doc no. - Radiation To Electronics (R2E)

advertisement

CERN

LHC Project Document No.

LHC-LJ-EC-

CH-1211 Geneva 23

Switzerland

EDMS Document No.

the

Engineering Change requested by ( Name & Div./Grp. ) :

Large

Hadron

Collider

A. L. Perrot / EN-MEF, R2E Project

project

Date: 3/12/2016

The 2Figures

…a n

Engineering Change

Request

– Class I

Protection of equipment located in UJ56

Brief description of the proposed change(s) :

The level of radiation expected from the collisions at the interaction point 5, and more

precisely the flux of hadrons with energy in the multi MeV range, will induce Single

Event Errors of the standard electronics present in many of the control equipment

located in UJ56. Such events would perturb the LHC, possibly leading to critical

situations for the machine elements. It is furthermore proposed to relocate part of the

equipment installed in UJ56 (almost all first floor racks) into the UL557 bypass gallery,

where the amount of radiation is reduced. The relocation of the SEE sensitive

equipment identified by the RADWG is foreseen for the first LHC long shutdown. This

ECR documents this implementation.

Equipment concerned :

Drawings concerned :

Equipment installed in

UJ56

Documents concerned :

Reference Database

PE in charge of the item :

PE in charge of parent item in PBS :

M. Brugger / A. L. Perrot

Samy Chemli

Decision of the Project Engineer :

Decision of the PLO for Class I changes :

Rejected.

Accepted by Project Engineer,

no impact on other items.

Actions identified by Project Engineer

Accepted by Project Engineer,

Not requested.

Rejected.

Accepted by the Project Leader Office.

Actions identified by Project Leader Office

but impact on other items.

Comments from other Project Engineers required

Final decision & actions by Project Management

Date of Approval :

Date of Approval :

Actions to be undertaken :

Date of Completion :

Visa of QA Officer :

Note : when approved, an Engineering Change Request becomes an Engineering Change Order/Notification.

LHC Project Document No.

LHC-LJ-ECPage 2 of 20

1. DETAILED DESCRIPTION

by A. L. Perrot

The level of radiation expected from the collisions at the interaction point 5 has been

simulated with the FLUKA code [1, 2] for the LHC design values. Critical radiation levels

are found in the UJ56. Therefore, for 2011/2012, hadrons with E>20 MeV fluence

between 3.5x107 and 1.1x108 cm-2 per year was predicted on average at relevant

critical equipment locations in UJ56. This fluence will reach up to 5.3x108 cm-2 per year

and 2.1x109 cm-2 per year, respectively, at LHC nominal and ultimate conditions. For

comparison, at CNGS, before additional shielding implementation, SEE failures (leading

to the stop of the facility) were observed for hadrons with E>20 MeV fluences of the

order of 107 cm-2 per year.

The relocation actions to be performed to reduce the SEE in the UJ56 electronics have

been divided into 3 phases. The first two phases were performed during the 2010-2011

and the 2011-2012 Christmas breaks while the third and major phase is foreseen

during the first long shutdown. The first phase consisted into moving the critical safety

elements (ODH and fire detection central units) [3]. The second phase consisted into

relocating the UPS units. The third phase will consist into relocating and protecting the

remaining SEE sensitive equipment identified by the RADWG [4].

This document describes the second and third phases of the strategy proposed by the

R2E Mitigation Project in terms of relocation to minimise radiation induced failures in

electronics located in UJ56.

1.1 IRRADIATION TESTS RESULTS OF THE EQUIPMENT TO BE RELOCATED

by M. Brugger and G. Spiezia

The equipment installed in the UJ56 mostly consists of commercial electronics not

specifically designed nor tested to be operated in a radiation environment. For example,

previous test results on PLCs, Ethernet repeaters, QPS control, etc., as well as 2011

LHC operation have shown that the radiation tolerance of the existing equipment cannot

be guaranteed and that LHC operation would be significantly impacted in case no

mitigation measures are applied. In order to further evaluate the radiation sensitivity of

the equipment exposed to the above mentioned radiation levels, some of the most

affected devices/systems located in the UJ56 have been submitted to irradiation tests

at the CNRAD test area [4]. During these tests not all UJ56 equipment could be tested

(due to beam time limitation, complexity/size of the equipment to be tested) and it is

furthermore important to note that testing commercial equipment/components does not

guarantee that a similar type of equipment would lead to the same failure crosssections. This is due to the number of used components, possible different producers

and component batches, where no control can be performed from the user side nor

guarantee be given from the manufacturer. For the case of the power-converters,

additional tests of full power-converter units were performed in a new R2E test-area,

H4IRRAD [5]. This allowed for both, confirm the 2010/2011 LHC observation and study

intermediate patch-solutions in order to minimize the impact during 2012 operation.

