Six Sigma Executive Overview - Excellence in Financial Management

Thomas A. Little, Ph.D.

President, Thomas A. Little Consulting

1

© TLC, SSEO 1.5 22002

Audience

382 Stanwick Street

Brentwood, CA 94513

1-925-285-1847 drlittle@dr-tom.com

www.dr-tom.com

Presentation is designed for those Executives and Managers who are considering implementing Six Sigma and want to understand its core concepts and benefits.

Provides an overview and orientation of six sigma methodologies and organizational requirements. The Executive Overview is presented prior to six sigma implementation,

Champion and Black Belt training.

2

© TLC, SSEO 1.5 22002

Objectives

As a result of attending this course the participant will be able to:

• Describe the Six Sigma Breakthrough strategy

• Understand the Champion’s role in the Six Sigma Initiative

• Relate the roles and responsibilities of the Champion, Black Belt,

Green Belt and Team Members

• Identify projects with high probability for success

• Understand the DMAIC methodology and how it applies to improvement projects

• Establish and utilize dashboard metrics

• Assist in project management and project goal completion

3

© TLC, SSEO 1.5 22002

Presentation Outline

Section I

Section II

Six Sigma Introduction

Management and Organizational Infrastructure for Six Sigma

Section III DMAIC Breakthrough Methodology

Section IV Implementation Strategy

4

© TLC, SSEO 1.5 22002

Section I

Section I Six Sigma Introduction

What is Six Sigma?

Three elements of Six Sigma

DMAIC roadmap

Expected benefits of Six Sigma

Corporate results of Six Sigma

5

© TLC, SSEO 1.5 22002

Technical Definition of Six Sigma

Technical Definition (Motorola)

LSL

12.5%

75%

±

1.5

s

3.4 DPMO

Cp=2 Cpk=1.5

Cp=Cpk = 2

Cp=2 Cpk=1.5

USL

12.5%

3.4 DPMO

6s -5s -4s -3 s -2s -1s 0 +1s +2s +3s +4s +5s +6s

6 s to LSL

6 s to USL

Evolution to:

A Management driven, scientific methodology for product and process improvement which creates breakthroughs in financial performance and Customer satisfaction

6

© TLC, SSEO 1.5 22002

What is Six-Sigma?

• Management mandated and directed improvement program focused on breakthroughs in financial performance and customer satisfaction

• Uses Champions, Black Belts and Green Belts to facilitate change

• Focused on core business and Customer needs

• A systematic method for process and product improvement

• A Greek symbol for measuring performance variation

• A metric for evaluating performance quality

• A standard of excellence (3.4 defects per million opportunities)

7

© TLC, SSEO 1.5 22002

Customer Satisfaction + Efficient Systems =

Improved Profitability

Two types of projects to improve financial performance:

Increase Revenue “Grow the Business”

Improve Customer satisfaction, sales, capacity and market position

Decrease the Cost of Goods Sold

Reduce variation and defects

Improve yields

Understand root cause of issues and eliminate the source of problems

Automate process “workflow”

Improve process performance and reduce waste using lean principles

8

© TLC, SSEO 1.5 22002

Reduce Process Variation & Defect Rates

Off-Target Too Much Variation

Center

Process

Centered

On-Target

Reduce

Spread

The objective is to understand customer requirements and reduce process variation and defects

9

© TLC, SSEO 1.5 22002

Breakthrough and Continuous Improvement

Breakthrough Strategy

1 2 3 4 5

10

© TLC, SSEO 1.5 22002

Three Emphasis Areas for Six Sigma

Focused on product design excellence, design for manufacturability,

Customer satisfaction and cost reduction within all components of the development and new product introduction process.

Focused on operational excellence, Customer satisfaction and cost reduction within all components of the operation. Areas of focus include Sales, HR, Finance, Materials, etc.

Focused on product production excellence, variation and defect reduction, lean production techniques, Customer satisfaction and cost reduction within all components of the production and delivery process.

Six Sigma touches on all aspects of the Business Enterprise

11

© TLC, SSEO 1.5 22002

Past Improvement Activity Failure Modes

Unsuccessful Projects

No clear Management mandate

No roadmap for the project… not sure where we are going

No dedicated resources

No Management and performance review

No ability to measure performance and examine effectiveness… not sure if we accomplished anything

No financial ROI during project definition and measurement at completion

No clear answer as to “ why are we doing this project?”

12

© TLC, SSEO 1.5 22002

What Makes Six Sigma Work?

• Select and work on the most important problems and projects to the business and Customer

• Assure those projects impact customer satisfaction and financial performance

• Allocate the time to get the work done

• Have your best people work on them

• Provide those individuals with all the training, tools, and resources they need to make the performance breakthrough

• Provide Management direction, support and routine review of performance

• Require a well thought out, objective and data driven solution

• Verify the dollar savings of your efforts

• Sustain the benefits of the solution over time

13

© TLC, SSEO 1.5 22002

Six Sigma 3 Critical Elements

Defining and using business objectives and metrics that focus our attention on performance and defects that are most important to the customer and have the greatest potential for impacting the bottom line

Dedicated resources and focused infrastructure , trained in the use of the 6

Sigma problem solving and process improvement methodology

Systematic

Approach to improving performance and reducing defects which are important to the customer

(qualitative & statistical)

14

© TLC, SSEO 1.5 22002

Strategic Business and Quality Metrics

CSI, Sales, delivery times, cost per unit, Yield, DPU, DPMO, customer response times, Web hit rates,

Rework/scrap rates, etc.

(Critical Business Elements)

Management objectives and dashboard forms the core of the strategic

Business & Quality

Metrics and is flowed down to other departments and process areas to provide leading and lagging indicators of performance

15

© TLC, SSEO 1.5 22002

Hierarchy of Operational Dashboards

Executive

Dashboard

Level 1

Processes

Director

Level

Level 2

Processes

Manager

Level

Level 3

Processes

Engineering

Level

Level 4

Processes

Operator

Level

Can we see measurable progress in our key business critical metrics?

16

© TLC, SSEO 1.5 22002

Six Sigma DMAIC Road Map

Define

Identify Project, Champion and Project Owner

Determine Customer Requirements and CTQs

Define Problem, Objective, Goals and Benefits

Define Stakeholder/Resource Analysis

Map the Process

Develop Project Plan

Measure

Determine Critical Xs and Ys

Determine Operational Definitions

Establish Performance Standards

Develop Data Collection and Sampling Plan

Validate the Measurements

Measurement Systems Analysis

Determine Process Capability and Baseline

Analyze

Benchmark the Process or Product

Establish Causal Relationships Using Data

Analysis of the Process Map

Determine Root Cause(s) Using Data

Improve

Design of Experiments

Develop Solution Alternatives

Assess Risks and Benefits of Solution Alternatives

Validate Solution using a Pilot

Implement Solution

Determine Solution Effectiveness using Data

Control

Statistical Process Control

Determine Needed Controls (measurement, design, etc.)

