Process costing

advertisement

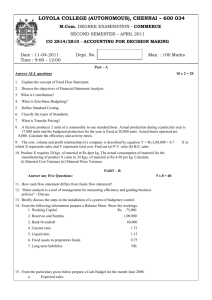

Process, Joint and BYProduct Costing © www.paperhint.com 14-1 Process Accounting Process costing system measures the cost of products under conditions of continuous production, sequential processing and homogeneous output. The procedure under such a system of costing essentially involves averaging the total costs of a process or a department. It is used in industries such as chemicals, food processing, breweries, petroleum refining, paper, glass, metal manufacturing and so on. Process costing assumed a sequential flow of cost from one process to another as unit of output pass through a number of specified production processes. © www.paperhint.com 14-2 COST ACCUMULATION IN PROCESS COSTING The procedure to determine the cost will depend on, firstly, the stage of completion of the product, in each process, secondly, the extent of wastage, spoilage of units in the process and, thirdly, the inter-process profits. In cases where some units are complete, while others are incomplete or partially complete, for the purpose of cost accumulation, the partially completed units are to be converted into comparable equivalent units. Equivalent units = [Actual number of partially completed units × Stage of completion] © www.paperhint.com 14-3 Completed Units Example 1: A product passes through two processes, A and B. During the month ended June 30, 1,500 units were produced. The detailed cost break-up is as follows: Process A Process B Rs 90,000 Rs 75,000 Direct labour 75,000 1,50,000 Direct expenses 15,000 18,000 Direct materials Indirect overhead costs during the period were Rs 60,000 apportioned to the processes on the basis of direct labour cost. No work-in-progress existed at the beginning and end of the period. Prepare relevant process accounts. © www.paperhint.com 14-4 Solution Process A Account To direct materials To direct labour To direct expenses To indirect overheads (Rs 60,000 × 1/3) Rs 90,000 By Cost of output 75,000 transferred to 15,000 process B 20,000 2,00,000 Rs 2,00,000 ________ 2,00,000 Process B Account To process A (cost transferred) To direct material To direct labour To direct expenses To indirect overheads (Rs 60,000 × 2/3) Rs 2,00,000 75,000 1,50,000 18,000 By cost of output transferred to finished goods inventory 40,000 4,83,000 Rs 4,83,000 ________ 4,83,000 Finished Goods Inventory To process B (cost of output) 4,83,000 © www.paperhint.com 14-5 Example 2 From the following information of ABC Manufacturers Limited, prepare a statement of equivalent units. Opening inventory: Partially completed units (40 per cent complete) Units introduced during the period Closing inventory (partially completed units: 70 per cent complete) 600 10,000 2,000 Solution Statement of Equivalent Units 1. Work necessary to complete opening inventory (600 × 0.60) 2. Work necessary to start and finish units introduced during the current year (10,000 – 2,000 partially completed units) 3. Work performed on closing inventory (2,000 × 0.70) Total number of equivalent units © www.paperhint.com 360 8,000 1,400 9,760 14-6 Example 3 From the following production record of XYZ Manufacturing Company Ltd, prepare a statement of equivalent units: Units in process-opening Stage of completion (%): 2,000 material 100 labour 60 overheads 50 New units introduced 20,000 Units completed 18,000 Units in process-closing Stage of completion (%): 4,000 material 100 labour 50 overheads 40 © www.paperhint.com 14-7 Solution Table 1 Statement of Equivalent Units Input Opening inventory 2,000 units + 20,000 units introduced during the current period _____ 22,000 Particulars Work expended on opening inventories (100 per cent stage of completion) Units started and completed during the current period (18,000 total units completed inventory) Closing inventory (work-in-process) Number of units (comple ted or otherwi se) Work performed during the current period [stage of completion (per cent)] Equivalent produced units: input units× stage completion in respect of Mate rial Lab our Overheads Materia l Labour 2,000 Nil 40 50 — 800 1,000 16,000 100 100 100 16,000 16,000 16,000 4,000 22,000 100 50 40 4,000 20,000 2,000 18,800 1,600 18,600 © www.paperhint.com Overheads 14-8 Process Accounts/Production Cost Report The cost of production is shown