- Victoria Hands (LSE) and Kara Jones (WRAP)

advertisement

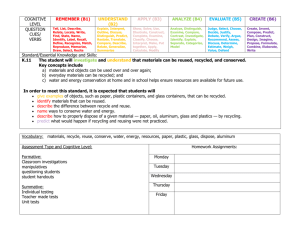

Closing the Recycling Loop in University Halls of Residence Victoria Hands Environmental & Sustainability Coordinator, London School of Economics London’s University Halls of Residence Recycling Project Founder Outline Background Why halls of residence Reuse - end of term schemes Recycling – win win win scenarios Purchasing • Reuse to reduce purchasing • Buy recycled to close the loop Benefits for Halls of Residence • Potential waste management cost savings • Response to increased student demand for recycling facilities • Empowering residents to be aware • Reducing end of term waste peak • Providing low or no cost items Benefits for Universities • Competitive advantage for attracting students and staff • Contributing to high environmental standards • Demonstrating social responsibility • Backing up academic expertise with everyday practice Benefits for Local Authorities • Meeting government recycling targets • Extending recycling provision • Creating a healthier environment Why Halls of Residence? • • • • • • • • • High density Waste audit - 50-70% recyclable Life change Contractual obligations Established communications Backing up teaching Habitual behaviour Vocal active students Role out across campus!! The Waste Hierarchy REDUCE Halls can reuse & buy recycled content REUSE Halls save on waste disposal & purchasing and extend service provision RECYCLE Halls can access free or low cost recycling LAST OPTION LANDFILL A Practical Approach • • • • • • Identification of stakeholders Background research Initial contact Interviews / questionnaires / reports Partnership building & dialogue Contact sheet & monitoring Key Stakeholders • Local Authorities (recycling officers) • Waste management division • Universities (environmental manager) • Academic • Operational • Students union • Halls of Residence (management) • Cleaners • Students Project Origins Experiences from: • Students • Cleaning staff (including contractors) • Hall management • Universities • Local Authorities • Reuse charities The Waste Paper, issue 68 October 2000 Reuse Schemes • Reuse Implementation Plan – (RIP Waste) • Notices • Collection points • Sorting and volunteers – Types of donations • Liaison with charities – Hostels, reuse, London Remade • Cleaning up Reuse Donations • • • • • • • 1 box of cutlery, 1 box of utensils 3 boxes of plates, 4 boxes of pans 40 black bin bags of men’s clothing 10 toasters, 11 kettles 2 computers, 8 screens 30 drying racks, 40 dish drainers 8 computer chairs Reuse Scheme 2005 • 10 halls of residence – 3,748 students • Estimated reuse participated rate: 10% - 300 students • 6 tonnes diverted from landfill – 20 kg per student (textiles, IT equipment, furniture) Textiles 2005: 650kgs from 650 students Estimated 65 participants = 10 kg of textiles per student Recycling • Waste audit – 20% paper/card – 18% compostable – 14% glass – 13% plastic – 4% cans Start of term most effective Design Challenges • Micro kitchens and source separation – Same as other urban MODs – Small on floorspace – Could look good/trendy/cool – Reuse is real use!! – Standard source separation does not respond to the reality of micro living Design Challenges • Design of new halls of residence and greening the campus – Sustainable living – Energy, water, waste – Responsibility and empowerment • Refurbishment of older halls of residence – Often without lifts Action Plan 1. Recycle • Facilities and collections (external & internal) 2. Reuse • End of term schemes and collaborations 3. Raise Awareness • Communication materials (kitchen posters, student tips leaflet) • Events with users (freshers fayres) and staff training 4. Reduce • Green procurement • Influence student purchasing power Findings Issues Findings Responsibility Responsibility to take out recycling materials given to students. Results in full learning experience and responsible actions. Cleaners and all hall staff have a new learning experience to take into their non-working lives. Ease Recycling is not difficult if good infrastructure and effective awareness raising is provided. In fact, waste is easier to manage. The benefits of segregated waste include reduced odour. Costs Low or no cost because of recycling targets set for local authorities by Europe Kitchen space Most kitchens do have space for recycling containers. There are many designs of bins. New builds must design in recycling provision. External space In many central London halls space is limited to the pavement (also used by public-difficult to