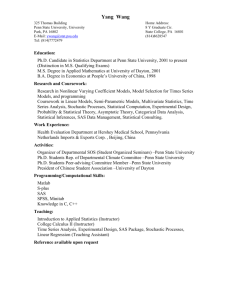

Final Presentation ppt - Penn State University

advertisement

Introduction South Halls Renovation and New Construction The Pennsylvania State University University Park, PA Penn State Architectural Engineering Senior Capstone Project Quaid Spearing | Construction Option Advisor: Dr. Anumba April 15, 2014 Project Overview Project Overview Analysis 1: Modular Bathrooms Background Information Planning & Procurement Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Team Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements • • • • • • • Size: 71,002 GSF Stories: Four plus Basement Function: Residential & Assembly Construction Dates: 05/13 – 12/13 Total Project Cost: $94.1M GMP Phase Project Cost: $15.2M Delivery Method: Design-Build Source: Bing Maps Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Analysis 1: Modular Bathrooms Analysis 3: Prefabrication of Limestone Façade • Improve quality of bathrooms through modularization, while also reducing the construction schedule. • Fabricate stone panel wall system offsite to increase productivity and accelerate project schedule Architectural Breadth Structural Breadth • Decrease the number of bathroom layouts to improve design efficiency and increase offsite productivity • Analyze loads of traditional limestone façade on existing columns Analysis 2: SIPS • Implement a new construction sequencing through the use of SIPS, with a goal to deliver the student rooms 1 week sooner. Analysis 4: Phase Resequencing • Develop an alternate master phasing plan to accelerate the completion of the project and allow generation of revenue sooner. Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Analysis 1 Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Modular Bathrooms Project Overview Background Information Analysis 1: Modular Bathrooms Analysis 1: Modular Bathrooms Problem Background Information Planning & Procurement • Quality of finish work and in Bathrooms Design Evaluation – Arch. Breadth Results ▫ Bathroom finishes accelerated to maintain schedule ▫ Rework of Tile Analysis 2: SIPS Background Information Approach Potential Solution Results Analysis 4: Phase Resequencing • Modularize the bathroom units to be constructed offsite Background Information Process ▫ Improve finish quality ▫ Accelerate bathroom schedule Results Final Recommendation Acknowledgements Images taken by Quaid Spearing Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 1: Modular Bathrooms Planning & Procurement Analysis 1: Modular Bathrooms Bathroom Pod Manufacturer Background Information Planning & Procurement • Ameripod LLC Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Bathroom Pod Summary Background Information Approach Results Manufacturer Ameripod Cost Per Bathroom $ 13,460.00 Potential Solution Design Fees/Design Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Source: Google Maps $ 7,500.00 Manufacturing: Days/Pod 15 Manufacturing: Pods/Week 30 Installation Pods/Day 12 Distance from Jobsite (miles) 231 Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 1: Modular Bathrooms Planning & Procurement Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Bathroom Pod Manufacturer Background Information Planning & Procurement Transportation • Ameripod LLC Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Bathroom Pod Summary Background Information Approach Results Manufacturer Ameripod Cost Per Bathroom $ 13,460.00 Potential Solution Design Fees/Design Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Source: Google Maps $ 7,500.00 Manufacturing: Days/Pod 15 Manufacturing: Pods/Week 30 Installation Pods/Day 12 Distance from Jobsite (miles) 231 Potential Solution Project Overview Analysis 1: Modular Bathrooms Design Evaluation – Arch. Breadth Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Original Bathroom Layout Background Information Planning & Procurement • 10 different unit types Design Evaluation – Arch. Breadth Results Analysis 2: SIPS I Background Information • Goal: reduce number of layouts for modularization Approach Results ▫ Followed existing layout J Analysis 4: Phase Resequencing ▫ Increase fabrication productivity Background Information Process Results Final Recommendation Acknowledgements Original Roll-In Shower Layout Potential Solution Original Ewing Layout Original Cross Layout Project Overview Analysis 1: Modular Bathrooms Design Evaluation – Arch. Breadth Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Proposed New Bathroom Layout Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS I Background Information Approach Results J Potential Solution Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Original Roll-In Shower Layout Original Ewing Layout Proposed Roll-In Shower Layout Proposed Typical Layout Original Cross Layout Project Overview Analysis 1: Modular Bathrooms Design Evaluation – Arch. Breadth Analysis 1: Modular Bathrooms Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information 60 A.3 1 4 B 8 32 C 7 28 Final Recommendation D 8 32 Acknowledgements E 1 4 Total 40 160 Analysis 4: Phase Resequencing Background Information Process Results ▫ Increase benefits of modularization by optimizing layout Module Qty/Bldg Qty/Project 15 Results • Reduced number of layouts from 10 down to 6 Bathroom Module Designs A.1/A.2 Approach Original Bathroom Layout Proposed New Bathroom Layout Background Information Quaid Spearing| Construction Option South Halls Renovation | Penn State University Potential Solution Proposed Roll-In Shower Layout Proposed Typical Layout Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Results Analysis 1: Modular Bathrooms Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Hoisting and Sequencing Ewing Cross Stick Built • All floors working simultaneous Modular Potential Solution • Construction sequenced 1st to 4th • 4 deliveries per stack ▫ Just in time deliveries Hoisting Sequencing Truck A B C D Day 1 Day 2 # PODS 8AM 9AM 10AM 11AM 12PM 1PM 2PM 3PM 4PM 8AM 9AM 10AM 11AM 12PM 1PM 2PM 3PM 4PM 5 5 5 5 Analysis 1: Modular Bathrooms Project Overview Analysis 1: Modular Bathrooms Background Information Planning & Procurement Constructability Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information • Intense Coordination • Duct Risers Approach • Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Sequencing • Complete Punchlist Sooner • Increased Quality • Safer Work Environment Results Quaid Spearing| Construction Option South Halls Renovation | Penn State University Results Analysis 1: Modular Bathrooms Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement Constructability Cost Analysis Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information • Intense Coordination • Duct Risers Approach • Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Sequencing • Complete Punchlist Sooner • Increased Quality • Safer Work Environment Potential Solution $2.32M $122,000 in Savings Results Analysis 1: Modular Bathrooms Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement Constructability Cost Analysis Schedule Analysis Schedule Comparison of Construction Methods Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information • Intense Coordination • Duct Risers Approach • Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements • Sequencing Complete Punchlist Sooner • Increased Quality • Safer Work Environment Construction 7/29 Method 8/5 Potential Solution $2.32M Modular Pod Ewing $122,000 in Savings 9/2 9/9 9/16 9/23 9/30 10/7 10/14 10/21 10/28 11/4 Construction of Cross Bathrooms Construction of Ewing Bathrooms Stick-Built Modular Pod Cross 8/12 8/19 8/26 Risers Pods Follow-on Work Risers Pods Follow-on Work SAVINGS • Schedule Savings = 21 working days ▫ Overall schedule cannot be reduced; bathrooms are on separate critical path Implement Modular Bathrooms Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Analysis 2 Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements SIPS for Student Rooms Project Overview Background Information Analysis 