CHAPTER 11: PHASE TRANSFORMATIONS

advertisement

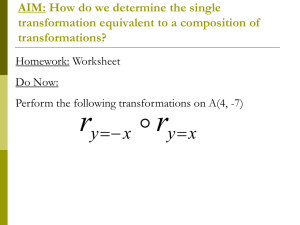

CHAPTER 11: PHASE TRANSFORMATIONS ISSUES TO ADDRESS... • Transforming one phase into another takes time. Fe (Austenite) C FCC Fe C 3 Eutectoid transformation (cementite) + (ferrite) (BCC) • How does the rate of transformation depend on time and T? • How can we slow down the transformation so that we can engineer non-equilibrium structures? • Are the mechanical properties of non-equilibrium structures better? 1 Phase Transformations • Introduction and Motivation – Microstructure Processing Properties – Our previous discussions focused on the equilibrium phase diagrams • These tell you what can happen – Now we will talk about the rates of phase changes to find out what does happen – Why is this important? Many materials are not processed under equilibrium conditions • Heating/cooling rates Phase Transformations • Phase Transformation – – – A phase transformation is an alteration in the number and/or compositions of the phases present in a material These are usually not instantaneous processes (hence our interest in rates) Organize these into 3 categories 1. 2. 3. Diffusion dependent processes with no change in the composition or number of phases – solidification, allotropic transformations, grain boundary growth, recrystallization Diffusion dependent process with a change in the number and/or composition of phases – eutectic, eutectoid, peritectic reactions Diffusionless processes – form metastable states (haven’t seen these yet) FRACTION OF TRANSFORMATION • Fraction transformed depends on time. Adapted from Fig. 10.1, Callister 6e. • Transformation rate depends on T. Adapted from Fig. 10.2, Callister 6e. (Fig. 10.2 adapted from B.F. Decker and D. Harker, "Recrystallization in Rolled Copper", Trans AIME, 188, 1950, p. 888.) • r often small: equil not possible! 2 Phase Transformations • Kinetics of phase transformations – Phase transformations are not usually instantaneous – Hence from a processing viewpoint their rates are of interest • These transformations have two key events – Nucleation – formation of small clusters (~10’s –100’s of atoms) of the new phase – Growth – little clusters get bigger Phase Transformations • Kinetics of phase transformations – Nucleation – two types • Homogeneous nucleation – nuclei of the new phase are formed uniformly throughout the parent or original phase • Heterogeneous nucleation – nuclei of the new phase form preferentially at heterogeneities (surfaces, impurities, etc.) – The energetics (and hence kinetics) of these processes are typically different • The discussion of energetics will use free energies – Remember the Gibbs free energy DG? – DG < 0 for transformation occur spontaneously DG DH TDS TRANSFORMATIONS & SUPERCOOLING super Adapted from Fig. 9.21,Callister 6e. (Fig. 9.21 adapted from Binary Alloy Phase Diagrams, 2nd ed., Vol. 1, T.B. Massalski (Ed.-in-Chief), ASM International, Materials Park, OH, 1990.) super For cooling, transformations are shifted to lower temperatures than indicated by the phase diagram 3 NUCLEATION AND GROWTH • Reaction rate is a result of nucleation and growth of crystals. Adapted from Fig. 10.1, Callister 6e. • Examples: 5 Phase Transformations • Nucleation – – Homogeneous nucleation – start with simple picture: what is the free energy of a small spherical particle of a solid in a continuous media of the liquid (i.e. solidification) Two major contributions to the free energy 1. 2. Free energy difference between the solid and liquid phases (book calls it the volume free energy) DGv Free energy of the solid-liquid phase boundary 4 1. r 3 DGv 3 2. 