assess). Wheelie bins may be an option here. Champions High rotation of students and local authority staff but continuity can be found through wardens, managers and local councillors. London Boroughs Universities / Intercollegiates Barking & Dagenham Barnet Camden Ealing Enfield Greenwich Hackney Hammersmith & Fulham Haringey Hillingdon Islington Kensington & Chelsea Kingston Upon Thames Lambeth Lewisham Richmond Upon Thames Southwark Tower Hamlets Wandsworth Westminster Total 1 Halls of residence No. of Students Estimated No. of Kitchens 1 2 5 1 1 2 5 2 5 1 5 3 1 2 2 1 4 3 3 8 1 5 33 1 4 5 5 2 8 8 13 11 4 4 7 1 14 24 25 18 508 1,007 6,620 331 815 1,480 642 261 795 2,661 2,574 906 2,212 726 1,127 218 4,928 1,536 3,414 3,710 85 168 1,103 55 136 247 107 44 133 444 429 151 369 121 188 36 491 256 569 618 57 193 36,471 5,748 38,295 6,382 Total 1 + 5% Cost of reusable bags £0.97 per unit for quantities over 1000 £ 6,190 Cost of reusable box £4.99 per unit £ 31,848 Cost of convert bins £14.95 per unit £ 95,417 Closing the Loop Reuse - end of term schemes Recycling – win win win scenarios Purchasing • Reuse to reduce purchasing • Buy recycled to close the loop • National support?? London’s University Halls of Residence Recycling Project www.crispej.org.uk/hallsrecycling Victoria Hands v.e.hands@lse.ac.uk Closing the loop by procuring higher recycled content in paper and construction EAUC Annual Conference - 11 April 2006 Jim Wiltshire - Procurement Project Manager Kara Jones – WRAP Paper Advocate Outline ● About WRAP ● Materials resource efficiency - why recycled ● Using procurement ● The opportunities in paper ● The opportunities in construction ● WRAP assistance WRAP exists to Create stable and efficient markets for recycled materials and products, and Remove barriers to waste minimisation re-use and recycling Closing the loop – why specifying recycled is so important Business investment and development Specifying recycled in procurement of goods, works and services Product development Waste segregation, home composting etc. CREATING ECONOMIC VALUE FOR RECOVERED MATERIALS Waste awareness and minimisation Materials resource efficiency Materials resource efficiency cycle Materials efficiency Reduce raw material use Save resources Materials with recycled content Recycling Reduce waste Reduce landfill A two thirds reduction in consumption of fossil fuels and virgin materials is needed to achieve a sustainable and globally equitable level WWF – “One planet living study” - 2004 What are we talking about? Reclaimed materials Waste minimisation, segregation & recycling Materials Resource Efficiency Renewables Recycled Content Procurement policy drivers Landfill Tax (1996) ODPM-PPS1 Govt. Sustainable Procurement Group Scottish Executive Policy Commitment 2003 OGC-AE11 SBTG Buying into Sustainable Procurement (WPI) 2004 Code for Sustainable Homes Scottish Executive Policy Proposal 2005 Increasing thrust of sustainability policy 2006 Where do we start ? - major applications to consider Construction Estates management Printed matter Tissue – catering and hygiene Using procurement Identifying need Requirement specification Supplier selection Tender evaluation Contract management Key point of intervention European Commission handbook on environmental public procurement: “As a contracting authority, you have the right…to demand a minimum percentage of recycled and reused content where possible”. OGC AE11: “The (project) brief should include an outcome-based requirement for overall materials efficiency, such as a minimum requirement for recycled content in the project .” Kara.Jones@wrap.org.uk Recycled content office & publication papers for your organisation Why? 11th Apr-06 To cover: • • • • Paper waste context Why?......... environmental Why?......... CSR / marketing Why?......... quality and cost • Product range • How the Advocate Team can help Paper waste in context • UK > 100,000,000T commercial, industrial & municipal waste per year. • UK consumes approx 12,800,000T paper & board • We recycle approx 7,000,000Tpa of paper & board • But…….. More than 5,000,000Tpa still goes into landfill • Landfill over 1,500,000T of paper from offices per year • Less than 4% of office / marketing / business papers have any recycled content Landfill / incinerate or recycle ? • Landfill sites are filling up • Landfilled paper produces methane and leakage contributes to global warming • Waste incineration not optimum and a long planning cycle • Landfill or incineration is a waste of a valuable resource • Most LCA’s show recycling is best • We can recycle - economically • Now a legal requirement to reduce landfill = Recycle Your customers are aware.. • National and EU push to increased recycling • Increased recycling and promotion: – Rolling out more kerbside collection – National advertising – Local advertising • Government announcements on environmental issues and sustainability • Increasing central and local government sustainable procurement • Constant press coverage on all things environmental In the media… In the media… In the media… Why buy recycled content paper?......... Recycling = “collection” + “buy-recycled” Your impact The prime “buy-recycled” argument is not about…. saving trees …is about avoiding…. landfill Why?......... Environmental Landfill, methane production… also: • Recycled paper also typically: – uses less energy in production – creates less VOC’s, – uses less transport miles – has a significantly smaller “environmental footprint” – reduces pressure on forest resources Why?.... CSR / marketing Your customers: • Your “customers” are increasingly being asked to recycle • 50% of the population describe themselves as “committed recyclers” (source NOP tracking survey Mar 2005) • Recycled / recycling is seen as “good”. Opportunity to be associated with a positive feelings such as: – – – – • caring future looking ethical doing your bit… Universities, and other higher education authorities, are seen as exemplars, providing education, values and the future for the next generation Why?.... CSR / marketing Stakeholders / Investors • Corporate Social Responsibility (CSR) a necessity for high profile organisations • Purchasing recycled materials is a positive action. • >50% of your staff are committed recyclers, positive reinforcement of your organisational values • Supporting government commitment to sustainable procurement • Recycled content paper is: – a “quick” win – A demonstration you are doing something So what is available? • • • • • • • Paper for printed publications Magazine papers Envelopes Copier / printer paper Tissue papers Boxes ……….. Why?....... quality and cost • You do not need to compromise “quality” by procuring recycled content papers – full colour publication papers – office papers • Technical developments have significantly improved the performance and cost of recycled papers – brands are readily available which match the performance of virgin papers. – need not pay more • You can have a “traditional recycled look” if you want It doesn’t have to be 100% recycled Suggested minimum specification for recycled content. • Copier / Office paper 70% • Printing Papers 50% (for marketing and publications) • Tissue 100% What is recycled content? • Post & pre-consumer waste. • Not mill broke How WRAP can help you • Advocacy team one2one support – Advice on product availability – On effective specification and policy for recycled content – Technical advice – Facilitate trial material. – Free – Provided by a team experienced in paper and print • Procurement guides: – Recycled content Office and publication papers – Recycled content Tissue papers – Recycled content Business process papers • Case studies • Technical information sheets • …… Summary Recycling = “collection” + “buy-recycled” Recycled paper: – Same quality – Need not cost more – Reduces landfill – Supports your CSR and marketing You could say…. …. using recycled paper is a no brainer! thank you The case for recycled in construction Materials efficiency in construction M tonnes Overall material consumption by construction industry (~420 Mt per year) Quantity of construction and demolition waste generated (~90 Mt per year) Waste construction materials that are recycled (~45 Mt per year) Headline Construction Figures One of the UK’s most productive sectors, contributing almost 9% to the GDP 50% UK energy consumption associated with buildings – construction & use 90% non-energy minerals extracted used in construction - <1% new buildings uses reclaimed materials Biggest consumer of material resources: 420 million tonnes/year KEY SUSTAINABILITY GOALS Energy Materials Minimising environmental Efficient use of finite damage natural materials Material & Product selection Water Material use & waste management Using locally sourced CDW Waste avoidance and minimisation Use products with high recycled content Return packaging & reduce over-ordering Use of renewable materials Collection segregation & recycling Specifying materials with low env impact Mainstream, not green Many mainstream products already include recycled content A range of products offer above-average recycled content at no extra cost The potential for diversion