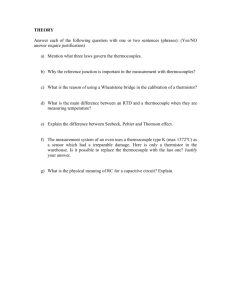

Temperature Measurements

advertisement

1 Temperature Measurements 2011 Temperature Measurements Lecture Notes Systems & Biomedical Engineering Department Faculty of Engineering, Cairo University Prof. Bassel Tawfik Biomedical Measurements 1/1/2011 Temperature Measurements 2 Lecture Outline 1. 2. 3. 4. The Concept of Heat Types of Temperature Sensors Comparison of Different Types Applications in Medicine 1. The Concept of Heat Temperature is an indication of the thermodynamic state of an object or system. It is a macroscopic description of the collective microscopic kinetic energy in a given material. If two bodies are at the same temperature, they are said to be in thermodynamic equilibrium with each other. This implies that if they were connected to each other, there would be no net flow of heat from one to the other. Kinetic energy is a measure of the activity of the atoms which make up the molecules of any material. Therefore, temperature is a measure of the kinetic energy of the material in question. Interestingly, temperature is not a measure of the unit thermodynamic energy of a body; unit masses of differing materials can require differing amounts of energy to be added or removed to change their temperature by a given amount. Identical temperature of two bodies merely implies there would be no transfer of heat between the two, regardless of the actual energy stored as heat in each body. Most temperature measuring devices use the energy of the material or system they are monitoring to raise (or lower) the kinetic energy of the device. A normal household thermometer is one example. The mercury in the bulb of the thermometer expands as its kinetic energy is raised. By observing how far the liquid rises in the tube, you can tell the temperature of the measured object. Biomedical Measurements | Bassel Tawfik 3 Temperature Measurements 2. Types of Temperature Sensors 2.1 RTD (Resistance temperature Detectors) Introduction RTD’s are electrical resistors whose resistance increases with temperature. RTD’s are manufactured using different metals as the sensing element. The most commonly used material is Platinum. Platinum is preferred to other materials because of (1) its high temperature coefficient, (2) excellent stability, and (3) repeatability (reproducibility). Other materials used to make RTD’s are nickel, copper, and nickel-iron. These materials are becoming less common now that the cost of platinum RTD’s is coming down. RTD elements are usually long, spring-like wires surrounded by an insulator and enclosed in a sheath of metal. Figure 1 shows the internal construction of an RTD. Characteristics Since RTDs’ resistance increase as the temperature increases, they are referred to as a positive temperature coefficient devices. RTD’S are manufactured with a base resistance at some temperature point. This temperature is most commonly 0°C (32°F). The most common base resistance is 100, which means that if the RTD is at 0°C, the resistance would be 100. There are other base resistances at different temperatures. Figure 1 Figure 2 The relationship between the temperature and the electrical resistance is usually non-linear and described by a higher order polynomial: R(t) = Ro(1 + At + Bt2 +C(t – 100)3) Where: Ro is the nominal (base) resistance, “t” is the temperature, and the coefficients A, B, C depend on the conductor material and basically define the temperature-resistance relationship. Biomedical Measurements | Bassel Tawfik 4 Temperature Measurements For temperatures above 0° C, the “C” coefficient equals zero. Therefore, for temperatures above 0° C, this equation reduces to a quadratic. Another common term used with RTD’s is temperature coefficient. This refers to the rate of change of resistance with respect to temperature. The most common platinum RTD has a temperature coefficient of .00385 //°C. This means that a 100 platinum RTD will increase in resistance .385 for every 1°C increase in temperature. The temperature coefficient, called alpha (), is defined as the change in RTD resistance from 0 to 100°C, divided by the resistance at 0°C, divided by 100°C: (//°C) = (R 100 - R0)/(R0 * 100° C) Where R100 is the resistance of the RTD at 100° C, and R0 is the resistance of the RTD at 0° C. The maximum temperature rating for For example, a 100 platinum RTD with RTD’s is based on 2 different factors. First = 0.003911 will measure 139.11 at 100° C. is the element material. For instance, Platinum RTD’s can be used as high as 650°C (1202°F). The other determining factor for temperature rating is probe construction. Finally, the tolerance or accuracy for RTD sensors is stated at one point only, which is usually 0°C (32°F). ASTM publications recognize 2 grades of platinum RTD elements while DIN (Europe’s version of ASTM, also called IEC/DIN) recognizes 2 classes of elements. They are as follows: ASTM E-1137 grade B = ± .10% @ 0°C (32°F) ASTM E-1137 grade A = ± .05% @ 0°C (32°F) DIN 43760 class B = ± .12% @ 0°C (32°F) DIN 43760 class A = ± .06% @ 0°C (32°F) An RTD does not produce any voltage and so it requires a source of power for its operation. On the other hand, RTD’s are generally more expensive to manufacture or purchase than thermocouples because of the expensive nature of