Unit Operation Lab

advertisement

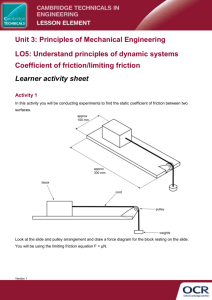

Unit Operation Lab K S Chou Ch E, N T H U 1 A: Fluid Flow Experiments A1 - Friction Coefficient in Tubes A2 - Flowmeters Types of flowing fluid: gas (natural gas), liquid (tap water), solid, bubbled liquid, slurry, gas-solid (fluidization), solidliquid-gas system; Fluid flow: transportation friction coefficient, viscosity, pressure drop, power required for transportation, choice of pumps, choice of tubes; 2 Fermentation reactor: one example of solidliquid-gas system 3 PT ( 壓力計) 90º elbow PT (壓力計接頭) Straight pipe 180º elbow water Trap Storage tank T0 PT T0 PT PI PI Buffer tank rotameter Orifice meter PI pump Globe valve 45º elbow flange Reduction Enlargement Ball valve Venturi meter Expansion Gate valve Contraction 流體流動實驗裝置圖 4 Fundamentals Pipes are connected by: screws, welding, flanges; materials: many choices such as steel, PP, PVC, glass, ceramics etc; Pipe specs: size, wall thickness; nominal value for diameter may have different meaning for different pipes (outside, inside, none above); often follow some standards such as IPS, NPS; Selection of pipe size: mainly due to cost: material, installation, flow rate, density characteristics; power required; (cost ~ dia^1.5; power ~ dia^-4.8) Fluids are powered by pumps; 5 Friction Coefficient Bernoulli eq. (incompressible fluid, steady state condition) Pa/ + g Za/gc + a Va2/2gc = Pb/ + g Zb/gc + b Vb2/gc + hf pressure energy + potential energy + kinetic energy + frictional loss = total energy simplest case: pressure drop = frictional loss (Pa – Pb)/ρ = hf 6 fD = 4 fF = 4 Fw/(A K) where fD = Darcy’s friction factor; fF = Fanning friction factor; Fw = friction force; A = area of flow; K = kinetic energy/vol; Taking circular tube as example: fF = (-ΔP g D) / (2 ΔL ρV2)…. Get data on the right hand side to calculate friction factor In general: f = f(e/D, Re) e = surface roughness of tube wall; Re = d u ρ/; changes in both velocity and viscosity would change Re For laminar flow: fD = 4 fF = 64/Re For turbulent flow: (depending on smoothness of tube) ex. smooth tube 1/√fF = 4.06 log (Re √fF) + 2.16 7 Function of surface roughness 8 fittings: splits, bend, elbow, U-tube, flanges, valves, etc different loss due to different designs empirical correlations are used mostly General expression hf = Kf Va2/2 gc, with Kf as an empirical friction coefficient Total friction loss = friction in straight tube + due to contraction + due to expansion + due to various fittings for this experiment 9 Various Flowmeters orifice meter, Venturi meter, rotameter, etc. discharge coefficient = f(Re); for orifice meter: Vo = Co √(2 gc P/) 圖A2-2 銳孔流量計之流出係數與Re關係。 其測 壓點屬corner tap 10 Venturi flowmeter and its discharge coefficient Vo= Cv/√(1-4) √(2 g (ΔP/) = (d/D) 11 12 Pictures from Google to show different design of rotameter 13 Other Types of Flowmeters Magnetic flowmeter: used for dirty fluids or slurry, such as waste water; no moving part; based on Faraday principle: voltage generated E ~ V * B (magnetic field strength) * D (length of conductor) Claim to account for 20% of all flowmeters Taken from: Omega Engineering Technical Reference 14 Ultrasonic Flow Meter non-invasive; two types: Doppler type (frequency shift ~ velocity) and transit time type (t ~ velocity) taken from Flow meter directory 15 Electromagnetic Flowmeters CEP, May 2010 Advantages: no pressure drops; no moving parts subject to wear; linear output over a wide range of velocities; Disadvantage: fluid has to be conductive; often have temperature limits; (mho = 1/ohm) One of the key technology: keeping magnetic field constant ; electrode material will contact process fluid and cleaning fluids (compatible issue); 16 Universal flow monitors (UFM) webpage 17 18 Consideration: Durability, pressure loss, control ability etc. Check valve: one direction flow 19 Pump performance: (taken from Walrus webpage) 20