4r 2 Few points: 1) DGv is negative if T < T solidification 2) The surface free energy is always positive So, 4 DG r 3 DGv 4r 2 3 Phase Transformations • Nucleation – – Homogeneous nucleation So what does the plot of DG versus r look like? 4 DG r 3 DGv 4r 2 3 There is a clear maximum in DG as a function of r This size r* has physical meaning Particles smaller than this will not lead to nuclei Particles this size or larger will grow (they are called nuclei) DG* can be thought of as an energy barrier to nucleation embryo (r < r*) nucleus (r > r*) What is the value of DG* ? Phase Transformations d DG d 4 3 2 r DGv 4r 0 dr dr 3 4r 2 DGv 8r 0 2 r DGv • Sub into Original eqn. Nucleation – – 4 3 DG r DGv 4r 2 3 Homogeneous nucleation – DG*, r* Take derivative of DG with respect to r and set it equal to zero! 16 3 DG 2 3DGv Some observations – DGv is the driving force for nucleation (solidification) It is a function of temperature! At the equilibrium melting temperature Tm its value is zero! Can I relate this to enthalpies? Of course! Phase Transformations • Nucleation – – DGv Homogeneous nucleation – DG*, r* Relations using enthalpy DH f Tm T Tm What do the equations tell you? Both r* and DG* decrease as T decreases for T < Tm T2 < T 1 2Tm 1 r DH T T f m * 3 2 16 Tm 1 DG * 3DH 2 T T 2 f m Phase Transformations • Nucleation – Homogeneous nucleation – How many nuclei? * D G * n K1 exp k BT Qd vd K 2 exp k BT Increase T, fewer nuclei (not immediately clear from this!) Frequency of attachment (how often do clusters collide and combine) – why is this related to diffusion? Put all this together … the rate of nucleation is … * Qd D G * exp N K 3 n vd K1 K 2 K 3 exp k BT k BT K3 is the number of atoms on a nucleus surface Phase Transformations • Nucleation – Homogeneous nucleation – rate! DG * Qd * exp N K 3 n vd K1 K 2 K 3 exp k BT k BT Plots clearly show there is an optimal temperature for maximizing the nucleation rate. EUTECTOID TRANSFORMATION RATE ~ DT • Growth of pearlite from austenite: Adapted from Fig. 9.13, Callister 6e. • Reaction rate increases with DT. Adapted from Fig. 10.3, Callister 6e. 4 Phase Transformations • Nucleation – Homogeneous nucleation – supercooling • It can turn out that to have appreciable nucleation take place the sample temperature must be well below the equilibrium melting (solidification) temperature – This is called supercooling – the degree of supercooling can be significant! TRANSFORMATIONS & SUPERCOOLING Adapted from Fig. 9.21,Callister 6e. (Fig. 9.21 adapted from Binary Alloy Phase Diagrams, 2nd ed., Vol. 1, T.B. Massalski (Ed.-in-Chief), ASM International, Materials Park, OH, 1990.) super For cooling, transformations are shifted to lower temperatures than indicated by the phase diagram 3 NUCLEATION AND GROWTH • Reaction rate is a result of nucleation and growth of crystals. Adapted from Fig. 10.1, Callister 6e. • Examples: 5 Phase Transformations • Example Problem 11.1 – For the solidification of pure gold, calculate r* and DG* if nucleation is homogeneous. DHf = -1.16 x 109 J/m3, = 0.132 J/m2. Use supercooling value from table 11.1 (230 C) 2Tm 1 r DH T T f m 20.132 J / m 2 1064 273K 1 * r 9 3 1 . 16 10 J / m 230 K * r * 1.32 10 9 m 1.32nm 16 3Tm2 1 DG 3DH 2 T T 2 f m 2 2 3 16 0 . 132 J / m 1064 273K 1 * DG 230 K 2 9 3 2 3 1.16 10 J / m * DG * 9.64 10 19 J *Where did the 1064 C come from? That is the melting temperature of gold! Phase Transformations • Example Problem 11.1 – (b) Now determine the number of Au atoms in a nucleus of critical size. Assume a lattice parameter of 0.413 nm. # unit cells critical nucleus volume particle unit cell volume 4 r* # unit cells 3 particle a3 3 4 1.32nm 3 3 137 3 0.413nm How many atoms: 4 x 137 = 548 atoms/critical nucleus Phase Transformations • Nucleation – Heterogeneous nucleation • • Following up on the last point, in fact large degrees of supercooling are usually not observed Why? Turns out you can have heterogeneous nucleation as well – • Exactly what it sounds like – the solid nucleates from an interface » Preexisting surface, impurity atom, etc. Can use similar approach as before to describe energetics of heterogeneous nucleation Phase Transformations • Nucleation – Heterogeneous nucleation • Consider a flat surface or interface and a solid particle that nucleates off it • Now there are three interfacial energy terms • Interface-liquid (IL), solid-liquid (SL), solid-interface (SI) (*SL was the one from before) • If you write a force balance for the surface tension in the plane of the surface you get IL SI SL cos *Note: there is still a free energy difference between the solid and liquid (next slide) Phase Transformations • Nucleation – Heterogeneous nucleation • Using same approach before to find the maximum Gibbs free energy (and corresponding r) gives 2 SL r DGv * 3 16 SL S DG 3 3DGv Few points about the equations: 1. S() is only a function of the wetting angle and varies between 0 and 1. 