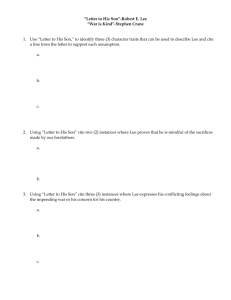

Control Systems EE 4314

Control Systems

EE 4314

Lecture 7

February 4, 2014

Spring 2014

Woo Ho Lee whlee@uta.edu

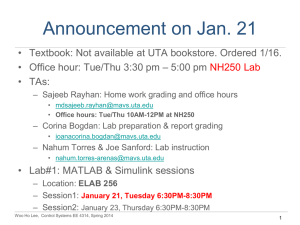

Announcement

• Lab#2: Identification of DC motor transfer function

– Location: NH250

– Feb. 4, Tuesday

• 101A (3:30-5:20PM)

• 102A (5:30-7:20PM)

– Feb. 5, Wednesday

• 103A (2:00-3:50PM)

• 104 (4:00-5:50PM)

• Class website: www.uta.edu/ee/ngs/ee4314_control

– Homework #1: Due by Feb. 6.

– Lab #1 report is due by Feb. 13.

– Lab #2 handout is posted.

Woo Ho Lee Control Systems EE 4314, Spring 2014

2

TAs Update

• TAs:

– Sajeeb Rayhan: Home work grading and office hours

• mdsajeeb.rayhan@mavs.uta.edu

• Office hours: Tue/Thu 10AM-12PM, Mon 4PM-6PM at NH250

– Corina Bogdan: Lab preparation & homework and report grading

• Email: ioanacorina.bogdan@mavs.uta.edu

• Office: NH250

– Joe Sanford: Lab lecture

• Email: joe.sanford@MAVS.UTA.EDU

• Office: NH250

Woo Ho Lee Control Systems EE 4314, Spring 2014

Labs Schedule

• Four Sessions (Total: 42 students)

Session 101: Tue: 3:30PM-5:20PM (12 students)

101A (6)

101B (6)

Session 102: Tue: 5:30PM-7:20PM (11 students)

102A (6)

102B (5)

Session 103: Wed: 2:00PM-3:50PM (12 students)

103A (6)

103B (6)

Session 104: Wed: 4:00PM-5:50PM (7 students)

Woo Ho Lee Control Systems EE 4314, Spring 2014

4

Labs #2 Schedule

Lab #2: NH250

– 101A and 102A: Feb. 4 (Tue)

– 103A and 104: Feb. 5 (Wed)

– 101B and 102B: Feb. 11 (Tue)

– 103B: Feb. 12 (Wed)

Tuesday

101 (3:30-5:20)

102 (5:30-7:20)

Wednesday

103 (2-3:50)

104 (4-5:50)

Woo Ho Lee Control Systems EE 4314, Spring 2014

5

Session (12)101A & 101B

101B 101A

X

X

Saad Akhtar

Sanjeeb Banjara

Asrat Beshah

Blake Farmer

Hawariya Gebremedhien

Nadim Giotis

Daniel Goodman

Leighlan Jensen

Kevin Oseguera

Prabesh Poudel

Eric Reiser

Caroline Storm

Woo Ho Lee Control Systems EE 4314, Spring 2014

X

X

X

X

X

X x

6

Session (11) 102A & 102B

102B

Laury Arcos

Matthew Barboza

Monica Beltran

Victoria Brandenburg

Israel Fierro

John Fierro

Haile Fintie

Samuel Luce

Blen Mamo

Nisha Shrestha

Christopher Williams

Woo Ho Lee Control Systems EE 4314, Spring 2014

102A

X

X

X

X

X

X x

7

Session (12) 103A & 103B

103A 103B

X Joshua Berry

Pasquier Biyo

Aaron Dyreson

Pursottam Giri

Prem Kattel

Gregory Martin

Bardia Mojra

Vihang Parmar

Abison Ranjit

Thyag Ravi

Sharad Timilsina

Hannah Vuppula

Woo Ho Lee Control Systems EE 4314, Spring 2014

X

X x

X

X

X

X

X

X

X

X

8

Electromechanical Systems

• Physics

– Law of motors: 𝐹 = 𝐵𝑙𝑖

• Convert electric energy ( i ) to mechanical work ( F )

– Law of generator: 𝑒 𝑡 = 𝐵𝑙𝑣

• Mechanical motion

electric voltage

Where 𝐵 : strength of magnetic field 𝑙 : length of a coil 𝑣 : velocity of the conductor