2: SIPS Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Problem • Punchlist and turnover to owner were critical for student rooms, with no room for error ▫ Several activities took longer than scheduled duration Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Goal • Implement SIPS for the student rooms in an effort to promote earlier turnover to owner; allow FF&E to begin sooner Quaid Spearing| Construction Option South Halls Renovation | Penn State University Approach Analysis 2: SIPS Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Zone 1 2 3 4 5 6 7 8 9 Area Per Zone Floor Square Footage 4th 5600 3rd 5600 2nd 5600 1st 5600 4th 5600 3rd 5600 2nd 4650 1st 4260 1st 5650 Building Zones 4th FLOOR 3RD FLOOR Approach Analysis 2: SIPS Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Zone 1 2 3 4 5 6 7 8 9 Area Per Zone Floor Square Footage 4th 5600 3rd 5600 2nd 5600 1st 5600 4th 5600 3rd 5600 2nd 4650 1st 4260 1st 5650 Building Zones 2ND FLOOR 3RD FLOOR Approach Analysis 2: SIPS Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Zone 1 2 3 4 5 6 7 8 9 Area Per Zone Floor Square Footage 4th 5600 3rd 5600 2nd 5600 1st 5600 4th 5600 3rd 5600 2nd 4650 1st 4260 1st 5650 Building Zones 2ND FLOOR 1ST FLOOR Approach Analysis 2: SIPS Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results SIPS Methodology Crew Size Adjustments • Analysis 2: SIPS Background Information Approach Results • Adjust crew sizes to achieve 5 day durations Parallel production of dorm wings Student Room SIPS Area 6/3 Zone 1 1 Zone 2 Zone 3 Zone 4 June 6/10 6/17 6/24 7/1 2 3 4 5 1 2 3 4 1 2 3 1 2 7/8 6 5 4 3 July August 7/15 7/22 7/29 8/5 8/12 8/19 8/26 9/2 7 8 9 10 11 12 13 14 6 7 8 9 10 11 12 13 5 6 7 8 9 10 11 12 4 5 6 7 8 9 10 11 2013 September October November December 9/9 9/16 9/23 9/30 10/7 10/14 10/21 10/28 11/4 11/11 11/18 11/25 12/2 12/9 12/16 12/23 12/30 15 16 17 18 19 20 21 22 23 24 14 15 16 17 18 19 20 21 22 23 24 13 14 15 16 17 18 19 20 21 22 23 24 12 13 14 15 16 17 18 19 20 21 22 23 24 Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements • 5 Day work weeks; Saturday serves as catchup day Zone 5 Zone 6 Zone 7 Zone 8 Zone 9 1 2 1 3 2 1 4 3 2 1 1 2 3 4 5 5 4 3 2 1 6 5 4 3 2 7 6 5 4 3 8 7 6 5 4 Layout and Top Track Perim. Bedroom Framing/Insulation Ductwork MEP Coring Elec. Rough In & Tele-Data 9 8 7 6 5 6 7 8 9 10 10 9 8 7 6 11 10 9 8 7 12 11 10 9 8 13 12 11 10 9 14 13 12 11 10 Perim. Bedroom Piping Door Frames & Clg/Bulkhead Framing Sprinkler Rough In Plumbing Rough In Hang GWB 15 14 13 12 11 11 12 13 14 15 16 15 14 13 12 17 16 15 14 13 18 17 16 15 14 Finish GWB Windows Prime & Paint Lights & Final Tele-Data Install Flooring 19 18 17 16 15 16 17 18 19 20 20 19 18 17 16 21 20 19 18 17 22 21 20 19 18 23 22 21 20 19 FCU & Mech Trim Out Doors & Hardware Adjust Sprinkler Heads Elec/Tele/Fire Alarm Trim Out Suite/Lobby Case & Window Treat 24 23 22 21 20 24 23 22 21 21 22 23 24 24 23 22 24 23 24 Final Paint Carpet Final Clean & Punchlist Owner FF&E Analysis 2: SIPS Project Overview Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Cost Analysis • No additional costs incurred • Manhours remained the same • No perceivable cost savings due to schedule reduction Results Quaid Spearing| Construction Option South Halls Renovation | Penn State University Results Analysis 2: SIPS Project Overview Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Cost Analysis • No additional costs incurred • Manhours remained the same • No perceivable cost savings due to schedule reduction Schedule Analysis Cross Orginal Ewing Original Cross SIPS Process Results Final Recommendation Acknowledgements Ewing SIPS Area 6/3 Zone 1 Zone 2 Zone 3 Zone 4 June 6/10 6/17 6/24 7/1 7/8 July 7/15 7/22 7/29 8/5 August 8/12 8/19 8/26 9/2 2013 September October November December 9/9 9/16 9/23 9/30 10/7 10/14 10/21 10/28 11/4 11/11 11/18 11/25 12/2 12/9 12/16 12/23 12/30 Zone 5 Zone 6 Zone 7 Zone 8 Zone 9 Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7 Zone 8 Zone 9 • 10 day schedule