APTA Media Presentation - Engineered Machined Products

advertisement

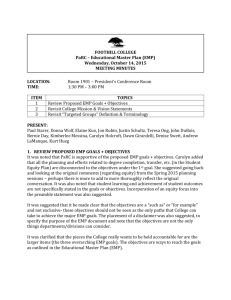

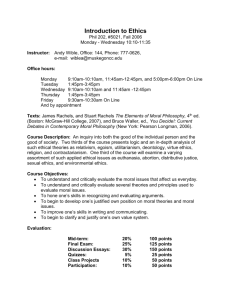

APTA Media Presentation Mini-Hybrid & Power 450 Company Overview Established 1981 Current Employment ~500 2007 Sales ~$130M Precision Machining Facility, Escanaba, MI Assembly Facility, Greenfield, IN Engineering, Validation, Assembly Facility, Escanaba, MI (Mini-Hybrid Production) TS and Six Sigma certified Current OEM Customers: Caterpillar, International, Sauer Danfoss, John Deere, Cummins, DDC/Freightliner, Volvo/Mack, Eaton, Newflyer, Paccar, Misc. Key Awards: 2001, 03, 04 Design News Award for Electric Pump, Advanced Filter, Electric Thermostat/Valve 2001 Michigan Manufacturer of the Year, 2005 R&D Excellence in Business Award EMP CONFIDENTIAL APTA Press Releases October 6, 2008 • Going Green, Without Going into the Red – Launching mini-Hybrid cooling system cost effective alternative to full hybrid systems • EMP Collaborates with New Flyer Inc. on Launch of mini-Hybrid Cooling system – Industry leader New Flyer first to offer factory installed mini-Hybrid cooling system • EMP Launches 450 Amp/24 Volt Brushless Alternator for Transit Bus Markets – 280 amps at engine idle, “More power were you need it” APTA Press Releases October 6, 2008 • EMP Announces New Model Applications for mini-Hybrid Cooling Systems – EMP releases 3 kits covering most aftermarket applications and 2007 ISL diesel engine(both factory and aftermarket) • EMP Electric Pump Improves Passenger Comfort – New brushless DC circulation pump for transit market, half the weight & cost while delivering more power • EMP Collaborates with BAE Systems on Next Generation Hybrid Energy Transit buses – EMP provides cooling modules, brushless DC fans and Oil Pump • EMP launches new and approved web site – www.emp-corp.com What is in a Mini-hybrid? Components included in MiniHybrid Base Kit: • (8) EMP F11 24 Volt Pusher Fans • (8) EMP C20 Fan Controllers • (1) EMP CS20 System Controller • (1) Radiator • (1) Charge Air Cooler • (1) Powder coated Steel Frame & Fan Shroud • Jacket Water & Charge Air Temperature Sensors •(1) Power 450 Alternator Optimized Radiator and CAC Power 450 CS-20 System Controller F11 Electric Fans C-20 Fan Controllers Current Mini-Hybrid Sites How Does It Work? Mini-Hybrid (MH8) is an electric only fan system that replaces traditional mechanical fan. MH8 is electronically controlled to cool both charged air and engine coolant separately. MH8 is independent of engine speed and control - capable provide full load cooling at engine idle. 2 1 4 5 Shared Fans 3 6 Charged Air Cooler Fans 8 Engine Coolant Fans 7 CAC Radiator Fuel Consumption Fuel Savings - MARTA Study MH8 provides more fuel savings throughout the engine rpm range. Typical fuel economy ranges from 3% to 10% based on duty cycle, climate, and engine type. Average Fuel Economy Improvement With EMP Mini-Hybrid System 0.08 7% 0.07 Fuel Savings 0.06 0.05 0.04 3% 7 0.03 0.02 0.01 0 Winter Summer Power to the Wheels! Put the power where you need it, at the wheels. MH8 provides up to an additional 50 HP at the wheel. At the second speed setting of (1800 rpm) of the MH8 kit has less parasitic loss than the mechanical fan turned off! Horsepower Delivered to Wheels 300 Engine Data Sheet 275 Electric System Engine Power (HP) 250 Conventional System 225 200 175 150 125 100 75 50 25 0 Peak Power Peak Torque Power Savings Noise and Weight Advantages The Mini-Hybrid fans run under 2000 rpm the majority of the time. At this level, the cooling system produces only an additional 2 dBA over fan off mode. With the removal of the hydraulic pump, fluid, fan, etc., MH8 is a 300 lb weight savings over the conventional cooling system. Curb Side Quite RPM Fan Speeds and Full Load Cooling MESA and Phoenix Bus History Data Fan Operation Percent of Time at Fan Speeds 100% 90% 90% 160 80% 80% 140 70% 60% 120 Mesa 8-months 100 WMATA - 9 months 50% MARTA - 12 months 80 40% 60 30% TriMet - 14 months Amps 30% 20 10% 0 0% 3000 4000 5000 120 40% 10% 2000 130 50% 20% 1000 140 60% 40 0 150 70% 20% 0% 160 110 LAT During Test 180 % Time Engine Speed 100% Engine RPM Cumulative RPM LAT Conventional LAT EMP 100 500 1000 1500 2000 90 2500 Engine RPM RPM Fan Speed % Time On Off 19.3% 750 RPM 30.6% 1813 RPM 27.1% 2875 RPM 20.5% 3938 RPM 2.0% 5000 RPM 0.7% 5500 RPM 0.0% 99% of the time, cooling system demand is less than 125 amps 97% of the time, cooling system demand is less than 71 amps 76% of the time, cooling system demand is less than 34 amps 49% of the time, cooling system demand is less than 15 amps Safety, Maintenance, Diagnostics Mini-Hybrid reduces thermal events by eliminating the hydraulic fan system. Maintenance is easy with manual reverse feature. Also, MH8 comes with both a diagnostic light and service technician tool. Reversal Push Button Diagnostics LED Visit EMP at APTA Booth APTA San Diego, October 2008 • Booth 7443, 20’ x 30’ display area • Featuring MiniHybrid (MH8), Power 450, WP29 Recirculation pump • Key feature: MH8 full cooling module simulation with diagnostic feedback • Stop by the EMP booth for a live demonstration Top 5 Facts about Mini-Hybrid 1. 2. 3. 4. 5. Reduces parasitic loads on engine providing better fuel economy, reduction of green house gases and more power to the wheels. MH8 operates on over 150 Transit buses in 20+ properties, accumulated 2 million miles the last 2 years. EMP components have been designed and validated for Military and Off-Highway applications. Mini-Hybrid all but eliminates hydraulics providing a safer and easier maintainable cooling system. MH8 payback is less than 18 month, see your EMP Regional Sales Manager for details