Consistent with observations during LHC operation, the performed radiation tests

confirmed clearly that various systems show soft failures (requiring reset) already at

relatively low radiation levels of the order of 1x107 cm-2 (PLC control systems) and

destructive failures (power-supplies) as from a few 1x108 cm-2 accumulated highenergy hadron fluence onwards. Even though some of the tested components showed a

higher resistance during the radiation tests, it was decided between the equipment

owners, the RadWG and the R2E mitigation project to relocate all concerned systems:

where failures under radiation tests where observed;

where the equipment type is known to be radiation sensitive (e.g. complex

control or powering systems);

LHC Project Document No.

LHC-LJ-ECPage 3 of 20

where the relocation of other sensitive equipment makes it more efficient for the

equipment to be relocated with (cabling/access/maintenance).

The equipment remaining in critical areas exposed to radiation is thus only equipment

which was tested under radiation (e.g. designed similarly for the LHC tunnel) or passive

equipment not or less prone to SEE induced errors.

1.2 EQUIPMENT TO BE RELOCATED AND ASSOCIATED MODIFICATIONS

by A. L. Perrot

For complete information about the equipment and the reason inducing its relocation,

please refer to the ‘Point 5 - equipment inventory document [3]. The current locations of

the equipments to be relocated are presented in Figures 1 to 4 while their locations after

relocation are presented in Figures 5 to 7. Relocating the equipment will not have any

impact on the machine functionality.

1.2.1 POWER CONVERTERS EQUIPMENT

This equipment is located in the UJ56 –level 1 and consists of 15 power converters used

for the powering of the Inner Triplet (IT) quadrupoles circuits of Point 5 right and their

correctors (see Table 1). The misbehaviour / failure of one of these devices will lead to

the beam dump and possible access for reparation. All the equipment will be relocated

in UL557 as close as possible to UJ56/UP56 (see Figure 6). Two amongst the four spare

racks (RYSAxxx) will be relocated further away on the other side of the bypass. The two

remaining spare racks today located in UJ56 will be removed. Two spare racks are

already located in USC55 machine area. The integration of the power converters in the

bypass takes into account the volume required for their installation (with connection)

and their maintenance (1.4 m in front of the equipment to remove the power supply

modules). The 2 calibration racks (RYCA01-02) have to be accessible from both sides

and stay together. The only integration solution for these both racks leads to their

partial interference with the transport volume. This implies their removal for the

passage of the transport (see paragraph 1.4). To minimise the length of the watercooled cables from DFBX several ducts will be drilled in the wall between the machine

and UJ56 and between UJ56 and UL557 bypass (see paragraph 1.3). In addition the

bypass sector door (YCPS01=UJ561) will be displaced 10 meters away in UL56. This will

allow relocating the power converters as close as possible to the cables arrival in the

bypass.

To ensure the functionality of the power converters in their new location the following

constraints will have to be filled:

- ensure the cooling of the equipment by chilled and demineralised water,

- provide new links to WorldFip and PIC equipment,

- provide Ethernet access in the bypass,

- redefine the length/section of the DC cables in view to avoid getting over the

maximum voltage delivered by the power converter (see paragraph 1.2.10),

- group together the IT Quadrupoles racks and ensure a common grounding (via a

common Copper plate installed below these racks).

LHC Project Document No.

LHC-LJ-ECPage 4 of 20

Table 1. Power converters

Rack Reference

RQX.R5

Converter/Rack Type

LHC8kA-08V

Power Converter Name

RPHFC.UJ56.RQX.R5

[RYPFB, RYPFA01, RKHF,

Circuit Name

‘RQX.R5’ (Cf LHC DataBase Layout)

IT quadrupoles

RYPFA02, RYHF01]

RTQX2.R5 [RYPFA03, RKHG

RYPFA04, RYHG01]

