Complex fluids

advertisement

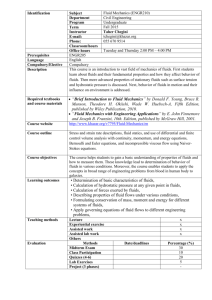

Complex fluids and applications in the process industries: fluid homogenization and transport Tuomas Koiranen / LUT, Finland Introduction to complex fluids problematics (Definitions, classification), rheologies process conditions in applications and typical process equipment Complex fluids definitions: 1) Fluids showing non-linear viscous behaviour, as well as viscoelastic materials, are Complex Fluids. (Complex fluids engineering laboratory, Universidad Huelva, Spain) 2) Typically multicomponent systems, complex fluids are highly nonlinear with respect to composition changes, and often the fluid states that provide the desired mechanical or chemical properties are metastable and accessible only through precisely controlled processing and formulation steps. (Carnegie Mellon, Center for Complex fluids Engineering) - Summary of Definitions: Complex fluids have 2 or more fluid phases which have physical interaction with each other, and they can have typically a complex microstructure. Fluid phases refer to disperse systems. Classification of disperse systems Continuous medium (Björn Lindman, Surfactants and Cellulose polymers in aqueous solutions-course, Physical chemistry, Lund University, Sweden, 2013) GAS LIQUID SOLID GAS None Foam (whipped cream, shaving cream, flotation cell foam) Solid foam (aerogel, polymer foam, pumice) Dispersed phase LIQUID Liquid aerosol (fog, hair sprays) Emulsion (milk, mayonnaise, lotions, ointments) Gel (agar, gelatin jelly) SOLID Solid aerosol (air particles, smoke) Sol (blood, pigmented ink, fiber suspensions) Solid sol (gemstone, jewel) Liquid-gas: foams, gas-liquid dispersions Gas-liquid: fog, liquid aerosols Gas-solid: solid aerosols, powders Solid-gas: solid foams Liquid-liquid: liquid-liquid dispersions , emulsions Solid-liquid: gels, pastes Liquid-solid: solid-liquid suspensions, slurries, sols Bulk rheologies (EKATO Mixing handbook, 2000) - The macroscale fluid rheology Bulk rheologies - The macroscale fluid rheology Sol-gel viscosity example as a function of shear rate at different temperatures. Gelling at 20 °C curve. Bulk rheologies - The macroscale fluid rheology Solution rheology example: Sol-gel transition Illustration of the viscoelastic structure and gelation phenomenon at elevated temperature. (Metzger 2011, Kalanti 2015) Microrheology (Rep. Prog. Phys. 68 (2005) 685, J. Non-Newtonian Fluid Mech. 112 (2003) 237). 1) Microrheology is concerned with how materials store and dissipate mechanical energy as a function of length scale. 2) It is closely connected to the field of microfluidics (ink jet printing, microreactors, valves etc.) 3) Classification (Waigh 2005) 1) Large amplitude oscillatory shear (LAOS) behavior studies of complex fluids in forming microstructures. Type I. Strain thinning: most polymer solutions or melts Type II. Strain thickening: ion dipoles or hydrogen bonding (PVA+Na2B4O7, alcohol+clay with water bridge) Type III. Weak strain overshoot: surfactant solutions, biopolymers (dough), liquid emulsions Type IV. Strong strain overshoot: HASE polymers (acid/acrylate with ethoxylated hydrophobe) Microstructures (Quemada, 1997) Required shear rates in different applications Typical shear rates of different processes (Fried, 1995; Paul et al. 2004;Kessler, 1998) Process Shear rate, 1/s Application Particle sedimentation in suspension Extrusion, pipe flow Mixing in stirred tank Spray drying High speed coating 1E-6 - 1E-3 1 - 1E+3 10-1000 1E+3 - 1E+5 1E+4 - 1E+6 paints, medicines food, polymers food, chemicals food, chemicals paper Mixing power for Production of O/W dispersions (Paul et. al, 2004) Emulsions (John Texter, Practical Survey course on small particle formation, Strider Res. Co. 2009) - Emulsions are unstable but microemulsions are stable. - Critical micelle forming concentration + charged Small to long chain - charged long to small chain Mesophases (John Texter, Practical Survey course on small particle formation, Strider Res. Co. 2009) Microstructure formation (Lindman, 2013) PARTICLE STABILIZATION - Hard wall and electrostatic repulsion, and Van der Waals attraction forces define the electrostatic stabilized colloids -In steric stabilization polymer chains form steric hindrance for particles to form aggregates Mixers for complex fluids Static mixers - Large variety of fluids mixing (Laminar/Turbulent, S/L/G) - Short residence times (τc) - Large shear rate region and dispersed phase/continuous phase –ratios (Rµ) based on different geometries - Simple sizing procedures (pump) P = ∆𝑝𝑄 Mixers for complex fluids Mixing tanks - Large residence time regions - Large distributions of shear rates - Liquids, emulsions, gels, pastes Some special cases - Ultrasonication can be used for emulsification, difficult slurry formations (e.g. nanomaterial wetting). - Electrocapillarity: Internal phase breaks into emulsion droplet in continuous phase when electric potential difference is applied between phases (Watanabe et