ppt - Erice Crystallography 2004

advertisement

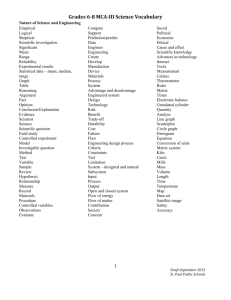

Thermal Methods in the Study of Polymorphs and Solvates Susan M. Reutzel-Edens, Ph.D. Research Advisor Lilly Research Laboratories Eli Lilly & Company Indianapolis, IN 46285 Presented at: “Diversity Amidst Similarity: A Multidisciplinary Approach to Polymorphs, Solvates and Phase Relationships” (The 35th Crystallographic Course at the Ettore Majorana Centre) Erice, Sicily June 9-20, 2004 Thermal Analysis Techniques A group of techniques in which a physical property is measured as a function of temperature, while the sample is subjected to a predefined heating or cooling program. Differential Thermal Analysis (DTA) • the temperature difference between a sample and an inert reference material, DT = TS - TR, is measured as both are subjected to identical heat treatments Differential Scanning Calorimetry (DSC) • the sample and reference are maintained at the same temperature, even during a thermal event (in the sample) • the energy required to maintain zero temperature differential between the sample and the reference, dDq/dt, is measured Thermogravimetric Analysis (TGA) • the change in mass of a sample on heating is measured Basic Principles of Thermal Analysis Modern instrumentation used for thermal analysis usually consists of four parts: 1) sample/sample holder 2) sensors to detect/measure a property of the sample and the temperature 3) an enclosure within which the experimental parameters may be controlled 4) a computer to control data collection and processing DTA power compensated DSC heat flux DSC Differential Thermal Analysis sample holder • sample and reference cells (Al) alumina block sensors heating coil • Pt/Rh or chromel/alumel thermocouples • one for the sample and one for the reference • joined to differential temperature controller sample pan reference pan furnace • alumina block containing sample and reference cells temperature controller • controls for temperature program and furnace atmosphere inert gas vacuum Pt/Rh or chromel/alumel thermocouples Differential Thermal Analysis advantages: • instruments can be used at very high temperatures • instruments are highly sensitive • flexibility in crucible volume/form • characteristic transition or reaction temperatures can be accurately determined disadvantages: • uncertainty of heats of fusion, transition, or reaction estimations is 20-50% DTA Differential Scanning Calorimetry • DSC differs fundamentally from DTA in that the sample and reference are both maintained at the temperature predetermined by the program. • during a thermal event in the sample, the system will transfer heat to or from the sample pan to maintain the same temperature in reference and sample pans • two basic types of DSC instruments: power compensation and heat-flux power compensation DSC heat flux DSC Power Compensation DSC individual heaters sample pan controller DP reference pan sample holder • Al or Pt pans sensors inert gas vacuum inert gas vacuum thermocouple DT = 0 • Pt resistance thermocouples • separate sensors and heaters for the sample and reference furnace • separate blocks for sample and reference cells temperature controller • differential thermal power is supplied to the heaters to maintain the temperature of the sample and reference at the program value Heat Flux DSC heating coil sample holder • sample and reference are connected by a low-resistance heat flow path • Al or Pt pans placed on constantan disc sample pan reference pan constantan chromel/alumel wires sensors inert gas vacuum thermocouples chromel wafer • chromel®-constantan area thermocouples (differential heat flow) • chromel®-alumel thermocouples (sample temperature) furnace • one block for both sample and reference cells temperature controller • the temperature difference between the sample and reference is converted to differential thermal power, dDq/dt, which is supplied to the heaters to maintain the temperature of the sample and reference at the program value Modulated DSC (MDSC) • introduced in 1993; “heat flux” design • sinusoidal (or square-wave or sawtooth) modulation is superimposed on the underlying heating ramp • total heat flow