Fasteners in Aviation

advertisement

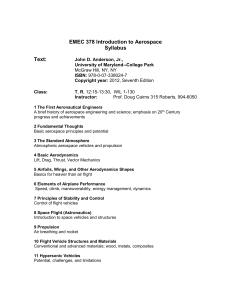

Aerospace Fastener Applications Part 2 An Aerospace Manufacturing Perspective 1 Aerospace Rivets 2 Primarily used to fasten aerospace skins to the sub-structure Concerned mainly with shear and tension loads. Two types of rivets: – Solid Rivet – Blind Rivet Aerospace Solid Rivets 3 Aerospace Solid Rivets 4 Aerospace Solid Rivets - Identification 5 Rivets manufactured in accordance with the AN/MS standards are identified by a four part code: 1. AN or MS specification and head type 2. one or two letters that indicate the material 3. shank diameter in 1/32nd inch increments 4. a dash followed by a number that indicates rivet length in 1/16th inch increments. Aerospace Solid Rivets - Identification Example: rivet identification standard universal head solid rivet Material: 2117-T4 aluminium 1/8 inch diameter 5/16 inch in length Rivet ID = either AN470AD4-5 or MS20470AD4-5 6 Aerospace Solid Rivets - Identification 7 Same rivet, different material:1100 aluminium – AN470A4-5 or MS20470A4-5. AN470 or MS20470 denote the specification for universal head types AD is the material code for 2117-T4 – (A=1100, B=5056, C=copper, D=2017, DD=2024, F=stainless and M=Monel) 4 = 4/32 or 1/8 inch diameter -5 = 5/16 inch length Aerospace Blind Rivets 8 Used when you cannot physically access one side of the work Blind rivets are hollow, and thus weaker than solid rivets To retain strength of the joint: – stronger material, larger diameter rivets, or more are necessary and of course 20–50% heavier than a solid rivet because of steel stem Aerospace Blind Rivets 9 Quality Assurance of Aerospace Fasteners 10 Aerospace Fasteners Material Selection Aerospace Fasteners Testing Aerospace Fasteners Material Selection Background Some factors to be considered before material selection are: The max. and min. operating temperatures The corrosiveness of the environment Fatigue and impact loading Always try to use standard fasteners, such as AN, MS, MIL, NAS, SAE 11 Aerospace Fasteners Material Selection 12 Alloy Steels Aluminum Titanium Stainless Steel Superalloys Aerospace Fasteners Material Selection 13 Aluminum is the predominant material used in the manufacture of commercial aircraft. Table 3 lists the typical aluminum alloys used in commercial aircraft. Basic Aerospace Fasteners Application The basic applications (or needs) for aerospace fasteners are: – – – – – – 14 Shear Tension Fatigue Fuel tightness High temperature Corrosion control Aerospace Fasteners Testing Analyzing a Joint – Calculate all the load required for each type of joint failure: – 15 Rivet Shear Sheet Tensile Bearing Sheet Shear Failure will occur in the mode that corresponds with the lowest load carrying capability. Aerospace Fastener Standardization Most aerospace hardware is manufactured per government standards The three most common aircraft fastener standards used are: – – – 16 AN = Air Force/Navy NAS = National Aerospace Standards MS = Military Standards Common Standardized Fasteners – – – – – – – – 17 Bolts Nuts Washers Turnbuckles Cotter pins Screws Rivets Plumbing fittings (pipes and tubes)