Platinum. Yet, Platinum is not without defects. RTD elements become quite fragile at temperatures above 320°C (600°F). An RTD sensor will not hold up well at these elevated temperatures if there is any vibration present. Finally, it has been observed that the tolerance (accuracy) of an RTD generally decreases as temperature increases. Biomedical Measurements | Bassel Tawfik 5 Temperature Measurements Figure 3: Variable shapes of RTD’s. RTD Circuitry (1) Two-wire voltage-source (or current source) configuration Since the RTD is a resistance which varies with temperature, if we pass a current through it, the voltage drop across it will reflect the amount of resistance and hence the temperature. There is a catch however! As you can see from figure 3 above, the RTD sensor is “usually” placed at the end of a Figure 4a: Simple RTD connection to a voltage long wire to avoid placing the entire electronics near source. the source of heat, thereby avoiding harming these sensitive components. Since the long wire has a significant non-zero resistance, the following situation arises when the RTD is connected to a voltage source directly (as shown in figure 4). Here, we are measuring the voltage across the RTD at points R, R (Red and Red) at the tips of the 2 long wires connected to the RTD. If the RTD resistance is Figure 4b: 2-wire voltage source RTD in a 100 and each wire has a resistance of 5 (actual Wheatstone bridge. value is unknown), then the total resistance of the 2 wires and the RTD will be 110 . Ideally, it should be just 100 . Now there is an error of 10% in measured resistance which translates to another error in the estimation of temperature. If the relationship between temperature and resistance is linear, the error in temperature Biomedical Measurements | Bassel Tawfik 6 Temperature Measurements estimation will also be 10% but this is strictly not true. This 2-wire voltage-source circuit produces the largest error in temperature measurements. Notice that the same problem occurs when using a Wheatstone bridge in which one arm of the Bridge is the RTD and the 2 lead wires. (2) Three-wire voltage-source configuration To reduce the error incurred by the 2-wire voltage source method, a 3-wire circuit is constructed as shown in figure 5a. The idea is to add a third wire with a resistance and material equivalent to the first and second wires. By measuring the resistance between the red and the white leads and then subtracting the resistance between the two reds, we end up with the RTD Figure 5a: 3-wire RTD connection to a voltage resistance only (100 ). The main assumption source. R= Red, W=White. here is that all three wires have exactly the same values all the time. The above circuit is fine except that it requires mathematical subtraction in order to obtain just the RTD true value. By using the Wheatstone bridge shown in figure 5b, the effects of the lead wires cancel each other electrically. Using this method the two leads to the sensor are on adjoining arms. There is a Figure 5b: 3-wire RTD connection to a voltage lead resistance in each arm of the bridge so source using Wheatstone bridge. that the 2 resistances are cancelled out (so long as the two lead resistances are exactly the same). This configuration allows up to 600 meters of cable. It remains to say, however, that the Wheatstone bridge shown in Figure 5 creates a nonlinear relationship between resistance change and bridge output voltage change. (3) Three-wire current-source configuration Another way to connect the 3-wire configuration using a current source is shown in figure 6a. The RTD element is shown to the left with two terminals: Hi and Lo, while the signal conditioning (SC) is the box to the right. The 2 lead wires are called W1 and W2, while the compensating (third) wire is called W3. The constant current Iexc flows from ehi to RTD Hi through wire W1. Figure 6a: Another configuration of the 3-wire RTD circuit using a current source. The circuit details are shown in figure 6b. The assumption is that the resistances of the two lead wires are equal. Biomedical Measurements | Bassel Tawfik 7 Temperature Measurements Figure 6b: Details of the circuit in figure 6a. The circuit to the right is a bit more simplified than that on the left but they are essentially the same. The objective is to measure the voltage across the RTD. This is equivalent to measuring Va – Vb (the right hand circuit). Va and Vb are accessible for measurement because they are at the Signal Processing end not the RTD end. (4) Four-wire Current-Source Configuration The four-wire configuration is the most accurate method. A constant current is passed through L1 and L4, while L2 (lead 2) and L3 (lead 3) measure the voltage drop across the RTD. With a constant current flowing in the outer circuit, very small current flows into the inner circuit, thereby rendering the voltage drop across L1 and L2 negligible. This configuration is illustrated in Figure 7. This configuration is slightly more expensive than the 3-wire one because of the high cost of a good current source. Figure 7: Four-wire configuration. Theoretically, the current through RT is constant. Consequently, no current flows through L1, L2. Hence, no matter how high the resistances of L1, L2 are, Vout is only a function of RT. Notice