signal contains all of the thermal transitions of standard DSC • Fourier Transformation analysis is used to separate the total heat flow into its two components: heat capacity (reversing heat flow) glass transition melting Modulated DSC Heating Profile kinetic (non-reversing heat flow) crystallization decomposition evaporation enthalpic relaxation cure Analysis of Heat-Flow in Heat Flux DSC • temperature difference may be deduced by considering the heat flow paths in the DSC system temperature heating block DTR Tfurnace DTS TRP TSP TR reference DTL sample TS thermocouple is not in physical contact with sample • thermal resistances of a heat-flux system change with temperature • the measured temperature difference is not equal to the difference in temperature between the sample and the reference DTexp ≠ TS – TR DSC Calibration baseline • evaluation of the thermal resistance of the sample and reference sensors • measurements over the temperature range of interest 2-step process • the temperature difference of two empty crucibles is measured • the thermal response is then acquired for a standard material, usually sapphire, on both the sample and reference platforms • amplified DSC signal is automatically varied with temperature to maintain a constant calorimetric sensitivity with temperature DSC Calibration temperature • goal is to match the melting onset temperatures indicated by the furnace thermocouple readouts to the known melting points of standards analyzed by DSC • should be calibrated as close to the desired temperature range as possible heat flow • use of calibration standards of known heat capacity, such as sapphire, slow accurate heating rates (0.5–2.0 °C/min), and similar sample and reference pan weights calibrants • • • • • • high purity accurately known enthalpies thermally stable light stable (hn) nonhygroscopic unreactive (pan, atmosphere) metals • In 156.6 °C; 28.45 J/g • Sn 231.9 °C • Al 660.4 °C inorganics • KNO3 128.7 °C • KClO4 299.4 °C organics • polystyrene 105 °C • benzoic acid 122.3 °C; 147.3 J/g • anthracene 216 °C; 161.9 J/g Sample Preparation • accurately-weigh samples (~3-20 mg) • small sample pans (0.1 mL) of inert or treated metals (Al, Pt, Ni, etc.) • several pan configurations, e.g., open , pinhole, or hermetically-sealed pans • the same material and configuration should be used for the sample and the reference • material should completely cover the bottom of the pan to ensure good thermal contact • avoid overfilling the pan to minimize thermal lag from the bulk of the material to the sensor * small sample masses and low heating rates increase resolution, but at the expense of sensitivity Al Pt alumina Ni Cu quartz Thermogravimetric Analysis (TGA) • thermobalance allows for monitoring sample weight as a function of temperature • two most common instrument types reflection null • weight calibration weights using calibrated Sample: Calcium Oxalate Size: 7.9730 mg File: Y:\Data\TGA\Calcium oxalate\032304.001 Operator: SLT Run Date: 23-Mar-04 14:57 Instrument: 2950 TGA HR V5.4A TGA 120 • larger sample masses, lower temperature gradients, and higher purge rates minimize undesirable buoyancy effects 100 12.15% 80 19.32% Weight (%) • temperature calibration based on ferromagnetic transition of Curie point standards (e.g., Ni) 60 29.99% 40 20 0 20 40 60 80 Time (min) 100 120 140 160 Universal V3.7A TA Instruments TG curve of calcium oxalate Typical Features of a DSC Trace for a Polymorphic System endothermic events melting sublimation solid-solid transitions desolvation chemical reactions exothermic events sulphapyridine crystallization solid-solid transitions decomposition chemical reactions baseline shifts glass transition Recognizing Artifacts sample topples over in pan sample pan distortion shifting of Al pan mechanical shock of measuring cell cool air entry into cell sensor contamination electrical effects, power spikes, etc. RT changes intermittant closing of hole in pan lid burst of pan lid Thermal Methods in the Study of Polymorphs and Solvates polymorph screening/identification heat flow • heat of fusion • heat of transition • heat capacity 1.0 0.5 0.0 Heat Flow (W/g) thermal stability • melting • crystallization • solid-state transformations • desolvation • glass transition • sublimation • decomposition -0.5 -1.0 -1.5 ––––––– ––––––– ––––––– ––––––– ––––––– -2.0 Form II Form Form IIII Form Variable Form III Hydrate Dihydrate Acetic acid solvate -2.5 0 50 100 Exo Up 150 200 Temperature (°C) mixture analysis • chemical purity • physical purity (crystal forms, crystallinity) phase diagrams • eutectic formation (interactions with other molecules) 250 300 350 Sample: INDIUM CRIMPED PAN CHECK Size: 7.6300 mg Method: indium Comment: P/N 56S-107 File: C:...