Home-fabricated AT - National AgrAbility Project

advertisement

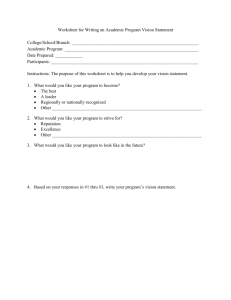

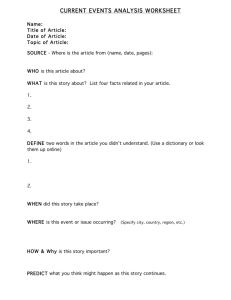

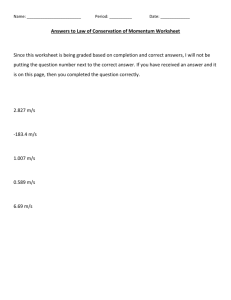

Evaluating Agricultural Workplace Assistive Technology for Secondary Injury Hazards ( ) Pre-conference workshop, National AgrAbility Training 2010, October 11, 2010 Charleston, West Virginia Presented by William E. Field & Samuel N. Mathew This resource is developed as a part of the NIFA/USDA National AgrAbility Project Grant no. CSREES/USDA-2008-41590-04796 Workshop Objectives At the end of session, the attendee will be able to: 1. Explain the reasons for higher workplace injuries in agriculture compared to other industries. 2. Explain the primary causes of agricultural workplace injuries. 3. Explain what is meant by secondary injuries 4. Explain how disabilities increase the risk of injury, especially in agricultural workplace Workshop Objectives 5. Explain why safety assessment of AT for farmers with disabilities will result in successful vocational rehabilitation funding. 6. Identify critical hazards on AT used in agricultural workplaces 7. Conduct a basic safety assessment of AT used in agricultural workplace Definition of Assistive Technology Assistive Technology (AT) means any item, piece of equipment, or product system, whether acquired commercially off the shelf, modified, or customized, that is used to increase, maintain, or improve functional capabilities of an individual with a disability - ‘The Tech Act” (Technology-Related Assistance for individuals with Disabilities Act of 1988) Examples of Assistive Technology in Agricultural Workplace Person lifts Added steps Hand controls Modified tools Ramps Definition of Secondary Injury Secondary injury can be defined as injury caused by limitations associated with disabling conditions and/or resulting from the use of modified practices or AT to compensate for disabling conditions. Examples of Secondary Injury Burns Fractures Pressure sores Amputation Loss of hearing Background Farming is one of the most hazardous occupations among American industries – – – – – – – Working alone Diverse hazards (fire, chemicals etc.) Age of worker (young/old) Repetitive motion Unpredictable environment Diverse terrain Lack of workplace safety regulations Background Estimated number of farmers, ranchers and other agricultural workers with disabilities appears to range from 1.14 million to 2.23 million individuals (Deboy et al., 2008) The Need Physical and mental disabling conditions can increase the potential of injuries for farmers who continue to perform tasks Studies indicate that > 72% of farmers with disabilities fabricate their own AT to continue to perform tasks Both commercial and home-fabricated AT can cause injuries (Allen et al., 1995; Willkomm, 2004) The Need Currently there are no comprehensive safety guidelines or regulations for farmers who fabricate AT Currently, rehabilitation professionals and funding agencies like ‘VR’ do not have a validated assessment process to – assess suitability of AT – evaluate safety of home-fabricated AT – satisfy their procedural requirements for providing funding Prior Reports/Research Tormoehlen, R. L., & Field, W. E. (1983). Plowshares #1. Special Breaking New Ground technical report: Potential health and safety risks of farming with physical handicaps. West Lafayette, IN: Breaking New Ground Resource Center, Purdue University. Allen, P. B., Field, W. E., & Frick, M. J. (1995). Assessment of work-related injury risk for farmers and ranchers with physical disabilities. Journal of Agricultural Safety and Health, 1(2), 71-81. Willkomm, T. (1997). Risks in using modified tractors by operators with spinal cord injuries and their co-workers. (Doctoral Dissertation, University of Pittsburgh, Pittsburgh, PA, 1997), Dissertations and Theses (PQDT). Prior Reports/Research Gruver, M.L., Allen, P.B., Field, W. E., & Schweitzer, J. (1997). Plowshares #27. Special Breaking New Ground technical report: Potential health and safety risks of farming/ranching with a disability. West Lafayette, IN: Breaking New Ground Resource Center, Purdue University. Yoder, A. M. (2002). Ergonomic evaluation of commercially available operator lifts for farmers with disabilities. (Doctoral dissertation, Purdue University, West Lafayette, IN, 2002), ETD Collection for Purdue University. Prior Reports/Research Breaking New Ground. (2005). Conducting agricultural worksite assessments: A user's guide for professionals assisting farmers & ranchers with physical disabilities (3rd ed.). West Lafayette, IN: Breaking New Ground Resource Center, Purdue University. Kelso, S. A., & Mann, D. D. (2005). Assistive technology adaptations for farmers with physical disabilities Paper presented at the CSAE-SCGR 2005 Annual Meeting. Prior Reports/Research Kelso, S. A., Stangherlin, A. M., & Mann, D. D. (2008). Evaluation of mechanical tractor pedal