𝐹 : Force acting on the conductor 𝑒(𝑡) : voltage across the conductor

Woo Ho Lee Control Systems EE 4314, Spring 2014

Magnetic Force on Current Carrying Wire

• Force F = 𝑙 × B I

I : current

B : strength of magnetic field 𝑙 : length of a wire that carries current I through a magnetic field 𝑙

Woo Ho Lee Control Systems EE 4314, Spring 2014

Torque in Magnetic Field

• Force F = B𝑙I

• Torque T = 2F𝑎 = 2B𝑙aI = KtI

• Torque constant

K t

= 2B𝑙a 𝑙

F

I

I

F

B a =radius of wire loop

Woo Ho Lee Control Systems EE 4314, Spring 2014

Torque in Permanent Magnet DC Motor

• Torque T = 2nB𝑙aI = KtI

• Torque constant

K t

= 2nB𝑙a n=5 n = number of loops

Woo Ho Lee Control Systems EE 4314, Spring 2014

DC Motor

•

• Find dynamic equations

Find transfer function

𝑚 𝑣 𝑎

= 𝑑𝜃 𝑑𝑡

Woo Ho Lee Control Systems EE 4314, Spring 2014

Woo Ho Lee Control Systems EE 4314, Spring 2014

DC Motor

DC Motor Block Diagram

Woo Ho Lee Control Systems EE 4314, Spring 2014

Loudspeaker

• Force acting on moving mass

𝐹 = 𝐵𝑙𝑖 l=2a

n n : number of turns a : radius of core

𝐹

Woo Ho Lee Control Systems EE 4314, Spring 2014

Magnetic Levitation Model

• Applying KVL

• Applying Newton’s law

Woo Ho Lee Control Systems EE 4314, Spring 2014

Heat Flow

• Heat flow 𝑞 =

1

𝑅

(𝑇

1

− 𝑇

2

) q : heat energy flow (J/sec)

R : thermal resistance

T : temperature

• Relation between temperature of the substance and heat flow

𝑇 =

1

𝐶 𝑞

C : thermal capacity

Woo Ho Lee Control Systems EE 4314, Spring 2014

Heat Flow

• Find the differential equations that determine the temperature in the room 𝑇

1

(four sides are thermally insulated)

𝑇

1

Woo Ho Lee Control Systems EE 4314, Spring 2014

Heat Flow

• Find the differential equations that determine the temperature in the room 𝑇

1

(four sides are thermally insulated)

𝑇

1

=

1

𝐶

1

(−𝑞

1

− 𝑞

2

1

)=

𝐶

1

1

𝑅

1

𝑇

0

− 𝑇

1

1 1

+

𝐶

1

𝑅

2

𝑇

0

− 𝑇

1

1

=

𝐶

1

1

(

𝑅

1

+

1

𝑅

2

) 𝑇

0

− 𝑇

1

𝑇

1

Woo Ho Lee Control Systems EE 4314, Spring 2014

Water Tank Example

• Physics governing fluid flow

Continuity equation: 𝑚 = 𝑤 𝑖𝑛 where

− 𝑤 𝑜𝑢𝑡 m : fluid mass within the system ( 𝑚 = 𝜌𝑉 = 𝜌𝐴ℎ) w in

: mass flow rate into the system w out

: mass flow rate out of the system

Differential equation that governs the height of water

ℎ = 1 𝜌𝐴

(𝑤 𝑖𝑛

−𝑤 𝑜𝑢𝑡

) (1)

A: area of the tank 𝜌 : density of water h : height of water 𝑚 = 𝜌𝐴 ℎ

Woo Ho Lee Control Systems EE 4314, Spring 2014

Water Tank Example

• Fluid flow through an orifice

1 𝑤 𝑜𝑢𝑡

= 𝑝

1

− 𝑝𝑎 (2)

𝑅 where 𝑝

1

= 𝑔ℎ + 𝑝 𝑎

: hydrostatic pressure 𝑝 𝑎

: ambient pressure

• Substituting (2) into (1) gives

ℎ = 1

(𝑤 𝑖𝑛

−

1

𝑅 𝑝

1

− 𝑝𝑎 ) (3) 𝜌𝐴

• Linearization involves selecting the operating point 𝑝

1

= 𝑝 𝑜

+ 𝑝 (4)

Woo Ho Lee Control Systems EE 4314, Spring 2014

Water Tank Example

• Substituting (2) into (1) gives 𝑤 𝑜𝑢𝑡

=

1

𝑅 𝑝 𝑜

1

− 𝑝𝑎 =

𝑅

𝑝 + (𝑝 𝑜

=

= 𝑝 𝑜

−𝑝𝑎

𝑅 𝑝 𝑜

−𝑝𝑎

𝑅

𝑝+ (𝑝 𝑜

−𝑝𝑎)