in the form of a production cost report and/or process cost account. The total cost of production of each process is split into the cost of output and the closing inventory /work-in-process. The distribution between these two elements depends on the method of valuation of work-in-process, namely, (i)weighted average method and (ii) first-in-first-out (FIFO) method. © www.paperhint.com 14-9 Weighted Average Cost Method Under this method, total costs in process are divided by equivalent units produced by the process to ascertain the cost per equivalent unit. Exhibit 1: Process Account (Weighted Average Cost Method). ToWork-in-process (opening inventory) To Current costs Material Labour Overheads To Closing work-in-process inventory to be carried to the next period By Cost of completed units transferred to next process/finished goods inventory A/c By Closing work-in-process © www.paperhint.com 14-10 FIFO Method Unlike the weighted average cost method, this method is based on the assumption that units in process at the beginning of the period are the first to be completed and accordingly the first costs incurred in the current period should be attached to the units of the opening work-in-process inventory. Exhibit 2: Process Account (FIFO Method) To Work-in-process opening inventory during the current period (units partially completed in earlier period) To Current costs 1. To complete opening inventory units 2. To work initiated on new units in the current period in this process: (a)Some of which are completed and transferred (b)Some of which are not yet completed and carried as opening inventory for next period To Closing work-in-process inventory to be carried forward to the next period By units completed 1. Units started in earlier period and completed during the current period 2. Units started and completed during the current period 3. Units started but not completed during the current period © www.paperhint.com 14-11 Example 4 For the firm in Example 3, assume the following: Cost of 2,000 units in process (opening): Materials Labour Overheads Processing costs during the current period Materials Labour Overheads Rs 6,000 3,600 2,400 69,900 56,560 58,360 Prepare a cost of production report for the current period using (a) weighted average, and (b) FIFO costing methods. © www.paperhint.com 14-12 Solution Cost of Production Report of Process A (Weighted average cost method) Flow of completed or partially completed units: Opening 2,000 Introduced 20,000 Total in process 22,000 Less completed 18,000 In process 4,000 Equivalent units in process: Conversion costs Material Labour Overhead Units completed Equivalent inventory units in 18,000 18,000 18,000 4,000 2,000 1,600 22,000 20,000 19,600 ending © www.paperhint.com 14-13 (Contd.) Total cost to be accounted for: Material Labour Overhead s Total Rs 6,000 Rs 3,600 Rs 2,400 Rs 12,000 Current costs 69,900 56,560 58,360 1,84,820 Total cost in process 75,900 60,160 60,760 1,96,820 Equivalent units (EU) in process 22,000 20,000 19,600 — 3.45 3.008 3.1 9.558 Work-in-process (opening) Cost per equivalent unit in process (Total cost ÷ EU) Costs accounted for: Transferred to finished goods inventory (18,000× Rs 9.558) 1,72,044 Work-in-process (closing inventory) Materials (4,000× 100 per cent× Rs 3.45) Rs 13,800 Labour (4,000× 0.50× Rs 3.008) 6,016 Overheads (4,000× 0.40× Rs 3.1) 4,960 Total costs accounted for 24,776 1,96,820 © www.paperhint.com 14-14 Cost of Production Report of Process A (FIFO method) Flow of completed or partially completed units: Opening 2,000 Introduced 20,000 Total in process 22,000 Less completed 18,000 In process 4,000 Equivalent units manufactured: Conversion costs Material Units completed Labour Overheads 18,000 18,000 18,000 4,000 2,000 1,600 22,000 20,000 19,600 in 2,000 1,200 1,000 Equivalent units manufactured 20,000 18,800 18,600 Equivalent inventory units in ending Equivalent units in process Less equivalent opening inventory units © www.paperhint.com 14-15 (Contd.) Total costs to account for: Material Opening process — Overhead Total s — Rs 12,000 Rs 69,900 Rs 56,560 Rs 58,360 1,84,820 work-in- Current costs Labour — Total costs in process 1,96,820 Equivalent units manufactured 20,000 18,800 18,600 — Cost per equivalent unit manufactured 3.495 3.0085 3.1376 9.6411 Costs accounted for: Transferred