2. r* is the same as before 3. The expression for DG* is similar to before (except for the S() function) 4. Note that the expression for the free energy for heterogeneous nucleation is always lower than that for homogeneous nucleation DGhet DGhom S Phase Transformations • Nucleation – Heterogeneous nucleation • What does this mean physically? Heterogeneous nucleation is faster than homogeneous nucleation! • The N vs T curve is shifted to higher temperatures for heterogeneous nucleation Phase Transformations • Growth – Growth begins once an embryo (or cluster) has exceeded the critical size r* and becomes a stable nucleus – Nucleation still occurs during the growth phase – Growth ceases in a region where particles of the new phase meet – Physical mechanism of growth – long-range diffusion processes • Diffusion in the liquid phase to the growing phase – Since the growth rate is governed by diffusion it can be written in the form Q G C exp k BT Phase Transformations • Growth – Few comments based on figure below • Want large grains – solidify the material close to Tm • Want small grains – solidify far below Tm • Cool quickly enough – can form non-equilibrium phases Phase Transformations • Kinetics of solid-state transformations – So now you have some idea about the mechanism of solidification • How do you describe the kinetics of this? • Issue 1 – need way to monitor phase transformation • S-shaped or sigmoidal curves are often observed in plots of the fraction of transformation ( y) v log(time) • The mathematical expression is often referred to as the Avrami equation y 1 exp( kt n ) k, n are material specific Another convention is that the rate of transformation is taken as the time needed for the transformation to proceed halfway (t0.5) rate 1 t 0 .5 Phase Transformations • Kinetics of solid-state transformations – One other point – the kinetics of the transformation depend strongly on T – Now some pictures … FRACTION OF TRANSFORMATION • Fraction transformed depends on time. Adapted from Fig. 10.1, Callister 6e. • Transformation rate depends on T. Adapted from Fig. 10.2, Callister 6e. (Fig. 10.2 adapted from B.F. Decker and D. Harker, "Recrystallization in Rolled Copper", Trans AIME, 188, 1950, p. 888.) • r often small: equil not possible! 2 Phase Transformations • Metastable versus equilibrium structures – Many ways to induce phase transformations, but temperature is the easiest – You have seen that on the phase diagrams – Additionally, the phase diagrams are based on equilibrium states, but contain no information about the rate equilibrium is achieved – So what? It turns out that in practice the cooling/heating rates to achieve equilibrium states are prohibitively slow – Transformations are shifted to lower temperatures than the phase diagrams indicate • Ex. Iron-carbon eutectoid is shifted by 10 – 20 C below the equilibrium T for normal cooling rates used Phase Transformations • Metastable versus equilibrium structures – But there is more – Often the heating and cooling rates are such that one achieves metastable states (i.e. non equilibrium states) that exist between the initial and equilibrium states • This may actually be very desirable – This is why kinetics matter! • Isothermal Transformation Diagrams – Use these to understand rates of phase transformations – Consider the iron-iron carbide eutectoid reaction cooling, heating 0.767 wt %C 0.022wt %C Fe3C 6.70wt %C • This is a very important reaction in terms of microstructure development in steel – this reaction leads to pearlite formation • The isothermal transformation diagram will tell you