acceleration Quaid Spearing| Construction Option South Halls Renovation | Penn State University Results Analysis 2: SIPS Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Cost Analysis • No additional costs incurred • Manhours remained the same • No perceivable cost savings due to schedule reduction Schedule Analysis Cross Orginal Ewing Original Cross SIPS Process Results Final Recommendation Acknowledgements Ewing SIPS Area 6/3 Zone 1 Zone 2 Zone 3 Zone 4 June 6/10 6/17 6/24 7/1 7/8 July 7/15 7/22 7/29 8/5 Constructability August 8/12 8/19 8/26 9/2 2013 September October November December 9/9 9/16 9/23 9/30 10/7 10/14 10/21 10/28 11/4 11/11 11/18 11/25 12/2 12/9 12/16 12/23 12/30 Zone 5 Zone 6 Zone 7 Zone 8 Zone 9 Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7 Zone 8 Zone 9 • 10 day schedule acceleration • Increased Collaboration • Timely Deliveries • Subcontractor Buy-in • More predictable durations • Other Construction Activities • Enclosure • Bathrooms Implement SIPS Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Analysis 4 Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Master Phase Resequencing Project Overview Background Information Analysis 4: Phase Resequencing Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Problem • Current Project Schedule = 33 months • Difficult to shuffle students between dormitories Potential Solution • Renovate two buildings at once ▫ Reduce overall schedule ▫ Quicker turnover = Revenue generated sooner Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 4: Phase Resequencing Analysis 1: Modular Bathrooms Background Information Planning & Procurement PSU Capacity Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements • Typ. 1000 – 1200 fewer students ▫ PSU would have capacity for multiple renovations Process Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 4: Phase Resequencing Process Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement PSU Capacity Design Evaluation – Arch. Breadth • Phase 1 saw Chace and Haller – Lyons built together Results ▫ Logical to maintain this level of staffing for P2 Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Project Management Staff • Typ. 1000 – 1200 fewer students ▫ PSU would have capacity for multiple renovations Current Phase 2 Staffing Project Director Project Manager Project Engineer Senior Superintendent Project Technician Intern - Proposed Phase 2 Staffing Project Director Project Manager Senior Project Engineer Project Engineer Senior Superintendent Field Superintendent Field Superintendent Project Technician Intern Intern Project Overview Process Analysis 4: Phase Resequencing Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements New Master Phasing Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Process Analysis 4: Phase Resequencing Analysis 1: Modular Bathrooms New Master Phasing Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements • New Phasing = left to right flow ▫ Eliminate temp landscaping between H-L and H-S • Redifer = buffer for P2 construction • Renovate E-C and C-H together Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 4: Phase Resequencing Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Constructability • Site Logistics ▫ Offsite Fabrication • Manpower Results Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Results Analysis 4: Phase Resequencing Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Constructability Schedule Analysis • Site Logistics ▫ Offsite Fabrication • Manpower Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements • 5 month schedule reduction • South Halls fully opened for fall 2014 Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Results Analysis 4: Phase Resequencing Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Constructability Schedule Analysis Cost Analysis • Site Logistics ▫ Offsite Fabrication • Manpower Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements • 5 month schedule reduction • South Halls fully opened for fall 2014 • Would add $31K to