to finished goods inventory © www.paperhint.com 14-16 First batch: Work-in-process inventory opening Rs 12,000 Add conversion costs: Labour 3.0085) (2,000× 0.40× Rs 2,406.8 Overheads (2,000× 0.50× Rs 3.1376) 3,137.6 Rs 17,544.4 Second batch: Started and completed (16,000× Rs 9.6411) 1,54,257.6 Work-in-process (closing): Materials (4,000× 100 per cent× Rs 3.495) Labour 3.0085) (4,000× 0.50× 13,980 Rs 6,017 Overheads (4,000× 0.40× Rs 3.1376) 5,020.16 25,017.16 1,96,819.16 © www.paperhint.com 14-17 Comparison For comparison of the two costing methods, summary results of important items are listed below: FIFO Weighted average cost (A) Cost of output transferred from (i) Opening inventory (ii) Current production Rs 17,544.40 1,54,257.60 (B) Closing work-in-process © www.paperhint.com Rs 1,72,044 Rs 1,71,802 25,017.16 24,776 1,96,819.16 1,96,820 14-18 Spoilage The spoilage of units under process costing may take place due to a variety of reasons, like use of sub-standard material, poor workmanship, evaporation, shrinkage, break-down of machines, and so on. The effect of spoilage is that the number of actual units produced is less than the units introduced initially. The spoilage or wastage may be normal or abnormal. The unit cost with normal spoilage. = Total process costs – Salvage value of normal spoilage Total units introduced – Normal loss in units Abnormal Loss Abnormal loss = [(Abnormal loss in units × Unit production cost) – Salvage value of abnormal spoilage] Inter-Process Profits Inter-process profit is the profit arising out of transfer of the product of one process to the other on the basis of market/inflated price. © www.paperhint.com 14-19 Example 5 Six hundred kgs of material was charged to process I at the rate of Rs 4 per kg. The direct labour accounted for Rs 200 and the other departmental expenses amounted to Rs 760. The normal loss is 10 per cent of input. During the period, the actual production was 500 kgs and 100 kgs was scrap. Assuming that the scrap is saleable at Rs 2 per kg, prepare a ledger account of process I, showing the values of normal and abnormal losses. Solution Process I Account Particulars To materials Units (kgs) Amount Particulars 600 Rs 2,400 By normal 0.10) To wages Units Amount (kgs) loss (600× 200 By abnormal loss To departmental expenses By process II (500 units transferred at Rs 6 each) 60 Rs 120 40 240 500 3,000 600 3,360 760 600 3,360 © www.paperhint.com 14-20 Working Notes Cost per unit = (Rs 3,360 - Rs 120)/ 540 units = Rs 6 Amount of abnormal loss Units introduced 600 Less normal loss (10 per cent) 60 Normal output expected 540 Less actual output achieved 500 Abnormal loss (units) 40 (×) Cost per unit Rs 6 Total loss 240 Less sale value of scrap (40× Rs 2) Total 80 160 © www.paperhint.com 14-21 Inter-Process Profit Example 6 (Inter-Process Profits) A product passes through three processes, A, B, and C. The output of process A and B is charged to the next process at a price calculated to give a profit of 16.67 per cent on transfer price while the output of process C is charged to the finished stock account at a profit of 13.33 per cent on the transfer price. From the following particulars, prepare the process cost accounts and calculate the amount of reserve that should be made in respect of the stock in hand. Materials and labour Closing stock Process A Process B Process C Rs 7,000 Rs 2,800 Rs 4,800 2,000 2,800 2,000 There was no stock in hand at the beginning of the period. The closing stocks are valued at prime cost in each process. © www.paperhint.com 14-22 Solution Process A Account Particulars Amount Particulars Amount To materials and labour Rs 7,000 By closing stock Rs 2,000 To profit (Rs 6,000 × 0.1667) By process B (Rs 5,000 × 1,000 120/100) 6,000 8,000 8,000 Process B Account Particulars Amount Particulars To process A Rs 6,000 By closing stock To material and labour To profit (Rs 7,200 × 0.1667) 2,800 By process C 6,000 × 120/100) Amount Rs 2,800 (Rs 7,200 1,200 ________ 10,000 10,000 © www.paperhint.com 14-23 Process C Account Particulars To process B To materials and labour To profit (Rs 11,538 × 0.1333) Amount Particulars Rs 7,200 By closing stock 4,800 By finished goods (10,000 × 115.38/100) Amount Rs 2,000 11,538 1,538 ______ 13,538 13,538 © www.paperhint.com 14-24 Working Notes 1 Profit of 16.67 per cent on transfer means 20 per cent on cost price. 