how fast the pearlite phase forms at a given T This is the isothermal transformation diagram • Isothermal Transformation Diagrams – How do you read these? There are two solid lines One indicates the time at which the transformation begins The indicates when the transformation ends Dashed line – 50% completed These are also called time-temperaturetransformation (T-T-T) plots Also note that the initial composition is fixed in this plot! ISOTHERMAL TRANSFORMATION DIAGRAMS • Fe-C system, Co = 0.77wt%C • Transformation at T = 675C. Adapted from Fig. 10.4,Callister 6e. (Fig. 10.4 adapted from H. Boyer (Ed.) Atlas of Isothermal Transformation and Cooling Transformation Diagrams, American Society for Metals, 1977, p. 369.) 6 • Isothermal Transformation Diagrams – Figure below shows the same plot now with the isothermal heat treatment curve included (at the eutectoid composition) PEARLITE MORPHOLOGY Two cases: • Ttransf just below TE --Larger T: diffusion is faster --Pearlite is coarser. • Ttransf well below TE --Smaller T: diffusion is slower --Pearlite is finer. Adapted from Fig. 10.6 (a) and (b),Callister 6e. (Fig. 10.6 from R.M. Ralls et al., An Introduction to Materials Science and Engineering, p. 361, John Wiley and Sons, Inc., New York, 1976.) - Smaller DT: colonies are larger - Larger DT: colonies are smaller 8 EX: COOLING HISTORY Fe-C SYSTEM • Eutectoid composition, Co = 0.77wt%C • Begin at T > 727C • Rapidly cool to 625C and hold isothermally. Adapted from Fig. 10.5,Callister 6e. (Fig. 10.5 adapted from H. Boyer (Ed.) Atlas of Isothermal Transformation and Cooling Transformation Diagrams, American Society for Metals, 1997, p. 28.) 7 Phase Transformations • Isothermal Transformation Diagrams – Comments about pearlite structure – The thickness ratio of ferrite and cementite layers in pearlite is approximately 8:1 – However, the absolute thickness of the layers depends on the cooling profile (what T the isothermal transformation is allowed to occur) – Higher T (closer to eutectoid) – thick layers – coarse pearlite – Lower T (farther from eutectoid) – thin layers – fine pearlite Phase Transformations • Isothermal Transformation Diagrams – Bainite • Another microstructure that can form from austenitic transformations (in addition to Pearlite) – Note! Not a different phase, a different microstructure – Bainite is a mixture of ferrite and cementite phases • It forms as needles or plates – domain sizes are much smaller as compared to pearlite – No proeutectoid forms with bainite Structure obtained with electron microscopy Bainite: Needles of ferrite in a matrix of cementite • Isothermal Transformation Diagrams – Looking at the isothermal transformation plot a few points • Bainite forms at lower temperatures • Pearlite forms at higher temperatures – These phases form competitively! • Either form one microstructure or the other ( Note: there is no mixture of B+P) on the figure! Rate of transformation is a maximum at N • Isothermal Transformation Diagrams – Spheroidite • Another wrinkle – if I take the materials above containing either pearlite or bainite domains and heat it near the eutectoid temperature (e.g. 973 K) for a sufficiently long period of time, (18-24 h) another microstructure forms … spheroidite • Instead of lamellae (pearlite) or stripes of cementite and ferrite (bainite), here the cementite domains are spherical encapsulated in a ferrite matrix Phase Transformations • Isothermal Transformation Diagrams – Spheroidite • How does this happen? It is due to carbon diffusion with no change in the composition/relative amounts of ferrite and cementite • The driving force for this is the reduction of the ferrite-cementite phase boundary area • Final point: – Pearlite, bainite, spheroidite • These are all ferrite/cementite 2-phase solids • The difference? The microstructure – size/shape of the ferrite/cementite domains! Phase Transformations • Isothermal Transformation Diagrams – Martensite • Get this when you rapidly cool austenized iron-carbon alloys to low temperatures (e.g. ambient T) • This is a