1.Background - Lindum Group

advertisement

Health & Safety

During The Installation

of Polyurethane Resin

Flooring

Presented By:

Dr Derrick Hulett

Group Compliance Manager – John Lord Group of Companies

Member of FeRFA Technical Committee

CONTENTS

1. Background

2. Recent Developments

3. Control Measures

4. John Lord Approach

5. References

1.Background

•

Current Health & Safety Fears

•

•

•

•

•

Origin of the Health & Safety Issues

•

•

•

•

Is the MDI in polyurethane resin a Carcinogen?

Does the MDI also cause industrial Asthma?

Does the dust in the aggregates cause Silicosis?

Is the only safe way of protecting against these threats is to wear

positive pressure full face respirators

MDI exposure study reported in the Journal of Toxicological Science

(1994)

EU MDI Risk Assessment Report

Reclassification of MDI’s (2005)

HSE’s Involvement

•

•

•

Fit3 Disease Reduction Programme

Dust & Fume Project

REACH

1.Background

•

MDI as a Carcinogen

•

•

•

In 2008 the 30th Adaptation to Technical Progress (ATP) of the

Dangerous Substances Directive classified MDI (CAS No. 26447-40-5)

as R40 – Category 3 carcinogen “Limited evidence of a Carcinogenic

effect.”

In December 2010 the CLP regulations classified MDI as H351:

Suspected of causing cancer by inhalation. Cat 2 Carcinogen

“substances which it is assumed can cause cancer, on the basis of

reliable animal evidence.”

However

•

•

Different CAS Number (9016-87-9)

Animal study not representative of substance used in flooring. (to be

discussed later)

1.Background

•

MDI as a cause of Asthma

•

•

•

There are approximately 17,000 new cases of occupational asthma each

year .

One major cause is the inhalation of MDI mists particularly in the 2 pack

isocyanate paint spraying of vehicles.

However

•

In paint spraying the particle size and the aerosol state enables the

isocyanate to be inhaled. This is not the case with the MDI used in

polyurethane flooring.

1.Background

•

Silicosis from Dust in Aggregates

•

•

•

Workers exposed to fine dust containing quartz are at risk of developing

a chronic and possibly severely disabling lung disease known as

"silicosis".

In addition to silicosis, there is now evidence that heavy and prolonged

workplace exposure to dust containing crystalline silica can lead to an

increased risk of lung cancer. The evidence suggests that an increased

risk of lung cancer is likely to occur only in those workers who have

developed silicosis.

However

•

•

Excessive long term exposures to almost any dust, are likely to lead to

respiratory (breathing) problems.

Preventing inhalation through the use of a simple FFP3 dust mask (face

fit tested) will remove the problem.

1.Background

•

Use of Full Face (Air Fed) Respirators

•

•

•

Respirator manufacturers will advise that the only truly safe form of

respirator against respirable MDI is an air fed mask which does not

contain standard filters.

The reason for this is that although filters such as “Abek” and even FFP3

will filter out the MDI, the breakthrough period cannot be established.

However

•

The MDI used is not respirable.

1.Background

•

MDI Exposure Study

•

•

•

In 1994 an article was produced for the Toxicological society describing

MDI inhalation tests carried out on 60 Wistar rats (Reuzel et al 1994).

One conclusion was that chronic exposure to polymeric MDI at a level of

6.0 mg/m3 was related to the occurrence of pulmonary tumours.

However

•

•

•

•

•

60 rats were tested over a two year period.

The MDI was aerosolised to make it inhalable.

Exposures at other levels (0.2 & 1.0 mg/m3) did not lead to any

tumours.

Only 1 rat at the 6.0 mg/m3 dose developed a pulmonary tumour.

Some of the rats developed other tumours totally unrelated to the

study.

1.Background

•

EU MDI Risk Assessment

•

•

•

•

In 2005 a department of the Belgian government carried out a risk

assessment on behalf of the European Union into MDI (CAS No. 2644740-5) .

Among the conclusions from the assessment it was stated that “There

is a need for limiting the risks” to workers and consumers who come

into contact with this type of MDI.

This assessment undoubtedly influenced the subsequent reclassification

of MDI MDI (CAS No. 26447-40-5) .

However

•

•

The risk assessment used the findings of the study by Reuzel et al.

Once again, different CAS Number (9016-87-9)

1.Background

•

Reclassification of MDI

•

•

As mentioned earlier 30th ATP of the Dangerous Substances Directive

classified MDI (CAS No. 26447-40-5) as R40 – Category 3 carcinogen

“Limited evidence of a Carcinogenic effect” and the CLP regulations

classified MDI as H351: Suspected of causing cancer by inhalation. Cat

2 Carcinogen “substances which it is assumed can cause cancer, on the

basis of reliable animal evidence.”

However

•

•

Different CAS Number (9016-87-9)

As stated by ISOPA “There will be no impact on workplace health and

safety from this change beyond what is good practice today.”

1.Background

•

HSE Involvement – DRP

•

•

•

•

In 2002 the HSE agreed its “chemicals strategy” and programmes of

work were set up to address disease reduction and management in 3

areas: (Cancer, Respiratory disease and Skin disease.

