Papernol_Final_Presentation_Group_Edited

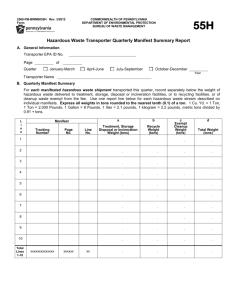

advertisement

Ethanol Production from Wastepaper Ben Dalton Cassia Davis John Ozbek Murat Ozkaya Marie Labrie Alex Saputa Steve Wild 4/15/09 Outline Project Purpose Assumptions Process Flow Pre-Treatment Saccharification & Fermentation Distillation/Purification CO2/H2O Footprint Economics Summary Project Purpose Design a facility that converts wastepaper into ethanol. Assumptions 100 Tons of Waste Paper per Day Waste Paper Contains 50% Cellulose Target Purity: 99.5wt% Ethanol WATER PAPER PRE-TREATMENT PURIFICATION YEAST & ENZYME PRODUCTION Ethanol SACCHARIFICATION & FERMENTATION Pulp Preparation Paper Water P-3 P-2 Acid P-4 Conveyor Shredder Filter Mixing Tank Enzymes-What are they? Proteins that catalyze reactions (increase the rate of) Like catalysts, enzymes work by lowering the activation energy for a reaction. This dramatically increases the rate of the reaction. Breaking up Cellulase (Saccharification) Breaking up cellulose requires three enzymes collectively called cellulases How Do You Produce Enzymes? Trichoderma reesei (yeast) Secretes cellulases One of the most powerful secretors of cellulases known to date Producing Enzymes Yeast Water Nutrients Water Nutrients + Yeast Enzyme 160 gal/day Production Yeast Mixture Culture Pre-Culture 4,800 gal 190 gal 30 °C 30 °C 2,400 gal/day Enzyme Non-Isothermal Continuous Saccharification and Fermentation (NCSF) Enzyme CO2 Slurry Ethanol Yeast Enzymatic Hydrolysis Fermentation NCSF Material Balance Enzyme 20 Tons CO2 400 Tons H2O 50ºC 45ºC 40ºC 35ºC 30ºC 400 Tons H2O 50 Tons Cellulose 21 Tons Cellulose 50 Tons Lignin 50 Tons Lignin Yeast NCSF Energy Balance 50ºC 24.3 MBtu/Day HPS 13.1 MBtu/Day 13.5 MBtu/Day 45ºC 40ºC 13.9 MBtu/Day 35ºC 14.3 MBtu/Day 30ºC Cooling H2O NCSF Reactor System Design 81 % Conversion to Ethanol in 25 Hours Tank Volume = 8,000 gal Distillation & Purification L-511 L-508 V-4 L-505 V-3 Distillate L-506 6 L-504 E-502 P-502 3 L-512 L-508 2 Feed Molecular Sieve T-101 L-502 T-102 L-503 L-501 Product Storage F 1 V-1 P-501 L-507 L-508 L-514 TK-501 4 L-513 E-501 V-2 F 5 L-510 F Recycle L-509 TK-502 Distillation: Material Balance FEED F= 420 tons/day XF= 0.050 wt% EtOH f= -0.102 DISTILLATE D= 23 tons/day XD= 0.906 wt% EtOH BOTTOMS B= 400 tons/day XB= 3x10-4 wt% EtOH Distillation: Condenser Duty QC CONDENSER QC= 110 MBTU/day AHT= 2080 ft2 AgentHT= Cooling Water V L Distillation: Reboiler Duty V L REBOILER QR= 195 MBTU/day AHT= 2860 ft2 AgentHT= HPS QR Distillation: McCabe Thiele Method 1.0 0.9 Program prepared by: Dr. J. R. Cunningham Mr. M. B. McGann 0.8 0.7 y 0.6 0.5 0.4 N = 10 actual stages and the partial reboiler Nf = 8 0.3 0.2 0.1 0.0 0.0 0.2 0.4 x 0.6 0.8 1.0 Distillation: Column Specifications Sieve tray 1 stage 2 ft 40 ft 20 stages 11 ft Sieve Dimensions Column Height = 60 ft Packing Diameter = 3.0 ft Packing Height = 50 ft Adsorption Phase 23 Total Tons / Day 11 Tons 21 Tons EtOH + 2 Tons H2O Synthetic Zeolite ~21 Tons EtOH Regeneration Phase ~ 6 Tons Hot CO2 + 2 Tons H2O Vapor 11 Tons 6 Tons CO2/ Day 7.1 MBtu/Day Synthetic Zeolite Per Day Waste Utilization Lignin 720 MBtu/Day Steam Boiler High-Pressure Steam 520 MBtu/Day ***120 tons of CO2 released per day CO2 Footprint CO2 emissions require an operating permit…… Papernol Produces 55,000 tons CO2/year Papernol H2O Footprint In the near future fresh water use will be as regulated as CO2 emissions…….. Papernol Papernol Plant Uses Grey Water 7,000 tons/year Economic Analysis Capital Costs Equipment Cost = $4.4M Plant Heuristic x (2.4) Total Capital Cost = $10.5M Annualized Capital Cost i (1 i ) N A P N (1 i ) 1 i (1 i ) N A P N (1 i ) 1 0.05(1 0.05) 5 A 10.5M 5 (1 0.05) 1 0.05(1 0.05) 5 A 10.5M 5 (1 0.05) 1 A $2.4Million A $2.4Million Annual Operating Costs Wastepaper Water Enzyme & Yeast Nutrients Electricity Cooling Total Operating Cost $300K $200K $33K $1.3M $1.4M $21K $3.8M Production Costs Annualized Capital Cost $2.4M Annual Operating Cost $3.8M Annual Production 2.3M Gal Production Cost $2.70/Gal Energy 1,300 MBtu/Day Papernol Plant 500 MBtu/Day Summary Project Purpose Assumptions Process Flow Pre-Treatment Saccharification & Fermentation Distillation/Purification CO2/H2O Footprint Economics Conclusion This design project is not economically feasible due to current market conditions. Future technology advances may lower production costs.