that this is not a bridge circuit. Exercise (2-wire circuit) If the lead resistance, RL, in each wire is 0.3, then, the total lead resistance of 0.6 causes an error in the temperature measurement. For a platinum RTD with = 0.00385, show that this additional resistance causes an error in temperature of 1.6° C. [Hint: Assume a linear resistancetemperature relationship]. Biomedical Measurements | Bassel Tawfik 8 Temperature Measurements 2.2 (NTC) Thermistors Background The word thermistor is derived from “THERMally sensitive resISTOR”. The NTC (Negative Temperature Coefficient, i.e. exhibit a decrease in electrical resistance with increasing temperature) thermistor can be more accurately classified as a ceramic semiconductor. The most prevalent types of thermistors are glass bead, disc, and chip configurations. On a historical note, Michael Faraday (1791-1867), the British chemist and physicist, best known for his work in electromagnetic induction and electrochemistry, has a less familiar 1833 report on the semiconducting behavior of Ag2S (silver sulfide), which can be considered the first recorded NTC thermistor. As the reliability of thermistors improved during the 1980s, the use of electronic thermometers in the health care industry increased. The rising costs of sterilization and concerns about crossinfection among patients led to the demand for low-cost disposable temperature probes, for which cheap thermistors were well suited. Throughout the 1980s and 1990s, the use of NTC thermistors has continued to grow in the automotive, food processing, medical, HVAC, and telecommunications markets. Characteristics Depending on the materials and methods of fabrication, NTC thermistors are generally used in the temperature range of 50°C to 150°C, and up to 300°C for some glass-encapsulated units. The resistance value of a thermistor is typically referenced at 25°C (abbreviated as R25). For most applications, the R25 values are between 100 and 100 k. Other R25 values as low as 10 and as high as 40 M can be produced, and resistance values at temperature points other than 25°C can be specified. Figure 8: Over the range of -50°C to 150°C, NTC thermistors offer a distinct advantage in sensitivity to temperature changes compared to other temperature sensors. This graph illustrates the R/T characteristics of some typical NTC thermistors and platinum RTD. Biomedical Measurements | Bassel Tawfik 9 Temperature Measurements Circuit Applications The following are simple applications utilizing thermistors to indicate temperature. The first circuit Circuit # 1: Qualitative heat indicator When the thermistor is cold (no heat applied to it), its resistance is high, and no current passes through it. Hence, no current reaches the base of the Darlington pair. When warm, the resistance becomes small and the base is fed with enough current to open the transistor pair and current flows through the LED which is lit. The preset resistor can be turned up or down to increase or decrease resistance, in this way it can make the circuit more or less sensitive to heat. Notice that this circuit can be used as an indicator light for the operation of the hair dryer itself! Circuit # 2: Measuring the thermistor’s resistance This circuit measures the resistance of a thermistor or RTD and provides an output voltage proportional to the resistance. When built with common op amps, the circuit functions best when the thermistor has a resistance greater than a few hundred ohms. Biomedical Measurements | Bassel Tawfik 10 Temperature Measurements 3. Comparison of Types of Temperature Sensors Source: Temperature Product Group, 2670 Indian Ripple Road, Dayton, Ohio45440-3605 USA (www.meas-spec.com) Biomedical Measurements | Bassel Tawfik 11 Temperature Measurements Source: Agilent Technologies, Application Note # 290, “Practical Temperature Measurements”. Biomedical Measurements | Bassel Tawfik 12 Temperature Measurements 4. Applications in Medicine 4.1 Hemodialysis Temperature measurement and control is important in hemodialysis because small arterio-venous temperature gradients in the extracorporeal circulation can cause considerable transfer of thermal energy between the patient and the environment. If this transfer continues for some time, thermal energy accumulates. Accumulation of thermal energy over a prolonged period of time increases body temperature and may eventually lead to heat stress. Almost all hemodialysis machines are equipped with a system to control for a desired dialysate temperature. Until recently a dialysate temperature of 37°C was considered adequate for everyday hemodialysis. Even if a dialysate temperature of 37°C is somewhat higher than the average physiologic core temperature, the excess was accepted as a rough compensation for unavoidable heat losses in the venous part of the extracorporeal circulation. However, in the early eighties research has confirmed that a low dialysate temperature in the range of 34 to 35.5°C improves intra-dialytic hemodynamic stability when compared to dialysate temperature set at 37°C or higher. It has been demonstrated that lower dialysate temperature improves cardiac contractility and increases venous tone. Biomedical Measurements | Bassel Tawfik 13 Temperature Measurements 4.2 Cryogenics Cryogenics is the study of