Implement and Validate Controls

Develop Transfer Plan

Realize Benefits of Implementing Solution

Close Project and Communicate Results

Key Analytical Tools

Process Mapping and

Modeling

Measurement Systems

Analysis & Process

Capability

Statistical Tests, Modeling

& Root Cause Analysis

Brainstorming

Design of Experiments,

FMEA, & Validation

Statistical Process Control

17

© TLC, SSEO 1.5 22002

Process Flow for achieving 70%+ Improvement

Champion

Select project that is considered critical to operational success

Review performance and assure results

Review and approve solutions

Authorize process change

Communicate and celebrate results

Black Belt

Form team and follow DMAIC for project management

Develop alternative solutions and complete benefit and risk assessment

Determine financial benefit

Process or

Product

Understand root cause of problem

Validate

Solution

Implement and standardize process changes

For a breakthrough to occur… everything is on the table

18

© TLC, SSEO 1.5 22002

Six Sigma Results

Improved Customer satisfaction

• Assure products and services meet customer requirements

Improved quality, efficiency and cost of goods sold

• Waste, defect and variation reduction

• Financial savings (hard and soft)

Self-sustaining infrastructure

• Defined roles and responsibilities

• Empower Champions, Black Belts and all employees to make meaningful improvements in performance

• Communication

Commonality

• Language, training materials, tools & software

• Methodology

• Expectations

• Solutions

• Financial tracking (establish, maintain metrics)

19

© TLC, SSEO 1.5 22002

Honeywell & DOW Results

"We achieved $600 million in Six Sigma cost savings in 1999, but cost savings are only one part of the story. Delighting customers and accelerating growth completes the picture. When we are more efficient and improve work flow throughout every function in the company, we provide tremendous added value to our customers – through higher quality solutions that are more competitively priced, delivered on time and invoiced correctly. That makes us a more desirable business partner."

- Honeywell 1999 Annual Report http://www-a.honeywell.com/investor/ar99_intro_smarter.html

"We expect Six Sigma to elevate our company to an entirely new level of operational performance, delivering $1.5 billion in EBIT cumulatively by 2003 from the combined impact of revenue growth, cost reductions and asset utilization."

- Dow 1999 Annual Report http://www.dow.com/financial/99ann/letter03.htm

20

© TLC, SSEO 1.5 22002

GE & DuPont Results

"The Six Sigma initiative is in its fifth year — its fifth trip through the operating system. From a standing start in 1996, with no financial benefit to the Company, it has flourished to the point where it produced more than $2 billion in benefits in 1999, with much more to come this decade."

- GE 1999 Annual Report http://www.ge.com/annual99/letter/letter_three.html

"Six Sigma implementation continues to gain momentum. At the end of the year 2000, there were about 1,100 trained Black Belts and over 3,400 active projects. The potential pretax benefit from active projects was $700 million."

- DuPont Fourth Quarter and Full Year 2000 Earnings Report http://www.dupont.com/corp/whats-new/releases/01/010124.html

21

© TLC, SSEO 1.5 22002

Section II

Section II Management Infrastructure for Six Sigma

Site Champion and Executive Staff

Hands on Champions

Master Black Belt

Black Belts / Green Belts

All Employees

22

© TLC, SSEO 1.5 22002

Interrelationship Digraph of Six Sigma Infrastructure

23

© TLC, SSEO 1.5 22002

Site Champion and Executive Staff

Functions

Set the vision

Create the mandate for improvement

Initiate and fund the activity

Establish and maintain the reporting structure

Responsibilities (10%+ of time)

Identify Champions in each functional area

Monthly review of projects by Champion

Measure Champion results

Training

4 hour Executive Overview

2 day Champion Training

24

© TLC, SSEO 1.5 22002

Hands-On Champion

Functions

Communicate the vision

Create the mandate for improvement

Provide direction and remove barriers

Achieve financial results and communicate success

Responsibilities (10%+ of time)

Identify Black Belts and Green Belts

Identify and approve all Six Sigma projects

Biweekly review of all projects

Measure Black Belt performance

Training

2 day Champion Training

25

© TLC, SSEO 1.5 22002

Master Black Belt

Functions

Provide technical expertise on Six Sigma and Lean methodology to Black Belts and Green Belts

Work in support of the Black Belt and Champion

Assist in education and training activities

Responsibilities (100% of time)

Work daily with team members, Black Belts and

Champions

Participate in the review of projects

Monitor all Six Sigma projects

Training

15 day Black Belt Training, 2 years minimum as a

Black Belt and a Masters Degree in a related field

26

© TLC, SSEO 1.5 22002

Black Belts and Green Belts

Functions

Black Belts 100% dedicated for 2 years to process improvement, Green Belts 20%

Work on improvement projects with other Green

Belts and Team Members

Achieve financial results for each project Goal of

$350K+

Responsibilities (100 – 20%+ of time)

Use the DMAIC methodology to create breakthroughs in performance

Report progress to the Champion

Hold team meetings and provide excellent project management

Work with the Master Black Belt

Training

15 day Black Belt Training

5 day Green Belt Training

27

© TLC, SSEO 1.5 22002

All Employees

Functions

Work to achieve excellence in daily work

Participate in Six Sigma projects

Support team activities

Identify opportunities for improvement

Responsibilities (5-10%+ of time)

Participate in Six Sigma activities as requested

Complete action items as assigned by the team

Attend team meetings

Training

1 day Six Sigma Employee training

28

© TLC, SSEO 1.5 22002

Section III

Section III DMAIC Breakthrough Methodology

Define

Measure

Analyze

Improve

Control

29

© TLC, SSEO 1.5 22002

DMAIC Process Improvement Methodology

30

© TLC, SSEO 1.5 22002

DMAIC Process

Establish Control s on the critical Xs so the improvements will be maintained

Identify ways to improve the process and validate the solution

X

1

X

2

X

3

X

4

PROCESS

Measure and Analyze data and process performance to determine the critical variables and root cause of the problem

Y

1

Y

2

Y

3

Metrics (Ys) linked to

CTQs

Define the Problem

Project Objective

Project Goal

31

© TLC, SSEO 1.5 22002

Six Sigma DMAIC Define

Define Activities

Identify Project, Champion and Project Owner

Determine Customer Requirements and CTQs

Define Problem, Objective, Goals and Benefits

Define Stakeholder/Resource Analysis

Map the Process

Develop Project Plan

Define Quality Tools

Project Charter and Plan

Effort/Impact Analysis

Process Mapping

Tree Diagram

32

© TLC, SSEO 1.5 22002

“Define” Flow

VOC,

Examine

Candidate

Projects

Define Customer

CTQs

CTQ(s)

Resource Requirements

Project No:

Project Name:

Project Leader:

GB/BB:

Master BB:

H/O Champion:

Team Members: Name Function % Time

SIX SIGMA

Project Charter

Initials

General Information

Location:

Business

Segment:

Business

Objective:

Customer

CTQ(s):

Current

Process

Capability:

Date:

Sigma, C pk

, DPMO, Cycle-time, etc.

Project Definition

Project Problem Statement:

Review Schedule

Activity

Start

Date

D

M

A

I

C

Close

Project Objective Statement:

Project Scope/Limitations:

Project Goals and Targets:

Project Plan:

See page 2 of the project charter. Project Plan and Gantt Chart

Expected Benefits:

Hard Dollar Savings:

Soft Dollar Savings:

Strategic:

Other Benefits:

Hands On Champion:

Name:

Signature:

Functional Manager:

Name:

Signature:

Other:

Name:

Signature:

Date:

Stakeholder Approval

Master Black Belt:

Name:

Signature:

Black / Green Belt:

Name:

Signature:

Other:

Name:

Signature:

Time frame:

Response

(Y)

Operational

Definition

Specification

Limit(s)

Complete

SIPOC and

Process Map

Effort/Impact

Analysis

Develop and

Approve Project

Charter

5

4

3

2

1

0

8

7

6

10

Effort / Impact Analysis

GB Projects BB Projects

9

0 2 4 6

Effort

8 10 12

Impact

Who are the suppliers for our product or service? How capable are they in

What must my suppliers provide to my process to meet

Suppliers

1

2

3

4

Add additional rows where needed

Input

1

3

1

2

1

2

2

3

2

3

3

1

What is the most

Determine the start and end points of the process associated with the problem and the major steps appropriate end point for the process? What

Who are the customers for our product or service? product or service does What are their the process deliver to requirements for in the process.

the customer?

performance

Process

(High Level)

Start Point:

Output

1

9

10

11

6

7

4

5

8

1

2

3

Operation or Activity

2

3

4

5

6

Customers

1

2

1

2

2

1

2

1

1

2

1

2

End Point:

© Thomas A. Little Consulting 2002

33

© TLC, SSEO 1.5 22002

Voice of the Customer (VOC)

• Why don’t you guys learn how to meet a schedule?

