Regulatory Issues: CLIA, JCAHO,CAP and States

advertisement

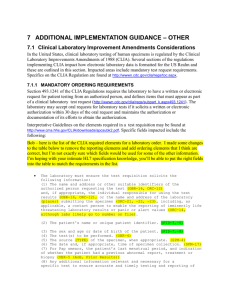

EQC: What’s the Story Today! Sharon S. Ehrmeyer, Ph.D. UNIVERSITY OF WISCONSIN MADISON, WI Ultimate Goal of Regulations Quality Results for Quality Healthcare!! Quality 2006 – Test Site’s View Meeting “the” Regulations and Passing Inspection CLIA (CMS) “the feds” JCAHO CAP etc. Quality Patient Test Results? In U.S., estimated 44,000 to 98,000 deaths / year due to “medical errors”* May be as high as 198,000 deaths each year** Lab provides ~70% of information for health care ~ 7 billion lab tests performed in U.S. each year *To Err is Human, US Institute of Medicine Report – 2000 **Newsweek, 2004 Total Analytical error distribution Error Source Ross and Boone1 Plebani et al.2 Pre-analytical 46% 68% Analytical 7% 13% Post-analytical 47% 19% 1Ross and Boone, Inst. of Critical Issues in Health Lab Pract, DuPont Press, 1991 2Plebani and Carraro, Clin Chem 43:1348, 1997 CLIA - 24 January 2003 NEW http://www.phppo.cdc.gov/clia/pdf/CMS-2226-F.pdf Quality Systems Approach Now CLIA’03 is organized and has quality requirements that emphasize quality for the entire testing process Pre-analytical Analytical Post-analytical Quality Systems Approach CLIA’s pre- and post-analytical process requirements: Policies/procedures to ensure RIGHT patient test sample processing patient record Quality assessment (assurance) practices to assess effectiveness of all these policies/procedures Quality Systems Approach Government’s Philosophy: Following the CLIA regulations should yield higher quality results CLIA –Analytical Phase QC procedures must monitor the complete analytical process Take into account: – performance specifications of the method – detect immediate errors – monitor long-term precision and accuracy Unless CMS approves a procedure in Appendix C of the SOM that provides “equivalent” quality testing… CLIA’03 -- Analytical Phase CLIA’s answer to analytical quality– “equivalent” quality testing… Minimum Quality and Minimum QC? Equivalent Quality Control (EQC)??? January 2004 -- CLIA Appendix C (SOM) “Survey Procedure & Interpretive Guidelines for Laboratories and Laboratory Services” Government’s way to introduce new concepts Interprets the regs for both surveyor and lab – Provides probes to ascertain compliance – D-tags associated with reg used to cite deficiencies Explains equivalent quality testing (control) http://www.cms.hhs.gov/CLIA/03_Interpretive_Guidelines_ for_Laboratories.asp#TopOfPage EQC does not mean Electronic QC EQC = Electronic Quality Control CLIA’03 and Quality Control Acceptable, minimum quality control: At least 2 external, liquid quality control materials analyzed per test per day CLIA’03 and EQC All other quality control approaches – From electronic to sophisticated internal quality checks All must be qualified under EQC CLIA’03 and EQC To use instruments with “built-in” electronic/procedural/internal controls, labs must either: Analyze at least 2 external liquid controls per test per day OR Qualify the “built-in” controls as equivalent (to external liquid QC) EQC Qualification Process Each test site must prove that the instrument’s “built-in” controls are equivalent to the traditional mandated, minimum, external (liquid) QC procedures CLIA and EQC The “Devil is in the Details” EQC Option 1 Qualification Process To qualify an instrument with “built-in” controls that evaluate the “entire” analytical process: Test sites need to analyze 2 external QC materials daily for 10 consecutive days EQC Option 1 If test site judges “built-in” and external QC results as “acceptable,” then Test site reduces external QC analysis from daily to once every 30 days EQC Option 2 Qualification Process To qualify an instrument with “built-in” controls that evaluate “part ” of analytical process: Test sites need to analyze 2 external QC materials daily for 30 consecutive days EQC Option 2 If test site judges “built-in” and external QC results as “acceptable,” then Test site reduces external QC analysis from daily to once every 7 days EQC Option 3 Qualification Process To qualify an instrument with NO “built-in” controls : Test sites need to analyze 2 external QC materials daily for 60 consecutive days EQC Option 3 If test site judges external QC results as “acceptable,” then Test site reduces external QC analysis from daily to