Since 2004/5 the work has continued under the HSE's Disease

Reduction Programme (DRP).

The objective of the Disease Reduction Programme is to deliver

reductions in the incidence of ill health related to chemicals in the

workplace.

The approach is to target industries for inspection based on the

perceived size of the problem.

1.Background

•

HSE Involvement – Dust & Fume Project

•

•

The Respiratory Diseases Unit within the Long Latency Health Risks

Division (LLHRD) are working on a ‘Dust and Fumes Project’, which aims

to reduce the incidents of respiratory disease by raising awareness of

the long term health effects of inhaling dust and fumes in the

workplace.

Using information gathered over a number of years, five ‘high risk’

industries have been identified for targeted campaigns – (stoneworking,

construction, foundries, quarries and welding.)

1.Background

•

HSE Involvement – REACH

•

•

•

•

•

•

On 22nd June 2009 Annex XVII to Regulation (EC) No 1907/2006

(REACH Regulations) was amended by Commission Regulation (EC) No

552/2009.

In the amended Annex XVII, substance No. 56. Methylenediphenyl

diisocyanate (MDI) CAS No 26447-40-5 EC No 247-714-0 was amended as

follows.

1. Shall not be placed on the market after 27 December 2010, as a constituent of

mixtures in concentrations equal to or greater than 0,1 % by weight of MDI for

supply to the general public, unless suppliers shall ensure before the placing on

the market that:

Gloves provided

Warning notices regarding sensitisation, asthma, ventilation and type

1 masks (ABEK)

Comment

•

The above points in bold highlight some of the confusions

1.Background

•

HSE Involvement – REACH

•

•

HSE is the competent authority (CA)for assessing REACH Compliance in

the UK.

HSE have issued the following statement regarding their future work as

the REACH CA:

•

Targeted inspection campaigns

•

This year sees the launch of a series of substance-specific

inspection campaigns. These campaigns will identify dutyholders

on the basis of detailed intelligence on supply chain activity

surrounding the substances subject to inspection. By comparing

this intelligence to records of registration and pre-registration, we

will be able to target and approach those dutyholders that appear

to be in breach of the core requirements in REACH to register

substances ('no data, no market[8]'). In addition, this will present

us with opportunities to assess compliance with other aspects of

REACH.

2.Recent Developments

•

ISOPA Position Paper

•

HSE Laboratories Research Document

HSL/2005/60

•

FeRFA Consultation with HSE

2.Recent Developments

•

ISOPA Position Paper

•

•

•

ISOPA is the European Diisocyanate and Polyol Producers Association.

In May 2011 ISOPA produced a document entitled: Timeline For The Reclassification And Labeling Of MDI As Substance And Mixtures.

Conclusions of the paper include:

•

The concentration required to cause tumours in the lungs of the

test animals was 6 mg/m³, which is more than 100-times the

MAK-value (0.05mg/m³). These aerosols had to be respirable,

what means that the droplets need to have a so-called

aerodynamic diameter of 10 μm.

•

The particle size, even of aerosol droplets, in industry are

massively larger than this (in excess of 40 μm) making them not

respirable.

•

Health surveillance programmes involving around 12,000 workers

in the MDI processing industry did not show any increased risk of

lung cancer.

2.Recent Developments

•

HSE Laboratories Research Document

HSL/2005/60

•

•

•

Tests were carried out on diisocyanates in 2-pack paint systems.

Although not the exact same process as involved in the installation of

polyurethane resin flooring it is representative.

The following conclusions were arrived at:

•

The laboratory tests found no airborne isocyanate during small

scale mixing and brush and roller application.

•

The static samples were carried out close to the operations under

test and so represent a "worst-case" series of results.

•

These results suggest that airborne isocyanate is not a significant

hazard during these operations

•

The biological monitoring results associated with this work found

no evidence of isocyanate exposure suggesting that the personal

protective equipment (PPE) worn during these operations was

adequate to prevent exposure.

2.Recent Developments

•

FeRFA Consultation with HSE

•

•

•

•

•

FeRFA is the Resin Flooring Association and represents manufacturers

and installers of polyurethane resin flooring.

On the 14th June 2011 members of the Technical Committee of FeRFA

met with representatives of HSE including HM Principal Specialist

Inspector, Head of Health Risks, Management Unit.

At the meeting FeRFA presented evidence broadly as outlined in this

presentation and specifically:

Referred to the MDI Exposure study by Reuzel et al (1994) and

commented that the tests had been carried out at 300 times the

Occupational Exposure Level using a specially prepared finely dispersed

respirable aerosol.

It was also stated that:

•

MDI is not aerosolised in flooring applications

•

MDI has very low vapour pressure

2.Recent Developments

•

FeRFA Consultation with HSE

•

•

FeRFA produced evidence to show that:

•

MDI is not aerosolised in flooring applications

•

MDI has very low vapour pressure

•

The reclassification of MDI has no impact on workplace health &

safety beyond what is good practice today.