2 Likewise, profit of 13.33 per cent on transfer price means 15.38 per cent on cost. 3 Provision for unrealised profit: Process A: Nil Process B: (Rs 1,000 × 2,800)/8,800 = Rs 318 Process C: Closing stock of process C of Rs 2,000 is made up of respective cost proportions of C: B, that is, 2:3 (Rs 4,800: Rs 7,200). © www.paperhint.com 14-25 Process C’s share is = Rs 2,000 × 2/5 = Rs 800 Process B’s share is = Rs 2,000 × 3/5 = Rs 1,200 Profit included in Rs 1,200 (process B’s cost) is = Rs 1200 × 20/120 = Rs 200 (i) Profit included in Rs 1,000. This includes part of process A’s costs: Rs 1,000 × 60/88= Rs 682. Rs 682 includes profit element of = Rs 682 × 20/120 = Rs 113 (ii) Total profit included in process C = Rs 313 (200 + 113) (i + ii) Statement of Profit Process A Rs 1,000 Process B Rs 1,200 Less provision for unrealised profit Process C 318 882 1,538 Less provision for unrealised profit Profit realised 313 1,225 3,107 © www.paperhint.com 14-26 Alternatively Process A Account Particulars To materials and labour To profit (Rs 5,000 × (50/3) × (3/250) Total (Rs) 7,000 Cost (Rs) 7,000 Profi Particulars t (Rs) — By closing stock By process B (transferred) 1,000 — 1,000 8,000 7,000 1,000 © www.paperhint.com Total (Rs) Cost (Rs) Profit (Rs) 2,000 2,000 — 6,000 5,000 1,000 8,000 7,000 1,000 14-27 Process B Account Total (Rs) To process A To materials labour and Cost (Rs) Profit (Rs) Total (Rs) Cost (Rs) Profit (Rs) 6,000 5,000 1,000 By Closing stock (2,800 × 1,000) ÷8,800 2,800 2,482 318 2,800 2,800 — By process C 7,200 5,318 1,882 10,000 7,800 2,200 (transferred) To profit and loss A/c (Rs 6,000 × (50 × 3) ÷ (3 × 250)) — 1,200 10,000 7,800 2,200 1,200 © www.paperhint.com 14-28 Process C Account To process B Rs 7,200 Rs 5,318 To materials and labour 4,800 4,800 1,538 — 1,538 13,538 10,118 3,420 To profit and loss A/c (0.1333 × Rs 11,538) Rs 1,882 By closing Rs 2,000 stock — By finished goods A/c (at 115.38 per cent of cost) © www.paperhint.com Rs 1,687 Rs 313 11,538 8,431 3,107 13,538 10,118 3,420 14-29 Joint Products Two or more products produced simultaneously from a common set of inputs through a single manufacturing (joint) process are called joint products. The joint products can be sold either at the stage of production (split-off point) itself or they can be processed further. The costs incurred before the split-off point are called joint/common/inseparable costs and the costs incurred beyond that point are known as separable costs. The crucial factor in accounting for joint products is the allocation of joint costs among the joint/multiple products from the joint process. Split-off Point Split-off point is that stage in the manufacturing process where joint products are separately identifiable. © www.paperhint.com 14-30 Allocation of Joint Costs The commonly used methods of allocating joint process costs are: (1) Physical Quantities Method/Unit Method (2) Relative Sales Value/Net Realisable Value (NRV) Method (3) Net Realisable Value Less Normal Profit Method (4) Weighted Average Method © www.paperhint.com 14-31 Physical Quantities Method/Unit Method Under the physical quantities method, the total joint costs are allocated to the joint products in proportion to the physical measurement of output. Example 7. (Allocation of Joint Costs Under Unit Method) Royal Industries Ltd manufactures products X, Y and Z by processing a specific raw material in Department 1. The production process is such that every 1,100 kgs of raw materials that is put into Department 1 yields 400 kgs of X, 250 kgs of Y and 350 kgs of Z. The total cost of processing a batch of 1,100 kgs of raw materials through Department 1 is Rs 22,000. Allocate the joint costs to the three products using the physical quantity method. Solution Joint Cost Allocation Using Unit Method Product X Y Z Output (kgs) 400 250 350 1,000 Rates (per cent) 40 25 35 100 © www.paperhint.com Allocated joint cost Rs 8,800 5,500 7,700 22,000 Cost per unit Rs 22 22 22 22 14-32 This method results in identical unit costs for each product. Identical benefits exist only if the products are homogeneous. It will, therefore, provide a satisfactory basis of allocating joint cost if the different products are homogeneous and their sale prices are relatively close to each