• Your service quality to poor

• When will you learn how to provide service and a Customer first attitude?

• Why don’t you tell us when there is a problem?

• I sent out e-mail after e-mail with no response!

• Why do you try and make your customers responsible for your quality problems?

• Your RMA frequency is unacceptable

DMAIC

Methodology

Define

VOC is often full of emotions.

We need to restate customer statements into fact based, performance requirements that we need to focus on

Of course… Customers expect perfection

34

© TLC, SSEO 1.5 22002

Critical to Quality (CTQ) Characteristics

Detailed

Specifications

Use the tree diagram to define Customer CTQs

Response

(Y)

DMAIC

Methodology

Define

Performance to

Schedule

Customer

Needs

Customer

Requirement

Product arrives on-time

Measure

Target

Deviation from schedule in completed units

100% of committed ships prior to 5:00 pm as received on Customer receiving dock

LSL = 0 hours late

USL = 6 hours early

Specification

Limit(s)

Allowable defect

Rate

< 3.4 DPMO

35

© TLC, SSEO 1.5 22002

Moving to Specific Candidate Projects

DMAIC

Methodology

Define

Critically examine

Business

Objectives and select projects aligned to them with financial impact and benefits

Champions drive the project selection as they own the business objectives aligned to the Executive Staff

Interview

Customers

(Internal and

External), on core business issues and opportunities for improvement

Use Voice of the Customer when collecting and analyzing data

Complete

CTQ gap analysis and prioritization

Determine a candidate project list

Estimate project benefits in financial and measurable terms & rank projects by their impact

Determine the effort required for each project

Conduct effort to impact analysis and prioritize the project list

Select the top projects and determine the

Champion and Owner

Candidate

Six Sigma

Project(s)

With financial impact!!!

36

© TLC, SSEO 1.5 22002

Potential Projects

DMAIC

Methodology

Define

Determine a candidate project list and potential benefits:

Manufacturing

Materials

Management

NPI

Finance

Design

HR

Conduct effort to impact analysis and prioritize the project list

Project

1

8

9

6

7

4

5

2

3

10

Effort

6

8

1

2

5

3

4

7

10

9

Impact

1

6

9

6

6

3

3

3

3

9

Projects with high impact are preferred

7

6

5

4

3

2

1

0

10

9

8

0

Candidate Six

Sigma Project(s)

Project

Champion and

Owner

Effort / Impact Analysis

Impact

2 4 6

Effort

8 10 12

37

© TLC, SSEO 1.5 22002

Detailed Project Selection Criteria

DMAIC

Methodology

Define

• Achieving breakthroughs requires prioritization of opportunities.

There are many more opportunities than there is time and resources to work on them.

• When selecting a process, we are trying to prioritize exactly which problem to solve. If the problem is clear we move on to define the problem.

• In selecting a project, consider these issues: a.

Financial and strategic benefits b.

Improved customer satisfaction, CSI c.

Compatible with current goals and objectives d.

Translatable to other areas of the business e.

Probability of success f.

Level of effort, amount of resources needed to complete project

38

© TLC, SSEO 1.5 22002

Example: Prioritizing Projects

DMAIC

Methodology

Define

Are your projects the things you like to do, easy to do or important to do?

Rank Potential Projects

2 Reduce lead time

3 Receiving process

4 Customer complaints

5 MRO material reduction

6 Change control system

1 Inventory reduction

7 Chip test yields

Project name

Champion Financial Translatability Defined Supports

HC

MP

DS

LC

JM

AB

JF

9

6

6

6

6

9

6

Benefits

9

9

6

3

9

9

3

Business Goals

9

6

6

6

0

9

0

6

9

0

9

3

9

9

Clear

6

9

9

6

9

9

9

Risk

Complexity

6

6

6

9

6

6

6

Manager responsible for results

Hard dollar savings

Solutions are likely to be applicable across the site and the corporation

Currently defined business objective

Supports immediate goals and objectives for the org.

Clear problem definition with clear project boundaries

Complexity is a function of time to complete and the difficulty of the problem. Scope

(target for BB project is 7-8)

Probability of success

3 < $100k

6 = $300k

9> $1M

3 = local

6 = some external

9 = all locations

3 = <3 months

6= 4-5 months

9= 6+ months p(S)

6

6

6

3

9

6

6

Total

80%

77%

73%

70%

63%

93%

53%

0%

0%

0%

© TLC, 2002

39

© TLC, SSEO 1.5 22002

Develop Charter

In this step you will establish direction for the project by documenting

•

Problem

•

Objective & Scope

•

Goal/target

•

Resource requirements

•

Financial benefits

•

Strategic benefits

•

Team resources

•

Project approval

DMAIC

Methodology

Define

Resource Requirements

Project No:

Project Name:

Project Leader:

GB/BB:

Master BB:

H/O Champion:

Team Members: Name Function % Time

SIX SIGMA

Project Charter

Initials

General Information

Location:

Business

Segment:

Business

Objective:

Customer

CTQ(s):

Current

Process

Capability: Sigma, C pk

, DPMO, Cycle-time, etc.

Date:

Review Schedule

Activity

Start

D

M

A

I

C

Close

Date

Project Definition

Project Problem Statement:

Project Objective Statement:

Project Scope/Limitations:

Project Goals and Targets:

Project Plan:

See page 2 of the project charter. Project Plan and Gantt Chart

Expected Benefits:

Hard Dollar Savings:

Soft Dollar Savings:

Strategic:

Other Benefits:

Hands On Champion:

Name:

Signature:

Functional Manager:

Name:

Signature:

Other:

Name:

Signature:

Date:

Stakeholder Approval

Master Black Belt:

Name:

Signature:

Black / Green Belt:

Name:

Signature:

Other:

Name:

Signature:

Time frame:

40

© TLC, SSEO 1.5 22002

Develop Charter – Problem Statement

A clear description of the problem to communicate to other people in the process and rally support to improve it

• A description of the issue or problem

• What, when, where and how the problem occurs

• What is critical to quality (CTQ) from the customer perspective? What is nonconforming to specifications?

• Define the boundaries of the problem, how big is the problem?

• What are the consequences of the problem to the

Company and or Customer?

• Do not state a solution when describing a problem

DMAIC

Methodology

Define

Description of the “Pain”

41

© TLC, SSEO 1.5 22002

State Objective and Scope

DMAIC

Methodology

Define

Project Objective and Scope

•

•

•

•

•

What process will the team focus on?

What are the boundaries of the process we are to improve?

Where does the process begin? Where does it end?

Which customers will be affected / included

What is outside of scope for the team?

What constraints or timelines must the team work under?

Customer or Suppliers Site or Line Process

Process 1

Process 2

Process 3

42

© TLC, SSEO 1.5 22002

Goal Statement

DMAIC

Methodology

Define

Describe, in measurable terms, what success will look like when you’ve solved the problem

Include a statement of the performance level that will satisfy your

CTQ and the time frame in which you plan to implement the improvement. State targets and tolerances where appropriate.

