Business Value of CMMI Level 5

advertisement

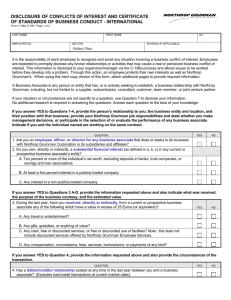

Is CMMI High Maturity Worth the Investment? Southern California SPIN 2 February 2007 Rick Hefner, Ph.D. Director, Process Management Northrop Grumman Corporation Copyright 2005 Northrop Grumman Corporation Background Until recently, Level 3 was considered the industry standard Now, several organizations have achieved high maturity and are touting its benefits To others, high maturity (Levels 4 & 5) is perceived as expensive and of little benefit Do high maturity processes cost more? Is Level 4 and 5 worth the effort? 2 Copyright 2005 Northrop Grumman Corporation CMMI Levels Improving, addressing common causes of variation Quantitatively managed, eliminating special causes of variation 3 Level Process Areas 5 Optimizing Causal Analysis and Resolution Organizational Innovation and Deployment 4 Quantitatively Quantitative Project Management Organizational Process Performance Managed Work proactively managed, organizational standard processes 3 Defined Work planned and tracked (reactively managed) 2 Managed Work performed, but in an ad hoc fashion Requirements Development Technical Solution Product Integration Verification Validation Organizational Process Focus Organizational Process Definition Organizational Training Risk Management Integrated Project Management (for IPPD*) Integrated Teaming* Integrated Supplier Management** Decision Analysis and Resolution Organizational Environment for Integration* Requirements Management Project Planning Project Monitoring and Control Supplier Agreement Management Measurement and Analysis Process and Product Quality Assurance Configuration Management 1 Performed Copyright 2005 Northrop Grumman Corporation The Project Manager’s Dilemma at Level 3 I want to use the organization’s standard process, but… … Does it’s performance and quality meet my customer’s expectations? … If not, how should I tailor the process? 4 Copyright 2005 Northrop Grumman Corporation CMMI Level 4 Organizational Process Performance Establishes a quantitative understanding of the performance of the organization’s set of standard processes Provides process performance data, baselines, and models to quantitatively manage the organization’s projects measurement repository organizational standard process organizational performance data & models tailoring project performance 5 project’s defined process customer and project objectives Quantitative Project Management Quantitatively manage the project’s defined process to achieve the project’s established quality and process-performance objectives. Copyright 2005 Northrop Grumman Corporation Exercise – What is Quantitative Management? Suppose your project conducted several peer reviews of similar code, and analyzed the results Mean = 7.8 defects/KSLOC +3σ = 11.60 defects/KSLOC -3σ = 4.001 defects/KSLOC I Chart for Defects What would you expect the next peer review to produce in terms of defects/ KSLOC? What would you think if a review resulted in 10 defects/KSLOC? 12 UCL=11.60 3 defects/KSLOC? Individual Value 11 10 9 8 Mean=7.8 7 6 5 4 LCL=4.001 How would this be useful to your project/ organization? Was the review effective? Was the process different? Is the product different? 3 0 5 10 15 Observation Number 6 Copyright 2005 Northrop Grumman Corporation Exercise – What is Required for Quantitative Management? What is needed to develop the statistical characterization of a process? I Chart for Defects 12 UCL=11.60 Individual Value 11 10 9 8 Mean=7.8 7 6 5 4 LCL=4.001 The process has to be stable (predictable) Process must be consistently performed Complex processes may need to be stratified (separated into simpler processes) There has to be enough data points to statistically characterize the process Processes must occur frequently within a similar context (project or organization) 3 0 5 10 15 Observation Number 7 Copyright 2005 Northrop Grumman Corporation Typical Choices in Industry Most customers care about: Delivered defects Cost and schedule Defect Detection Profile 180.00 160.00 140.00 120.00 Defects/KSLOC So organizations try to predict: Defects found throughout the lifecycle Effectiveness of peer reviews, testing Cost achieved/actual (Cost Performance Index – CPI) Schedule achieved/actual (Schedule Performance Index – SPI) 100.00 All Projects New Process 80.00 60.00 40.00 20.00 0.00 Req'mts Design Code Unit Test Integrate Sys Test Del 90 Days Phase Process performance • Process measures (e.g., effectiveness, efficiency, speed) • Product measures (e.g., quality, defect density). 