nonequilibrium single-phase solid – Diffusionless transformation of austenite ( on phase diagram) • Transformation product that competes with bainite, pearlite formation • Observe martensite when quenching is fast enough to prevent carbon diffusion Rapid quench Austenite (FCC) Body centered tetragonal (BCT) Martensite (BCT) Phase Transformations • Isothermal Transformation Diagrams – Martensite • The BCT structure you get is the the original structure elongated • Carbon is still in the interstitial positions – another view is that martensite is supersaturated in carbon • Since this transformation does not involve diffusion it occurs almost instantly • Martensite and other microconstituents can coexist Martensite forms as platelets/needles Phase Transformations • Isothermal Transformation Diagrams – Martensite • Why don’t you see martensite on the phase diagrams? • You do see it on the isothermal transformation diagrams • See martensite lines – Note they are horizontal – why do you think that is? – Transformations like this are called athermal – why? They are only a function of the quenching temperature (the transformation is time independent) • Isothermal Transformation Diagrams – Summary • Ok, time to wake up! – Here is the picture summarizing all this! Phase Transformations • Example problem 11.2 – using the figure below, specify the final microstructures obtained from a sample, that is initially at 760 C possessing a homogeneous austenite structure, which is then a) b) c) Rapidly cooled to 350 C, held at 350 C for 104 s, and then quenched to RT Rapidly cooled to 250 C, held at 250 C for 102 s, and then quenched to room temperature Rapidly cooled to 650 C, held at 650 C for 20 s, rapidly cooled to 400 C, held at 400 C for 103 s, and then quenched to RT Phase Transformations • Example problem 11.2 – using the figure below, specify the final microstructures obtained from a sample, that is initially at 760 C possessing a homogeneous austenite structure, which is then a) Rapidly cooled to 350 C, held at 350 C for 104 s, and then quenched to RT What is the microstructure? PURE BAINITE Phase Transformations • Example problem 11.2 – using the figure below, specify the final microstructures obtained from a sample, that is initially at 760 C possessing a homogeneous austenite structure, which is then b) Rapidly cooled to 250 C, held at 250 C for 102 s, and then quenched to room temperature What is the microstructure? PURE MARTENSITE Phase Transformations • Example problem 11.2 – using the figure below, specify the final microstructures obtained from a sample, that is initially at 760 C possessing a homogeneous austenite structure, which is then c) Rapidly cooled to 650 C, hold at 650 C for 20 s, cool rapidly to 400 C, hold for 103 s, and then quenched to room temperature What is the microstructure? 50/50 Pearlite/Bainite NON-EQUIL TRANSFORMATION PRODUCTS: Fe-C • Bainite: -- lathes (strips) with long rods of Fe3C --diffusion controlled. • Isothermal Transf. Diagram Fe3C (cementite) (ferrite) 5 m (Adapted from Fig. 10.8, Callister, 6e. (Fig. 10.8 from Metals Handbook, 8th ed., Vol. 8, Metallography, Structures, and Phase Diagrams, American Society for Metals, Materials Park, OH, 1973.) Adapted from Fig. 10.9,Callister 6e. (Fig. 10.9 adapted from H. Boyer (Ed.) Atlas of Isothermal Transformation and Cooling Transformation Diagrams, American Society for Metals, 1997, p. 28.) 9 OTHER PRODUCTS: Fe-C SYSTEM • Spheroidite: (1) -- crystals with spherical Fe3C (ferrite) --diffusion dependent. --heat bainite or pearlite for long times --reduces interfacial area (driving force) Fe3C • Isothermal Transf. Diagram (cementite) 60 m (Adapted from Fig. 10.10, Callister, 6e. (Fig. 10.10 copyright United States Steel Corporation, 1971.) Adapted from Fig. 10.9,Callister 6e. (Fig. 10.9 adapted from H. Boyer (Ed.) Atlas of Isothermal Transformation and Cooling Transformation Diagrams, American Society for Metals, 1997, p. 28.) 