Goal Statement:

Reduce late shipment costs (Express Mail) to all customers by 70% from $1.5M to $45K by January 200x.

Where When How Much

43

© TLC, SSEO 1.5 22002

Determine Resources

DMAIC

Methodology

Define

Determine the Stakeholders

Who will need to be involved and at what level for this project to be successful?

Determine Team Members

Who will need to be on the team and at what % of their time?

Determine any Capital, Test or HR

Requirements

What materials, testing, software programming, outside services or equipment will be needed? Are those costs acceptable to management?

Other Support to be Successful

44

© TLC, SSEO 1.5 22002

Project Plan

SIX SIGMA Project Plan

Site:

Problem Statement:

Location:

Project Name & Number:

Revision Date:

Improvement Objective and Scope:

Metric(s)

DMAIC

Methodology

Define

Goal and Targets

Benefits

Baseline Goal Improvement Goals

Date

Date

Date

Date

Assigned to: Start Date: End Date: Status:

Project

Review Date

Project plan remains through the life of the project

Phases

Define

Measure

Tasks and Timelines

Activity

Project's Customer CTQ

Project Charter

SIPOC

Financial analysis of project's benefits

Detailed process map

Analyze

Improve

Control

Team Members

Team Leader:

Team BB:

Team Members:

Champion:

On Plan/On Schedule

Behind Plan, with effort can return to schedule

Behind Plan

Task Completed 45

© TLC, SSEO 1.5 22002

Benefits

DMAIC

Methodology

Define

Benefits may include any of the following:

• Hard dollar savings (cost reduction)

• Soft dollar savings (cost avoidance)

• Improved Customer satisfaction

• Improvement in the performance metrics (cycle time, yield, defects, etc.)

• Improved job satisfaction (reduction in frustration)

• When considering benefits… what must change for the savings to occur?

46

© TLC, SSEO 1.5 22002

Financial Benefits Example

DMAIC

Methodology

Define

Cost Improvements Quantified:

Process

Touch-up & Handsolder

Wash

QA/ Final Inspection

Rework

QA (QA E ngineers)

Production Control/Expediting

Curr Cost

($1, 000's per w eek)

$ 73

New Cost

$ 70

$ 24

$ 58

$ 20

$ 5

$ 27

$

$

$

23

45

16

$

$

4

26

95%

95%

78%

78%

78%

95%

$ 10,782 k $ 9,525 k per Year

Improvement

$ 3.7

$ 1.2

$ 12.5

$ 4.4

$ 1.0

$ 1.4

Total per week for costs elements above $ 207 $ 183 per Week $ 24.2

Total per Year $ 1,257 k

Determine costs of current baseline and the impact to cost if the goal is achieved. Consider also the full impact to all effected lines and production operations. If financial analysis shows poor ROI you may want to select another project.

47

© TLC, SSEO 1.5 22002

Begin Mapping the Process with a SIPOC

DMAIC

Methodology

Define

48

© TLC, SSEO 1.5 22002

Move to a detailed Process Map

DMAIC

Methodology

Define

49

© TLC, SSEO 1.5 22002

Model and Automate Workflow

Discrete Transactions

Performance Monitoring and Improvement

JMP for analysis and root cause determination

Workflow

Automation

Database

50

© TLC, SSEO 1.5 22002

Begin Management/Champion Reviews

DMAIC

Methodology

Define

Once the project charter has been approved and the team formed around the project it is essential to begin periodic management reviews of project performance.

Black Belts and Green Belts meet with Management to report performance.

Champions report to executive staff on project performance.

Where possible integrate reviews into current management forums.

51

© TLC, SSEO 1.5 22002

Six Sigma DMAIC Measure

DMAIC

Methodology

Measure

Measure Activities

Determine Project Critical Xs and Ys

Determine Operational Definitions

Establish Performance Standards

Develop Data Collection and Sampling Plan

Validate the Measurements

Measurement Systems Analysis

Determine Process Capability and Baseline

Measure Quality Tools

Quality Function Deployment (QFD)

Measurement Systems Analysis (MSA)

Check sheet

Process Capability

52

© TLC, SSEO 1.5 22002

“Measure” Flow

List Of

Measures

(Xs and Ys)

Data Collection,

Process Baseline and Capability

Determination

Add

Specifications and Compute

Sigma and

Capability

Baseline

Data Collection Plan

& Sample Size

Data Collection Plan

Define What to Measure

Measure

Type of

Measure

Operational

Definition

Define How to Measure

Measurement Data Tags Needed or Test Method to Stratify the Data

Data Collection

Method

Who will

Do it?

Person(s)

Assigned

What?

Sample Plan

Where?

When?

How Many?

Name of X or Y Clear definition of parameter attribute or the measurement or condition discrete to be data, measured product or process defined in such a way as to achieve

Visual inspection or automated test? repeatable results Test instruments from multiple are defined. data observers

Procedures for data collection are defined.

Data tags are defined for the measure. Such as: time, date, location, tester, line, customer, buyer, operator, etc.

Manual?

Spreadsheet?

Computer based?

etc.

State who has the responsibility?

What measure is being collected

Location for data collection

How often the data is collected

The number of data points collected per sample

MSA, GR&R,

Inspector

Effectiveness

Goal

Restate

Improvement

Goals

53

© TLC, SSEO 1.5 22002

Determining Critical Xs and Ys

(Xs) Leading Process --> Product -->

XZY errors

Temperature

Offset

Viscosity

Pressure

DPU/Yield

Scrap

Rework, RMA

Supplier,

Receiving and Process

Times

Processing time

Wait time

Delivery time

Transactional and product defects and errors by operation

Accuracy of transaction

Transaction time

Product or service quality

T&Cs, planning systems, production systems

Inventory levels

Materials management

Lagging (Ys)

Manufacturing

Cost of Quality

Transaction Cycle

Time

Customer satisfaction

Materials costs

54

© TLC, SSEO 1.5 22002

Using QFD to Prioritize and

Select Project Ys and Xs

Product or Process: Current Measures Needed Measures

DMAIC

Methodology

Measure

Customer Wants

Rapid schedule confirmation

On time performance

Defect free products

Routine cost reduction

Routine WIP reduction

Minimum lead times

4

5

7

1

2

6

3

3

3

9

0

0

0

3

0

0

9

0

3

6

3

6

6

3

0

6

3

0

9

0

3

3

0

3

0

3

0

0

0

3

3

0

3

0

0

3

0

6

3

0

0

9

0

0

0

9

3

3

6

0

9

0

0

3

0

9

Total

Unit of Measure

Raw data available?

Std. report available?

Reliable data source?

Frequency of the report?

Needed frequecy?

Target

Lower Limit

Upper Limit

Measurement capability

Measurement validated?

Competitive comparison

Ranking

Relationship key:

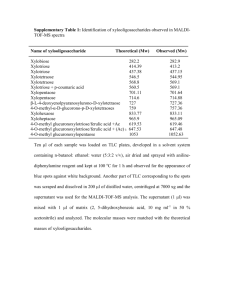

18 12 27 18 12 6 12 12 21 21

Min.

Y

Y

Y

Daily Wk

Daily Wk

5:00 0

4:45

5:15 n/a

1

#

Y

Y

Y

CSI PPM

Y

Y

Y

Y

Y

Y

#

Y

Y

Y

%

Y

Y

Y

#

Y

N

N

Min.

Y

N

Y

%

Y

N

Y

Hrs.

N

N

N

Wk Wk Daily Daily Daily Daily Daily n/a

Wk Daily Daily Daily Daily Daily Shift Daily

5 0 Plan 100% 0 0 100% 1 hr.