\10C per min crimped\DSC010920A.3 Operator: Ron Vansickle Run Date: 20-Sep-01 09:13 Instrument: 2920 MDSC V2.6A Definition of Transition Temperature DSC 0.5 156.50°C 28.87J/g 0.0 extrapolated onset temperature Heat Flow (W/g) -0.5 -1.0 -1.5 peak melting temperature -2.0 157.81°C -2.5 140 Exo Up 145 150 155 160 Temperature (°C) 165 170 175 Universal V3.3B TA Instruments Melting Processes by DSC pure substances • linear melting curve • melting point defined by onset temperature impure substances eutectic melt • concave melting curve • melting characterized at peak maxima melting with decomposition • exothermic • endothermic • eutectic impurities may produce a second peak Glass Transitions • second-order transition characterized by change in heat capacity (no heat absorbed or evolved) • transition from a disordered solid to a liquid • appears as a step (endothermic direction) in the DSC curve • a gradual volume or enthalpy change may occur, producing an endothermic peak superimposed on the glass transition Sample: INDIUM CRIMPED PAN CHECK Size: 7.6300 mg Method: indium Comment: P/N 56S-107 File: C:...\10C per min crimped\DSC010920A.3 Operator: Ron Vansickle Run Date: 20-Sep-01 09:13 Instrument: 2920 MDSC V2.6A Enthalpy of Fusion DSC 0.5 156.50°C 28.87J/g 0.0 Heat Flow (W/g) -0.5 -1.0 -1.5 -2.0 157.81°C -2.5 140 Exo Up 145 150 155 160 Temperature (°C) 165 170 175 Universal V3.3B TA Instruments Burger’s Rules for Polymorphic Transitions monotropy endothermic endothermic enantiotropy Heat of Transition Rule • endo-/exothermic solid-solid transition • exothermic solid-solid transition Heat of Fusion Rule • higher melting form; lower DHf • higher melting form; higher DHf Enthalpy of Fusion by DSC single (well-defined) melting endotherm • • • • area under peak minimal decomposition/sublimation readily measured for high melting polymorph can be measured for low melting polymorph multiple thermal events leading to stable melt • solid-solid transitions (A to B) from which the transition enthalpy (DHTR) can be measured* DHfA = DHfB - DHTR crystallization of stable form (B) from melt of (A) DHfA = area under all peaks from B to the stable melt * assumes negligible heat capacity difference between polymorphs over temperatures of interest Purity by DSC • eutectic impurities lower the melting point of a eutectic system • purity determination by DSC based on Van’t Hoff equation RTo2 c Tm = To DHo . 1 f • applies to dilute solutions, i.e., nearly pure substances (purity ≥98%) 97% 99% benzoic acid 99.9% • 1-3 mg samples in hermetically-sealed pans are recommended • polymorphism interferes with purity determination, especially when a transition occurs in the middle of the melting peak melting endotherms as a function of purity. Plato, C.; Glasgow, Jr., A.R. Anal. Chem., 1969, 41(2), 330-336. Effect of Heating Rate • many transitions (evaporation, crystallization, decomposition, etc.) are kinetic events … they will shift to higher temperature when heated at a higher rate • the total heat flow increases linearly with heating rate due to the heat capacity of the sample … increasing the scanning rate increases sensitivity, while decreasing the scanning rate increases resolution • to obtain thermal event temperatures close to the true thermodynamic value, slow scanning rates (e.g., 1–5 K/min) should be used DSC traces of a low melting polymorph collected at four different heating rates. (Burger, 1975) Effect of Phase Impurities • lots A and B of lower melting polymorph (identical by XRD) are different by DSC 0 Lot A - pure 2046742 FILE# 022511DSC.1 Heat Flow (W/g) -1 -2 Lot B - seeds 2046742 FILE# 022458 DSC.1 Form II ? -3 -4 -5 80 