[1 +

2 (𝑝 𝑜

= 𝑝 𝑜

1

−𝑝𝑎

𝑝

−𝑝𝑎)

] p o

−pa

R

−𝑝𝑎)

1 +

𝑝

(𝑝 𝑜

−𝑝𝑎)

(5)

• Substituting (5) into (3) gives

ℎ =

1 𝜌𝐴

(𝑤 𝑖𝑛

− 𝑝 𝑜

• Since

𝑝 =

𝑔

ℎ

−𝑝𝑎

𝑅

[1 +

1

2 (𝑝 𝑜

𝑝

−𝑝𝑎)

]) (6)

ℎ =

−𝑔

2𝐴𝑅 𝑝 𝑜

−𝑝𝑎

ℎ + 𝑤 𝑖𝑛

𝐴

− 𝑝 𝑜

−𝑝𝑎

𝐴𝑅

Woo Ho Lee Control Systems EE 4314, Spring 2014

Hydraulic Actuator with Valve

• Find nonlinear differential equations relating the movement

of the control surface to the input displacement x of the valve.

Fluid in

Fluid out

Input

Output

Woo Ho Lee Control Systems EE 4314, Spring 2014

Hydraulic Actuator

• Flow goes inside of piston

𝑄

1

1

= 𝜌𝑅

1 𝑝 𝑠

− 𝑝

1 𝑥

• Flow come out of piston

𝑄

2

1

= 𝜌𝑅

2 𝑝

2

− 𝑝 𝑒 𝑥

• Continuity relation

𝐴 𝑦 = 𝑄

1

= 𝑄

2

A: piston area

• Force equation

𝐴 𝑝

1

− 𝑝

2

− 𝐹 = 𝑚 𝑦 m : mass of piston and attached rod

• Moment equation

𝐼 𝜃 = 𝐹𝑙 cos 𝜃 − 𝐹 𝑎 𝑑

I : moment of inertia of the control surface and attachment

• Kinematic relationship between

and y

Woo Ho Lee Control Systems EE 4314, Spring 2014 𝑦 = 𝑙 sin 𝜃

Key Equations for Dynamic Models

• Mechanical system

– Newton’s 2 nd law (translation):

F = ma

– Newton’s 2 nd law (rotation):

M = I

– Hook’s law: F=kx

• Electrical system

– KCL (Kirchhoff’s current law):

𝐼 in

=

𝐼

– KVL (Kirchhoff’s voltage law ):

V out closed loop

=0

– Ohm’s law

• Electromechanical system

– Law of motors: 𝐹 = 𝐵𝑙𝑖

Convert electric energy ( i ) to mechanical work ( F )

– Law of generator: 𝑒 𝑡 = 𝐵𝑙𝑣

Mechanical motion

electric voltage

– Torque developed in a rotor: T = 𝐾 𝑡 𝑖

– Back emf: 𝑒 = 𝐾 𝑒

𝜃 𝑚

Woo Ho Lee Control Systems EE 4314, Spring 2014

Chapter 3: Block Diagrams

• Block Diagram Model:

– Helps understand flow of information (signals) through a complex system

– Helps visualize I/O dependencies

– Elements of block diagram:

• Lines: Signals

• Blocks: Systems

• Summing junctions

• Pick-off points

U(s)

H(s)

Y(s)

U1

+

U2

U1+U2

Transfer Function Summer/Difference

Woo Ho Lee Control Systems EE 4314, Spring 2014

U

U

Pick-off point

U

Three Examples of Elementary Block Diagrams

(a) Cascaded system G

1

(s)G

2

(s) (b) Parallel system G

1

(s)+ G

2

(s)

(b) Negative feedback system

Woo Ho Lee Control Systems EE 4314, Spring 2014

𝐺

1

(𝑠)

1 + 𝐺

1 𝑠 𝐺

2

(𝑠)

Block Diagram: Simplification Rules

=

=

Woo Ho Lee Control Systems EE 4314, Spring 2014

Block Diagram: Reduction Rules

=

=

Woo Ho Lee Control Systems EE 4314, Spring 2014

Block Diagram Simplification

• Example: Simplify the block diagram

Woo Ho Lee Control Systems EE 4314, Spring 2014

Woo Ho Lee Control Systems EE 4314, Spring 2014