extensions. Journal of Agricultural Safety and Health, 14(4), 431-439. Cooperative State Research Education and Extension Service. (2008). Assistive technology program for farmers with disabilities: State and regional AgrAbility projects. Retrieved August 20, 2009. from http://www.csrees.usda. gov/funding/rfas/pdfs/08_agrability.pdf. The Problem Most AT used by farmers is locally made and may not comply with current engineering, regulatory or safe workplace standards Assessment Tool Objectives Building on work previously done for the agricultural workpace – “Conducting an Agricultural Worksite Assessment” AgrAbility professionals should strive to ensure that whatever they recommend will result in NO HARM to the client Assessment Tool - Objectives Provide an evaluation method for funding agencies to reasonably estimate the safety of home-fabricated AT Training tool for rehabilitation professionals to assess AT used by farmers with disabilities Prevention of secondary injuries Assessment Tool - Objectives Help the assessor to identify potential for injury to the user The assessor can provide suggestions for preventive /corrective measures to avoid or minimize risk of injury Development Process Case Studies of farmers Inputs from professionals who serve farmers’ with disabilities having AT needs Development of prototype assessment tool Content validation by expert panel Forms of Assistive Technology Commercially available Modifications to commercially available AT Home-fabricated AT Common AT Used by Farmers with Disabilities Designed by self or friends and family Fabricated by self or local craftsmen Specific devices custom-built for a purpose or modifications to standard equipment Both power- or manual- operated Most complex ones are lifts of various kinds to access farm equipment operator seat Home-fabricated AT – Lifts Home-fabricated AT – Hand Control Home-fabricated AT – Added Steps Home-fabricated AT – Cultivating Cart Home-fabricated AT – Utility Vehicle Home-fabricated AT – Lift Home fabricated AT –- Home Access Lift Home-fabricated AT – Seat Actuator on Tractor Home-fabricated AT – Sprayer Home-fabricated AT – Lift Home-fabricated AT – Added Steps Home-fabricated AT – Added Spring Loaded Steps Home-fabricated AT – Movement and Speed Home-fabricated AT – Lift Home-fabricated AT – Lift Attached to Tractor Home-fabricated AT – Steps Home-fabricated AT – Lift Attached to Combine Home-fabricated AT – Sprayer Platform BREAK TIME Contents of Assessment Tool Section I – Introduction Section II – Steps in Assessment Process Section III - Reference sheets – w/Descriptions and Pictures Section IV – Assessment Example with all Worksheets filled Section V Copy ready assessment sheets (Worksheets A to F) Contents (…contd) Worksheet A Client & Disability Information Worksheet B AT Information Worksheet C Quick Reference sheet Worksheet D Assessment Questions Worksheet E Problems Observed/Solutions Worksheet F Results & Recommendations Practice Time Open your packet to Section I page I-1 Familiarize with – – – – – Section descriptions at bottom of page I-1 The purpose of the tool Page I-1 Who should use the tool & why Page I-2 Component description (Worksheets) Page I-2 Computer program to enter data & print report Page I-3 – Recommended toolkit page I-4 Pause for Questions Questions on Section I? How to Use the Assessment Tool? Conversation with the client – – – – Establish personal rapport Understand client’s disabilities and strengths Obtain & fill client information in worksheet A Obtain & fill AT information in worksheet B Observe operation of the AT /Examine AT Read Quick Reference worksheet C and check mark (X) the items to be assessed. (Note: If in doubt, check the item) How to Use the Assessment Tool? Take pictures of AT where ever required Refer to Section III as often as required Systematically check items and answer questions in Worksheet D Prepare Worksheet E based on Worksheet D Discuss, the observations and possible solution suggestions with the client Prepare Worksheet F based on Worksheet E Computer Program Start the program and enter all the items in Worksheet A,B,D and fill in Worksheet F. Upload pictures simultaneously. Before uploading mark/highlight pictures, if needed Save file in an appropriate directory with appropriate ‘filename’ and exit program Open ‘filename.html’ in browser and print report that contains Worksheet A,B,D and F Practice Time Turn to Section II on page II-1 Review the sub-sections – Before the Evaluation – During the Evaluation – After the Evaluation Turn to Section IV on page IV-1. Familiarize with Worksheet A and B Demonstration of Computer Program: observe data being entered on screen in Worksheet A and B Pause for Questions Questions on : – Section II ? – Worksheet A or B? – Computer Program? The Reference Sheets – Section III One-to-one correspondence to Quick Reference sheet (Worksheet C) and Assessment Questions (Worksheet D) Brief explanation