10 OTHER PRODUCTS: Fe-C SYSTEM (2) • Martensite: --(FCC) to Martensite (BCT) Fe atom sites x x x potential C atom sites x x x (Adapted from Fig. 10.11, Callister, 6e. 60 m (involves single atom jumps) • Isothermal Transf. Diagram Martentite needles Austenite (Adapted from Fig. 10.12, Callister, 6e. (Fig. 10.12 courtesy United States Steel Corporation.) Adapted from Fig. 10.13, Callister 6e. • to M transformation.. -- is rapid! -- % transf. depends on T only. 11 COOLING EX: Fe-C SYSTEM (1) Adapted from Fig. 10.15, Callister 6e. 12 COOLING EX: Fe-C SYSTEM (2) Adapted from Fig. 10.15, Callister 6e. 13 COOLING EX: Fe-C SYSTEM (3) Adapted from Fig. 10.15, Callister 6e. 14 Phase Transformations • Continuous Cooling Transformation Diagrams – Turns out that isothermal heat treatments are not the most practical (why?) – Continuous cooling is more practical – this means we need to look at things differently • Isothermal transformation diagrams assume T is fixed • Continuous cooling transformation (CCT) diagrams – T is changing, the cooling rate is fixed – Turns out the time required for reaction is longer (why?) • Continuous Cooling Transformation Diagrams – Comparison between T-T-T and CCT diagrams • Big difference – plots for CCT diagrams you are constantly cooling the sample down instead of holding it at a fixed T! Does this make sense? For the slow cooling curves what do I have at the end? Where is the bainite? Should there be any? Should there be any martensite? Note: transformation ceases at the point of intersection Phase Transformations • Continuous Cooling Transformation Diagrams – Comparison between T-T-T and CCT diagrams Time for the class to talk 1. Tell me with the T-T-T curves mean 2. What does the CCT curves mean? Phase Transformations • Continuous Cooling Transformation Diagrams – Martensitic transformations • To see martensite need to cool quickly • Trajectory is tangent or to the right of the “nose” • If trajectory does not cross line indicating 100% pearlite formation, get pearlite + martensite, not pearlite + bainite – why? Critical cooling rate: minimum quenching rate that produces only martensitic structure Phase Transformations • Continuous Cooling Transformation Diagrams – Full story .. “real steel” vs binary mixtures … MECHANICAL PROP: Fe-C SYSTEM (1) Adapted from Fig. 9.27,Callister 6e. (Fig. 9.27 courtesy Republic Steel Corporation.) Adapted from Fig. 9.30,Callister 6e. (Fig. 9.30 copyright 1971 by United States Steel Corporation.) Adapted from Fig. 10.20, Callister 6e. (Fig. 10.20 based on data from Metals Handbook: Heat Treating, Vol. 4, 9th ed., V. Masseria (Managing Ed.), American Society for Metals, 1981, p. 9.) 15 MECHANICAL PROP: Fe-C SYSTEM (2) Adapted from Fig. 10.21, Callister 6e. (Fig. 10.21 based on data from Metals Handbook: Heat Treating, Vol. 4, 9th ed., V. Masseria (Managing Ed.), American Society for Metals, 1981, pp. 9 and 17.) 16 MECHANICAL PROP: Fe-C SYSTEM (3) • Fine Pearlite vs Martensite: Adapted from Fig. 10.23, Callister 6e. (Fig. 10.23 adapted from Edgar C. Bain, Functions of the Alloying Elements in Steel, American Society for Metals, 1939, p. 36; and R.A. Grange, C.R. Hribal, and L.F. Porter, Metall. Trans. A, Vol. 8A, p. 1776.) • Hardness: fine pearlite << martensite. 17 TEMPERING MARTENSITE • reduces brittleness of martensite, • reduces internal stress caused by quenching. Adapted from Fig. 10.25, Callister 6e. (Fig. 10.25 adapted from Fig. furnished courtesy of Republic Steel Corporation.) Adapted from Fig. 10.24, Callister 6e. (Fig. 10.24 copyright by United States Steel Corporation, 1971.) 