add design files Pick a device Copyright © 2005 Altera Corporation 28 Step 1 (Setup Project for QII5_1) Under File, Select New Project Wizard…. A new window appears. If an Introduction screen appears, click Next. Copyright © 2005 Altera Corporation 29 Step 2 (Setup Project for QII5_1) Page 1 of the wizard should be completed with the following working directory for this project <lab_install_directory> \Dsp_7_segment\ name of project Dsp_7_segment top-level design entity Dsp_7_segment Copy “state_machine.v” and past in Dsp_7_segment Click Next to advance to the Project Wizard: Add Files [page 2 of 5]. Copyright © 2005 Altera Corporation 30 Step 3 (Setup Project for QII5_1) Using the browse button, select state_machine.v Add to the project. Click Next. Copyright © 2005 Altera Corporation 31 Step 4 (Setup Project for QII5_1) On page 3, select Stratix as the Family. Also, in the Filters section, set Package to FBFA, Pin count to 780, and Speed grade to 5. Select the EP1S25F780C5 device from the Available devices: window. Click Next. Copyright © 2005 Altera Corporation 32 Step 5 (Setup Project for QII5_1) On page 4 , you can specify any third party EDA tools you may be using along with Quartus II. Since these exercises will be done entirely within Quartus II, click Next. Copyright © 2005 Altera Corporation 33 Step 6 (Setup Project for QII5_1) The summary screen appears as shown. Click Finish. The project is now created. Copyright © 2005 Altera Corporation 34 Quartus II Basic Training Quartus II Quick Start LAB2 Copyright © 2005 Altera Corporation Objectives Create a counter using the MegaWizard Plug-in Manager Build a design using the schematic editor Analyze and elaborate the design to check for errors Copyright © 2005 Altera Corporation 36 Step 1 Create schematic file Select File New and select Block Diagram/Schematic File. Click OK. Select File Save As and save the file as <lab_install_directory> \Dsp_7_segment\ Dsp_7_segment.bdf Copyright © 2005 Altera Corporation 37 Step 2 Build an 23 bits counter using the MegaWizard Plug-in Manager 1.Choose Tools MegaWizard Plug-In Manager. In the window that appears, select Create a new custom megafunction variation. Click on Next. 2.On page 2a of the MegaWizard expand the arithmetic folder and select LPM_COUNTER. 3.Choose Verilog HDL output For the name of the output file, type timer_1s. Click on Next Copyright © 2005 Altera Corporation 38 Step 3 1. 2. 3. Set the output bus to 27 bits. For the remaining settings in this window, use the defaults that appear .. Select next .Turn on “Modulus , with a count modulus of “and key in 79999999 Select finish Copyright © 2005 Altera Corporation 39 Step 4 In the Graphic Editor, double-click in the screen so that the Symbol Window appears. Inside the symbol window, click on to expand the symbols defined in the Project folder. Double-click on timer_1s. Click the left mouse button to put down the symbol inside the schematic file.. The symbol for “timer_1s” now appears in the schematic. Copyright © 2005 Altera Corporation 40 Step 5 1. 2. 3. 4. From the File menu, open the file state_machine.v From the File menu, go the Create/Update menu option and select Create Symbol Files for Current File. Click Yes to save changes to Dsp_7_segment.bdf. Once Quartus II is finished creating the symbol, click OK. Close the state_machine.v file In the Graphic Editor, double-click in the screen so that the Symbol Window appears again. Double-click on state_machine in the Project folder. Click OK... The symbol for state_machine now appears in the schematic. Copyright © 2005 Altera Corporation 41 Step 6 Add Pins to the Design 1. 2. 3. 4. . Input Output sys_clk 7_out[6..0] reset Dig1 For each of the pins listed in left Table , you must insert a pin and change its name To place pins in the schematic file, go to Edit Insert Symbol OR double-click in any empty location of the Graphic Editor. Browse to libraries primitives pin folder. Double-click on input or output Hint: To insert multiple pins select Repeat Insert Mode. To rename the pins double-click on the pin name after it has been inserted. Type the name in the Pin name(s) field and Click OK Copyright © 2005 Altera Corporation 42 Step 7 Connect the Pins and Blocks in the Schematic 1. In the left hand tool bar click on button to draw a wire and button to draw a bus. Another way to draw wires and busses is to place the cursor next to the port of any symbol. When you do this, the wire or bus tool will automatically appear. 