other. Otherwise, it may lead to misleading results in that there will be wide divergence in the gross margin of the different products as shown in Table 2. Table 2 Gross Margin of Different Products Product X Sales price Product Y Product Z Rs 33 Rs 44 Rs 66 Less cost of production 22 22 22 Cross margin 11 22 44 33.33 50 66.67 Gross margin percentage © www.paperhint.com 14-33 Relative Sales Value/Net Realisable Value (NRV) Method In the net realisable value method, joint costs are pro-rated on the basis of the market value of the joint products. From the facts in Example 7 and Table 2 and assuming all products are sold at the split-off point, joint cost allocation under the relative sale value method would be, as shown in Table 3. Table 3 Joint Cost Allocation Using Sales Value Method Product Output (kgs) Market price Market value Rates Allocated joint cost Cost per unit X 400 Rs 33 Rs 13,200 132/473 Y 250 44 11,000 110/473 5,116 20.46 Z 350 66 23,100 231/473 10,744 30.70 22,000 22.00 1,000 47,300 Rs 6,140 Rs 15.35 Thus, the costs per unit are in proportion to the sale prices. The relative sale price method generates the same margin percentage (53.48 per cent) for all products. Thus, this approach implies a matching of input costs with revenues generated by each output. © www.paperhint.com 14-34 Assuming that for the firm in Example 7, the additional processing for products X, Y and Z is done in departments 2, 3 and 4 respectively. Following are the costs incurred in these departments to process the batch of 1,100 kgs of materials: Product Output (kgs) Department Further processing/ Unit separable cost cost X 400 2 Rs 6,000 Rs 15 Y 250 3 4,500 18 Z 350 4 7,000 20 © www.paperhint.com 14-35 Assuming no change in market price, joint costs of Royal Industries Ltd would be allocated as shown in Table 4. Table 4 Allocation of Joint Costs [Net Realisable Value (NRV) Method] Product Output (kgs) Market price Market value Separab le cost Net realisable value Rat es Allocated joint costs Joint cost per unit X 400 Rs 33 Rs 13,200 Rs 6,000 Rs 7,200 72/2 98 Rs 5,315 Rs 13.28 Y 250 44 11,000 4,500 6,500 65/2 98 4,799 19.19 Z 350 66 23,100 7,000 16,100 161/ 298 11,886 33.96 47,300 17,500 29,800 22,000 22.00 1,000 © www.paperhint.com 14-36 The gross margin rates for each product according to this method are shown in Table 5. Table 5 Gross Margin Rates Product X Sales price Product Y Product Z Rs 33.00 Rs 44.00 Rs 66.00 Joint cost 13.28 19.19 33.96 Separable cost 15.00 18.00 20.00 28.28 37.19 53.96 Gross margin 4.72 6.81 12.04 Gross margin rate (percentage) 14.3 15.5 18.21 Less cost of production: © www.paperhint.com 14-37 Net Realisable Value Less Normal Profit Method The net realisable value less normal profit method differs from the net realisable value method to the extent the joint costs less normal profits are pro-rated. Table 6 Joint Cost Allocation Using NRV Less Normal Profit Method Product Output (kgs) Market value Normal profit Separabl e costs Joint Joint cost cost per unit allocatio n X 400 Rs 13,200 Rs 2,177 Rs 6,000 Rs 5,023 Rs 12.557 Y 250 11,000 1,814 4,500 4,686 22.744 Z 350 23,100 3,809 7,000 12,291 35.117 1,000 47,300 7,800 17,500 22,000 Working Notes Normal profit ratio = 100 per cent – [Total costs – (Joint + Separable)× 100] ÷ Total market value = 100 per cent – [(Rs 22,000 + Rs 17,500)× 100 ÷ Rs 47,300, 83.5 per cent = 16.5 per cent] © www.paperhint.com 14-38 Weighted Average Method Where the joint products are heterogeneous, the weighted average cost method provides a reasonable basis for allocating the joint costs. Continuing with the example of Royal Industries Ltd, assume that the following are the weights assigned to products X, Y and Z after taking into consideration a variety of factors: X, 1; Y, 2; Z, 4. Using the weighted average method, the joint costs are allocated in Table 7. Table 7 Joint Cost Allocation Using Weighted Average Method Product Output (kgs) Weight Weighte d output Ratio Allocated joint cost Cost per unit X 400 1 400 4/23 Rs 3,826 Rs 9.56 Y 250 2 500 5/23 4,783 19.13 Z 350 4 1,400 14/23 13,391 38.26 1,000 2,300 © www.paperhint.com 22,000 14-39 By-Products A by-product is incidental to the process of manufacturing the main/joint product. The accounting treatment depends on whether the by-product is sold at the split-off point or is processed