of the intent of the question How to Use the Reference Sheets? Read the reference sheet before answering the assessment item Understand the context, the importance of the assessment question If more clarity is needed, ask an expert (e.g. electrician or Professional Engineer) or take a second opinion based on the observation The Quick Reference Sheet – Worksheet C Checklist to initially identify which all items are relevant to the AT under evaluation Same sequence as Worksheet D Overview of the assessment in one page Field accessory for the assessor Optional to use but helpful for organizing the assessment process Assessment Questionnaire – Worksheet D 55 questions on potential situations for injuries Items categorized in 8 groups for easier use Each item has 3 choices Items ‘not applicable’ can be marked and ruled out Space for problems observed, solutions suggested Alternate computer program to enter same data and produce a report with recommendations Practice Time Turn to Section IV. Worksheet C on page IV-5. Refer to Section III as needed Turn to Section IV. Worksheet D on page IV-6 and familiarize with the questions from IV-6 to IV-12. Refer to Section III Turn to Section IV Worksheet E page IV-15 to IV-24. Turn to Section IV Worksheet E on page IV-25 Pause for Questions Questions on : – Section III ? – Section IV Worksheet C, D, E or F? – Section V – Copy ready sheets of Worksheet A, B, C, D, E and F? Suggested Toolkit for Assessment Clipboard Digital Camera Measuring tape Angle finder Calculator Wire brush Magnifying glass Screwdriver Pliers Fish scale Voltage tester Level Toolkit Price : Total $ 65.39 Screwdriver (4 piece) + 16’ measuring tape + Pliers + Knife (‘Task Force’ Brand kit from Lowe’s) $9.98 Angle finder (Swanson) from Lowe’s $9.86 Zebco Fish scale from Wal-mart$5.59 Level from Lowe’s $ 2.00 Ultraoptix Magnifying glass from Staples- $6.99 Wire brush from Tractor Supplies $4.00 Ideal Brand Voltage tester from Lowe’s - $9.98 Clip board with calculator from Staples - $16.99 Tips on Completing Assessment Don’t assume without knowing all facts If in doubt, ask the client or an expert Take variety of pictures, draw diagrams to explain the problem clearly, and take video clips. It will help during review session with the client or another expert Tips on Completing Assessment Describe situation in simple terms Ask an expert if second opinion necessary Observe the AT during operation Take measurements, operate levers, examine closely Tips on Completing ‘Solutions Suggested’ Discuss the possible solution(s)with client Discuss the consequences of not implementing a solution for the observed problem Consider cost, suggest economical solutions Suggest easily achievable modifications Provide information on resources available (e.g. VR) Tips on Recommendations Consider suitability of AT to the user Discuss the problems observed with the user before making recommendations Discuss solutions and help the user understand the potential for injury Consult with experts or take a second opinion if required Sample Home-fabricated AT - Lift •Frail construction (1) •No emergency exit (5) •Winch mechanism not certified for human lifting (6) •Dangling wires (18) •Sharp edges and corners (25) •Projections on moving parts (26) •No proper seat belts (38) •No stabilizing supports (41) •No back-up power source (47) •No back-up control switches (48) •No operating instructions (49) •And many more ….. Home-fabricated AT – Cultivating Cart •No brakes (12) •Pinch points (22) •Sharp edges and corners (25) •Unshielded moving parts (27) •Weather related restrictions (37) Home-fabricated AT -Skid Loader Platform • • • • Overall weight (8) Sharp edges or corners (25) Slippery surfaces (30) Handrails and handholds (42) Limitations of Assessment Tool Not a certification but a guideline No pass or fail score There may be features not included All items not applicable to all ATs No engineering details Who Should Use This Tool ? AT Fabricators AT Assessment Professionals Benefit To estimate the potential for secondary injury when implementing ATs for farmers with disabilities Who Should Use This Tool ? AT users Benefit To have the assurance about the general safety of the home-fabricated ATs (that do not undergo rigorous testing and certification as in the case of a commercially manufactured equipment) Who Should Use This Tool ? Rehabilitation Funding agencies Benefit Use the assessment report that documents the general safety aspects of home-fabricated ATs used by farmers with disabilities. Who Should Use This Tool ? AgrAbility Staff Benefit As a training instrument to identify potential disability-related hazards on home-fabricated AT in the agricultural workplace Practice Session Time for practice Use assessment process on a real AT Follow instructions about group activity depending upon size of class THANK YOU! Comments or Questions? National AgrAbility Project bng@ecn.purdue.edu Phone: 800-825-4264