2. Connect all of the pins and blocks as shown in the figure below Copyright © 2005 Altera Corporation 43 Step 8 Save and check the schematic 1. 2. 3. Click on the Save button in the toolbar to save the schematic. From the Project menu, select Add/Remove Files in Project. Click on the browse button to make sure the Dsp_7_segment.bdf, timer_1s and state_machine are added to the project. From the Processing menu, select Start Start Analysis & Elaboration. 4. Analysis and elaboration checks that all the design files are present and connections have been made correctly. Click OK when analysis and elaboration is completed Copyright © 2005 Altera Corporation 44 Quartus II Basic Training Quartus II Quick Start LAB3 Copyright © 2005 Altera Corporation Objectives Pin assignment Perform full compilation Build a design using the schematic editor How to Download programming file Copyright © 2005 Altera Corporation 46 Step 1 1. 2. 3. Choose Assignments Assignment editor. From the View menu, select Show All Know Pin Names. Please click Pin in Category Copyright © 2005 Altera Corporation 47 Step 2 1. 2. 3. 4. 5. 6. 7. Pls install DSP Development Kit Stratix edtion CD Open ds_stratix_dsp_bd.pdf from C:\megacore\stratix_dsp_kit-v1.1.0\Doc Check clk , pushbotton and seven segment display pin location from ds_stratix_dsp_bd.pdf Key your pin number in location Click on the Save button in the toolbar From Assignments, select Device. Click Device & Pin options. Click Unused pins .Select As input tri-stated from Reserve all unused pins From the Processing menu, select Start Compilation Copyright © 2005 Altera Corporation 48 Step 3 1. 2. 3. 4. From the Tools menu, select programmer Click on Add File. Select Dsp_7_segment.sof. Check Hardware Setup. Select your download cable on Currently selected hardware(ByteBlasterII) Select JTAG from Mode Copyright © 2005 Altera Corporation 49 Step 4 1. 2. 3. Turn on Program/configure. Or see figure below Click Start See 7-segment status Copyright © 2005 Altera Corporation 50 SignalTap II Agenda SignalTap II Overview & Features Using SignalTap II Interface Advanced Triggering Copyright © 2005 Altera Corporation 51 SignalTap II ELA Captures the Logic State of FPGA Internal Signals Using a Defined Clock Signal Gives Designers Ability to Monitor Buried Signals Connects to Quartus II through FPGA JTAG Pins Captures Real-Time Data Up to 200 Mhz Is Available for Free Installed with Full Subscription or Web Edition Installed with Stand-Alone Programmer Copyright © 2005 Altera Corporation 52 SignalTap II Device Support Stratix & Stratix II Stratix GX Cyclone & Cyclone II Excalibur Mercury APEX II APEX 20K/E/C Copyright © 2005 Altera Corporation 53 How Does It Work? 1. Configure ELA 2. Download ELA into FPGA along with Design 3. ELA Samples Internal Signals 4. Quartus II Communicates with ELA through JTAG Copyright © 2005 Altera Corporation 54 Stratix/Cyclone Sample Resource Usage Number of Channels Logic Elements Trigger Level 1 Trigger Level 2 Trigger Level 3 8 316 371 426 32 566 773 981 256 2900 4528 6156 Number of Channels M4Ks Based on Sample Depth 256 512 2K 8K 32K 8 <1 1 4 16 64 32 2 4 16 64 256 256 16 32 128 512 Copyright © 2005 Altera Corporation 55 Modes of Operation Three Different Configurations Internal RAM ELA Configuration Debug Port ELA Configuration Hybrid Approach Provides Flexibility Based on Available Device Resources Memory Resources Are Limited Use Debug Port Configuration Pin Resources Are Limited Use Internal RAM Configuration Copyright © 2005 Altera Corporation 56 Supported Download Cables USB Blaster USB Port Cable ByteBlaster™ II Parallel Port Cable ByteBlasterMV™ Parallel Port MasterBlaster™ USB / Serial Port Cable Copyright © 2005 Altera Corporation 57 SignalTap II Key Features Setup Data Triggering Data Capture Data Analysis Copyright © 2005 Altera Corporation 58 Setup Features Up to 1024 Data Channels Multiple Analyzers in One Device Supports Analysis