hazard communication - Oklahoma State University

advertisement

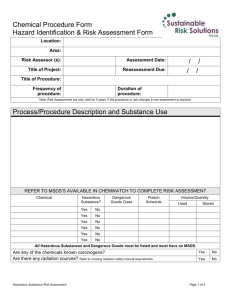

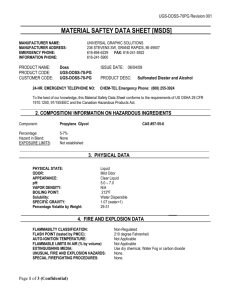

HAZARD COMMUNICATION Train-the-Trainer RIGHT-TO-KNOW PROGRAM Train-the-Trainer October 2011 OSU Environmental Health & Safety Dept. Oklahoma Hazard Communication Standard Enacted: April 11, 1986 Scope: The Oklahoma standard applies to all public employers who use hazardous substances, to any person who imports and sells a hazardous substance to any public employer in the state, and to manufacturers who produce or distribute hazardous substances in the state. State Agency: Oklahoma Department of Labor 4001 North Lincoln Boulevard Oklahoma City, Oklahoma 73015 (405) 528-1500 Authority: Title 40 O.S. Sections 407 et seq Oklahoma Dept. of Labor, effective July 1, 2009, adopted the Federal Hazard Communication Standard in 29 CFR 1910.1200, with the exception that training is required annually. To Whom Does This Program Apply? Cities Counties Public Authorities Public Schools Universities All State and Local Government Employers Five Stages of Hazcom Program 1. Material Safety Data Sheets (MSDS) 2. Labeling & Marking System 3. Employee Training Sessions 4. Written Plan 5. Chemical Inventory (Online) COMPONENT ONE Material Safety Data Sheets Material Safety Data Sheets Purpose: • Prepared by Chemical Manufacturers or Importers to describe characteristics of product and provide information concerning potential hazards. • Must be readily available for employee review at all times the employee is in the work place. What Information is on an MSDS? • Company Information • Hazardous Ingredients • Physical Data • Fire and Explosion Hazard Data • Health Hazard Data • Reactivity Data • Spill or Leak Procedures • Special Protection Information • Special Precautions 02/24/99 46 Review MSDS for Completeness It is the responsibility of the end user to determine that an MSDS is complete and has useable information. Some manufacturers have a tendency to gloss over hazards and certain facts. COMPONENT TWO Labeling & Marking System Labeling & Marking System • Manufacturer's Responsibility Name and Address Identity of Hazardous Components Appropriate Hazard Warnings • User's Responsibility Identity of Hazardous Components Appropriate Hazard Warnings CAS# -- Chemical Abstract Service Number Assure that Manufacturer's label is not defaced or removed OSU’s HMLS (Hazardous Materials Labeling System) Code-Oriented Easy to Learn Complements the Manufacturer’s Labeling "*" next to the Health number means that the substance has chronic health effects. Label Chemical: Isopropyl Alcohol Cas# 67-63-0 Health Flammability Instability Personal Protection Oklahoma State Hazard Communication HEALTH 4 3 2 1 0 FLAMMABILITY INSTABILITY Deadly Very Flammable May detonate Extreme Danger Flammable under most conditions Explosive Dangerous May ignite—use caution Unstable Slight Hazard Must be preheated to ignite Normally stable No Hazard Will not burn Stable OSU’s Personal Protection Symbols Problem Solving Session Signs & Placards All buildings on Oklahoma State University property will be placarded in compliance with the law. Each building that contains over the TPQ (threshold planning quantity) of a hazardous substance will bear the appropriately numbered, diamond-shaped placard approved by the National Fire Protection Association (NFPA). ISOPROPYL ALCOHOL HAZARD COMMUNICATION WORKSHOP ANSWERS • MEK 1*30 (Depends) • TOLUENE 2*30 (Depends) Not Regulated (Depends) 2*01 (Depends) • WOW • Aluminum COMPONENT THREE Employee Training Program Employee Training Program REQUIRED: • Within 30 Days of Initial Assignment • Whenever New Hazards Are Introduced • Annual Review Is Required Training & Information Requirements Employees must be informed of: • Requirements of Regulations • Any Operations in Their Area Where Hazardous Chemicals Are Used • Location and Availability of MSDS and Plan Training must cover: • Method to Detect Presence of Release • Physical and Health Hazards • Measures for Personal Protection • Details of Written Hazard Communication Plan Proposed Training Program Format Follows the Five Program Stages 1. Material Safety Data Sheets 2. Marking and Labeling System 3. Employee Training 4. Written Plan 5. Chemical Inventory Proposed Training Program Format Describe Policies and Procedures Hazard Detection Spill Response Use of Protective Equipment Open Book Test Conducting the Training • It will take a minimum of 30 to 45 minutes to conduct the basic Hazard Communication Training. • If there are any specific hazardous substances or situations to be trained on, the session will take longer to complete, depending on the type and number of hazardous substances. EXAMPLE: Office Employees with no specific hazardous substances. 30 - 45 minutes per session Paint Shop Employees with 4 specific substances to be trained on (paints, solvents, etc.) 1 to 1½ hours, depending on their training needs Choosing Specific Substances for Training Train on any substance having an OSU HMLS rating of... HEALTH: FLAMMABILITY: REACTIVITY: 3 or above 3 or above 2 or above If none of the above, choose 4 or 5 of the worst substances that you do have and use them in the training. Training (Comments) • Training isn't handing out MSDS/s and asking them to read. • Training should be accompanied by a simple test with signature, and filed for documentation. • Training probably occurs in two phases: 1. General chemical safety, spill response, labeling procedure, etc. Perhaps film or tape. 2. Specific work place. Specific labels, MSDS/s, emergency plans, etc. Training (Comments) • Phase 2 (specific) trainers should be trained and provided guidelines. • If decentralized, periodic audits will help. • Annual retraining or when new hazard is introduced. • Trainers should not criticize program. • Training packages are available: * computer self-paced instruction * films * video tapes • There is no substitute for workplace-specific training. Sample Test for Hazard Communication 1. MSDS means: 2. What does this emblem mean and where can you expect to see it? 3. This training session is your required Hazard Communication training (true or false). 