al., 1978) - Initial dispersion is pressed through porous membrane to form emulsion (Omi et al., 1994). Summary of homogenization methods Type of complex fluids Paints Adhesives Paint pastes Greases Ceramics (heavy consistency) Fibrous mixes Resins (heavy consistency) Rubbers&Elastomers (stiff gels) Mineral slurries Emulsions (food, cosmetics, pharma) Foams (gas-liquid) Mixers used rotor-stators, stirred tanks (shearing action) kneaders, rotor-stators roll mills, ball mills, tube mills, rotor-stators stirred tanks (dual action), kneaders (sigma blade, dispersion blade) pan mixers, pug mills, planetary mills kneaders, sigma/dispersion blade), intensive mixers (Banbury type) kneaders, roll mills, intensive mixers (Banbury, rotor-stator) intensive mixers, roll mills, kneaders stirred tanks (dual action), in-line mixers (rotorstators) paddle stirred tanks, static mixers, in-line mixers (rotor-stators), pressure homogenizer Gas-liguid Injectors, stirred tanks - Complex fluids can also be present in changing process conditions: Chemical reactions, crystallizations, melting processes etc. - Complex fluids transport Centrifugal pumps are the most common pumps for fluid transport The problems arise typically for 1) shear thickening fluids=> viscosity increases=> flow rate decreases 2) high solid contents => material abrasion 3) preserving fluid microstructure => shear rate changes occur Special pumps can be used in complex fluids transport: peristaltic pumps, positive displacement pumps like eccentric screw pumps (e.g. Flowrox Ltd) Literature :Equipment EKATO Handbook of Mixing Technology, EKATO Rühr- und Mischtechnik GmbH, 2000 Matijevic, E., Good, R.J. (eds.), Surface and colloid science Vol 13, Ch. 1: Electrochemistry of oil-water interfaces, Springer, USA, 1984 McDonough,R.J., Mixing for the Process Industries, Van Nostrand Rheinhold, New York, USA, 1992 Paul, L.E., Atiemo-Obeng, V., Kresta, S., (eds.), Handbook of industrial mixing, Wiley, 2004 Pehrman, N., Slurry flows in progressive cavity and peristaltic hose pumps, LUT 2014 Thakur, R.K. et al., Static mixers in the process industries - a review, Trans IChemE 81 A, (2003) 787-826 Grace, H.P., Chem Eng Commun 14 (1982), 225–277 Zlokarnik, M., Judat, H., Ullmann's Encyclopedia of Industrial Chemistry, Vol. B2., Ch. 25: Stirring , VCH Verlagsgesellschaft GmbH, Germany, 1988 Literature: Processes Florence, A.T., Attwood, D. (eds.), Physicochemical principles of pharmacy, Pharmaceuitical press, UK, 2011 Dickinson, E., Leser, M. (eds.), Food colloids – self-assembly and material science, RSC publishing, UK, 2007 Fried, J.R., Polymer science and technology, Prentice Hall, USA, 1995 Kessler, H.G., Food and bio process engineering – dairy technology, Verlag A. Kessler, Germany, 1998 Mixing in polymer processing, Rauwendaal, C. (ed.), Marcel Dekker, USA, 1991 Omi, S., Katami, K., Yamamoto, A., Iso, M., Synthesis of polymeric microspheres employing SPG emulsification technique, J. Appl. Polym. Sci. 51 (1994) 1-11 Watanabe, A. et al., J. Colloid Interface Sci 64 (1978) 278 Literature: Complex fluids, disperse systems, rheology and microrheology Chen, D.T. et al., Rheological microscopy: local mechanical properties from microrheology, Phys. Rev. Lett. 90 (2003) 108301-1 - 108301-4 Lindman, B., Surfactants and cellulose polymers in aqueous solutions (course material), Physical Chemistry Dept., Lund University, Sweden, 2013. Luckham, P.F., Rossi, S., The colloidal and rheological properties of bentonite suspensions, Advances in Colloid and Interface Science 82 (1999) 43-92 Texter, J., Practical survey course on small particle formation (course material), Strider Research Company, USA, 2009 Quemada, D., Rheological modelling of complex fluids. I. The concept of efective volume fraction revisited, Eur. Phys. J. AP 1 (1998) 119-127 Quemada, D., Berli, C, Energy of interaction in colloids and its implications in rheological modeling, Advances in Colloid and Interface Science 98 (2002) 51-85 Gelbart, W.M., Ben-Shaul, A., The “New” Science of “Complex Fluids”, J. Phys. Chem. 100 (1996) 13169-13189 Waigh, T.A., Microrheology of complex fluids, Rep. Prog. Phys. 68 (2005) 685–742 Sim, H.G., Ahn, K.H., Lee, S.J., J. Non-Newtonian Fluid Mech. 112 (2003) 237–250 Mezger T. The Rheology Handbook. 3rd Edition, Vincentz Network, 2011. Kalanti A. 2014. Basics of rheology (course material in Finnish), Anton Paar. Imatra, Finland, 2015. Some research questions 1) Is the response of one probe particle a true measure of the bulk rheology? An interconnection of microstructures to bulk rheology is welcome. 2) The equipment selection and sizing are based on dynamic viscosity data. Elastic and viscous moduli data are available for a vast amount of different complex fluid systems. Focus also for dynamic rheology measurements. 3) Complex fluid structures formation. Systematic, uniform and technoscientific approach for product design ? e.g. formation energies, characteristic residence times, critical surface areas, etc. THANK YOU / KIITOS