project cost Project Overview Results Analysis 4: Phase Resequencing Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Constructability Schedule Analysis Cost Analysis • Site Logistics ▫ Offsite Fabrication • Manpower Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements • 5 month schedule reduction • South Halls fully opened for fall 2014 • Would add $31K to project cost • However, PSU could generate $1.3M in revenue Implement Phase Resequencing Project Overview Conclusion Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Analysis 1: Modular Bathrooms • Decrease bathroom schedule by 4 weeks • $122,000 cost savings • Improved finished quality Analysis 2: SIPS • Accelerates student room schedule by 10 days • Allow owner FF&E to begin sooner Analysis 4: Phase Resequencing • Accelerates Schedule by 5 months • $1.3M in potential revenue Recommendations • Implement modular bathrooms • Implement SIPS • Implement Phase Resequencing Total Savings Through all 4 Analyses • $264,000 saved in project costs • $1.3M in potential revenue for owner • 5 month schedule acceleration Project Overview Acknowledgements Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Acknowledgements Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Thank You! Barton Malow Company Clark Nexsen Penn State University Dr. Anumba: CM Advisor Penn State AE Faculty My Family & Friends Project Overview Appendix A – Analysis 1 Transportation Requirements Analysis 1: Modular Bathrooms Background Information Planning & Procurement Transportation Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Pennsylvania Truck Information Size Limitations Width 8 feet Height 13 feet 6 inches Length 53 feet trailer Maximum Gross Weight Two-Axle Motor Vehicle 38,000 lbs • Typical delivery could hold 5 pods Potential Solution Potential Solution Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Appendix A – Analysis 1 Bathroom Pod Design Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Appendix A – Analysis 1 Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results I Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements J Bathroom Pod Design Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Appendix A – Analysis 1 ADA Code Compliance Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Appendix A – Analysis 1 Stick-built Bathroom Costs Quaid Spearing| Construction Option South Halls Renovation | Penn State University Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Bathroom Pod Costs Appendix A – Analysis 1 Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Item Stick Built Bathroom Modular Bathroom Layout A.1/A.2 Layout A.3 Layout B Layout C Layout D Layout E Design Fees for Pods 25 Ton Hydraulic Crane, Truck Mounted Total Costs/Savings Cost Analysis of Modular Bathrooms Quantity Total Quantity Cost/POD /Building Cost/Bldg (Total Project) Total Cost/Project $ 15,240.00 40 $ 609,600.00 160 $ 2,438,400.00 $ $ $ $ $ $ $ 14,222.00 14,222.00 14,801.00 14,801.00 12,134.00 13,907.00 7,500.00 15 1 8 7 8 1 6 $ $ $ $ $ $ $ 213,330.00 14,222.00 118,408.00 103,607.00 97,072.00 13,907.00 45,000.00 60 4 32 28 32 4 6 $ $ $ $ $ $ $ 853,320.00 56,888.00 473,632.00 414,428.00 388,288.00 55,628.00 45,000.00 $ 1,807.00 4 $ 7,228.00 16 $ 28,912.00 $ 122,304.00 $ (3,174.00) Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Bathroom Pod Schedule Appendix A – Analysis 1 Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Anticipated Schedule Reduction for a Typical Floor Original New Total Days Activity Duration Duration Saved/Added Framing 5 0 5 Plumbing Rough-In 15 0 15 Electrical Rough-In 15 0 15 Duct Rough-In 15 3 12 Sprinkler Rough-In 15 0 15 Close-In Inspection 1 0 0 Hang & Finish Drywall 8 4 4 Install Shower Bases 3 0 3 Prime & Coat First Paint 2 2 0 Install Ceramic Tile 12 2 10 Plumbing Fixtures 2 1 1 Accessories 3 1 2 Mech/Elec Trim Out 3 2 1 Place Bathroom Pods 0 1 1 Final MEP Connection 0 3 3 Total 54 19 35 Schedule Analysis Schedule Comparison of Construction Methods 7/29 Framing 8/5 8/12 