LHC6kA-08V

RPHGC.UJ56.RTQX2.R5

LHC600A-10V

RPMBC.UJ56.RTQX1.R5

RYMCC01

RYCA01

DCCT Calibration

RYCA02

DCCT - ADC Electronics

RYMCB02

LHC600A-10V

RYMCB03

LHC600A-10V

RYMCB04

LHC600A-10V

RYMCB05

LHC600A-10V

RYLB01

LHC120A-10V

RYLC01

LHC120A-10V

RYSA01

Spare Parts

RYSA02

Spare Parts

RYSA03

RYSA04

Spare Parts

Spare Parts

RYSC01

Hot Spare Parts

RPMBB.UJ56.RCBXH3.R5

RPMBB.UJ56.RCBXH2.R5

RPMBB.UJ56.RCBXV3.R5

RPMBB.UJ56.RCBXH1.R5

RPMBB.UJ56.RCBXV1.R5

RPMBB.UJ56.RCBXV2.R5

RPMBB.UJ56.RQSX3.R5

RPLB.UJ56.RCOX3.R5

RPLB.UJ56.RCOSX3.R5

RPLB.UJ56.RCSX3.R5

RPLB.UJ56.RCSSX3.R5

RPLB.UJ56.RCTX3.R5

RCBXH3.R5

RCBXH2.R5

RCBXV3.R5

RCBXH1.R5

RCBXV1.R5

RCBXV2.R5

RQSX3.R5

RCOX3.R5

RCOSX3.R5

RCSX3.R5

RCSSX3.R5

RCTX3.R5

1.2.2 SURVEY

The electronics of the low beta magnet monitoring and repositioning system is located

in three racks (GYPOS01-03) today installed in UJ56 level 1. The failure of the system

would prevent for further adjustment of the inner triplets. GYPOS01 hosts the sensor

data acquisition modules (SAS) for both triplets and electronics cards for temperature

measurements while GYPOS02-03 host the motor electronics for remote positioning

system of both triplets (one rack per triplet). The three racks will be relocated in

UL557 bypass taking into account the maximum length of 270 m for the cables

powering the motors and the sensors data acquisition.

One of the GGPSO reference positions located in UL557 bypass will be hidden by one

of the racks to be relocated in that area. To ensure the continuity between the

different survey reference points, the survey group will install new reference points in

UL557 bypass and in UL56.

1.2.3 ACCESS SYSTEM

The five racks YYACS01-05 located in UJ56 level 1 are dedicated to the access

system. Only one of them, the YYACS05 rack, contains sensitive electronics. It

ensures the control and the management of all the underground doors. Its failure

would lead to the misbehavior of the control of all the underground sector doors. This

rack will be relocated in USC55 level 2 machine area (see Figure 7).

1.2.4 CRYOGENICS PROFIBUS EQUIPMENT

Three racks QYC01-03 located in UJ56 level 1 are dedicated to the cryogenics

instrumentation. The QYC01 and 03 racks contain ‘profibus crates’ which are sensitive

to radiation field. A failure of these crates could severely degrade the cryogenic

operation requiring a beam dump to provide access for reparation. The 2 racks will be

relocated in UL557 bypass (see Figure 6).

LHC Project Document No.

LHC-LJ-ECPage 5 of 20

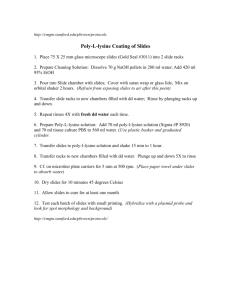

Figure 1: Point 5 general area layout.

Figure 2: Point 5 general area view UJ56- UL557 bypass.

Figure 3a: Equipment location in UJ56 – level 0 (in red equipment to be relocated).

LHC Project Document No.

LHC-LJ-ECPage 6 of 20

Figure 3b. Present location of the control cabinet UIA0-00560 in UJ56 – level 0.

Figure 4:. Equipment to be removed from UJ56 – level 1 (inside blue thick borders).

Figure 5: Overall view of UJ56-UJL557 bypass area after equipment relocation.

LHC Project Document No.

LHC-LJ-ECPage 7 of 20

Figure 6: UL557 bypass after equipment relocation.

Figure 7: USC55 machine area after equipment relocation.

1.2.5 QUENCH PROTECTION SYSTEM (QPS) AND ENERGY EXTRACTION

The racks DYPG01-02 located in UJ56 level 1 host the electronics dedicated to the

protection of the inner triplets and correctors. Their failures may lead to the

transmission of corrupted data, to the loss of communication and supervision of the

LHC Project Document No.