further. The two most commonly-used methods of accounting for byproducts are: (1) Miscellaneous income method (ii) Net realisable value method, (NRV) Recognisation of No Profit on the Sale of By-products Recognisation of Some Normal Profit on the Sale of By-products © www.paperhint.com 14-40 (i) Miscellaneous Income Method Under the miscellaneous income method, the income generated by the by-products is treated as a miscellaneous income and all the associated costs are charged to the main product. (ii) Net Realisable Value Method, (NRV). According to the NRV method, the by-product is valued at its net realisable value and the joint costs are pro-rated between the main product and the by-product. Joint process cost allocated to by-product = (Sale price of by-products – Selling and distribution costs of by-products). A variation of this is to recognise some normal profit from the sale of by-products. Joint cost allocated to by-products = (Sale price of byproducts – Normal profit – Selling and distribution costs of byproduct). © www.paperhint.com 14-41 Example 8 For the facts contained in Example 7, let as assume further that joint production process also yields by-product (70 kgs) in addition to three main products X, Y, Z. Its selling price is Rs 2 per kg and selling costs are Rs 0.50 per kg. Determine the share of joint costs (i) if firm does not recognize profit on the sale of its by-product; and (ii) if it recognizes 10 per cent profit on such sales. Solution Share of Joint Costs (i) When no profits are recognized: Sales revenue (70 kgs × Rs 2) Less selling costs (70 kgs × Rs. 0.50) Share of joint costs (70 kgs × Rs 1.50) (ii) When 10 per cent profits are recognised: Sales revenue (70 kgs × Rs 2) Less normal profit (Rs 140 × 0.10) Less selling costs (70 kgs × Rs 0.50) Share of joint costs (70 kgs × Rs 1.30) © www.paperhint.com Rs 140 35 105 140 14 35 91 14-42 SELL NOW (AT SPLIT-OFF POINT) OR PROCESS FURTHER © www.paperhint.com 14-43 Example 9 (Sell Now or Process Further: Single Product) A B C Ltd manufactures a single product which it sells to firms which process it further before sale. The normal quarterly operating volume for the company is 50,000 units produced and sold. The relevant cost data are as follows: Selling price Rs 10.00 Less standard costs: Direct materials Rs 3.00 Direct labour 1.50 Variable manufacturing overheads 1.00 Fixed manufacturing overheads (Rs 25,000 per quarter) 0.50 Variable selling overheads 1.00 Fixed selling expenses (Rs 12,500 per quarter) 0.25 Standard profit per unit 7.25 2.75 © www.paperhint.com 14-44 The company’s management is considering the possibility of further processing the product and selling it directly to the customers. The management estimates that the product can be sold @ Rs 14 per unit after further processing. The following are the estimates of the additional (per unit/ quarter) costs of processing 50,000 units: Direct labour Rs 1.00 Variable manufacturing overheads 0.50 Variable selling costs 0.20 Additional fixed manufacturing overheads (per quarter) Additional sales expenses (per quarter) 10,000 5,000 You are required to compute the cost (i) without, and (ii) with further processing. Is further processing advisable? © www.paperhint.com 14-45 Solution Cost Comparison: Incremental Analysis Particulars Without further processing With further processing Difference from further processing Total Per unit Total Per unit Rs 10.00 Rs 5,00,000 Rs 14.00 Rs 7,00,000 Rs 4.00 Rs 2,00,000 3.00 1.50 1,50,000 75,000 3.00 2.50 1,50,000 1,25,000 0.00 1.00 50,000 1.00 1.00 6.50 3.50 50,000 50,000 3,25,000 1,75,000 1.50 1.20 8.20 5.80 75,000 60,000 4,10,000 2,90,000 0.50 0.20 1.70 2.30 25,000 10,000 85,000 1,15,000 Per unit Sales Less variables costs: Direct material Direct labour Manufacturing overheads Selling overheads Total Contribution Less separable identifiable fixed costs: Manufacturing Sales Product margin Less common fixed costs: Manufacturing Sales Net income — — 1,75,000 10,000 5,000 2,75,000 25,000 12,500 1,37,500 25,000 12,500 2,37,500 Total 10,000 5,000 1,00,000 — — 1,00,000 Since further processing would result in a greater product margin and net income, the new proposal is acceptable. 