LEC 23 CH-07 - KFUPM Open Courseware

advertisement

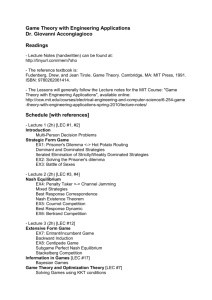

ME 307 Machine Design I Dr. A. Aziz Bazoune King Fahd University of Petroleum & Minerals Mechanical Engineering Department Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 1 ME 307 Machine Design I Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 2 ME 307 Machine Design I 7-10 Stress Concentration Factor and Notch Sensitivity In fatigue: Stress concentration should always be taken into account. Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 3 ME 307 Machine Design I Some materials are not fully sensitive to notches and a reduced value of Kt is used and the maximum stress is calculated as follows: (7-29) Kf is the fatigue stress concentration factor, for simple loading: (Ex 7.7) or Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 4 ME 307 Machine Design I Notch sensitivity q index is defined by (7-30) 0 q 1 To find q use Fig. 7-20 for steel and Al alloys , for reversed bending or reversed axial load. For reversed torsion use Fig. 7-21. For cast iron use q 0.20 to be conservative. For q 0 , then K f 1 and the material has no sensitivity at notch at all. For q 1 , then K f Kt and the material has full notch sensitivity. Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 5 ME 307 Machine Design I Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 6 ME 307 Machine Design I In analysis or design work Find first from the geometry of the part Specify the material Find Solve for from the following Equation (7-31) Figure 7-20 has its basis the Neuber equation, which is given by (7-32) Where Dr. A. Bazoune is defined as the Neuber constant and is a material constant. Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 7 ME 307 Machine Design I Equating Eqs. (7-31) and (7-32) gives the notch sensitivity equation (7-33) For steel, with in kpsi, the Neuber equation can be approximated by a third polynomial fit of data as (7-34) Where Dr. A. Bazoune is defined as the Neuber constant and is a material constant. Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 8 ME 307 Machine Design I A distinction in the configuration of the notch is accounted for in the modified Neuber equation (after Heywood), where the fatigue stressconcentration factor is given as (7-35) where Table 7-8 gives values of for steels for transverse holes, shoulders and grooves. Dr. A. Bazoune Table 7-8 Heywood’s Parameter for steels Feature (a)1/2 (in)1/2 Sut in kpsi (a)1/2 (mm)1/2 Sut in MPa Transverse hole 5/Sut 174/Sut Shoulder 4/Sut 139/Sut Groove 3/Sut 104/Sut Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 9 ME 307 Machine Design I (Textbook) ka 4.51 520 Dr. A. Bazoune 0.260 0.859 Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 10 ME 307 Machine Design I Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 11 ME 307 Machine Design I (Textbook) SOLUTION Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 12 ME 307 Machine Design I (Textbook) SOLUTION Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 13 ME 307 Machine Design I Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 14 ME 307 Machine Design I (Textbook) SOLUTION See next page Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 15 ME 307 Machine Design I Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 16 ME 307 Machine Design I Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 17 ME 307 Machine Design I a 0.062 in=0.312 mm With 2.5% lower than a) and b) Dr. A. Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC 23 Slide 18