LHC-LJ-ECPage 8 of 20

QPS system. Even, if all the protection systems are fully redundant it has been

decided to relocate these 2 racks. The QPS systems cannot be moved to the surface

as their maximum distance to the corresponding DFB is restricted to about 100 m.

The 2 racks will thus be relocated in UL557 bypass taking into account these 100 m

(see Figure 6). With increasing length of the quench heater power cable from the

DQHDS heater power supplies to the DFBX a larger part of the available energy (2.9

KJ per supply) will be deposited in the cable. That means less energy will be deposited

in the triplet magnet heater. Calculations estimate that with the present configuration

33% of the energy is deposited in the cable and 67% in the magnet heaters. With the

new length of cables, 43% of the energy will go in the cable and thus only 57 % in

the magnet heaters. Taking these numbers into consideration the experts concluded

that the functionality of the system will be ensured with the 2 racks in their new

location.

1.2.6 FIRE AND ODH DETECTION EQUIPMENT

The relocation of this equipment has been treated in a dedicated ECR [4]. In view of

the amount of material that will be relocated in UL557 bypass, it has been decided to

install new fire detection pipe to protect UP56, TU56 and UJL557 bypass areas.

1.2.7 CONTROL EQUIPMENT

Collimators control: The racks TYCFL01 and TYCCR01 located in UJ56 level 1 are

dedicated to the control of the collimators. Their failure will lead to the

requirement of a beam dump. This control system is linked to the Beam Interlock

System (BIS), to the remote reset rack and to the LHC timing. The system can be

relocated up to 200 m from its present location due to cables length limitation for

sensor and stepper motor driver. The two racks will be relocated in USC55 in the

machine area (see Figure 7). The rack TYCFL01 will be renamed TYCFL02 while

the TYCCR01 crates will be merged inside the already existing TYCCR01 rack.

Power Interlock Controller (PIC): The complete protection system for the

inner triplet R5 and the two PLCs controlling the remote I/Os for the matching

section and the long arc cryostat (themselves installed in RR57) are currently

installed in the rack CYCIP01 in level 1 of UJ56. The main clients connected to the

system are the LHC quench protection system (QPS) and the power converters. In

addition the system receives interlock signals from the cryogenics, the UPS and

AUG and is sending beam dump requests to the Beam Interlock System (BIS).

Any failure in the magnet powering infrastructure or the interlock system itself will

lead to an interlock to the LHC power converters and for most circuits to a dump

of both particle beams. The PLCs can be separated from the remote I/Os through

a Profibus link up to ~ 1km, while the I/Os shall remain close to the QPS and

power converters to keep the local controls cabling reasonably short. All systems

currently installed in level 1 of UJ56 will be relocated into UL557 bypass, close to

the QPS racks (DYPG01/02) and the power converters powering the inner triplet

R5 (see Figure 6).

Beam Interlock Controller (BIS): one Beam Interlock Controller (BIC) is

located in the CYCIB01 rack in UJ56 level 1. The connected user systems are:

Vacuum, Collimation, PIC, FMCM and both CMS and TOTEM experiences. Each user

system delivers via a dedicated interface (CIBU) its own local permit for beam

operation. Any failure of the system will lead to a beam dump and will block

further beam operations. In addition to the BIC, the CYCIB01 rack contains

another machine interlock system: the ‘Fast Magnet current Change Monitor’

(FMCM) unit attached to the RD1.LR5 circuit. The full rack will be relocated in

USC55 machine area (see Figure 7). To ensure the functionality of the BIS in its

new location the following constraints will have to be filled:

- the extended cable length must stay below 1200 m,

LHC Project Document No.

LHC-LJ-ECPage 9 of 20

- the cables extension and optical fibers installations will have to be performed

with a very special care as these cables transmit the beams ‘user permit’. A non

high quality extension may lead to non requested beam dumps,

- Ethernet connections available in the rack;

- UPS network available in the rack.

Current lead heaters: The rack DYXF01 located in UJ56 level 1 contains the

control equipment of the current lead heaters providing the temperature

regulation of the top part of the current lead. Their failure will stop their heating

function and possibly lead to a non start of the power converters at the restarting

of the LHC machine. It has been decided to relocate the rack in USC55 machine

area (see Figure 7).