4.5

n/a n/a

100

5% 95%

5% n/a

1

1

-0:15 50%

0:15 n/a n/a

2 hr.

0 0 0

5 9 6 8

9 Strong relationship

6 Moderate relationship

3 Weak relationship

0 No relationship

7 10 2 1 4 3

Total

24

39

33

30

12

21

Translate customer requirements into objective measures and prioritize project metrics

55

© TLC, SSEO 1.5 22002

Performance Standards for Each Y

All Processes Need Clear Specifications

DMAIC

Methodology

Measure

Larger is Better

One-sided - lower specification limit only

LSL

Unacceptable Good

Smaller is Better

Target zero and upper specification limit

USL

Good Unacceptable

Target is Best

Two-sided specifications

LSL USL

Unacceptable Good Unacceptable

56

© TLC, SSEO 1.5 22002

Develop Data Collection Plan

DMAIC

Methodology

Measure

Elements for a data collection plan

Data Collection Plan

Define What to Measure

Type of

Measure Measure

Operational

Definition

Define How to Measure

Measurement Data Tags Needed Data Collection or Test Method to Stratify the Data Method

Who will

Do it?

Person(s)

Assigned

What?

Sample Plan

Where?

When?

How Many?

Name of X or Y Clear definition of Visual parameter attribute or the measurement inspection or condition discrete defined in such a or automated to be data, way as to achieve test? measured product or repeatable results Test instruments location, tester, process from multiple are defined. line, customer, data observers

Procedures for buyer, operator, etc.

data collection are defined.

Data tags are Manual?

defined for the Spreadsheet?

measure. Such Computer based?

as: time, date, etc.

State who has the

What measure is being

Location for data responsibility?

collected collection

How often the data is collected

The number of data points collected per sample

Data means nothing… without an understanding of what the data is, how it was collected, and the conditions under which it was measured

Data properly collected and analyzed will help us to understand the root cause(s) of the problem

57

© TLC, SSEO 1.5 22002

Collect Visual Data to See the Problem

DMAIC

Methodology

Measure

Where possible use a Digital or Video Camera and capture the defect or process problem. “A picture is worth a thousand words in” understanding and communication of the origin and nature of problems.

58

© TLC, SSEO 1.5 22002

MSA for Validated Measurement

Short Term

Capability

True Value x

A x

B x

C

Accuracy

Reproducibility

Repeatability x

A x

B x

C

DMAIC

Methodology

Measure

Long Term

Capability

Stability

First period of time Second period of time

Useful for characterization of variable gages and inspection capability

The data is only as good as the quality of the measurements

59

© TLC, SSEO 1.5 22002

Six Sigma DMAIC Road Map

Analyze Activities

Benchmark the Process or Product

Establish Causal Relationships Using Data

Analysis of the Process Map

Determine Root Cause(s) Using Data

Analyze Quality Tools

Statistical analysis of data

Cause and effect or event diagram

Histogram

Pareto diagram

Run chart

Scatter graph

DMAIC

Methodology

Analyze

60

© TLC, SSEO 1.5 22002

Analyze Flow

Project Data

Xs and Ys

Root Cause

Analysis

Summary

Measure

Responses or Outputs (Ys)

Dependent Variable

Factors (Xs)

USL LSL Target Independent Variable(s)

© Thomas A. Little Consulting 2002

USL LSL Target

Analysis and

Stratification of Data

% Explained and % Unexplained

Root Cause

Validation

61

© TLC, SSEO 1.5 22002

Benchmarking

DMAIC

Methodology

Analyze

No company is the best at all it does. Typically there are some core competencies that make a company great. There is much to be learned by benchmarking other companies who are the best at what they do.

Benchmarking begins with identification of the process or business area we wish to examine.

This should be clear from our problem statement and objective.

Knowledge that there are other ways of doing things can be obtained from benchmarking.

Benchmarking often speeds up the solution generation process.

62

© TLC, SSEO 1.5 22002

Root Cause Analogy

DMAIC

Methodology

Analyze

Like pulling weeds… unless we address the root that causes the problem, poor results will keep coming back.

Addressing the results or symptoms of a problem will never provide lasting solutions given a little time… the problem will come back

We need to understand the Root

Cause of the problem from our problem statement

63

© TLC, SSEO 1.5 22002

Forward Problem Solving Versus Backwards

DMAIC

Methodology

Analyze

Forward

Problem Solving

No Idea of Root Cause

Define Problem

Collect Problem Related Data

Analyze Data

Determine Root Cause(s)

Validate

Determine what is unexplained

Define Problem

List Probable Root Causes

Collect Supporting Data

Validate

Determine what is unexplained

Backwards

Problem Solving

Strong Idea of Root Cause

64

© TLC, SSEO 1.5 22002

Evaluate Data to Determine Root Cause

DMAIC

Methodology

Analyze

Goal is to determine cause & effect relationships

65

© TLC, SSEO 1.5 22002

Stratify Data to Understand Root Cause

DMAIC

Methodology

Analyze

Data

Collection

Late

Deliveries

25

20

15

10

5

0

IBM

Vendor Purch.

Order Mat.

Week in

Agent Date Type Quarter ordered

1

2

3

DEC HP

Vendor

NEC

100

80

60

40

20

0

ASICs Connectors Flex c.

SMT parts Solder

Material Type 25

20

15

10

5

0

Tom Shauna Kris Adam

Purchasing Agent

John

MOT

Stratification : Analysis of the same data grouped and classified by the data tags to examine frequencies at different logical levels

66

© TLC, SSEO 1.5 22002

List Of Vital Few Xs and Critical Ys

Collected X and Y data

DMAIC

Methodology

Analyze

Hypothesis testing t-test

F-test

ANOVA

Chi-square

Logistical regression

Regression analysis and Model fitting

List Of Probable Root Causes and key process sensitivities

67

© TLC, SSEO 1.5 22002

Analysis of Data

DMAIC

Methodology

Analyze

Provides the ability to visualize the relationship between process variables and to understand the source and fundamental behavior of problems

68

© TLC, SSEO 1.5 22002

Analyze the Process Map for Waste

DMAIC

Methodology

Analyze

When Mapping the Process Consider the Following:

What you think it is...

What it actually is...

What it could be...

69

© TLC, SSEO 1.5 22002

Check List for Root Cause Determination

DMAIC

Methodology

Analyze

Check and investigate all those that apply to the problem under consideration

Measurement

Poor repeatability

Poor reproducibility

Poor accuracy

Poor stability

Poor linearity

Invalid measurement or test method

Excessive test or measurement

Methods

Incorrect definition

Incorrect sequence

Missing definitions, implicit rules

Poor process controls

Poor measurement controls

Lack of critical information

Incorrect information

Excessive queues or out-time

Handling

Orientation

Poor management of change

Incorrect revision

Machine (process & test)

Machine maintenance or calibration

Machine controls or lack of controls

Machine fault or defect

Software or network fault

Machine related contamination

Machine tooling or fixtures

Incorrect machine or tester

Materials

Defective

People

Off-specification

Contaminated

Improper storage conditions

Labeling or identification

Incorrect amount or quantity

Improper transportation or handling

Expiration date exceeded or unknown

Problem with product design

Wrong materials

Environment

Physical environment (temperature, lighting, ESD)

Security or safety systems

Distractions in the environment

Particulates

Contamination

Level of staffing

Training

Competency or experience

Supervision

Conflicting goals

Compliance with procedures

Personality issues

Physical ability or function

Cognitive ability and function

Knowledge deficit

Communication with peers or supervisor

70

© TLC, SSEO 1.5 22002

5 Whys Example

DMAIC

Methodology

Analyze

State the problem, then ask why did this problem occur until you reach root cause.