18 SUMMARY: PROCESSING OPTIONS Adapted from Fig. 10.27, Callister 6e. 19 Phase Transformations • Precipitation hardening – Turns out you can modify the strength/hardness of some metal alloys by forming a 2nd phase which is small and uniformly dispersed in the original phase – This is done by temperature treatments – called precipitation hardening because the small particles are termed “precipitates” – Can try to understand this using phase diagrams! (We will stick to binary mixtures for simplicity…) Phase Transformations • Precipitation hardening – consider a theoretical AB binary mixture • Two requisite features have to be observed in the phase diagram to “have” precipitate hardening 1. An appreciable maximum solubility of one component in the other (here point M) 2. A solubility limit that rapidly decreases as T decreases Have both here… Phase Transformations • Precipitation hardening – consider a theoretical AB binary mixture • • Have those two points here … this is necessary but not sufficient! Two-step process to achieve precipitation hardening 1. Solution heat treatment – heat up alloy to form single solid phase (Co, heat to To). Follow by rapid cooling (to T1) to form a solid solution phase “supersaturated” in B Phase Transformations • Precipitation hardening – consider a theoretical AB binary mixture • Two-step process to achieve precipitation hardening 1. Solution heat treatment 2. Precipitation hardening treatment – heat back up to intermediate temperature (T2) in the two phase region so that diffusion becomes appreciable. Form b precipitate phase – final microstructure of b phase (i.e. domain size) depends on T chosen as well as the hold time. Phase Transformations • Precipitation hardening – consider a theoretical AB binary mixture • How do mechanical properties depend on precipitation hardening/aging? Phase Transformations • Precipitation hardening – microscopic view – Okay, so what preceded was a “macroscopic” view of the process that we rationalized via the phase diagrams – What happens at the microscopic level? – Use Al-Cu as an example (96-4 Al-Cu by weight) Idea: this is 2-phase < ~500 C 1. Heat up to get into phase 2. Quench 3. Then heat to induce formation of the phase as a precipitate Phase Transformations • Precipitation hardening – microscopic view – Use Al-Cu as an example (96-4 Al-Cu by weight) Idea: this is 2-phase < ~500 C 1. Heat up to get into phase 2. Quench 3. Then heat to induce formation of the phase as a precipitate After quench you have supersaturated in Cu (a) Heat up, start to form something looks like phase (’,”). These have considerable lattice strain (b) Eventually form phase (c) Phase Transformations • Precipitation hardening – Few final comments: • Not all alloys are amenable to precipitation hardening – Constraints given previously • Plus: must establish considerable strain at the precipitate-matrix interface to get the desired enhancement in hardness/strength – Good practical example of “precipitate hardening” • Rivets – aluminum alloys – Driven while soft, and age harden at ambient conditions PRECIPITATION HARDENING • Particles impede dislocations. • Ex: Al-Cu system • Procedure: --Pt A: solution heat treat (get solid solution) --Pt B: quench to room temp. --Pt C: reheat to nucleate small crystals within crystals. • Other precipitation systems: • Cu-Be • Cu-Sn • Mg-Al Adapted from Fig. 11.22, Callister 6e. (Fig. 11.22 adapted from J.L. Murray, International Metals Review 30, p.5, 1985.) Adapted from Fig. 11.20, Callister 6e. 20 PRECIPITATE EFFECT ON TS, %EL • 2014 Al Alloy: • TS peaks with precipitation time. • Increasing T accelerates process. • %EL reaches minimum with precipitation time. Adapted from Fig. 11.25 (a) and (b), Callister 6e. (Fig. 11.25 adapted from Metals Handbook: Properties and Selection: Nonferrous Alloys and Pure Metals, Vol. 2, 9th ed., H. Baker (Managing Ed.), American Society for Metals, 1979. p. 41.) 21 SIMULATION: DISLOCATION MOTION PEAK AGED MATERIAL • Peak-aged --avg. particle size = 64b --closer spaced particles efficiently stop dislocations. Simulation courtesy of Volker Mohles, Institut für Materialphysik der Universitåt, Münster, Germany (http://www. uni-munster.de/physik /MP/mohles/). Used with permission. Click on image to begin simulation 22 SIMULATION: DISLOCATION MOTION OVERAGED MATERIAL • Over-aged --avg. particle size = 361b --more widely spaced particles not as effective. Simulation courtesy of Volker Mohles, Institut für Materialphysik der Universitåt, Münster, Germany (http://www. uni-munster.de/physik /MP/mohles/). Used with permission. Click on image to begin simulation 23 STRENGTHENING STRATEGY 3: PRECIPITATION STRENGTHENING • Hard precipitates are difficult to shear. Ex: Ceramics in metals (SiC in Iron or Aluminum). 