Exo Up 130 180 230 Temperature (°C) 280 Universal V3.3B TA Instruments • Lot A: pure low melting polymorph – melting observed • Lot B: seeds of high melting polymorph induce solid-state transition below the melting temperature of the low melting polymorph Polymorph Characterization: Variable Melting Point • lots A and B of lower melting polymorph (identical by XRD) appear to have a “variable” melting point 0.1 -0.1 Lot A Heat Flow (W/g) -0.3 -0.5 Lot B -0.7 -0.9 DSC010622b.1 483518 HCL (POLYMORPH 1) DSC010622d.1 483518 HCL -1.1 110 Exo Up 120 130 140 150 Temperature (°C) 160 170 180 Universal V3.3B TA Instruments • although melting usually happens at a fixed temperature, solid-solid transition temperatures can vary greatly owing to the sluggishness of solid-state processes Reversing and Non-Reversing Contributions to Total DSC Heat Flow total heat flow resulting from average heating rate dQ/dt = Cp . dT/dt + f(t,T) reversing signal heat flow resulting from sinusoidal temperature modulation (heat capacity component) non-reversing signal (kinetic component) * whereas solid-solid transitions are generally too sluggish to be reversing at the time scale of the measurement, melting has a moderately strong reversing component Polymorph Characterization: Variable Melting Point • the low temperature endotherm was predominantly non-reversing, suggestive of a solid-solid transition • small reversing component discernable on close inspection of endothermic conversions occurring at the higher temperatures, i.e., near the melting point 0.2 0.00 reversing heat flow non-reversing heat flow Reversing (heat flow component) -0.05 Non-reversing (heat flow component) -0.10 0.0 Rev Heat Flow (W/g) Nonrev Heat Flow (W/g) Lot A -0.15 -0.20 -0.25 Lot B -0.30 Lot A -0.2 Lot B -0.4 -0.35 -0.40 -0.45 -0.6 DSC010622b.1 483518 HCL (POLYMORPH 1) DSC010622d.1 483518 HCL -0.50 110 Exo Up 120 130 DSC010622b.1 483518 HCL (POLYMORPH 1) DSC010622d.1 483518 HCL 140 150 Temperature (°C) 160 170 180 -0.8 110 Universal V3.3B TA Instruments Exo Up 120 130 140 150 Temperature (°C) 160 170 180 Universal V3.3B TA Instruments • the “variable” melting point was related to the large stability difference between the two polymorphs; the system was driven to undergo both melting and solid-state conversion to the higher melting form Polymorph Stability from Melting and Eutectic Melting Data • polymorph stability predicted from pure melting data near the melting temperatures (G1-G2)(Tm1) = DHm2(Tm2-Tm1)/Tm2 0.4 GON-GY, kJ/mole • eutectic melting method developed to establish thermodynamic stability of polymorph pairs over larger temperature range (b) TmA P1 A Tm1 Tm2 Y 0 Tt -0.2 -0.4 DSC Signal (G1-G2)(Tm2) = DHm1(Tm2-Tm1)/Tm1 sdf 0.2 eutectic melting ON TmRC 0 ON melting Y ON Y ON Y +benzil +thymol +azobenzene +acetanilide 60 T, oC 80 100 pure forms 120 (G1-G2)(Te1) = DHme2(Te2-Te1)/(xe2Te2) RC Te2 Te1 1 Y ON Y 40 P2 ON xe2 xe1 x 1 (G1-G2)(Te2) = DHme1(Te2-Te1)/(xe1Te1) Yu, L. J. Pharm. Sci., 1995, 84(8), 966-974. Yu, L. J. Am. Chem. Soc, 2000, 122, 585-591. “Hyphenated” Techniques • thermal techniques alone are insufficient to prove the existence of polymorphs and solvates • other techniques should be used, e.g., microscopy, diffraction, and spectroscopy • development of “hyphenated” techniques for simultaneous analysis Sample: SODIUM TARTRATE (ALDRICH) Size: 6.1176 mg Method: 25C TO 300 Comment: LOT# 22411A0 TG-DTA File: C:\TA\Data\Sdtcal\2004\TGA040105A.5 Operator: Ron Vansickle Run Date: 6-Jan-04 12:09 Instrument: 2960 SDT V3.0F TGA-DTA 120 4.2 15.55% (0.9513mg) 24.80°C 100.0% 179.95°C 84.45% Weight (%) 2.2 TG-FTIR TG-MS evolved gas analysis (EGA) 40 1.2 0.2 Temperature Difference (µV/mg) TG-DSC 3.2 80 0 -0.8 -40 -1.8 20 Exo Up 70 120 170 Temperature (°C) 220 270 Universal V3.3B TA Instruments TG-DTA trace of sodium tartrate Best Practices of Thermal Analysis • small sample size • good thermal contact between the sample and the temperature-sensing device • proper sample encapsulation • starting temperature well below expected transition temperature • slow scanning speeds • proper instrument calibration • use purge gas (N2 or He) to remove corrosive off-gases • avoid decomposition in the DSC