8/19 Construction 7/29 Method Original Bathroom Construction Sequence (Typical) 8/26 9/2 9/9 9/16 9/23 9/30 10/7 Plumbing Electrical Duct Sprinkler Potential Solution Modular Pod Ewing Shower Base Paint Tile Fixtures Accessories MEP Trim Out 8/12 8/19 8/26 9/2 9/9 9/16 9/23 9/30 10/7 10/14 10/21 10/28 11/4 Construction of Cross Bathrooms Construction of Ewing Bathrooms Stick-Built Modular Pod Cross *Close-In Inspection Hang/Finish GWB 8/5 Risers Pods Follow-on Work Risers Pods Follow-on Work • Schedule Savings = 21 working days ▫ Overall schedule cannot be reduced; bathrooms are on separate critical path SAVINGS Appendix B – Analysis 2 Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Crew Size Calculations Analysis 1: Modular Bathrooms New Duration and Production Rates Background Information Planning & Procurement Design Evaluation – Arch. Breadth No. Sample Calculation: Hang GWB Crew Size Adjustments Results Analysis 2: SIPS • 5600SF/ 6 Workers = 933 SF/Worker • (933 SF/Worker)/8 days = 117 SF/Day Background Information Approach Results Analysis 4: Phase Resequencing Background Information 5600 SF = (117 SF/Day)(5 Days)( X Wrkrs) • Process Results Final Recommendation Acknowledgements • X = 10 Man Crew Crew Size Adjustments • Adjust crew sizes to achieve 5 day durations • Combined several activities performed by same subcontractor(s) ▫ Schedule Adjusted to 23 activities | 1 week/activity 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 Activity Layout & Top Track Perimeter Bedroom Framing & Insulation Ductwork MEP Coring Electrical Rough In & Tele-Data Perimeter Bedroom Piping Door Frames & Clg/Bulkhead Framing Sprinkler Rough In Plumbing Rough In Hang GWB Finish GWB Windows Prime & Paint Install Lighting and Final Tele-Data Pull Install Flooring Install FCU & Mech. Trim Out Doors & Hardware Adjust Sprinkler Heads Elec/Tele/Fire Alarm Trim Out Suite/Lobby Casework & Window Treatment Apply Final Paint Floor Install/Carpet Base Final Clean New Duration Subcontractor Crew Size Production/Wrkr (SF/Day) 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 3 5 5 2 2 Penn Install Penn Install McClure McClure & FE FE McClure Penn Install SAC McClure Penn Install Penn Install NBS PAT FE NBS McClure Hood Co SAC FE Penn Install PAT NBS BMC 5 6 2 6 8 5 11 2 5 10 8 2 2 4 4 3 2 2 2 5 3 2 5 224 187 224 560 140 224 160 467 224 117 140 622 467 373 280 560 467 700 933 280 373 933 560 Student Room SIPS Appendix B – Analysis 2 Project Overview Analysis 1: Modular Bathrooms 2013 Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Quaid Spearing| Construction Option South Halls Renovation | Penn State University Area Zone 1 Zone 2 Zone 3 Zone 4 June July August September October November December 6/3 6/10 6/17 6/24 7/1 7/8 7/15 7/22 7/29 8/5 8/12 8/19 8/26 9/2 9/9 9/16 9/23 9/30 10/7 10/14 10/21 10/28 11/4 11/11 11/18 11/25 12/2 12/9 12/16 12/23 12/30 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Zone 5 Zone 6 Zone 7 Zone 8 Zone 9 1 2 3 4 5 1 2 1 3 2 1 Layout and Top Track Perim. Bedroom Framing/Insulation Ductwork MEP Coring Elec. Rough In & Tele-Data 4 3 2 1 6 7 8 9 10 5 4 3 2 1 6 5 4 3 2 7 6 5 4 3 Perim. Bedroom Piping Door Frames & Clg/Bulkhead Framing Sprinkler Rough In Plumbing Rough In Hang GWB 8 7 6 5 4 11 12 13 14 15 9 8 7 6 5 10 9 8 7 6 Finish GWB Windows Prime & Paint Lights & Final Tele-Data Install Flooring 11 10 9 8 7 16 17 18 19 20 12 11 10 9 8 13 12 11 10 9 14 13 12 11 10 FCU & Mech Trim Out Doors & Hardware Adjust Sprinkler Heads Elec/Tele/Fire Alarm Trim Out Suite/Lobby Case & Window Treat 15 14 13 12 11 21 22 23 24 16 15 14 13 12 17 16 15 14 13 Final Paint Carpet Final Clean & Punchlist Owner FF&E 18 17 16 15 14 19 18 17 16 15 20 19 18 17 16 21 20 19 18 17 22 21 20 19 18 23 22 21 20 19 24 23 22 21 20 24 23 22 21 24 23 22 24 23 24 Project Overview Appendix C – Analysis 4 Quaid Spearing| Construction Option South Halls Renovation | Penn State University Phase Resequence Schedule Analysis 1: Modular Bathrooms Background Information