UniMasr.com_0c362a27617df42706e5c5ae7072e1ab_1

advertisement

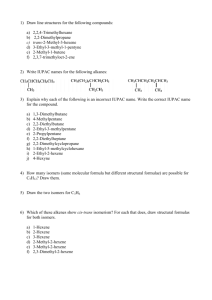

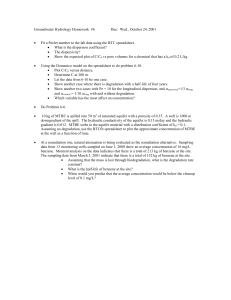

Introduction to chem. eng. Chapter 3 PROCESS DESIGN October 09 CONTENTS: • Products which will require the development of a Chemical Processes • Project Development Story • Examples of two Process Design Projects • Laboratory and Pilot Plant Data and Specifications (Example) • Qualitative Block-type Process Flow Sheet – Figure (1) • Simplified Equipment Flow Diagram – Figure (2) • Material Balance Flow Sheet – Figure (3) • Energy Balance Flow Sheet – Figure (4) • Equipment Symbols – Figure (5) Products which require the development of a Chemical Processes • A request from a customer to supply a material with properties not covered by any product in the market. • A new catalyst that can reduce manufacturing cost for a chemical our competitor produces. • The research team may have a new monomer whose properties look promising for producing a polymer for car bumpers. • Management may want us to discover a process where we can use up the surplus feedstock the company is currently producing. Project Development Story قصـة حياه مشـروع 1. Board of Director’s initiate a project مجلس إدارة الشركة يبحث عن بدائل لزيادة ربحية الشركة ودعم موقف الشركة التنافسى 2. Identification of New Projects - Project ideas - Possible sources of finance - Possible risks 3. Market Study - Potential customer’s reaction - Competition analysis 4. Planning and organizational Design إعداد خطة المشروع بد ًء من مرحلة التصميم – تحديد المسئوليات والمهام والتوقيتات Project Development Story تابـع قصـة حياه مشـروع 5. Preliminary Process Design: - Generates and evaluate alternative process flow diagram of the process - Select the most promising process flow diagram based on technical, economic and safety considerations. 6. Layout and Three Dimensional Modeling: - equipment selection - equipment sizing - conversion of the process flow diagram (PFD) into a piping and instrumentation diagram (P&ID) - layout design Project Development Story تابـع قصـة حياه مشـروع 7. Construction: بناء المصنع بمعرفة شركة أو شركات متخصصة فى األعمال المدنية والكهربائية والميكانيكية وعزل المعدات وتحديد المواسير وتمهيد الطرق وشبكات المياه والصرف الحصى والتليفونات والغاز...الخ. إدارة المشروع وفقا ً لألصول المحددة: • إدارة الجودة للتحقق من المواصفات الفنية • إدارة التكلفة للتحقق من أن التنفيذ يتم وفقا للميزانية المقررة • إدارة الزمن للتحقق من أن التنفيذ يسير وفقا للبرنامج الزمنى 8.Startup and commissioning: Get the plant started 9.Plant Operation: Get the product to the market Project Development Story تابـع قصـة حياه مشـروع 10. Debottlenecking: Make changes to improve process performance 11. Decommissioning: فى يوم ما – ربما بعد عقود عدة من يوم بدء تشغيله – البد وأن يتوقف المصنع عن اإلنتاج وتبدأ عملية معقدة لتفكيكه... وبتراكم الخبرة – أصبحنا نطلب اآلن من فريق تصميم المصنع الذى ربما يتم إنشاؤه هذا العام أن يأخذ فى االعتبار طريقة تفكيكه بعد خمسين عاما ً – من اآلن... Example of Process Design Project The market analysis staff of Company X, a mediumsized organic products company, has recommended to its management group that there was some chance to diversify their product line by developing a pesticide. The research and development (R&D) staff suggest that benzene hexachloride (BHC) might be a good possibility. It can be sold in the socalled crude form which contains 12 to 15 percent of the active pesticide, isomer of BHC, or it can be marketed as the concentrated product Lindane (99 percent isomer of BHC). Example of Process Design Project Cont’d Market analysis showed that an annual production of 600 ton of crude BHC or up to 100 ton of Lindane could be easily sold without undue competition. Management would like to compare the economics of crude BHC and Lindane production before making the final decision to spend money in a manufacturing plant. This requires process design study followed by a preconstruction cost estimate and profitability analysis. A statement of the chemical process for the production of crude benzene hexachloride is specified by the research and development group as follows: Chemical Process Considerations: • The production of benzene hexachloride is to involve the reaction of gaseous chlorine with liquid benzene at the refluxing temperature. • The reaction is to be carried out on a continuous basis in a glass-lined reactor fitted with a refluxing system; conversion of the chlorine is