14-46 © www.paperhint.com Example 10 (Sell or Process Further: Multiple Products) XYZ Ltd produces three products, A, B and C. One type of a raw material is used for all these products. Raw material enters the process in department 1 of the factory. Department 1 separates material for products A, B and C. During the last quarter, Rs 4,00,000 of material was issued to Department 1. Other direct costs of operating Department 1 were Rs 2,00,000. The output of products A, B and C from Department 1 was: A, 10,000 units; B, 5,000 units; C, 2,000 units. Products A, B and C can be sold after being processed from Department 1 (split-off point) at prices of Rs 60, Rs 30 and Rs 20 respectively. After the split off, product A could be processed further in Department 2. With additional processing, product A can be sold at Rs 70 per unit. After the split-off, product B could be processed further in Department 3 for Rs 30,000 additional cost, and will fetch Rs 35 per unit after processing. Product C is not suitable for further processing and has to be sold at the point of split-off. What action should be management take? © www.paperhint.com 14-47 Solution Sell or Process Further: Decision Analysis Particulars Sales Less separable costs Joint cost of Rs 6,00,000 from Department 1 Contribution (decrease) Product A Product B Sell now Process further Difference from further processing Sell now Process further Differenc es from further Processi ng Rs 6,00,000 — Rs 7,00,000 50,000 Rs 1,00,000 50,000 Rs 1,50,000 — Rs 1,75,000 30,000 Rs 25,000 30,000 1,45,000 (5,000) Irrelevant as costs not affected by the decision Rs 6,00,000 6,50,000 50,000 1,50,000 Thus, it is profitable to process product A further because it yields an incremental profit of Rs 50,000, (additional revenue being Rs 1,00,000 and additional cost, Rs 50,000). The decision is based on the assumption that there is no other opportunity cost for using the facilities of Departments 2 and 3. © www.paperhint.com 14-48 By-Product Processed Further There are several methods of accounting for costs of further processing: (1) Recognition of No Profit on Sale of By-products Method Under this method, share of joint costs allocated to by-products would be determined by subtracting both selling and further processing costs from the sale price of by-products. Sale price of by-products – Further processing cost beyond split-off point – Selling cost = Joint costs. (2) Recognition of Cost Method Normal Profit on Sale of By-Products/Reversal Under this method, by-products are valued at the price which would have been paid by the firm in making outside purchases for these products. (3) Separate Cost Record for By-products This method is most appropriate in situations when the joint manufacturing process yields by-products which are relatively of high value and/or of large quantity; they also require further processing after separation from the joint manufacturing process. © www.paperhint.com 14-49 Example 11 (Reversal Cost Method) In manufacturing the main product, Hypothetical Ltd processes the incidental waste into two products, A and B. From the following data relating to the products, you are required to prepare a comparative profit and loss statement showing the individual costs and other details. The total costs upto separation point were Rs 3,10,400. Main product Sales Costs after separation Rs 8,00,000 Rs 64,000 Rs 96,000 80,000 12,800 14,400 20 30 10 15 Estimated net profit (per cent to sales value) Estimated selling expenses (as per cent to sales value) By-product A By-product B 20 © www.paperhint.com 14-50 Solution Statement Showing Allocation of Joint Costs Particulars By-product A Sales By-product B Rs 64,000 Rs 96,000 12,800 28,800 6,400 14,400 separable costs 12,800 14,400 Share of joint costs allocated 32,000 38,400 Less: estimated net profit on sale (20 per cent, A; and 30 per cent, B) estimated selling expenses (10 per cent, A, and 15 per cent, B) Share of main products in joint costs, therefore, would be: Rs 3,10,400 – (Rs 32,000 + Rs 38,400) =Rs 2,40,000. © www.paperhint.com 14-51 Comparative Profit and Loss Account Particulars Sales revenue Main product By-product A By-product B Rs 8,00,000 Rs 64,000 Rs 96,000 2,40,000 32,000 38,400 80,000 12,800 14,400 Gross profit 4,80,000 19,200 43,200 Less selling expenses 1,60,000 6,400 14,400 Net profit 3,20,000 12,800 28,800 Less cost of production: Joints costs Separable costs © www.paperhint.com 14-52