South Halls Renovation Schedule Comparisons 2012 Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Original Phasing Schedule Background Information Process Results Final Recommendation Acknowledgements 2015 May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Haller - Lyons Chace Ewing - Cross Cooper - Hoyt Redifer Commons Closeout Hibbs - Stephens Chace Results Background Information 2014 Hibbs - Stephens Approach Analysis 4: Phase Resequencing 2013 New Phasing Schedule Haller - Lyons Redifer Commons Ewing - Cross Cooper - Hoyt Closeout SCHEDULE SAVINGS Project Overview Appendix C – Analysis 4 Phase Resequence Gen Cond. Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Cost Code 013113200220 013113200200 013113200180 013113200120 013113200100 013113200260 013113200240 013113200240 013113200020 013113200010 013113200010 Phase 1 Original Staffing Description Quantity Unit Project Executive 17 Weeks Project Director 44 Weeks Project Manager 87 Weeks Senior Project Engineer 87 Weeks Project Engineer 87 Weeks Senior Superintendent 87 Weeks Field Superintendent 87 Weeks Field Superintendent 87 Weeks Project Technician 87 Weeks Intern 13 Weeks Intern 13 Weeks Cost Code 013113200220 013113200200 013113200180 013113200100 013113200260 013113200020 013113200010 Phase 2 Original Staffing Description Quantity Unit Project Executive 12 Weeks Project Director 30 Weeks Project Manager 60 Weeks Senior Project Engineer 60 Weeks Senior Superintendent 60 Weeks Project Technician 60 Weeks Intern 13 Weeks Labor/Unit 3825 3350 2900 2050 1575 3100 2825 2825 570 1040 1040 Labor Total $ 66,555.00 $ 145,725.00 $ 252,300.00 $ 178,350.00 $ 137,025.00 $ 269,700.00 $ 245,775.00 $ 245,775.00 $ 49,590.00 $ 13,520.00 $ 13,520.00 $ 1,617,835.00 Labor/Unit 3825 3350 2900 2050 3100 570 1040 Subtotal Labor Total $ 45,900.00 $ 100,500.00 $ 174,000.00 $ 123,000.00 $ 186,000.00 $ 34,200.00 $ 13,520.00 $ 677,120.00 Background Information Process Results Final Recommendation Acknowledgements Quaid Spearing| Construction Option South Halls Renovation | Penn State University Cost Code 013113200220 013113200200 013113200180 013113200120 013113200100 013113200260 013113200240 013113200240 013113200020 013113200010 013113200010 Phase 2 New Staffing Description Quantity Unit Project Executive 8 Weeks Project Director 20 Weeks Project Manager 39 Weeks Senior Project Engineer 39 Weeks Project Engineer 39 Weeks Senior Superintendent 39 Weeks Field Superintendent 39 Weeks Field Superintendent 39 Weeks Project Technician 39 Weeks Intern 13 Weeks Intern 13 Weeks Labor/Unit 3825 3350 2900 2050 1575 3100 2825 2825 570 1040 1040 Subtotal Labor Total $ 29,835.00 $ 65,325.00 $ 113,100.00 $ 79,950.00 $ 61,425.00 $ 120,900.00 $ 110,175.00 $ 110,175.00 $ 22,230.00 $ 13,520.00 $ 13,520.00 $ 740,155.00 Project Overview Appendix C – Analysis 4 Phase Resequence Gen Cond. Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information Approach Results Analysis 4: Phase Resequencing Background Information Process Results Final Recommendation Acknowledgements Phase 1 Chace General Conditions Phase 1 General Conditions 015213400100 015213400120 015213400140 015213400160 01521340010 01521340010 01521340010 Misc. 014523505570 015113500140 015626500250 015813500020 015433406410 015433400010 024119190600 017413200010 Field Office Equipment Supplies Telephone Lights and HVAC Computer Equipment/Software Furniture Postage/Packaging Safety & Security Subtotal Safety/Security Quality & Testing Testing (1/month) Temporary Utilities Temporary Electrical Power Temporary Facilities Site Fencing Signage Temporary Toilets (4) Small Tools Small Tools/Equipment Cleaning and Waste Management Dumpsters (2) Final Cleaning 20 20 20 20 1 1 20 Month Month Month Month LPSM LPSM Month 217.8 100 88.11 165.33 50000 10000 200 $ $ $ $ $ $ $ 4,356.00 2,000.00 1,762.20 3,306.60 50,000.00 10,000.00 4,000.00 1 LPSM 10000 $ 10,000.00 20 Each 301.32 $ 6,026.40 1 LPSM 3268 $ 3,268.00 2700 200 80 LF SF Month 7.43 37.13 227.88 $ $ $ 20,061.00 7,426.00 