from landfill is substantial Mainstream brands 0% Recycled content Eco-brands Quick Wins Where will we find Quick Wins that are . . cost-effective with comparable performance and readily available? Many examples in Concrete blocks Asphalt Paving slabs Bricks Flooring Various aggregate Ceiling tiles Chipboard Plasterboard Insulation Roof tiles products Examples of mainstream products available Product type Option with lower recycled content Dense block 0% Hanson Conbloc - Up to 70% Wall insulation 0% Superglass Superwall Cavity Slab > 80% Concrete roof tile 0% Lafarge – various, e.g. Grovebury - 17% >10% Armstrong – various – 28 to 52% 50-70% Sonae – Sonaefloor – 90 to 95% Ceiling tiles Intermediate floors, e.g. timber Option with higher recycled content Project specific example Floor coverings – safety 0% BSW Regupol Everroll rubber flooring - 80% Using your procurement strategy to drive resource efficiency Sustainable Buildings Task Group: Specify 10% or higher minimum requirement for recycled content as a proportion of the value of materials for the whole project You can also encourage higher performance e.g. through tender evaluation criteria What is being achieved without asking for good practice? Type of project Detached/terraced house Commercial office School, hospital Road reconstruction Bridge reconstruction * Excluding building services Baseline/ actual practice % 6 - 26 10* - 22 12* - 20 8 - 16 18 - 23 Cost neutral good practice % 16-29 12*-30 15*-27 27-29 33-49 Housing example Standard/actual practice Good practice Timber-framed house, Hillcrest HA 7% 15% Timber-framed house, Milnbank HA 12% 21% Brick/block house, Taylor Woodrow 16% 20% – 28% (cost-neutral) Steel framed housing example Standard practice 20 – 23% As built specification 23 - 25% Good practice 26 – 29% Best practice 30 – 31% Product type Base case Insulation – Roof 0% General fill 0% Insulation wool – 50% external walls facing Brick 5% Quick Win 80% 50- 100% 70% 11 – 20% Evidence base - DfES Exemplar designs for schools Design S2 - Suburban edge of town setting Design S5 - Inner city sites City Academy, Brent – Recently completed Design S2 Design S5 City Academy, Brent Build cost of school £M 14.1 15.1 12.2 Approx value of materials £M 3.3 3.7 3.6 % recycled content – Standard practice 15.5% 17.3% 12.9% % recycled content – Product substitution 18.1% 21.2% 15.6% 400 490 830 3100 4800 4300 Tonnage avoiding landfill – Standard practice Tonnage avoiding landfill – Product substitution Case study – Glasgow school Best opportunities to increase recycled content Where Glasgow When 2004 Building Camstradden Primary School General fixtures, furnishings and equipment, flooring (inside) Plasterboard dry lining, partitions, ceiling (inside) Asphalt Total £3.4m construction works value Total materials value Excavating and filling £2m Interlocking brick, block roads, paving Mixing, casting, curing in-situ concrete Drainage below ground Quick Wins Top Quick Wins Coated macadam/Asphalt roads/Pavings Rubber/Plastics/Lino/Carpet tiling Actual (£) Readily achievable (£) Mixing/Casting/Curing in Situ concrete Excavating and filling Interlocking brick/Block roads/Pavings Plasterboard dry lining/partitions/ceilings Drainage belowground 0 10000 20000 Recycled Content Value £ 30000 40000 Who is taking action? Adopted minimum 10% value requirement Glasgow City Council Bristol City Council Aberdeen City Council Whipps Cross Hospital Dundee City Council Lancashire County Council Newcastle City Council Building Schools for the Future (BSF) Solihull MBC Raploch URC Sheffield CC Who is taking action? Increasing the use of recycled content BAA British Land Ely Bridge Worcestershire CC Yorkshire Forward Major supermarkets Major housebuilders - Redrow Glamorgan Gwent HA How WRAP can help WRAP assistance RC Toolkit Case studies Procurement advice Site waste management Demolition guidance Web resources AggRegain, tools, research reports Trailblazer projects Events Toolkit – data requirements Material Resource Efficiency in Construction www.wrap.org.uk/construction Publications & guidance Quick Win & Procurement guidance documents Housing Quick Wins Preliminary works General building Office & commercial refurbishment Highways maintenance Councillor briefing documents Resources for procurement Construction procurement template wording: Design/project brief Appointment of design team Supplier pre-qualification and audit Tender specification (D&B, traditional) Contract clauses Construction product listing For further information Thank you! www.wrap.org.uk/construction jim.wiltshire@wrap.org.uk