expected to be 99 percent and the reactor product should consist of about 33 percent benzene hexachloride dissolved in chlorobenzenes and unreacted benzene. • The crude product is to be continuously removed for further processing. • The accompanying 21.5 percent muriatic acid layer should be decanted and further concentrated to the salable 36 percent acid. Chemical Process Considerations Cont’d: • The concentration is to be accomplished in a tripping column which produces a bottoms of 20 percent HCl solution. • Since this bottoms product is not salable as such and since the HCl cannot be stripped farther without the use of excessively high pressures, it is to be recycled into the chlorinator for reconcentration. • The organic layer is to be neutralized with 1 percent NaOH solution and then concentrated to 56 percent BHC by evaporation of some of the volatile ingredients in a flash still. • The overhead from this still is largely benzene and monchlor benzene which are separated by fractionational distillation. • The benzene is recycled and the monochlor benzene is to be sold as a by-product. Chemical Process Considerations Cont’d: • A large fraction of the benzene hexachloride is to be crystallized out in a double-pipe “chiller” and the crystals removed by means of a continuous centrifuge. • The filtrate is to be recycled to a flash still for reconcentration. • The crystalline BHC product is to be dried in a rotary vacuum dryer equipped with a solvent recovery system. • The recovered solvents from various operations are to be combined and fractionated. • The overhead distillate consisting primarily of benzene is to be reused in the process whereas the chlorobenzol solvents in the bottoms are to be stored for sale as crude monochlorobenzene. Laboratory and Pilot Plant Data and Specifications (Example) 1. Raw materials specifications: Benzol, purified grade, considered as 99.5% benzene, 0.5% toluene Chlorine considered to be 100% pure Water catalyst, demineralized process water Sodium hydroxide, flake, 98% NaOH 2. Chlorinator conditions: Reaction temperature: 70°C Chorine conversion: 99% Laboratory and Pilot Plant Data and Specifications (Example) Cont’d 3. Characteristics of organic product layer from chlorinator: Composition Weight% Benzene 58.85 Water 0.31 Monochlorobenzene 7.08 Benzene Hexachloride Alpha Beta Gamma Delta and cogeners 23.44 2.04 4.22 3.55 Heptachlorocyclohexane 0.26 Trichlorobenzene 0.15 Hydrogen chloride 0.10 Total 100.00 Specific gravity at 70ºC: 1.034 Qualitative Block-type Process Flow Sheet The next step for the design engineering group is to translate the written description of the chemical process into a working pattern. It is important to explain that this working pattern can be developed in a number of ways. Each industry, each company, and each individual designer has a somewhat different approach to process design, particularly when it comes to pictorial representation of the design data. We can present only a few of the possible ways of working out a process design. Qualitative Block-type Process Flow Sheet Cont’d The main points that a student should realize are that the design should be: (1) technically sound, (2) on a reasonable basis, and (3) clearly pictured. An examination of this process description for manufacturing benzene hexachloride and the supporting data shows that the principal chemical reaction is that of chlorine addition. C6H6(l) Benzene + 3Cl2(g) Absence of actinic rays And substitution catalysts Chlorine Presence of H2O, 70ºC C6H6Cl6 Benzene hexachloride or cyclohexane, 1,2,-3,4,5,6hexachlorine Qualitative Block-type Process Flow Sheet Cont’d The working pattern for this process is put down on paper by drawing rectangular boxes and inserting the types of physical and/or chemical operations that take place, together with a description of the streams entering and leaving the box. The result is a qualitative block-type process flow sheet or flow diagram. Figure (1) illustrates this principle. The process engineer now has better idea of the overall process and obtains an insight as to further data he might require. Qualitative Block-type Process Flow Sheet Cont’d Figure (2) is a simplified equipment flow diagram of the same process. This was coded by letter for each key operation, for example, B for chlorination, D for acid concentration, etc. All the equipment conveniently associated with the key operation was numbered, for example, B-1, B-2, etc. A