once every 7 days EQC Qualification Process Just so you don’t miss the point – by adopting EQC after a comparison with external QC material for a short time, a test site can decide to reduce the frequency of “REAL” controls to once a month or once a week! EQC Qualification Process The key word in the CLIA regulations is “acceptable,” Unfortunately CLIA offers NO insight into what is acceptable EQC 2006 - Worst Case Scenario During evaluation period, absence actual “builtin” [electronic] control failure(s), we learn nothing about the control capabilities! If after 30 days, the mandated external QC fails, we - Must reevaluate patient results for the previous 30 days. What about the quality of reported patient results? EQC and Quality -- circa 2006 Comments from an “authority” on ways to protect the laboratory using just electronic EQC: Call EQC Equivocal not Equivalent QC Add “in god we trust” on all lab results Add “in George W Bush we trust” on all test results Definitely do not suggest adding “in Westgard we trust” on all test results http://www.westgard.com A Discontinuity in Logic of CLIA and EQC The laboratory director is responsible for the overall operation and administration of the laboratory … [the] testing systems … used [must] provide quality laboratory services for all aspects of test performance … including the preanalytic, analytic, and post-analytic phases of testing-----BUT A Discontinuity in Logic of CLIA and EQC CLIA makes the Laboratory Director Responsible --Responsible for a whole host of things he/she can not control! and EQC leads the list…. As the world turns so does CLIA! Look for changes with EQC! CLSI (NCCLS) Meeting EQC March 18, 2005 Judy Yost – “We blew it” Judy Yost – “until resolved, citations on new QC will continue to be educational” Excerpt from J. Yost Presentation CMS Survey Policy for CMS Surveyed labs receive educational surveys for requirements “ new to that lab” Labs with problems meeting new QC standards receive a letter urging them to correct in lieu of a deficiency statement Existing requirements [prior to January 24, 2003] must be met or are cited on a deficiency statement CAP, JCAHO, inspected sites continue to meet the AOs standards Excerpt from CMS Website … since the publication of the 2003 final regulations and accompanying guidelines, CMS has identified innovations in technology and has received input from technical experts that may lead to further modifications of QC policies in our interpretative guidelines. CMS is also undertaking a number of processes to acquire additional information, data and scientific input relative to such QC and technological advances in order that our policies will reflect these innovations. Excerpt from CMS Website, cont. Therefore, so long as laboratory directors, at a minimum, review manufacturers’ QC instructions, find those instructions to reasonably monitor the accuracy of the analytic process and the laboratory then follows those manufacturers’ instructions [follow the manufacturer’s labeling], we plan to continue the educational process noted above until any merited changes are incorporated into our guidelines, for the QC requirements contained in the 2003 modifications of the CLIA regulations. Latest QC Information from the Government (CLIA [CMS]) CLIA 2003 QC recommendations “new to the lab” are considered educational and will not be cited CMS is seeking additional information, data and scientific input from CLSI through guidelines Lab directors are in charge Follow manufacturers’ QC recommendations Include at least 2 levels of QC each day of testing CLIA – “Equivalent” QC (EQC) “The director must consider the laboratory’s clinical and legal responsibility for providing accurate and reliable patient test results versus the cost implications of reducing the QC testing frequency.” EQC is a choice! As the world turns so does CLIA! Bottom line with EQC for now! Follow Manufacturers’ Instructions EQC and JCAHO, CAP & COLA Do not recognize EQC No changes in QC regulations Follow manufacturers’ QC recommendations Include at least 2 levels of QC each day of testing CLIA Information http://www.cms.hhs.gov/clia/ Note: web address for links have changed on CMS’ new website Bottom Line – continually aim for: Right test Right result Right patient Right time Right record Thanks for you attention! Now it is your turn Questions and Answers