Missing Parts on the Board During NPI WHAT?

Improper cassette loading Missing cassette Machine Malfunction Why?

Failed to locate cassette Part not available

Why?

Supplier problem Order incorrect Lack of lead time Why?

Design change Customer schedule

Design error Performance improvement

Why?

Why?

71

© TLC, SSEO 1.5 22002

Root Cause(s) Determination

DMAIC

Methodology

Analyze

Root Cause is achieved when we have identified the source of the problem (use the 5+ Why approach)

For any problem there are typically many Roots. They vary in frequency of occurrence. We need to know each root and their associated frequency and or % of impact.

Proper Root Cause identification requires some explanation of the failure mechanism based on understanding the process, the physics, mechanics or chemistry. We must be able to explain how changes in X cause changes in Y (otherwise we don’t understand it!)

Root Cause is verified when we can recreate or manipulate the problem

To fix the Root Cause it must be controllable

Knowing Root Cause does not assure we know the solution to the problem. Solutions can be formulated once we know the root of the problem

72

© TLC, SSEO 1.5 22002

List of Potential Root Causes

DMAIC

Methodology

Analyze

Final investigation needs to be made to determine if the factors identified are actually the root cause of the problem

73

© TLC, SSEO 1.5 22002

Summarize All Root Cause Analysis

DMAIC

Methodology

Analyze

For each possible root cause, determine those you will verify.

Summarize each possible root cause with the following codes:

Non Contributor (NC)

Possible Contributor (PC)

Insufficient Data (ID)

Data not available (IDX)

Does not contribute to the problem

A factor which may have an effect on the response

Not enough data to determine the effect of the factor

(may require additional effort)

Data not available concerning the factor

Root Cause (RC) Determined to be a root cause of the problem

Non Controllable Root Cause (RCX) A root cause; however, outside the control of the company, individual or team

74

© TLC, SSEO 1.5 22002

Root Cause(s) Validation and Summary

DMAIC

Methodology

Analyze

• List all probable Root Cause(s)

• Rank them in terms of effect size

• Determine the additional tests and or manipulation you plan to use to validate the factors (X) which have the greatest effect on the response (Y)

• Identify potential methods for controlling the factors which create the problem

• When validation is complete summarize all selected Root

Cause(s) and their effect size

75

© TLC, SSEO 1.5 22002

Root Cause Analysis Example

DMAIC

Methodology

Analyze

Root Cause(s) Analysis Summary

Analysis Method

Process Review

Potential Factor

Priority 1

Process Map

Priority 3

Visual Analysis

Residual Material in Bulk Fill

Wrong Materials

Priority 4 Improper use of SOP

Cause and Effect (Event) Analysis

Priority 2 Invalid Assay

NC - Non Contributor

PC - Partial Contributor

ID - Insufficient Data

Completed

Review Date

15-Mar

9-Mar

12-Mar

Who?

Tien

Tien

Kris

Investigation

Method

Review use logs for PK

%

Result Effect

Validation

Method

RC 100% Test for residual material

Validation

Date

28-Mar

Review inventory use for PK NC 0%

Review SOP use on the line NC 0%

12-Mar Anna

IDX - Data not available

RC - Root Cause

RCX - Root Cause Not Controllable

Verify Test Procedure NC 0%

% Unexplained 0%

76

© TLC, SSEO 1.5 22002

Six Sigma DMAIC Improve

DMAIC

Methodology

Improve

Improve Activities

Develop Solution Alternatives

Assess Risks and Benefits of Solution Alternatives

Validate Solution using a Pilot

Implement Solution

Determine Solution Effectiveness using Data

Improve Quality Tools

Design of Experiments

Brainstorming

FMEA

Risk assessment

77

© TLC, SSEO 1.5 22002

Improve Flow

Based on RCA

Brainstorm Potential

Solutions, Costs,

Risks and Benefits

DMAIC

Methodology

Improve

Design Experiments where appropriate

Test and Validate solutions

DPU

Review and approve solutions with

Management

Installed

New

Process

Equipment

N

Implement changes and determine improved process capability.

Reach

Goals?

Y

Examine opportunities for standardization and translation

78

© TLC, SSEO 1.5 22002

Brainstorm Potential Solutions

DMAIC

Methodology

Improve

Use general brainstorming techniques to generate process and design change ideas which will eliminate the root cause of the problem.

Separate ideas into short term and long term.

Long term with take 3 months or more to implement, short term is less than 3 months.

Use voting and management involvement to generate consensus on direction of approach

A single solution is not required at this point in the improvement process. 2 - 3 short term solutions should be selected and ranked. 1 to 2 long term solutions should also be selected for evaluation and experimentation.

79

© TLC, SSEO 1.5 22002

Consider Solutions That Remove Process Waste

DMAIC

Methodology

Improve

Seven muda:

1.

2.

3.

4.

5.

6.

7.

Over production ahead of demand

Waiting for the next process step or information

Transporting materials unnecessarily

Over processing

Inventory that is more than bare minimum

Motion by employees that is unnecessarily

Producing non-conforming parts

For each area of waste, examine each process step to determine if waste occurs in the operation and how to remove the waste from the production system

80

© TLC, SSEO 1.5 22002

Solutions Centered on Lean Methods

Reduce inventories and production costs while improving quality

Production

Control

Material

Flow

Machine

Management

Workplace

Management

Process

Management

DMAIC

Methodology

Improve

81

© TLC, SSEO 1.5 22002

Consider Solutions that Automate the Workflow

Discrete Transactions

Performance Monitoring and Improvement

JMP for Analysis

DMAIC

Methodology

Improve

Periodic Management

Reports

Workflow

Automation

Database

82

© TLC, SSEO 1.5 22002

DOE to Characterize, Improve the Process or

Product and Get Ready to Control

DMAIC

Methodology

Improve

Design experiments which improve the robustness of the process. Improve process parameter design, tolerance design and reduce the source of defects.

Once experiments are complete critical process parameter sensitivities can be modeled and determined how to be targeted and controlled.

83

© TLC, SSEO 1.5 22002

Evaluate Cost, Complexity, Impact,

Benefit and Risk for Each Solution

DMAIC

Methodology

Improve

• Assure solution costs and timelines are acceptable to management

• Determine the complexity of each solution in terms of time and ease of completion

• Identify potential impact (change to the baseline) of each solution. Explain how each solution will address the root cause and impact real change in performance.

• Financial benefit = benefit of solution – cost to implement

• Assess the risks associated with each solution and the likelihood of occurrence

• Determine need to involve/notify customer concerning any product or process changes

• Make sure that proper validation occurs associated with the solution prior to across the board implementation

84

© TLC, SSEO 1.5 22002

Solution Evaluation Form

DMAIC

Methodology

Improve

Solution Evaluation Form

List Root Cause(s)

Root Cause 1

List Solutions

Solutions 1

% Effect

% of effect solution will have on the root cause

Estimated Cost Complexity Estimated Benefit cost of time or effort to solution implement implementation short term?

long term?

savings due to solution or improvement in customer satisfaction

Risk*

High

Medium or

Low

Priority Validation?

