IT-390 Chapt 2 Labor Analysis

advertisement

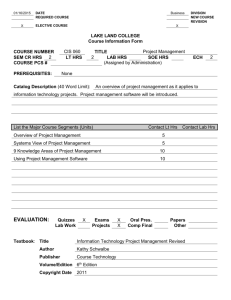

IT-390 Labor Analysis Ch 2 1 Introduction Direct labor 10% of product cost Hardest part of an estimate Labor costs are sporadic Classical methods for estimation of labor costs – – – – 1) Time Study (Stop Watch) 2) Standard Data (Man-hour Reports) 3) Predetermined Time Standards and Formulas 2 4) Work Sampling Labor Direct Labor – Directly linked to the manufactured part – Hands on Labor, or Touch Labor; Physical "touching" of the part and adding value 3 Labor Indirect Labor – Overhead charge » Engineers, first-line supervisors, managers, production control, quality control, etc. » Cost of running equipment, utilities, Inspection, indirect materials, etc. 4 Measured Time Frederick (1856-1915) Frank (1868-1926) Lillian (1878-1972) 5 Measured Time Evolve from Production Study to: – – – – 1) Time Study (Stop Watch) 3) Predetermined Time Standards and Formulas 2) Standard Data (Man-hour Reports) 4) Work Sampling 6 Time Study Analysis of an operation Standardize methods, equipment, and conditions Determine number of standard hours 7 Time Study The procedure is: – a) Methods analysis - improve if necessary – b) Record data - title block, elements of work, etc – c) Separate the operation into elements – d) Record time consumed by each element – e) Rate the pace or tempo – f) Determine the allowances – g) Convert elements to time standards 8 Time Study The equations are: – Operator Performance Factor = %Rating Factor 100% – Std Time = (time)(Operator Performance Factor)(Allowance Factor) or – Std Time = (% Working Time)(Total Working Time)(Performance Factor)(Allowance Factor) . Total # pieces produced 9 Time Study Equipment used - clipboard, stopwatch, and data collection forms Training is required Several cycles observed - average Number of cycles - judgment call. 10 Time Study Allowances – Personal body needs (around 4-5%), interruptions (around 2-8%), and fatigue (025%). These allowances are called PF&D (Personal, Fatigue, and Delay) Typical PF&D allowance is 15%, but can vary from 8-35%. 11 Time Study PF&D is determined by the equation: 100% Fa 100% PF & D% 12 Pre-determined Time Data MTM (Methods, Time, and Management) – MTM most widely used method – Developed five generations of MTM systems for estimating – Subdivides operator motions into small increments / easily measured. – Drawback - time intensive - training Very common and powerful method 13 Man-hour Reports Time standards called standard data. Standard data - collected by company on its own operations for similar activities. Deal with non-repetitive work Reports are generated from job tickets or Foreman reports. Cost codes are assigned Cost database 14 Problem 2.9 a (pg. 70) Determine the standard labor hours per drawing. Man-hrs/Print = 7.0(1) + 19.0(1) + 38.0(2) + 1.5 (¼) + 27.0(½) = 115.875 min. Adding in the allowance (15%): 100% Fa 100% PF & D% 100% Fa 1.176 100% 15% 115.875 (1.176) = 136.27 min. or 2.27 hrs. (136.27/60) Standard labor hours per drawing: 2.27 hours 15 Problem 2.9 b (pg. 70) How many aids will be required for 2500 drawings, and with a $25/hr rate, what will be the budget request? Standard labor hrs required:136.27 min x 2500 = 340675 min or 5678 hrs (340675/60) Hours in a year: (52 wk/yr) (40 hrs/wk) = 2080 hrs/yr 5678 / 2080 = 2.73 or 3 aids will be required Budget needed: 5678 hrs x 25 $/hr = $141,950 or $142,000 16 Work Sampling Method to count how often certain events happen Statistics - normal distribution form Statistics - accuracy of our observations Number of observations made 17 Equations 2.10 & 2.11 on page 49 Eq. 2.10 Eq. 2.11 Ni 4Z 2 pi (1 pi ) I2 and: R.A. = I/2pi Where: N= sample size Pi= proportion of time spent on the activity we’re interested in I= Internal estimate; two values between which we have confidence that the true value of “p” will lie Z= a value form a standardized normal distribution table reflecting the confidence (interval) level Confidence Level: likelihood that the true value of “p” lies within “I” 18 R.A.: Relative Accuracy Problem 2.13 (pg. 71) How many observations are necessary? Given: Confidence level = 95%Z = 1.96 (from Z values on pg. 38) Relative Accuracy = +/- 5% Pi = idle time = 25% Ni 4Z 2 pi (1 pi ) I2 RA = I/2pi = I = 2pi RA (using Algebra) I = 2(.25)(.05) = .025 Ni = 4(1.96)² (.25) (1-.25) (.025)² Ni = 4610 observations 19 Problem 2.14 a (pg. 71) To get a 0.10 interval on work observed by work sampling that is estimated to require 70% of the worker’s time, how many random observations will be required at the 95% confidence level? 95% confidence level Z = 1.960(from Z values on pg. 38) I = .10 Pi = .70 Ni 4Z 2 pi (1 pi ) I2 Ni = 4(1.96)² (.7) (1-.7) (.10)² = 322.7 or 323 20 Problem 2.14 b (pg. 71) If the average handling activity during a 20-day period is 85% and the number of daily observation is 45, then what is the interval allowed on each day’s percent activity? Confidence level is 90%. Pi = .85 (handling) N = (45 obs/day) (20 days) = 900 obs Z = 1.645 (pg. 38) .85(1 .85) I 2(1.645) 900 1/ 2 = 0.039 or 3.9% For a confidence level of 99%, just plug in the new “Z” value. 21