1 • Result: y ~ S 24 SIMULATION: PRECIPITATION STRENGTHENING • View onto slip plane of Nimonic PE16 • Precipitate volume fraction: 10% • Average precipitate size: 64 b (b = 1 atomic slip distance) Simulation courtesy of Volker Mohles, Institut für Materialphysik der Universitåt, Münster, Germany (http://www.unimunster.de/physik /MP/mohles/). Used with permission. 25 APPLICATION: PRECIPITATION STRENGTHENING • Internal wing structure on Boeing 767 Adapted from Fig. 11.0, Callister 5e. (Fig. 11.0 is courtesy of G.H. Narayanan and A.G. Miller, Boeing Commercial Airplane Company.) • Aluminum is strengthened with precipitates formed by alloying. Adapted from Fig. 11.24, Callister 6e. (Fig. 11.24 is courtesy of G.H. Narayanan and A.G. Miller, Boeing Commercial Airplane Company.) 1.5m 26 Phase Transformations • Time to finish this little voyage with a discussion of a few things you already know about, and to talk about polymers – Crystallization, melting, and glass transitions in polymers – Ok, you know about two of the three • Crystallization – process by which, upon cooling, an ordered crystalline phase forms from a liquid melt of polymer with a highly random structure • Melting – you know • Glass transition – cool polymer from liquid melt that becomes a noncrystalline solid … becomes rigid but has structural ordering reminiscent of the liquid state Phase Transformations • Polymer Crystallization – can describe this using approach described earlier in the chapter (Avrami eqn, etc.) – Molecular picture – chains go from a highly disordered state in the melt to a highly ordered state in the solid upon cooling • But remember, polymers are usually semicrystalline – Have regions of crystalline and amorphous polymer Polypropylene crystallization kinetics This plot is normalized Cannot completely crystallize PP Phase Transformations • Polymer Melting – go from a solid liquid melt as the polymer is heated above some temperature Tm • Few differences between polymers and metals/ceramics – Have a range of melting temperatures – the polymer does not completely melt at one temperature like a molecular compound • Why? – Melting behavior depends on the polymer “history” how it has been processed • Why would that be the case? Phase Transformations • The glass transition – cool from a melt, but get a disordered solid instead of a crystalline solid – Occurs due to reduction of motion of the segments of the polymer chains with decreasing temperature – Upon cooling: liquid rubbery material rigid solid – Glass transition temperature (Tg) is when the transformation from a rubbery material to a rigid solid is observed • Why do we care about the glass transition? Observe abrupt changes in material properties at Tg Phase Transformations • Tm and Tg are important for polymers – they define the temperature ranges a polymer can be used for applications! • Determine Tm and Tg for polymers by observing the specific volume as a function of temperature • Note differences in the plot for a crystalline solid, glass, and semicrystalline solid! Phase Transformations • Factors (some) that influence polymer melting temperatures 1. 2. 3. Chain stiffness – ease of rotation of bonds along backbone Molecular weight – generally increase MW Tm increases; but there is a range of Tm values Degree of chain branching – what would you expect the correlation to be here? Phase Transformations • Factors (some) that influence polymer glass transition temperatures 1. Chain stiffness 1. 2. 3. 2. 3. Bulky side groups Polar side groups Double-chain bonds and aromatic rings Molecular weight Crosslinking In general terms the same things that increase the melting temperature also increase the glass transition temperature Typically Tg ~ 0.5 – 0.8 Tm (K) ANNOUNCEMENTS Reading: Chapter 11 HW # 7:Due Monday, March 19th : 11.2; 11.4; 11.9; 11.12 HW # 8: Due Monday, March 26th : 11.15; 11.20; 11.24; 11.28; 11.32; 11.41; 11.44; 11.D2; 11.D5; 11.D8 0