the production of very low temperatures (below –150 °C, –238 °F or 123 K). Cryobiology is the branch of biology involving the study of the effects of low temperatures on organisms. This may be of interest in areas related to the cryopreservation and cryosurgery. When extremely fine slices of tissue samples are required, cryomicrotomes are used. EQUIPMENT MAINTENANCE Cryo Microtome – Courtsy Sakura, Tissue-Tek® Cryo3® Microtome/Cryostat Biomedical Measurements | Bassel Tawfik 14 Temperature Measurements 4.3 Incubators, baby (http://www.freepatentsonline.com/6679830.html) A. Incubators & Infant Warmers Incubators and infant warmers are enclosures used to maintain the oxygen content, relative humidity, and air temperature surrounding an infant or baby at appropriate levels. Climate control within the incubator is mainly performed by controlling the amount of circulating air flow (driven by blower motor 22) 5 6 7 8 9 10 11 12 13 14 15 16 17 The Incubator Head-end wall Platform Foot-end wall Infant Side wall Canopy 18 19 20 21 22 23 24 25 26 27 28 29 30 Enclosure Air circulation system Heater Blower motor Blower Control system Sensors IR Sensor Biomedical Measurements | Bassel Tawfik 15 Temperature Measurements Infant incubator control mechanisms operate in two general modes: manual control and servo-control. Selection of incubator control mode is often established by unit procedural guidelines or the nurse's personal experience or preference. The purpose of this investigation was to determine the effectiveness of servo-control and manual incubator operation in maintaining adequate infant body temperature. When using manual control, the nurse predetermines the air temperature setting for the incubator and incubator heat output is thermostatically controlled to maintain this air temperature. Thermal neutral zone charts are often used to estimate appropriate air temperature, given the infant's weight and age, however adjustments are typically based on infant's body temperature. Manual operation may involve frequent temperature checks and resultant time-based cost of care issues. With servo-control operation the heat output of an incubator is thermostatically linked to a specified infant skin temperature (servo-control set point). Adequacy of probe attachment, which is critical to servo-control operation, is often difficult in preterm infants who have high transepidermal water loss. The servo-control probe entails cost of care issues as well as consideration of skin integrity and additionally servo-control operation results in difficulty interpreting evidence of thermal instability. Data for this investigation were taken from a study of the maturation of infant temperature rhythm. Subjects for the secondary analysis were selected on the basis of incubator operation. Data collection occurred at 14 ± 2 days postnatal age. Servo-control was utilized in 16 infants and manual control was utilized in 14 infants. Gestational age at birth, which ranged from 26 to 31 weeks, was comparable in the two groups. While infant oxygen consumption is the gold standard for measuring the adequacy of the thermal environment, this measure is currently not feasible in clinical practice. Consequently infant body temperature was used to determine the effectiveness of thermal support provided by the incubator. While results address appropriateness of infant body temperatures the actual metabolic cost of thermoregulation was not assessed. Infant abdominal skin temperature and incubator air temperature were collected at one minute intervals throughout a 24-hour day using a battery-operated physiological monitor (Vitalog) and standard surface and ambient air temperature probes (YSI). Graphic displays of infant and incubator temperatures reveal irregular air temperatures in the majority Biomedical Measurements | Bassel Tawfik 16 Temperature Measurements of the servo-controlled incubators, with a 6 °C range in air temperatures. Analysis, currently in process, will determine the percentage of temperature measurement intervals that were above and below recommended parameters for infant abdominal temperature (36-36.5 °C) for both servo-control and manually operated incubators. Results will provide initial information regarding the clinical debate surrounding use of servo-control versus manual control incubators. 4.4 Clinical Lab Equipment A. Incubators1 Cell cultures require a strictly controlled environment in which to grow. Specialist incubators are used routinely to provide the correct growth conditions, such as temperature, degree of humidity and CO2 levels in a controlled and stable manner. Generally they can be set to run at temperatures in the range 28ºC (for insect cell lines) to 37ºC (for mammalian cell lines) and set to provide CO2 at the required level (e.g. 5-10%). Some incubators also have the facility to control the O2 levels. Figure xx: Collection of lab incubators Copper-coated incubators are also now available. These are reported to reduce the risk of microbial contamination within the incubator due to the microbial inhibitory activity of copper. The inclusion of water bath treatment fluid (Prod. No. S5525) in the incubator water trays will also reduce the risk of bacterial and fungal growth in the water trays. However, there is no substitute for regular cleaning. (Note “Sigma Clean” Prod. No. S5525 is harmful by inhalation, contact with skin or if swallowed and is also a severe irritant.) 