Order of potential

Need to solution verify implmentation effectiveness

1st, 2nd, 3rd of solution

Root Cause 2

* Use Risk Assessment Form

Evaluate solution alternatives to assure the best solution has been selected

85

© TLC, SSEO 1.5 22002

Evaluating Risk

DMAIC

Methodology

Improve

Risk Assessment Form

List the Solution or

Major Elements of

Your Solution

Failure Mode

(What can go wrong)

List each failure mode

1. New Software

2. Solution a) b) c) a) Software does not link

correctly to database b) Software is not available on

time c) Software needs revisions

prior to deployment

Severity

(1-10)

Probability

(10 is

Score

(High scores

10 is Worst very probable) need attention)

10

6

3

6

7

9

60

42

27

Action

Plan

Owner Due

Date

Need to test database link Fred 15-Feb early during implementation James

Need to review progress Bill during weekly meeting Watson

25-Feb

3. Solution a) b)

Evaluate failure modes and probability to minimize any negative effects of changes to the product or process

86

© TLC, SSEO 1.5 22002

Involve the Champion, Discuss with Management

DMAIC

Methodology

Improve

Once the team has completed their work it is now time to review solutions with Management.

Allow the team to benefit from a fresh perspective and add

Management’s insight and experience to the priorities.

This step improves the alignment of Management to the Teams efforts

87

© TLC, SSEO 1.5 22002

Evaluate Improvements in Series

DMAIC

Methodology

Improve

Retrained the

Workforce on the Process

Installed

New

Process

Equipment

DPU

(miss, no change) (hit, improvement)

Implement one solution at a time. Allow for sufficient time to determine effect, then move to next solution.

88

© TLC, SSEO 1.5 22002

Six Sigma DMAIC Road Map

DMAIC

Methodology

Control

Control Activities

Determine Needed Controls (measurement, design, etc.)

Implement and Validate Controls

Develop Transfer Plan

Realize Benefits of Implementing Solution

Close Project and Communicate Results

Control Quality Tools

Statistical Process Control

Out of Control Action Plan (OCAP)

Design Changes to eliminate the defect

89

© TLC, SSEO 1.5 22002

“Control” Flow

Based on Solution,

Brainstorm appropriate controls to sustain the gains

Select SPC controls where appropriate

Implement and validate controls

Cost Improvements Quantified:

Process

Touch-up & Handsolder

Wash

QA/ Final Inspection

Rework

QA (QA E ngineers)

Production Control/Expediting

Curr Cost

($1, 000's per w eek)

New Cost

$ 73

$ 24

$ 58

$ 20

$ 5

$ 27

$

$

$

$

70

23

45

16

$

$

4

26

95%

95%

78%

78%

78%

95%

$ 10,782 k $ 9,525 k per Year

Improvement

$ 3.7

$ 1.2

$ 12.5

$ 4.4

$ 1.0

$ 1.4

Total per week for costs elements above $ 207 $ 183 per Week $ 24.2

Total per Year $ 1,257 k

Determine costs of current baseline and the impact to cost if the goal is achieved. Consider also the full impact to all effected lines and production operations. If financial analysis shows poor ROI you may want to select another project.

Review and approve control plan with

Management

Realize savings and determine final financial benefits and ROI

Determine long term owner and close the project

90

© TLC, SSEO 1.5 22002

Benefits Of Control Phase

25

20

15

10

5

0

Time

Process

Improvement

Process

Improvement

Process

Improvement

No Controls

DMAIC

Methodology

Control

91

© TLC, SSEO 1.5 22002

Process Controls

DMAIC

Methodology

Control

TYPES of CONTROLS

Measurement Based Control

Management Dashboards & Review

Statistical Process Control

Documentation

Process Flow Diagrams

Product Drawings, Schematics

Process Management Plans

Written Procedures

Training

Design

Design out Product Problems

Mistake Proofing

Robust Design Concepts

Test & Inspection

Test (error prone)

Inspection (poor effectiveness and costly)

Periodic Checks

Scheduled Maintenance

Scheduled Calibration

Training and Operator Certification

Audits

Periodic Management Reviews

Incentives

Measures which are associated with a bonus

Measures which are associated with a penalty

92

© TLC, SSEO 1.5 22002

Elements of a Control System

DMAIC

Methodology

Control

Sensor

(measurement technology & control chart)

Allows the system to monitor the current process performance

Alarm

(control limits and trend rules)

Establish limit(s) and run rules which require attention

Control Logic

(OCAP)

A predefined set of actions to follow that are alarm specific

Validate

(next sample)

Assure the action was effective

Add alarms where needed and assure we do not ignore valid alarms. SPC methods should be used to establish alarms.

93

© TLC, SSEO 1.5 22002

Define Sustaining Requirements

What Vacuum will be created when you leave?

DMAIC

Methodology

Control

Now that the solution is known and you are ready to finish the project….

• Determine the activities that need to continue after the team is dissolved

• Define who is doing them now… who should be the long term owner?

• Determine who needs to do them in a sustaining long term mode

• Define the set of tasks or systems that must be installed prior to completing the project and backing out of the work

• What else will be needed to make the solution effective and sustainable?

• From the above issues, develop a transfer plan

94

© TLC, SSEO 1.5 22002

Realize the Benefits of Improvement

DMAIC

Methodology

Control

How did you justify the cost savings for the project?

What changes will have to occur to create the savings?

Based on the impact of the benefits of the solution have you made changes to the process to realize the benefits?

Possible Actions:

Re-deploy personnel

Reorganize the floor

Reduce inventory levels in Planning System

Eliminate inspection or test operations

Modify Vendor/Customer contracts

Other cost saving changes to the operation

95

© TLC, SSEO 1.5 22002

Close the Project or Improvement Team

DMAIC

Methodology

Control

•

The goals have been met and the team has been successful

•

The solutions have all been implemented and demonstrated to be effective

•

Assure all documentation is complete

•

Determine what standardization opportunities are available

•

Make sure the accomplishments of the individual or team are appropriately recognized personally and publicly

•

Measure and communicate results of the project (benefits and savings)

•

Celebrate! We did it!

96

© TLC, SSEO 1.5 22002

Section IV

Section IV Implementation Strategy

97

© TLC, SSEO 1.5 22002

How Do We Do It?

Define

Goal alignment

Roles and responsibilities

Develop

Assemble materials

Identify people

Select software

Select training/consulting resources

Deploy

Executive Overview

Champion training / black belt & project selection

Black Belt training / project execution

Management review of progress

Realize results

6 s

98

© TLC, SSEO 1.5 22002

Typical Six Sigma Implementation Timeline

Start 1 st Wave March-August, 2002

1 st Month

Six Sigma Executive Overview Training ½ day

Champion Selection

Champion Training 2 days

Select software ( JMP ) and schedule the training resource (ASQ-SVC)

Black Belt Selection and 1 st Wave Six Sigma Projects

2 nd Month

100% Commitment of Black Belts to Process Improvement

Begin Black Belt, Green Belt Training

2 days Define , 3 days Measure , 3 days Analyze , 3 days Improve , 3 days

Control , scheduled every three-four weeks for 5 sessions

Begin Management Review of Six Sigma projects

Select Master Black Belt (Hire or Contract)

6 + Months

Realize savings from 1 st Wave, savings fund second wave etc.