18,230.40 1 LPSM 5000 $ 5,000.00 174 1420.04 Weeks MSF 505 90.46 $ $ $ 87,870.00 128,456.82 361,763.42 015213400100 015213400120 015213400140 015213400160 01521340010 01521340010 01521340010 Misc. 014523505570 015113500140 015626500250 015813500020 015433406410 015433400010 024119190600 017413200010 Field Office Equipment Supplies Telephone Lights and HVAC Computer Equipment/Software Furniture Postage/Packaging Safety & Security Subtotal Safety/Security Quality & Testing Testing (1/month) Temporary Utilities Temporary Electrical Power Temporary Facilities Site Fencing Signage Temporary Toilets (4) Small Tools Small Tools/Equipment Cleaning and Waste Management Dumpsters (2) Final Cleaning 15 15 15 15 1 1 15 Month 217.8 Month 100 Month 88.11 Month 165.33 LPSM 50000 LPSM 10000 Month 200 $ $ $ $ $ $ $ 3,267.00 1,500.00 1,321.65 2,479.95 50,000.00 10,000.00 3,000.00 1 LPSM 10000 $ 10,000.00 15 Each 301.32 $ 4,519.80 1 LPSM 3268 $ 5,500.00 LF 7.43 SF 37.13 Month 227.88 $ $ $ 22,290.00 3,713.00 13,672.80 1 LPSM 5000 $ 5,000.00 128 415.78 Weeks MSF 505 90.46 $ $ $ 64,640.00 37,611.46 238,515.66 3000 100 60 Phase Resequence Gen Cond. Appendix C – Analysis 4 Project Overview Quaid Spearing| Construction Option South Halls Renovation | Penn State University Analysis 1: Modular Bathrooms Phase 2 Original General Conditions Background Information Planning & Procurement Design Evaluation – Arch. Breadth Results Analysis 2: SIPS Background Information 015213400100 015213400120 015213400140 015213400160 01521340010 01521340010 01521340010 Approach Misc. Results 014523505570 Analysis 4: Phase Resequencing Background Information Process Results 015113500140 015626500250 015813500020 015433406410 Final Recommendation 015433400010 Acknowledgements 024119190600 017413200010 Field Office Equipment Supplies Telephone Lights and HVAC Computer Equipment/Software Furniture Postage/Packaging Safety & Security Subtotal Safety/Security Quality & Testing Testing (1/month) Temporary Utilities Temporary Electrical Power Temporary Facilities Site Fencing Signage Temporary Toilets (4) Small Tools Small Tools/Equipment Cleaning and Waste Management Dumpsters (2) Final Cleaning Phase 2 New General Conditions 14 14 14 14 1 1 14 Month 217.8 Month 100 Month 88.11 Month 165.33 LPSM 50000 LPSM 10000 Month 200 $ $ $ $ $ $ $ 3,049.20 1,400.00 1,233.54 2,314.62 50,000.00 10,000.00 2,800.00 015213400100 015213400120 015213400140 015213400160 01521340010 01521340010 01521340010 1 LPSM 10000 $ 10,000.00 Misc. 14 Each 301.32 $ 4,218.48 014523505570 1 LPSM 3268 $ 3,268.00 015113500140 LF 7.43 SF 37.13 Month 227.88 $ $ $ 20,061.00 7,426.00 12,761.28 015626500250 015813500020 015433406410 LPSM 5000 $ 5,000.00 015433400010 122 Weeks 1420.04 MSF 505 90.46 $ $ $ 61,610.00 128,456.82 323,598.94 024119190600 017413200010 2700 200 56 1 Field Office Equipment Supplies Telephone Lights and HVAC Computer Equipment/Software Furniture Postage/Packaging Safety & Security Subtotal Safety/Security Quality & Testing Testing (1/month) Temporary Utilities Temporary Electrical Power Temporary Facilities Site Fencing Signage Temporary Toilets (4) Small Tools Small Tools/Equipment Cleaning and Waste Management Dumpsters (2) Final Cleaning 9 9 9 9 1 1 9 Month 217.8 Month 100 Month 88.11 Month 165.33 LPSM 50000 LPSM 10000 Month 200 $ $ $ $ $ $ $ 1,960.20 900.00 792.99 1,487.97 50,000.00 10,000.00 1,800.00 1 LPSM 10000 $ 10,000.00 9 Each 301.32 $ 2,711.88 1 LPSM 3268 $ 3,268.00 LF 7.43 SF 37.13 Month 227.88 $ $ $ 20,061.00 7,426.00 8,203.68 LPSM 5000 $ 5,000.00 78 Weeks 1420.04 MSF 505 90.46 $ $ $ 39,390.00 128,456.82 291,458.54 2700 200 36 1 Description Phase 1 Staffing Phase 2 Staffing Phase 1 Gen Cond. Phase 1 Chace Gen Cond. Phase 2 Gen Cond. Total General Conditions Summary Original $ New $ $ 1,617,835.00 $ 1,617,835.00 $ 677,120.00 $ 740,155.00 $ 361,763.42 $ 361,763.42 Cost Difference $ $ 63,035.00 $ - $ $ 238,515.66 291,458.54 $ $ (32,140.40) $ 3,249,727.62 $ 30,894.60 238,515.66 323,598.94 $ 3,218,833.02 $ $