8 Copyright 2005 Northrop Grumman Corporation What Can a Level 4 Project/Organization Do? Determine whether processes are behaving consistently or have stable trends (i.e., are predictable) Identify processes where the performance is within natural bounds that are consistent across process implementation teams Establish criteria for identifying whether a process or process element should be statistically managed, and determine pertinent measures and analytic techniques to be used in such management Identify processes that show unusual (e.g., sporadic or unpredictable) behavior Identify any aspects of the processes that can be improved in the organization's set of standard processes Identify the implementation of a process which performs best 9 Copyright 2005 Northrop Grumman Corporation What Drives the Effectiveness of Level 4? • Comparable projects? • Enough measures to stratify/analyze the data? measurement repository • How detailed are the standard processes? • What tailoring is allowed? organizational standard process • Enough data points? • How insightful/useful are the baselines and models? organizational performance data & models tailoring project performance • Stable processes? • Clean data? 10 project’s defined process • How much tailoring? • Does the project follow its process? customer and project objectives • Does the organization’s process fit the objectives? Copyright 2005 Northrop Grumman Corporation What Does Level 5 Add to the Organization? Level 5 Organizational Innovation & Deployment Goals are quantitative (e.g., reduce variation by X%, reduce mean by Y%) Incremental improvements – eliminate special causes of variation Innovative improvements - cause a major shift in process capability Potential improvements are analyzed to estimate costs and impacts (benefits) Level 3 Organizational Process Focus Improvements are piloted to ensure success Improvements are measured in terms of variation and mean Goals are qualitative (e.g., get better) The effects of the improvements are not estimated or measured 11 Copyright 2005 Northrop Grumman Corporation Peer Reviews – Improving the Process Reduce the variation Train people on the process Create procedures/checklists Strengthen process audits Increase the effectiveness (increase the mean) 12 Train people Create checklists Reduce waste and re-work Replicate best practices from other projects Copyright 2005 Northrop Grumman Corporation What Does Level 5 Add to the Project? Causal Analysis & Resolution Identify and analyze causes of defects and other problems Take specific actions to remove the causes The project can then take actions to prevent the occurrence of those types of defects and problems in the future Many projects implement Causal Analysis & Resolution at Level 4 Identify and eliminate special cause variations to stabilize the process 13 Copyright 2005 Northrop Grumman Corporation How Does Level 4 & 5 Benefit the Customer? Organizational process performance More accurate estimates Quantitative project management Problem behaviors are recognized faster, enabling quicker resolution Organizational innovation and deployment The project benefits from improvements found and proven on other projects Causal analysis The project fixes the source of defects to prevent future defects Level 5 reduces costs and improves quality (so we implement it on all projects) 14 Reference: How Does High Maturity Benefit the Customer?, R. Hefner, Systems & Software Technology Conference, 2005 Copyright 2005 Northrop Grumman Corporation Two Complementary Approaches to Process Improvement Data-Driven (e.g., Lean Six Sigma) Model-Driven (e.g., CMM, CMMI) Clarify what your customer wants (Voice of Customer) Critical to Quality (CTQs) Determine the industry best practice Benchmarking, models Determine what your processes can do (Voice of Process) Statistical Process Control Compare your current practices to the model Appraisal, education Identify and prioritize improvement opportunities Causal analysis of data Identify and prioritize improvement opportunities Implementation Institutionalization Determine where your customers/competitors are going (Voice of Business) Design for Six Sigma 15 Look for ways to optimize the processes Copyright 2005 Northrop Grumman Corporation Lean Six Sigma Provides the Needed Tools to Implement CMMI High Maturity Number of Noncompliances Process knowledge Process variation 12 UCL Process performance 16 Actual 14 Expected 8 12 95% limits _ X 4 8 4 2 Projects Audited in First Quarter UCL 1 UCL 2 0 1 2 3 4 Stabilize 16 Register allocation defect Incorrect processor register usage 6 0 Poor documentation Lack of processor knowledge 10 2 Can’t keep track Pass 1 architecture Can’t isolate 10 6 Side effects of register usage 5 6 7 7C 8B 8B 8C 8D 8F 20 21 22 LCL 2 23 LCL 1 Improve & Control Predict Level 4 Level 5 Understand project’s process capabilities based on process performance baselines Control process variation (remove “assignable causes”) Predict results using process performance models Manage to achieve goals Base improvement goals on future business needs Eliminate problem and defect causes (“common causes”) Select, predict, and measure improvements