Establish key metrics and dashboards if not present

Register in September for ASQ Certified Black Belt

2 nd Wave – September 2002 99

© TLC, SSEO 1.5 22002

Expected Cost/Benefits of One Wave of Training

Cost/Benefit Analysis of One Wave of Six Sigma

Costs

Training and Consulting Days Training Costs

Executive Overview

Champion Training

Black Belt Training

0.5

2

$ 1,475

$ 5,900

Master Black Belt

Define

Measure

Analyze

Improve

Control 3

50

3

3

3

3

$ 8,850

$ 8,850

$ 8,850

$ 8,850

$ 8,850

$ 60,000

Total Training and Consulting Costs

Employee Costs Number Days

Champions

Black Belts

Green Belts

5

8

12

60

1056

312

$ 111,625

Labor Costs

$ 60,000

$ 844,800

$ 249,600

$ 1,154,400

Benefits

Activity

Completed Projects

ROI (annualized)

Number Savings

15 $ 325,000

Total Benefits

$

$

4,875,000

3,608,975

% of ROI

0.0%

0.2%

0.2%

0.2%

0.2%

0.2%

0.2%

1.7%

3.1%

1.7%

23.4%

6.9%

32.0%

100

© TLC, SSEO 1.5 22002

Implementation Case Study

Six Sigma Financial Analysis

3Q

Total Department Expense $ 25,281.00

Six Sigma Project Benefits

Alta

Quote on Hold Process

PN Reduction

Lost Units

Defective from Stock

FTF

Fed Ex Sweep

NEC RMA Optimization

CSP Warranty

Total Six Sigma Project Benefits

$ -

$ -

$ -

$ -

$ -

$ -

$ -

$ -

$ -

$ -

4Q

$ 187,156.00

$ -

$ (5,074.13)

$ -

$ (187.60)

$ -

$ 25,740.00

$ 71,867.04

$ 562,328.94

$ 542,729.99

$ 1,197,404.24

Results from one wave of training as verified by the Finance department

YTD

$ 212,437.00

$ -

$ (5,074.13)

$ -

$ (187.60)

$ -

$ 25,740.00

$ 71,867.04

$ 562,328.94

$ 542,729.99

$ 1,197,404.24

101

© TLC, SSEO 1.5 22002

ASQ-SVC & TLC Team Up for Training Excellence

Six Sigma Improvement

Programs for West

Coast Industries

Certified Black Belt

Exam Date:

October 19, 2002

Registration:

August 23, 2002

The Statistical Discovery Software

TM

Workflow Modeling and Automation

102

© TLC, SSEO 1.5 22002

JMP and Ultimus Software Support

All ASQ-SVC Participants receive software use for six months during their Six Sigma training

JMP Software for

Windows and Macintosh links statistics with graphics, helping you explore your data, make discoveries and gain knowledge for better decision-making. See why so may professional choose JMP as their quality-improvement tool of choice for Six Sigma and quality improvement.

Ultimus software allows for effective process modeling, analysis and automation.

Transactional modeling and full workflow automation tools are available using

Ultimus

®

.

103

© TLC, SSEO 1.5 22002

Low Cost, High Quality, Local Six Sigma Training

Public and On-site Training

Champion Training

Six Sigma for Champions 16 hrs.

$975 Mar/21-22/02

Black Belt Training and ASQ National Black Belt Certification

BB Six Sigma “Define”

BB Six Sigma “Measure”

BB Six Sigma “Analyze”

BB Six Sigma “Improve”

BB Six Sigma “Control”

16 hrs.

24 hrs.

24 hrs.

24 hrs.

24 hrs.

$975

$1475

$1475

$1475

$1475

Apr/4-5/02

May/1-3/02

Jun/5-7/02

Jul/10-12/02

Aug/7-9/02

Green Belt Training

GB Six Sigma “Define”

GB Six Sigma “Measure”

GB Six Sigma “Analyze”

GB Six Sigma “Improve”

GB Six Sigma “Control”

Location

Harmonic, Inc.

549 Baltic Way, Sunnyvale, CA.

8 hrs.

8 hrs.

8 hrs.

8 hrs.

8 hrs.

$475

$475

$475

$475

$475

Apr/12/02

May/10/02

Jun/14/02

Jul/19/02

Aug/16/02

2 nd Wave begins in September

104

© TLC, SSEO 1.5 22002

Six Sigma for Champions

Six Sigma for Champions

Dates: March 21-22, 2002

Audience & Prerequisites:

Executive officers, Directors and Managers who will define and manage Six Sigma Projects

Content:

Section I

Section II

Six Sigma Introduction

Management Infrastructure for Six Sigma, Roles and Responsibilities

Section III Managing the DMAIC process

Section IV Project Selection and Charter

Section V

Section VI

Implementation Issues, timelines and Black Belt, Green Belt selection

Measures of Success

Location:

Harmonic, Inc.

549 Baltic Way

Sunnyvale, CA

Bring your own laptop

105

© TLC, SSEO 1.5 22002

Black Belt Six Sigma “Define”

Black Belt Six Sigma “Define”

Dates: April 4-5, 2002

Audience & Prerequisites:

Those individuals who will work on breakthrough projects as the

PRIMARY focus of their work activities. All individuals are required to have a project to work on and an identified Champion for the project.

Content:

Section I

Section II

Six Sigma Introduction

Identify Project, Champion and Owner

Section III Determine Customer Requirements and CTQs

Section IV Define Project Statement, Objectives, Goals and Benefits

Section V

Section VI

Define Resource/Stakeholder Analysis

Develop Project Plan

Section VII Map the Process

Section VIII Project Leadership

Location:

Harmonic, Inc.

549 Baltic Way

Sunnyvale, CA.

Bring your own laptop

106

© TLC, SSEO 1.5 22002

Green Belt Six Sigma “Define”

Green Belt Six Sigma “Define”

Date: April 12, 2002

Audience & Prerequisites:

Those individuals who will work on breakthrough projects as the

SECONDARY focus of their work activities. All individuals are required to have a project to work on and an identified Champion for the project.

Content:

Section I

Section II

Section III

Section IV

Section V

Section VI

Six Sigma Introduction

Determine Customer Requirements and CTQs

Define Project Statement, Objectives, Goals and Benefits

Define Resource/Stakeholder Analysis

Develop Project Plan

Map the Process

Location:

Harmonic, Inc.

549 Baltic Way

Sunnyvale, CA.

Bring your own laptop

107

© TLC, SSEO 1.5 22002

Project Based and Value Oriented

All training is Hands On and applied to your company’s projects. All training is done with computer applications.

Complete the training and complete a project.

Seating is limited! ~20 seats per class.

Registration Information

You can register on-line using www.asq-svc.org or www.dr-tom.com.

Or register for the Six Sigma public courses by contacting Tom Little at (925)-285-1847 or by e-mail drlittle@dr-tom.com.

www.asq-svc.org

www.dr-tom.com

108

© TLC, SSEO 1.5 22002

Six Sigma Executive Overview Summary

• There are tremendous improvement and savings available to companies in their operations if they will mobilize their resources toward reduction of waste and improvement of quality

• Six Sigma requires Leadership from the Executive Staff

• The roadmap is clear and the methods for improvement are well defined

• Software tools make the data collection and analysis clear

• Development of an implementation and training plan is the next step

109

© TLC, SSEO 1.5 22002

References & Resources

Books:

E.L. Grant & R.S. Leavenworth, Statistical Quality Control (New York: NY, McGraw Hill, 1996).

D.C. Montgomery, Design and Analysis of Experiments.

(New York: NY, John Wiley & Sons,

1996).

G.E. Box, J.S. Hunter & W.G. Hunter, Statistics for Experimenters: An Introduction to Design,

Data Analysis, and Model Building (New York: NY, John Wiley & Sons 1978).

Damelio, Robert. (1996). The Basics of Process Mapping . Productivity Press, Portland, OR.

Web Sites:

Thomas A. Little Consulting at www.dr-tom.com

ASQ Silicon Valley Section at www.asq-svc.org

Software: SAS JMP contact SAS Institute at www.jmpdiscovery.com

382 Stanwick Street

Brentwood, CA 94513

1-925-285-1847 drlittle@dr-tom.com

www.dr-tom.com

110

© TLC, SSEO 1.5 22002