•

There is no risk of aerosol isocyanate in normal use of the products

as flooring materials

•

The UK Occupational Exposure Limit (OEL TWA) = 0.02mg/m3 in

an 8 hour period, test

•

results show less than 3% of the OEL during an 8 hour working

period.

During the meeting an agreement was reached as to the control

measures required during the installation of polyurethane resin flooring.

3.Control Measures

•

Based on the evidence presented and

following the Consultation with HSE the

following control measures should be

adopted to provide protection against any

health hazards during the installation of

polyurethane resin flooring.

•

•

•

•

•

•

•

•

Method statement and risk assessments

COSHH assessments

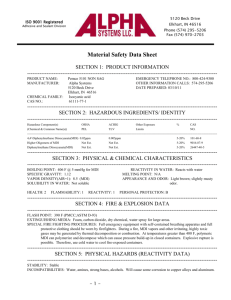

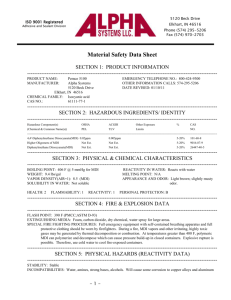

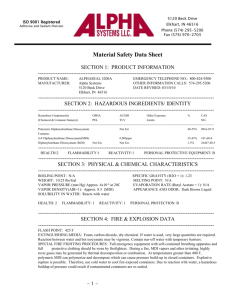

MSDS if required

Lung function health surveillance

Segregation

FFP3 disposable respirators for mixing and floor preparation

Respirators not required for MDI

PPE to prevent skin contact with MDI

4. John Lord Approach

•

The following is a list of Control Measures

adopted by John Lord

•

•

•

•

•

•

Every site has a method statement, risk assessments and COSHH

assessments detailing specific control measures.

Lung function health surveillance is carried out on all persons exposed

to MDI and Crystaline Silica (helps early detection of COPD).

Wherever possible ask for persons not essential to the process of

installing the resin flooring to be segregated from the activity (this is

mainly to remove the risk of skin contact with the MDI and to reduce

the possibility of spillages).

FFP3 masks worn when mixing and when creating dust through floor

preparation. Face fit testing carried out.

Overalls, Impermeable gloves, Safety glasses, Safety boots or shoes,

Special provisions regarding hard hats and glasses for floor layers

5. References

Reuzel, P.G.J, J.E.H Arts, L.G. Lomax, M.H.M Kuijpers, C.F. Kuper, C.

Gembardt, V.J. Feron and E. Löser 1994, Chronic Inhalation Toxicity and

Carcinogenicity Study of Respirable Polymeric Methylene Diphenyl

Diisocyanate (Polymeric MDI) Aerosol in Rats, Toxicol. Sci. (1994)

22(2): 195-210

http://toxsci.oxfordjournals.org/content/22/2/195.short

ISOPA, 2011, Timeline For The Re-classification and Labelling of MDI

as Substance and Mixtures, May 2011

http://www.isopa.org/isopa/uploads/Documents/documents/Timeline%20for%20ReC&L%20of%20MDI%20as%20subtance%20and%20Mixtures.pdf

ISOPA, 2011, EU, MDI-containing Consumer Products, May 2011

http://www.isopa.org/isopa/uploads/Documents/documents/Customer%20Information%20MDI

%20Risk%20Management%20%20EU%20Restrictions.pdf

5. References

Coldwell, M. and J. White, 2005, Measured Airborne Isocyanate from

Mixing and Brush and Roller Application of Isocyanate based 2-pack

Paints, Results - February 2005, HSL/2005/60

http://www.hse.gov.uk/research/hsl_pdf/2005/hsl0560.pdf

European Commission – Joint Research Centre, Institute for Health and

Consumer Protection, European Chemicals Bureau (ECB), European Union

Risk Assessment Report - methylenediphenyl diisocyanate (MDI) - CAS

No: 26447-40-5 EINECS No: 247-714-0, Series: 3rd Priority List Volume: 59

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:164:0007:0031:EN:PDF

Commission Regulation (EC) No 552/2009

Amending Regulation (EC) No 1907/2006 of the European

Parliament and of the Council on the Registration, Evaluation,

Authorisation and Restriction of Chemicals (REACH) as regards

Annex XVII, 22 June 2009

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:164:0007:0031:EN:PDF

5. References

Commission Directive 2009/2/EC, Amending, for the Purpose of its

Adaptation to Technical Progress, for the 31st Time, Council Directive

67/548/EEC on the Approximation of the Laws, Regulations and

Administrative Provisions Relating to the Classification, Packaging

and Labelling of Dangerous Substances, 15 January 2009

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:011:0006:0082:EN:PDF

Commission Directive 2008/58/EC, Amending, for the Purpose of its

Adaptation to Technical Progress, for the 30th Time, Council

Directive 67/548/EEC on the Approximation of the Laws, Regulations

and Administrative Provisions Relating to the Classification,

Packaging and Labelling of Dangerous Substances, 21 August 2008

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2008:246:0001:0191:EN:PDF

FeRFA 2011, Reclassification of MDI, 16 June 2011

http://www.ferfa.org.uk/html/pdf/ReclassificationMDInote.pdf