Timing and remote reset: there are two racks located in UJ56 level 1 hosting,

respectively, the timing (rack CYTIM01) and the remote reset (rack CYFRE01)

systems. Each system consists into a 3 units crate and manages the timing and

remote reset distribution for the front-end controls. A failure of the timing system

would induce a beam dump due to the lack of timing distribution for the

equipment related to the beam control. The two racks will be relocated in UL557

bypass where their user agents will be relocated (see Figure 6). The distance

between their present and future locations should be as short as possible.

Network: The racks CYNET01 and CYNET02 located in UJ56 level 1 are the

network star-points for UJ56. They provide the Technical Network (TN) and Global

Purpose Network (GPN) to the equipment installed in UJ56. Their failure will affect

all the users in the area. As a consequence it has been suggested to relocate

these two racks. It has been decided to merge them into one rack. The maximum

distance between the ‘star-point’ (i.e. the rack) and the Ethernet plugs installed all

around (i.e. the users) is 90 m. This drives the location at which the new rack

CYNET01 can be displaced. It will be installed in UL557 bypass where the major

part of the users will be relocated (see Figure 6).

Optical fibers: the rack CYFIB01 installed in UJ56 level 1 is the star-point for the

UJ56. It will not suffer from SEE as it consists of passive elements. However, new

racks CYFIB01 will have to be installed in UL557 bypass and UCS55 machine area

to ensure the dispatch towards the users that will be relocated in these areas.

WorldFip repeaters: Cryogenics and power converters are the only users of the

worldfip repeaters located in UJ56. The ten corresponding units are hosted in the

CYFRE01 rack in UJ56 level 1. A failure of one repeater unit implies that the

associated equipment cannot respond anymore. The four units dedicated to the

cryogenics are optical fibers /Cu type while the six units dedicated to power

converters are Cu/Cu type. Following the irradiation test results for both types of

repeaters it has been decided to relocate in UL557 bypass in the rack CYFRE01

only the worldfip repeaters units dedicated to cryogenics (see Figure 6).

1.2.8 ELECTRICAL EQUIPMENT

Uninterruptible Power Supply (UPS): there are two UPS systems (cabinets

EBS1/56, EBS11/56 and ESS12/56) located in UJ56 level 0. They power machine

equipment via the associated racks/switchboards installed in UJ56, USC55

(machine area) and RR53/57. The UPS modules are purchased as complete units.

They contain electronics to control voltage and current, and switches between

battery powered units and the main supply. The two UPS with their associated

distribution switchboards (EOD) may suffer from SEU. A failure of the UPS could

lead to a total loss of electrical power delivered to the users (see Table 2). In

particular it could lead to the loss of the vacuum system, the quench detection, the

radiofrequency equipment, the beam monitoring and the supervision system. It has

thus been decided to relocate the UPS modules in UL557 bypass (see Figure 6,

units EBS11/56, EJG11/56, EBS12/56, EJG12/56, EOD1/56, EOD3/56).

LHC Project Document No.

LHC-LJ-ECPage 10 of 20

Electrical services dedicated to the personal safety for Point 5: they are

installed in the safe room located in UJ56 level 0 (see Figure 3).

- General emergency stop ‘AUG’ system (EYU01 rack): its misbehaviour could

generate false safety alarms and power-off the electrical network. It will be

relocated in UL557 bypass in a ‘mini safe-room’.

- The Electrical Network Monitoring system (EYC01/02/03 racks): the three

racks host PLCs and industrial data acquisition units that are sensitive to SEE.

Their misbehaviour would corrupt the information on the status of the network

and could generate false alarms. They will be relocated in the UL557 bypass.

Following discussion with the Safety, they will be relocated outside the mini safe

room.

- 48 V dc system (ECD, ECG, ESU): it contains electronics that may be sensitive

to SEE. Its misbehaviour would lead to the power-off of EL safety equipment, 18

KV loop, EYC and AUG racks. In particular the ambient and Safety lightning in UJ

and the tunnel will be lost. To reduce the amount of equipment to be relocated in

the UL557 mini safe room, it was decided to feed directly the Safety lightning

system with 230 Vac through an UPS system located in surface. The 48V dc

chargers will be moved into UL557 bypass mini safe room in order to simplify the

cabling and to be able to replace them (if needed) by new ones (estimated more

sensible to radiation effects).

These relocations have been validated by Safety.

The new electrical layout is available in [6]. Table 3 presents the electrical

equipment to be installed in UL557 after the relocation process.

