Introduction - Techno Materials

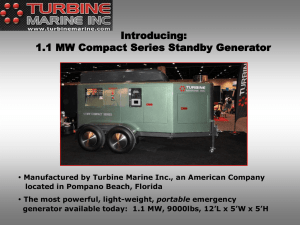

advertisement

A Presentation On Construction Of Turbo Generator contents Introduction Working principle of turbo generator Types of turbo generator General components of turbo generator Manufacturing process of conductors Testing of turbo generator Introduction A turbo generator is a mechanical device that is used to produce electrical power. It does so by turning a large turbine that is connected to a generator, which converts mechanical energy into electrical energy. They are mostly used as large capacity generator driven by steam/gas turbine. They are of three types namely:1. Steam turbine generator 2. Gas turbine generator 3. Hydro turbine generator Working principle of turbo generator The generator works on the principle of ELECTROMAGNETIC INDUCTION. A turbo generator is a turbine directly connected to the shaft of an electric generator, when a turbine is attached to the electrical generator the kinetic energy of the steam pushes against the fan-type blades of the turbine, causing the turbine, and therefore the attached rotor of the electrical generator, to spin and produce electricity. Working principle of Turbo Generator Types of turbo generator According to cooling system turbo generator are divided asi. THRI ii. TARI iii. THDI iv. THDD v. THDF vi. THFF T = turbo generator H/A = the cooling media used i.e. hydrogen gas or air. R/D/F/I = the type of cooling of rotor i.e. radial, indirect, forced, direct I/D/F = the type of cooling of stator i.e. indirect, direct, forced. The General Components of a turbo generator: Stator Stator frame Stator core Stator winding Bushing Excitation system Rotor Rotor shaft Rotor winding Retaining ring Rotor wedges Rotor fan Stator frame Stator body is totally enclosed gas tight fabricated structure made up of high quality mild steel and austenitic steel. It is the heaviest section in the generator. It also help to reduce vibration and to withstand the gas thermal pressure. Stator core Stator core is consists of thin lamination. Each lamination made of number of individual segment. Each lamination layer is made of individual section. The main feature of core areTo provide mechanical support. To carry efficiently electric, magnetic flux. In order to reduce hysteresis losses steel alloy is used for building up of core. In order to reduce eddy current thin laminations are used. Assembly of Core Stator winding Stator winding has a three phase, double layer winding with the pitch of the winding so adjust as to reduce the 5th and 7th harmonics . Each slots accommodated two bars. Each bar consists of solid as well as hollow conductor with cooling water passing through the latter. Alternate arrangement hollow and solid conductors ensure an optimum solution for increasing current and to reduce losses. Two types of bars are used- a) Upper bar b) Lower bar Bushing The beginning and ends of the three phase windings are brought out from the stator frame through bushings, which provides for high voltage insulation. The bushings are bolted to the stator frame at the exciter end. Rotor Shaft The rotor shaft is a single piece solid forging manufactured from a vacuum cast steel. Slots are made over it. Approximately 60% of the rotor body circumference is provided with longitudinal slots , which holds the field winding. Rotor winding The slots houses the field winding consists of several coils inserted into the longitudinal slots of rotor body. The coils are wound so that the two pole are obtained . The conductor are made up of copper with a silver content of approximately 0.1%. The rectangular cross section copper conductor have ventilating ducts on the two sides thus providing a channel for hydrogen flow. Rotor wedges: The rotor of turbo generator is rotating at a very high speed therefore to protect the winding against the effects from centrifugal forces they are secured firmly by rotor slot wedges. The slots wedges are made of copper alloy . Retaining rings: To protect the end winding of rotor from flying out from rotor due to centrifugal forces rotor retaining rings are used. Retaining rings are made from high tensile non- magnetic alloy steel forgings in order to reduce stray losses . Rotor fan The cooling air in generator is circulated by axial fans located on the rotor shaft. In 250 MW rotor two axial flow fans are located on both turbine as well as exciter end side whereas in 500 MW axial fans are located on turbine end side only. Assembly of Turbo Generator After the manufacturing of both the stator and rotor, these are assembled together on assembly bed. Excitation System The process of generating a magnetic field by means of an electric current is called excitation. Turbo generator is a doubly excited machine. The purpose of excitation system is to continuously provide the appropriate amount of D.C field current to the generator field winding. Mostly brushless excitation is used. The brushless exciter has mainly two parts such as1. permanent magnetic pilot exciter 2. three phase main exciter Cooling system 1. 2. 3. Cooling system is used to dissipate the heat generated by various losses and to prolong the life of insulating material. Cooling system is divided three parts such asAir cooling Hydrogen cooling Water cooling Manufacturing process of conductors 1. 2. 3. 4. 5. 6. 7. Insulation check Conductor cutting Transposition Cross over insulation Stack Pressing Forming End Conductor cutting 8. Pickling process 9. Brazing of coil lugs 10.Contact sleeve mounting 11.Reforming 12.Impregnation 13.Insulation 14.Finishing Testing of turbo generator ELECTRICAL TEST: Open circuit test Short circuit test High voltage test Inter strand test MECHANICAL TEST: Vibration test Temperature test Helium test Thank you