1 The first incubators were used in ancient China and Egypt, where they consisted of fire-heated rooms in which fertilized chicken eggs were placed to hatch, thereby freeing the hens to continue laying eggs. Biomedical Measurements | Bassel Tawfik 17 Temperature Measurements B. Ovens C. Tissue Processors Picture: Courtesy Shandon Corp. Blue = Air, Pink=Reagent, Yellow=Wax The Hypercenter XP is a computer-controlled, fluid transfer tissue processor with automated fixation, dehydration, cleaning and paraffin infiltration of tissue specimens. D. Refrigerators E. X-ray Film Processors Biomedical Measurements | Bassel Tawfik 18 Temperature Measurements F. Biosafety Cabinets A microbiological safety cabinet is probably the most important piece of equipment since, when operated correctly, it will provide a clean working environment for the product, whilst protecting the operator from aerosols. In these cabinets operator and/or product protection is provided through the use of HEPA (high efficiency particulate air) filters. The level of containment provided varies according to the class of cabinet used. Cabinets may be ducted to atmosphere or re-circulated through a second HEPA filter before passing to atmosphere. G. Steam Sterilizers (& Washers/Disinfectors) A table-top steam sterilizer that can be found in many hospital departments such as dental operatory, labs, central sterilization department (CSSD) and dermatology clinics. Biomedical Measurements | Bassel Tawfik 19 Temperature Measurements 4.5 General Device Design A. Temperature Compensation B. Protection against Overheating (Thermostats) The most obvious overheating protection mechanism that can be appreciated by most students is the fan that is placed on top of all computer processors. cozy.caf.org/.../manfreds-thermostat-circuit.jpg The following is taken from: http://web.mit.edu/3.082/www/team5/electronicdesign.html The thermostat circuit is a circuit that cuts off power when the local temperature reaches a certain set point. This circuit is needed for two reasons. One reason is to conserve as much battery power as possible. The other reason is to ensure that the temperature of the heating band stays at a comfortable temperature for the consumer. The main component in the thermostat circuit is the thermostat integrated circuit (IC) from Analog Devices. This device was chosen because the set-point temperature can be altered by Biomedical Measurements | Bassel Tawfik 20 Temperature Measurements adding resistors in place of Rset shown below. This device is also for a low voltage source, which fits the battery being used. The thermostat IC sends a voltage to the transistor, which acts as a switch and closes the circuit if the voltage sent is above a certain voltage (2V). The thermostat IC also contains a built-in hysteresis of 4deg C so that the entire circuit does not turn on and off rapidly. It is set so that the circuit turns on at 38deg C and then turns off when the temperature reaches 42deg C. The capacitor at the top of the circuit is there to steady any oscillating current/noise. The following circuit is taken from: electronics4everyone.blogspot.com Biomedical Measurements | Bassel Tawfik 21 Temperature Measurements Appendix (A) Response Time Time Response Characteristics The response of an ARi Resistance Temperature Detector is defined by 2 noticeable characteristics when exposed to an instantaneous (step) change in environmental temperature. These are: A) Time Constant (): The time to reach 63.2% of the complete step change in temperature B) Response Time: Time to reach within 0.5% of the final temperature in a step change. This is approximately equal to 5 times the time constant The response of a temperature sensor to a step change in ambient temperature tends to follow a second order differential equation. However, this is approximate, since if the mass of the sensor is small in relation to the mass of the fluid passing over it (such as in the case of a liquid), the response may approach a first order differential equation. A typical response is shown below. Time constant has application for more common experiences in process control, i.e., ramp change or sinusoidal changes in ambient temperature. Biomedical Measurements | Bassel Tawfik 22 Temperature Measurements The value of the time constant, , is related to the environmental conditions by the following approximate relation (Ref NASA TN 2599): Biomedical Measurements | Bassel Tawfik 23 Temperature Measurements Appendix (B) Summary of Application Note 3450: PT100 Transducer (http://www.maxim-ic.com/appnotes.cfm/an_pk/3450) Temperature is one of the most measured physical parameters. Thermocouple and resistance temperature detector (RTD) sensors are adequate for most high-temperature measurements, but one should choose a sensor that has characteristics best suited for the application. Table 1 offers general guidelines for choosing a sensor. Feature Thermocouple RTD Response time Better Maximum temperature Higher Ruggedness Better Cost efficiency Better Accuracy Better Long-term stability Better Standardization Better Platinum's long-term stability, repeatability, fast