Table 2. UPS users.

Distribution switch board

User

EOD103/56

EOK103/56 distribution busbar

EOD104/56

EOK104/56 distribution busbar

EOD105/56

EOK105/56 distribution busbar

EOD106/56

EOK106/56 distribution busbar

EOD107/56

EOD1/53 distribution busbar

EOD108/56

EOD1/57 power supply

EOD109/56

Power supply 1 FORCE F3 R561-R562-R571-R572-R58

EOD110/56

Power supply 2 FORCE F3 R561-R562-R571-R572-R58

EOD111/56

Power supply 1 FORCE F3 R531-R52

EOD112/56

Supply 2 FORCE F3 R52

EOD113/56

RESERVE

EOD114/56

Power supply EOJ9/55 USC55

EOD115/56

RESERVE

EOD116/56

Power supply RACK RYCA01-02

EOD117/56

RESERVE

EOD118/56

Power supply RACK CYNET01=UJ56

EOD119/56

Power supply RACK CYNET02=UJ56

EOD302/56

Power supply COFFRETS F3 NEW QPS R52

EOD303/56

Power supply COFFRETS F3 NEW QPS USC55-RR53

EOD304/56

Power supply COFFRETS F4 NEW QPS R58

EOD305/56

Power supply COFFRETS F4 NEW QPS RR57

EOD306/56

Power supply RACK DYPG01

EOD307/56

Power supply RACK DYPG02

EOD308/56

RESERVE

EOD309/56

Power supply CYCIB01=UJ56

LHC Project Document No.

LHC-LJ-ECPage 11 of 20

Table 3. Electrical equipment in UL557 after its relocation from UJ56.

Equipment reference in UL557

(after relocation)

EBD10/56 (new)

EBS11-12/56

ECD1-2/56

ECG1-2/56

EJG11-12/56

EOD3/56

ERD1/56

ESD4/56 (new)

ESU1-2/56

EYC04-07/56

EYU02/56 (new)

Equipment reference in UJ56

(before relocation)

EBS11-12/56

ECD1-2/56

ECG101-201/56

EJG11-12/56

EOD3/56

ERD1/56

ESU304

EYC01-03/56

Function

Low voltage switchboard

UPS cabinet

48 V dc commutation

48 V dc batteries

UPS batteries

UPS distribution switchboard

Power converters switchboard

Diesel switchboard

48 V dc chargers

EL monitoring controllers

AUG system

Relocation in UL557

outside mini safe room

outside mini safe room

in mini safe room

in mini safe room

outside mini safe room

outside mini safe room

outside mini safe room

in mini safe room

in mini safe room

outside mini safe room

in mini safe room

Location in UJ56

(present)

UJ56- level 0

UJ56- level 0- safe room

UJ56- level 0- safe room

UJ56- level 0

UJ56- level 0

UJ56- level 0

UJ56- level 0- safe room

UJ56- level 0 -safe room

1.2.9 CV EQUIPMENT

The control cubicle UIA0-00560 manages the air ventilation units of UJ56 and will

manage in the future those of UL557 bypass. It consists of one process PLC and one

PLC concentrator. The process PLC collects the information, the measurements, the

status of the ventilation in UJ56, RR53, RR57 and delivers alarm to CCC. The PLC

concentrator linked to Ethernet is connected by profibus to the process PLC. A failure

of the PLCs may lead to the loss of the ventilation alarm in the CCC, to the absence of

ventilation supervision in the UJ56, RR53 and RR57. The ventilation may be in an

indefinite state with possibly the overheating of one of the supervised areas. It was

decided to displace the PLCs from their present location in UJ56 level 0 to UJL557

bypass (see Figures 3b and 6).

1.2.10 DC CABLING

by J.C. Guillaume, H. Thiessen

Due to the relocation of the power converters, the DC cables between the converters

and the DFBX must be changed with new lengths and sometime new cross sections,

mainly for the main quadrupole circuit of the Inner Triplet of LSS5R. The Table 4 gives

the new characteristics of the DC circuits with the updated power dissipations of the

DC cables. To facilitate their integration the water cooled DC cables of the main

quadrupole circuit will be split in two. The 2000 mm 2 water cooled DC cables of the

RQX power converter will be realized with two 1000 mm 2 water cooled DC cables in

parallel and the 1600 mm2 water cooled DC cables of the RTQX2 power converter will

be realized with two 800 mm2 water cooled DC cables in parallel. With this

configuration, adapters must be inserted between the water cooled DC cables and the

electrical terminals of the DFBX and the power converters.