to change the process performance baselines shift the mean; tighten the variance Manage change Copyright 2005 Northrop Grumman Corporation Barriers and Challenges Engineering process measurements are often difficult to analyze Inherent process variations when human creativity is involved Dirty (or no) data Vague measurement definitions, human recording errors Infrequent measurements Non-normal data Need for stratification/aggregation Must demonstrate the value of quantitative data to managers Management style - reactive vs. proactive vs. quantitative Less value in a chaotic environment Must involve customers 17 Copyright 2005 Northrop Grumman Corporation Northrop Grumman Launch Workshop Strategy Prerequisite 2 week Six Sigma Green Belt training Launch 0 Executive Overview Launch 1 Intro to Quantitative Management • Finalize project goals • Obtain measurement data for the subprocesses the project will put under SPC analysis • Become familiar with Northrop Grumman Mission Systems QPM process • Definition of related six sigma project(s) • Incorporate and measure progress against the Level 4/5 plan tasks 18 Launch 2 Statistical Process Control • Collect relevant project historical data, review it and perform initial “clean up” • Collect data from project subprocesses and put on SPC charts • Complete project profile • Review business issues for clarity Launch 3 Quantitative Monitoring & Management Launch 4 CMMI Level 5 (OID &CAR) • Finish building models • Develop project CAR plan • Begin tracking to models • Start project CAR activities • Draft Quantitative Measurement Plan • Submit improvements to support OID (when applicable) • Draft QPM evidence • Measure progress against the Level 4/5 plan tasks • Measure progress against the Level 4/5 plan tasks • Identify Quantitative Measurement Plan data • Measure progress against the Level 4/5 plan tasks STM 925.1-Exec, 01, 05-05-04 Copyright Rev 2005 Northrop Grumman Corporation Lessons Learned (1 of 2) Based on over 35 Northrop Grumman CMMI Level 5 organizations 1) Level 3 metrics, measurement processes, and goal setting are generally inadequate for Levels 4 and 5 Better definitions of the measures Lower level metrics of lower level subprocesses Stratifying the data properly 2) When operating at Level 3, it is difficult to predict the measurement improvements needed Trying to understand and stabilize the key subprocesses will naturally drive you to the right metrics 3) CMMI and Six Sigma compliment each other CMMI can yield behaviors without benefit Six Sigma improvements based solely on data may miss innovative improvements (assumes a local optimum) 4) Six Sigma is an enabler for higher maturity Focus on data, measurement systems, process improvement Tying improvements to business goals Tools and methods support the Level 4/5 analysis tasks 19 Copyright 2005 Northrop Grumman Corporation Lessons Learned (2 of 2) 5) Projects have different quality and process performance needs, and should select different subprocesses to quantitatively manage This will also slow adoption, and complicate the organizational baselines and models 6) Training the staff as Six Sigma Green Belts has resulted in a change of language and culture Voice of Customer, data-driven decisions, causal analysis, etc. Better to use the tools in everyday work than to adopt the “religion” 7) The real ROI comes in institutionalizing local improvements across the wider organization CMMI establishes the needed mechanisms Having all the tools at Level 5 gives you the insight to manage each project the way the customer needs it to be managed 20 Copyright 2005 Northrop Grumman Corporation References 2006 CMMI Conference “Using ‘Voice of Customer’ Tools to Advance Organizational Innovation and Deployment”, Don Corpron “Making OID Effective,” Diane Mizukami “Statistical Control of System and Software Design Activities, “ Dr. Richard Welch and Ms. April King “Business Value of CMMI Level 5,” Gene Miluk, Lynn Penn, Rick Hefner and Rushby Craig Other Sources “Squeezing Variation for Profit”, Don Corpron, CMMI Technology Conference and User Group, 2005 “How Does High Maturity Benefit the Customer?,” Rick Hefner, Systems & Software Technology Conference, 2005 “Using a Process Database to Facilitate Transition to Level 4”, Rick Hefner, International Conference on Applications of Software Measurement, 2002 “Business Value and Customer Benefits Derived from High Maturity”, Alan Pflugrad, CMMI Technology Conference and User Group, 2002 http://www.isixsigma.com High Maturity with Statistics, SEI course 21 CMMI Implementation: Embarking on High Maturity Practices, Shivraj Kanungo, Asha Goyal Measuring the Software Process, William A. Florac, Anita D. Carleton Metrics and Models in Software Quality Engineering, Stephen H. Kan Understanding Variation: The Key to Managing Chaos, Donald J. Wheeler Copyright 2005 Northrop Grumman Corporation