response time, and wide temperature range make it a useful choice in many applications. As a result, platinum RTDs are recognized as the most reliable standard available for temperature measurement. The PT100 RTD is described by the following generic equation, which makes obvious a nonlinear relationship between temperature and resistance: RT = Ro(1 + AT + BT² + C(T-100)T³) Where: A = 3.9083 e-3 B = -5.775 e-7 C = -4.183 e-12 below 0°C, and zero above 0°C Biomedical Measurements | Bassel Tawfik 24 Temperature Measurements Figure 1. This two-wire connection affects measurement accuracy by adding resistance in series with the RTD. Figure 2. An additional third wire to the RTD allows compensation for the wire resistance. The only restriction is that the main connecting wires have the same characteristics. Biomedical Measurements | Bassel Tawfik 25 Temperature Measurements Figure 3. A four-wire approach enables Kelvin sensing, which eliminates the effect of voltage drops in the two connecting wires. You can connect a PT100 RTD to the measuring application using two wires, three wires, or four wires (Figures 1, 2, and 3). Several analog and digital approaches are available for compensating a PT100 RTD for nonlinearity. Digital linearization, for instance, can be implemented with a lookup table or by implementing the previous generic equation. A lookup table located in µP memory allows an application to convert (through interpolation) a measured PT100 resistance to the corresponding linearized temperature. On the other hand, the previous generic equation offers a possibility of calculating temperature values directly, based on the actual measured RTD resistance. A lookup table necessarily contains a limited number of resistance/temperature values, as dictated by the required accuracy and the amount of memory available. To calculate a specific temperature, you must first identify the two closest resistance values (those above and below the measured RTD value), and then interpolate between them. Consider a measured resistance of 109.73Ω, for example. If the lookup table has a resolution of 10°C, the two closest values might be 107.79Ω (20°C) and 111.67Ω (30°C). Interpolation using these three values leads to: This digital approach requires use of a microprocessor (µP), but the small circuit in Figure 4 performs accurate linearity compensation using the analog approach. It provides outputs of 0.97V at -100°C and 2.97V at 200°C. It may be necessary to add gain adjustment (span) and a level shift (offset) to cover an output range of -100mV at -100°C to 200mV at 200°C, for example. Biomedical Measurements | Bassel Tawfik 26 Temperature Measurements Figure 4. This analog circuit linearizes an RTD output The suggested way to compensate for nonlinearity in the PT100 element is to apply a small amount of positive feedback through R2. That feedback helps to linearize the transfer function by providing a slightly higher output at high PT100 values. The transfer function can easily be established by applying the superposition principle Figure 5 shows the raw PT100 output vs. a linear approximation of the form y = ax + b, and Figure 6 Biomedical Measurements | Bassel Tawfik 27 Temperature Measurements shows a linearized version of the circuit output vs. the linear approximation. Each figure shows the calculated relationship between temperature and resistance compared to the output calculated from the Figure 4 circuit. The graphs of Figures 7 and 8 illustrate the PT100 error before and after analog compensation. Figure 5. Raw output of a normalized PT100 vs. a linear approximation to that output. Figure 6. Analog-compensated output vs. a linear approximation to that output, showing the error after linearization. Biomedical Measurements | Bassel Tawfik 28 Temperature Measurements Figure 7. Normalized error, representing the deviation between raw PT100 output, and a linear approximation of the PT100 relation between temperature and resistance. Figure 8. Normalized error, representing the deviation between the linearized output of Figure 4 and a linear approximation of the PT100 relation between temperature and resistance. Normalizing the curves of Figures 7 and 8 makes it easy to assess the performance of the Figure 4 circuit. When calibrating an analog thermometer, it is always preferable to minimize the need for adjustments and control measurements during production and calibration. Normally, it is best to adjust only the offset and span at two PT100 values. That approach, however, requires a linear relationship between PT100 resistance and temperature, which is not the case. The exercise above shows that analog compensation can reduce PT100 errors by a factor of approximately 80, assuming the transfer function exhibits a linear correlation between the PT100 value and the measured temperature. Additionally, low power dissipation in the PT100 (0.2mW to 0.6mW) minimizes self-heating. Thus, PT100 signals linearized using the analog approach allow an easy interface to ±200mV panel meters, for example, without additional software overhead. Figure 9. Digital approach: An ADC converts the RTD output to digital under control of a µP. Then, the µP calculates the corresponding temperature using a lookup table. Biomedical Measurements | Bassel