Although the main quadrupole circuit of the Inner Triplet of LSS5L is not concerned by

the R2E project, the water cooled DC cables of this circuit will be changed at the same

time to increase their cross sections at 2000 mm 2 and 1600 mm2 instead of 1300 mm2

and 1000 mm2. With the present cables, the nominal parameters (nominal currents

and nominal didts) of the main quadrupole circuit of the Inner Triplet left of 5 cannot

be reached. To avoid this important constraint for the LHC, it is strongly recommended

to replace these DC cables. The Table 5 gives the new characteristics of the DC circuits

of the main quadrupoles of the Inner Triplet left of 5. As for the Inner Triplet right of

5, the water cooled DC cables of the main quadrupole circuit of the Inner Triplet Left

of 5 will be split in two.

LHC Project Document No.

LHC-LJ-ECPage 12 of 20

Table 4. DC circuit characteristics of the IT.R5.

Section

rau 40oC

Resistance

Vcable_ult

Vmagnet

Vtotal_ult

Pcables_ult

Pcables_ult

[H]

[A/s]

[V]

[A]

[A]

[m]

[mm2]

[Ohm.mm2/m]

[Ohm]

[V]

[V]

[V]

[Wair]

[Ww ater]

RCOX3.R5

0.004

1

0.1

100

110

150

35

0.019

0.081

8.91

0.004

9.12

981

0

RCOSX3.R5

0.003

1

0.1

100

110

150

35

0.019

0.081

8.91

0.003

9.12

981

0

RCSX3.R5

0.005

0.5

0.1

100

100

150

35

0.019

0.081

8.10

0.003

8.31

810

0

RCSSX3.R5

0.008

1

0.1

100

110

150

35

0.019

0.081

8.91

0.008

9.12

981

0

RCTX3.R5

0.029

1

0.1

80

86

150

35

0.019

0.081

6.97

0.029

7.20

599

0

RTQX1.R5

0.09

19.333

0.12

550

600

150

240

0.019

0.012

7.09

1.740

9.07

4255

0

RCBXH3.R5

0.287

5

0.12

550

600

150

240

0.019

0.012

7.09

1.435

8.77

4255

0

RCBXH2.R5

0.287

5

0.12

550

600

150

240

0.019

0.012

7.09

1.435

8.77

4255

0

RCBXV3.R5

0.175

5

0.12

550

600

150

240

0.019

0.012

7.09

0.875

8.21

4255

0

RCBXH1.R5

0.287

10

0.12

550

600

150

400

0.019

0.007

4.25

2.870

7.36

2553

0

RCBXV1.R5

0.175

10

0.12

550

600

150

240

0.019

0.012

7.09

1.750

9.08

4255

0

RCBXV2.R5

0.175

5

0.12

550

600

150

240

0.019

0.012

7.09

0.875

8.21

4255

0

RQSX3.R5

0.014

5

0.12

550

600

150

240

0.019

0.012

7.09

0.070

7.40

4255

0

RQX.R5

0.218

6

0.12

6800

7180

75

2000

0.019

0.001

5.09

1.642

6.97

0

36557

RTQX2.R5

0.038

8.777

0.12

4600

4780

80

1600

0.019

0.001

4.52

0.562

5.32

0

21603

CIRCUIT NAME

L TOT MAX DI DT U LEADS I NOMINAL I ULTIMATE Long cables

Table 5. DC circuit characteristics of the main quadrupole IT.L5.

CIRCUIT NAME

L TOT

MAX DI DT U LEADS I NOMINAL I ULTIMATE Long cables Section

[H]

[A/s]

[V]

[A]

[A]

[m]

RQX.L5

0.218

6

0.12

6800

7180

RTQX2.L5

0.038

8.777

0.12

4600

4780

rau 40oC

Rcable

Vcable_ult Vmagnet Vtotal_ult Pcables_ult Pcables_ult

[mm2] [Ohm.mm2/m]

[Ohm]

[V]

[V]

[V]

[Wair]

[Ww ater]

75.00

2000

0.019

0.001

5.09

1.642

6.97

0

56242

75.00

1600

0.019

0.001

4.24

0.562

5.04

0

32405

1.2.11 OVERVIEW OF THE EQUIPMENT TODAY IN UJ56

Tables 6a and 7b present the equipments today installed, respectively, in UJ56 level 0

and UJ56 level 1. They indicate in red the equipment that will remain in its present

location, in green the equipment to be relocated in UL557 or USC55 and in purple the

equipment to be removed / dismantled as it will not be used anymore after LS1.