of Multiple Clock Domains Each Analyzer Can Run Simultaneously Setup Data Triggering Data Capture Resource Usage Estimation Incremental Design Support Copyright © 2005 Altera Corporation 59 Data Analysis Data Triggering Features Up to 10 Trigger Levels Per Channel Setup Allows Application of Simple (Basic) & Complex (Advanced) Triggering Schemes Defines a Sequential Pattern of Logic Conditions Data Triggering Each Trigger Level is Logically ANDED If (L1 & L2 ... & L10) == TRUE Data Capture Data Capture Data Analysis Copyright © 2005 Altera Corporation 60 Data Triggering Features (Cont.) Three Main Trigger Positions Setup trigger Samples Captured Samples Captured Old Samples New Samples TIME Data Triggering Trigger Input Setup External Trigger to Trigger the Analyzer Trigger Output Data Capture Signifies Trigger Event Occurred with SignalTap II Use One ELA’s Trigger Output as Trigger Input for Another Copyright © 2005 Altera Corporation 61 Data Analysis Data Capture Features Up to 128K Samples Per Channel Setup Increases Chance of Catching Target Event Two Methods of Data Acquisition 1. Circular 2. Segmented Data Triggering Data Capture Mnemonic Tables Create User-Defined Labels for Bit Sequences (Ex. State Machine) Copyright © 2005 Altera Corporation 62 Data Analysis SignalTap II Design Flow 1) Use SignalTap II File (.STP) Use Quartus II GUI STP Separate from Design Files 2) Use Quartus II MegaWizard Instantiate Directly into HDL Copyright © 2005 Altera Corporation 63 Using STP File 1. Create .STP File • • • • • Assign Sample Clock Specify Sample Depth Assign Signals to STP File Specify Triggering Setup JTAG 2. Save .STP File & Compile with Design 3. Program Device 4. Acquire Data Copyright © 2005 Altera Corporation 64 1) Creating a New .STP File To Create a .STP File Method 1 Select the in Quartus II Method 2 Select New (File Menu) Other Files SignalTap II File Default File Name Will Be STP1.stp Copyright © 2005 Altera Corporation 65 Main .STP File Components .STP File JTAG Chain Configuration Instance Manager Waveform Viewer Copyright © 2005 Altera Corporation 66 Signal Configuration Instance Manager Instance Manager Selects Current ELA to Setup/View Displays the Current Status of each Instance Displays Size (Resource Usage) of ELA Copyright © 2005 Altera Corporation 67 Assign Sample Clock Use Global Clock for Best Results Data Written to Memory on Every Sample Clock Rising Edge Clock Signal Cannot Be Monitored as Data External Clock Pin Created Automatically if Clock Unassigned auto_stp_external_clock ELA Expects External Signal to be Connected to Clock Pin Copyright © 2005 Altera Corporation 68 Specify Sample Depth Sample Depth Set Number of Samples Stored for each Data Signal 0 to 128K Sample Depth 0 Selected When External Analyzer Is Used Select RAM Type for Stratix & Stratix II Devices Useful when Preserving a Specific Memory Type is Necessary Copyright © 2005 Altera Corporation 69 Data Capture Circular Specify Trigger Position Pre Center Post Continuous Segmented Specify Segment Depth Copyright © 2005 Altera Corporation 70 Triggering Trigger Levels Indicate up to 10 Trigger Conditions Trigger-In Any I/O Pin Can Trigger the SignalTap II Analyzer Generates auto_stp_trigger_in_n Pin Trigger-Out Indicates When a Trigger Pattern Occurs Generates auto_stp_trigger_out_n Pin Delayed 4 Clock Cycles after Actual Trigger Event Copyright © 2005 Altera Corporation 71 Waveform Viewer Setup Tab Describes the Signal Settings Data Signals vs. Trigger Signals Sets up Each Triggering Level (L1 – L10) Data Tab Displays Captured Data Copyright © 2005 Altera Corporation 72 STP File Waveform Viewer Setup Tab Data Tab Copyright © 2005 Altera Corporation 73 Basic Triggering All Signals Must Be True for Level to Cause Data Capture Right-Click to Set Value Copyright © 2005 Altera Corporation 74 Debug Port Routes Data Signals to Spare I/O Pins for Capture by External Logic Analyzer Quartus II Automatically Generates auto_stp_debug_out_m_n Pin m Represents the Instance Number of the Analyzer n Represents the Order the Debug Port Pin Occurs in the Signal List Copyright © 2005 Altera Corporation 75 Mnemonic Table Allows a Set of Bit Patterns to Be Assigned UserDefined Names