Tawfik 29 Temperature Measurements An example of the digital approach (Figure 9) involves an RTD, a difference amplifier, a current source, and an ADC controlled by a µP (not shown). A temperature measurement is accomplished by driving a current of 1mA to 2mA through the sensor and measuring the resulting voltage drop across it. Higher currents cause higher power dissipation in the sensor, which in turn causes measurement errors due to self-heating. An internal 4.096V reference simplifies the generation of excitation current for the sensor. To prevent wire resistance from affecting measurement accuracy, four separate wires connect the RTD to the differential amplifier. Because the sense wires connect to the amplifier's highimpedance inputs, they have very low current and virtually no voltage drop. The 4096mV reference and 3.3kΩ feedback resistor sets the excitation current to approximately 4096mV/3.3kΩ = 1.24mA. Thus, driving the ADC and current source with the same reference voltage produces a ratiometric measurement in which reference drift does not influence the conversion result. By configuring the MAX197 for an input range of 0V to 5V and setting the differential amplifier for a gain of 10, you can measure resistance values up to 400Ω, which represents about +800°C. The µP can use a lookup table to linearize the sensor signal. To calibrate the system, replace the RTD with two precision resistors (100Ω for 0°C, and 300Ω or higher for full span) and store the conversion results. Biomedical Measurements | Bassel Tawfik 30 Temperature Measurements Appendix (C) Hemodialysis Machines: An Overview Hemodialysis machine can be roughly divided into custody alarm system and blood dialysis fluid supply system in two parts. The alarm system: It includes blood monitoring, blood pump, heparin pump, hybrid pulse pressure monitoring and air monitoring; Dialysis fluid supply system: It includes temperature control systems, fluid distribution system, in addition to gas system, conductivity monitoring system, monitoring and ultrafiltration Blood Leak monitoring component. Three hemodialysis machine parts function 1. The alarm system of monitoring blood Blood alarm monitoring system for Gambro AK 95 shown in Figure 2, for example, function as part of the brief. A. blood pump (Blood Pump) Phoenix® Dialysis System - Courtesy: Gambro To promote blood circulation to maintain Corp. hemodialysis treatment is carried out smoothly. Generally speaking, often with blood pump some speed detection, used to monitor the patient’s blood, and blood flow with the removal of toxins (shown in Figure 3), and the blood pump cavity distance runner must set precise, and the need for regular adjustment of the pump under the catch, generally set spacing of 3.2 to 3.3mm, not too loose, this will not be allowed to flow detection; also not too strict, if too will cause pipeline rupture, the incident. Biomedical Measurements | Bassel Tawfik 31 Temperature Measurements B. heparin pump (heparin Pump) Heparin pump equivalent clinical application of micro-injection pump, to keep the patients in the blood injection of heparin. Since the patient’s blood in contact with air pump, it is prone to clotting phenomenon, the use of heparin pump prevent coagulation. C. hybrid pulse pressure monitoring Arterial pressure monitoring to monitor dialysis machines thrombosis, solidification and pressure changes. When inadequate blood flow, blood pressure will be reduced; When the dialysis machines with coagulation and thrombosis, arterial pressure will be increased; Venous pressure monitoring pipeline used to monitor blood pressure returned. When dialyzer clotting or thrombosis, and the lack of blood flow to return shedding needles, intravenous pressure will drop; If the return of profitable return needles or distorted plug to plug in, venous pressure will be increased. The above situation occurs when the machine will automatically alarm. D. air monitoring (Air Detector) The road used to monitor blood flow and intravenous drip pot in the air bubble. Ultrasonic detection by the general principle, in order to avoid air embolism in patients and set up. When monitoring the air bubbles, the detection system will be driven move, blocking blood flow to the road safe and prevent the occurrence of danger. 2. Part of dialysis fluid supply system A. Temperature Control System Including two heating and temperature measurement, in the normal dialysis, the treatment would be consistent with the general standard of reverse osmosis water heated to 36 ~ 40 ° C, Biomedical Measurements | Bassel Tawfik 32 Temperature Measurements with the mixture of concentrated liquid temperature sensor by detecting temperature, which makes dialysis fluid temperature control temperature and the temperature setting with general dialysis fluid temperature control 37 ℃, according to the patients can be appropriately regulated. With heat sterilization machine, in the heat sterilization, temperature can reach 100 ℃. B. Distribution System Solution Preparation qualified dialysis fluid to carbonate dialysis example, the proportion of its hybrid: A Solution: B liquid: water = 1:1.83:34. Many machines currently used ceramic pump ratio, by adjusting the speed to achieve speed preparation of dialysis fluid precision. C. degassing