study of this diagram will be helpful in following this particular plan of execution. The equipment pictured may not represent the final choice as subsequent material and energy balances could reveal that a certain type of equipment was not technically feasible to carry out the desired process step. From research to practice Research project: Study of co composting of agricultural residues and night soil, M. Sc. student thesis work, Hisham Sheref,1985 From research to practice The Practice: 1. A company specialized in delivering turn-key sorting and composting plants 2. A second company which offer contracts to manage and operate MSW recycling and disposal facilities More details about the transfer of research to practice… Research main objective: to design a system for the safe disposal of human waste and domestic solid waste The basic idea was to combine the organic fraction of the MSW which is high in carbon with th night soil high in nitrogen to produce useful product. water courses as the ultimate disposal site of human waste and municipal solid waste research experimental set up • Pilot scale experiments • Mixtures of agricultural residues and night soil collected from household vaults in the village of Shosha, Mynia, upper Egypt • Aerobic decomposition • Operating variables: – time – aeration rate – C/N ratio Rate factors 1. Moisture content: minimum 15% for bacterial activity optimum 50-60% 2. Time: it is the most important factor in determining the compost product quality allowance for maturation time Cont’d rate factors 3. Temperature: stages of the aerobic thermophilic composting temperature as a functioning indicator trade off: thermophilic microbial activity vs pathogen destruction 4. Particle size: another trade off: Oxygen diffusion in too fine particles vs higher rate of decomposition optimal size: 10-50 mm Cont’d rate factors 5. Aeration: optimal level of oxygen required for the growth of aerobic microorganisms Oxygen consumption in a composting mass depends on: stage of process, temp, degree of mixing, composition, particle size and moisture content Another trade off: too much aeration will cool down the mass, too little will result in low oxygen content . Cont’d rate factors 6. Nutrients: C/N as indicator of rate of decomposition optimal C/N ratio 7. pH control: range 6-8 when process shift to anaerobic, organic acids will bring pH to 4.5 level research project main activities • Temperature monitoring • Pathogens destruction rate • Mass and energy balance • Product quality assessment • Process design • Economic analysis First business opportunity • Establishment of a limited liability company, 1994 • Acquisition of 14,000 sq meters in the industrial estate in Mynia, 20 km from a major sugar factory • Detailed process and plant design of the first large scale production facility of agriculture residue based compost in Egypt Cont’d Mynia composting plant • • • • • Fixed capital Labor force Production capacity Marketing experience Main raw materials – Baggasse – Agriculture residues Continued R&D work • Sugar factory filter mud as an alternative raw material • Process and plant design of Co- composting of MSW and agricultural waste Global perspective on municipal solid waste quantities Generation rates kg/capita.day Low-income country Middle-income country High-income country Mixed urban wastelarge city 0.50 to 0.75 0.55 to 1.1 0.75 to 2.2 Mixed urban waste – small to medium city 0.35 to 0.65 0.45 to 0.75 0.65 to 1.5 Residential waste only 0.25 to 0.45 0.35 to 0.65 0.55 to 1.0 Global Perspective on Solid Waste Management Costs Versus Income Units Low Income Country Middle Income Country High Income Country Tons/cap. yr 0.2 0.3 0.6 $/cap.yr 370 2,400 22,000 Collection cost $/ton 10-30 30-70 70-120 Transfer cost $/ton 3-8 5-15 15-20 Sanitary landfill cost $/ton 3-10 8-15 20-50 Total cost without transfer $/ton 13-40 38-85 90-170 Total cost with transfer $/ton 16-48 43-100 105-190 per cent 0.7-2.6 0.5-1.3 0.2-0.5 Average waste generation Average income from GNP Cost as % of income Business opportunity is to convert this kind of waste To this kind of product and to get recyclable material in addition Municipal solid waste receiving area The waste is then transferred to sorting conveyors, each conveyor supporting 6 stations Two Lines sorting system picture Adding water for moisture content control compost turning machine in operation Screening of matured final product