Right-Click in the Setup View of an STP File & Select Mnemonic Setup Select Add Table Select Add Entry Ex. State Machines or Decoders/Encoders Copyright © 2005 Altera Corporation 76 JTAG Chain Configuration Select Programming Hardware Scan Chan Button Automatically Determines Devices Physically Connected to the Chain Detects Non-Altera Devices & Displays Them as Unknown Copyright © 2005 Altera Corporation 77 2) Save .STP File & Compile SignalTap II Logic Analyzer Control in Compiler Settings Assignments Settings Specify the STP File to Compile with Project Copyright © 2005 Altera Corporation 78 3) Program Device(s) Use Quartus II Programmer or STP File Program Button in the SignalTap II Interface Only Configures the Selected Device in Chain Use Quartus II Programmer to Program Multiple Devices Can Create a STP File for each Device in the JTAG Chain Copyright © 2005 Altera Corporation 79 4) Acquire Data SignalTap II Toolbar & STP File Controls Run Autorun Stop Read Data (Reads in Data from Last Analysis) Copyright © 2005 Altera Corporation 80 Displaying Acquired Data Format in Time or Sample Number Display Signal as Bar or Line Chart Export to Other Tools for Viewing or Analysis (File Menu) Creates .VWF, .TBL, .CSV, .VCD, .JPG or .BMP File Copyright © 2005 Altera Corporation 81 Using STP File Review 1. Create .STP File • • • • • Assign Sample Clock Specify Sample Depth Assign Signals to STP File Specify Triggering Setup JTAG 2. Save .STP File & Compile with Design 3. Program Device 4. Acquire Data Copyright © 2005 Altera Corporation 82 Recompilation Recompilation Required Addition/Removal of Instance, Data or Trigger Modifying the Sample Clock or Buffer Depth Enabling/Modifying Trigger-In/Trigger-Out Enabling the Debug Port Lock Mode Prevents Changes Requiring Recompilation Copyright © 2005 Altera Corporation 83 Reducing Recompilation Times Incremental Compilation Maintains Design Synthesis & Placement Recompiles Only Logic Analyzer Change SignalTap II Configuration without Affecting Existing Logic Incremental Routing Allows Switching Trigger & Data Nodes without Full Recompilation Cannot Be Used Together in 5.0 Use Incremental Compilation First, Switch to Routing Will Be Supported in Future Version of Quartus II Copyright © 2005 Altera Corporation 84 SignalTap II Incremental Compilation 1) Enable Full Incremental Compilation 2) Any User-Defined Partitions Must Be Removed (5.0 Limitation) Set Netlist Type of Top-Level Partition to Post-Fit Copyright © 2005 Altera Corporation 85 Assignments Menu SignalTap II Incremental Compilation 3) 4) Compile Design Enable SignalTap II Incremental Compilation Only Post Fitting Nodes Can Be Incrementally Compiled Quartus II Will Automatically Convert Pre-Synthesis Nodes to Post-Fitting Copyright © 2005 Altera Corporation 86 SignalTap II Incremental Routing 1) Enable Smart Recompilation 2) Manually Set the Number of Allocated Nodes Nodes Acts as Place Holders for Real Signals that Can Be Added Later Auto Creates Enough Nodes for Current Number of Data/Triggers Copyright © 2005 Altera Corporation 87 SignalTap II Incremental Routing 3) Add Post-Fitting nodes to STP file SignalTap II: Post-Fitting Nodes Always Incrementally Routed SignalTap II: Pre-Synthesis Nodes Always Cause Full Recompilation if Added Later Benefit of Enabling Incremental Routing on Pre-Synthesis Nodes is They Can Be Removed & Replaced with Post-fitting Nodes without Total Recompilation Pre-Synthesis Nodes Post-fitting Nodes Copyright © 2005 Altera Corporation 88 Quartus II Netlist Optimization New Synthesis Optimization Features Do Not Work Well with SignalTap II SignalTap II Nodes may Disappear Register Re-timing & WYSIWYG Re-Synthesis Should be Disabled if SignalTap II is Used Set Netlist Optimizations Logic Option to Never Allow on Entities which Have SignalTap II Nodes Copyright © 2005 Altera Corporation 89 Performance Preservation SignalTap II can Potentially Effect the Performance of a Design Routing and/or Placement Can Change Possible Solution Back-Annotate Design before Adding SignalTap II See Quartus II Handbook, Volume 3, Chapter 10 for More Suggestions Copyright © 2005 Altera Corporation 90 Thank You Copyright © 2005 Altera Corporation 91