Request for Quotation (RFQ)

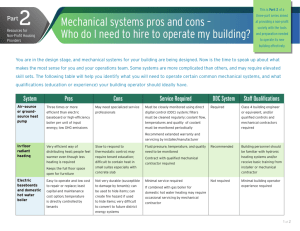

advertisement