system In the water and condensed liquid in a certain air, the process of preparation of dialysis fluid due to the presence of carbonate gas will also be the formation of these bubbles in dialysis fluid in the air may cause blood clotting, reduce waste clearance rate, the impact on dialysis fluid flow and pressure, thereby affecting the concentration of conductivity occurred, hence the need to remove dialysis fluid in the air. When using vacuum degassing principle, in addition to general set-600mmHg about pressure, but in high altitude areas due to lower negative pressure, such as Lanzhou, Kunming and other places can be set-500mmHg. D. conductivity monitoring system General carbonate dialysis function of hemodialysis machine configurations are often two to three conductivity monitoring module, the first of the concentration of A, A request to the concentration of liquid absorption of B, then the conductivity detection is the actual dialysis fluid conductivity. Conductivity monitoring module to monitor the conductivity value reached CPU circuit, and set conductivity, compared to further concentrate control of preparation, preparation to meet the requirements of the dialysis solution. Usually of dialysis fluid cation concentration in the range of 13.0 to 15.0ms/cm, dialysis fluid concentration of 13.8 to 14.2 in between. Biomedical Measurements | Bassel Tawfik 33 Temperature Measurements E. ultrafiltration (Ultrafiltration) Monitoring System Use of transmembrane pressure (Trans-membranous Press, TMP) pressure control or capacity to achieve control of ultrafiltration, remove blood in the water purposes. Transmembrane pressure increased, the corresponding time in the ultrafiltration of the circumstances will determine the increase (as shown in figure 4). Most hemodialysis patients kidney failure or complete loss of body water can not be ruled out, ultrafiltration system in hemodialysis machine is very important. The current market hemodialysis machine control system can be divided into ultrafiltration flow sensor system and the balance of two cavity, the use of the Gambro is the former, while others use most of it is the latter, advantages and disadvantages of each are passed through the comparison of before and after dialysis difference to calculate the flow of ultrafiltration, more accurate . F. Blood Leak monitoring (Blood Leakage) system Hemodialysis sometimes occur in the process of rupture of membrane dialysis phenomenon will occur when Blood Leak, in order to detect the occurrence of Blood Leak generally hemodialysis machine use optical detection of dialysis fluid in hemoglobin, the detection sensitivity of 0.25 ~ 0.35ml heme / or a dialysis solution, in the dialysis process if precipitation or too dirty, high incidence of false alarm, which requires the timely removal operators Blood Leak Detection parts of stolen goods. Four hemodialysis machine development Hemodialysis machine and the maturing of the development, operation and design of human nature are universal, as a treatment for type equipment, personalized treatment, safety performance and modular design of each manufacturer is the most important issue to consider. Actually, according to each patient’s electrolytes, can easily provide different dialysis fluid is hemodialysis machine an important direction of development; In order to improve the safety of hemodialysis, and some companies are linked to the concept of health; Engineering, Biomedical Measurements | Bassel Tawfik 34 Temperature Measurements hemodialysis machine design tends to modular design This maintenance to the machine’s performance. Biomedical Measurements | Bassel Tawfik 35 Temperature Measurements Appendix (D) 2-wire circuit Shown is a 2-wire RTD connected to a typical Wheatstone bridge circuit. Es is the supply voltage; Eo is the output voltage; R1, R2, and R3 are fixed resistors; and RT is the RTD. In this uncompensated circuit, lead resistance L1 and L2 add directly to RT. 4-wire circuit 4-wire RTD circuits not only cancel lead wires but remove the effects of mismatched resistances such as contact points. A common version is the constant current circuit shown here. Is drives a precise measuring current through L1 and L4; L2 and L3 measure the voltage drop across the RTD element. Eo must have high impedance to prevent current flow in the potential leads. 4-wire circuits may be usable over a longer distance than 3-wire, but you should consider using a transmitter in electrically noisy environments. 3-wire circuit In this circuit there are three leads coming from the RTD instead of two. L1 and L2 carry the measuring current while L3 acts only as a potential lead. No current flows through it while the bridge is in balance. Since L1 and L2 are in separate arms of the bridge, resistance is canceled. This circuit assumes high impedance at Eo and close matching of resistance between wires L1 and L2. TEMPCO matches RTD leads within 5%. As a rule of thumb, 3 wire circuits can handle wire runs up to 100 feet. If necessary you can connect a 2-wire RTD to a 3-wire circuit or 4-wire circuit, as shown. As long as the junctions are near the RTD, as in a connection head, errors are negligible. Biomedical Measurements | Bassel Tawfik 36 Temperature Measurements Biomedical Measurements | Bassel Tawfik