4. Where are the MSDS’s kept for your department? 5. If you have a question about the safe use of a chemical, always consult your: _________. • Signature & Date Emergency Information Signage COMPONENT FOUR OSU’s Written Program OSU’s Written Program Our written program is Oklahoma State University Policy and Procedure #3-0535 --- “Hazard Communication Program” COMPONENT FIVE Chemical Inventory Chemical Inventory Kept online at ehs.okstate.edu Virtually paperless Updated at least annually Updated when adding any new product Signs, Placards, Labeling Identify chemical hazards Chemical Safety Assistant (online inventory program) Chemical Safety Assistant (online inventory program) Inventory reports can be printed or saved as a PDF file. Methods of Instruction Conducting a Training Session INTRODUCTION NOTE: Make use of the training manual and contents in the packet when conducting the training session. 1. Have Trainees sign attendance sheet. 2. Introduce Right-To-Know and who it covers. 3. Briefly explain the intent of RTK legislation. 4. Introduce the five components of an RTK program. 5. Inform trainees that a test will be given at the end of the session. REMEMBER Make sure that the training session addresses the materials and situations encountered in your department. Component One MATERIAL SAFETY DATA SHEETS (MSDS) Explain the purpose of an MSDS. Explain what information is on an MSDS (use a material common in your department). Identify: Any health hazards (acute or chronic effects) Exposure Limits First Aid Procedures Material's Physical Characteristics Fire and Explosion Hazards Material's Reactivity Personal Protection Requirements Special Precautions Manufacturer's Name Emergency Phone Numbers Component One MSDS (continued) Inform the trainees of the location of the MSDS/s and CIL/s that apply to them and that they are readily available to the employees. OSU ADDITIONAL INFORMATION Explain the meaning of, and method of filling out, the Employee Exposure Report. POINTS TO STRESS Make sure everybody understands what an MSDS is and how to read one. Component Two LABELING Explain the OSU (HMLS) system for labeling hazardous materials and where it is used. Show an example label and explain. Allow the trainees to read a label for an example material common in your department. HAZARDOUS MATERIAL SIGNAGE Explain the OSU Uniform Laboratory Hazard Signs (ULHS) for work area hazardous materials and where it is used. Explain that EHS will put placards on campus buildings. Component Two POINTS TO STRESS Make sure trainees understand how to interpret the HMIS labeling scheme, and where they can expect to encounter it. Make sure trainees understand how to interpret the NFPA labeling scheme, and where they can expect to encounter it NOTE: Make use of the material provided with this manual when conducting training. Component Three TRAINING Explain when Right-To-Know training is required. Explain what this training must consist of. POINTS TO STRESS This training session is their required RTK training Component Four WRITTEN PROGRAM Explain OSU's Hazard Communication Policy (Policy & Procedures Letter 3-0535). Use and refer to OSU’s Hazard Communication Brochure, which is summary of the Policy. The brochure is available on the EHS website at http://ehs.okstate.edu/hazcom/brochure.pdf . POINTS TO STRESS The plan is available to employees on request, and where that plan is located. Component Five CHEMICAL INVENTORY Explain why a Chemical Inventory is required, citing what laws and regulations (federal and state), and how often it should be updated. Explain how it is used by emergency response personnel. Explain how campus hazard signage is determined and what its function is. Explain when an MSDS is required. Explain how access to the Online Inventory is obtained. POINTS TO STRESS Make sure everyone knows that the Chemical Inventory must be updated annually and any time a new substance is brought into the department. Specific Department Hazards Cover any hazards or situations unique to your department. Choose 4 or 5 of the worst materials encountered in your department. Train employees on how to recognize and deal with emergency situations concerning these specific materials. If there are any special Personal Protection Equipment requirements, then the employees should be trained on how to use the equipment. Explain procedures for dealing with spills and emergency situations. OSU-Specific Guidelines O Contingency Checklist Important to identify contact personnel as well as an evacuation route O Employee Exposure Report Responsibility of employee’s supervisor to fill out this report. It will be kept on file for 40 years from date of exposure. O Labels Available from EHS at no charge to departments. Please call 4-7241 to place an order for labels and how to obtain needed forms.