LHC Project Document No.

LHC-LJ-ECPage 13 of 20

Table 6a. Equipment today located in UJ56 level 0.

Equipment

UIAN -00503

UIAO-00560

water pumps

BRAN area - gaz control

anti-panic lightning unit

ODH detectors,

sirens

fire detectors

mobile shielding control

RAMSES detector

LACS control boxe (YJBC01=UJ56-0)

SAREP -0026 (previously CAR101UJ56)

SAREP-0025 (previously CBR101UJ56)

CTRIO1UJ56

CTER-00540

CYRR01

EAD1-2/56

EBD1-2/56

EBS1/56 *

EBS11-12/56

ECD1-2/56

ECG101-201/56

EJG11-12/56

EMD1/56

EMT103/56

EOD1/56

EOD3/56

EOX01/56

ERD1/56

ESD1-3/56*

ESU303-304*/56

EYP01/56

EYC01-02-03/56

EYB01/56

Function

To be relocated

within R2E

Equipment owner

Contact person

raw water pumps control

air ventilation control

no

yes

no

no

no

no

no

yes

no

no

yes

no

no

no

no

no

no

no

to be removed (no more used)

yes

yes

yes

yes

no

no

no

yes

yes

yes

to be removed (no more used)

no/yes

no

yes

no

EN/CV

EN/CV

EN/CV

BE/BI

EN/EL

GS/ASE

GS/ASE

GS/ASE

EN/HE

DGS/RP

GS/ASE

GS/ASE/AS

GS/ASE/AS

IT/CS

GS/ASE/AS

IT/CS

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

EN/EL

P. Valente

P. Valente

P. Valente

E. Bravin

N. Dos Santos

S. Grau

S. Grau

S. Grau

J. P. Granchelli

A. Day

R. Nunes

S. Grau

S. Grau

F. Chapron

S. Grau

F. Chapron

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

J.C. Guillaume/N. Dos Santos

safety

safety

safety

safety

safety

access

transmission alarms levels 2 & 3

transmission alarms levels 2 & 3

phone

red phone

GSM probe

emergency lightning

GS switch board

UPS cabinets

UPS cabinets

48 V dc commutation

48 V batteries

UPS batteries

HV switchboard

HT transformer

UPS distribution switch board

UPS distribution switch board

PIC alarm box

power converters switchboard

Diesel switchboard

48 V dc chargers

emergency lightning

EL monitoring controllers

LV switchboard protections

(*) Equipment to be removed / dismounted.

Table 6b. Equipment today located in UJ56 level 1.

Equipment

ODH detectors

siren

AUG

anti-panic lightning

UTA

WorldFIP boxes

BY01

CYCIP01

CYCIB01

GYPOS01-02-03

YYASC01-02-03-04-05

QYC01-02-03

CYFIB01

CYNET01-02

CYTIM01

CYFRE01

DYPG01-02

DYXF01

TYCFL01

TYCCR01

RQX.R5

RTQX2.R5

RYMCB02-03-04-05

RYMCC01

RYCA01-02

RYLC01

RYLB01

RYSC01

RYSA01-02

RYSA03-04

Function

To be relocated

within R2E

Equipment owner

Contact person

safety

safety

safety

safety

ventilation

no

no

no

no

no

no

no

yes

yes

yes

only YYASC05

QYC01 and QYC03

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

to be removed (no more used)

GS/ASE

GS/ASE

EN/EL

EN/EL

EN/CV

BE/CO

BE/BI

TE/MPE

TE/MPE

BE/ABP

GS/ASE

TE/CRG

EN/EL

IT/CS

TE/MPE

TE/MPE

TE/MPE

TE/MPE

EN/STI

EN/STI

TE/EPC

TE/EPC

TE/EPC

TE/EPC

TE/EPC

TE/EPC

TE/EPC

TE/EPC

TE/EPC

TE/EPC

S. Grau

S. Grau

N. Dos Santos

N. Dos Santos

P. Valente

J. Palluel

B. Dehning, E. Effinger

B.Puccio, I. Romera Ramirez

B. Puccio, C. Martin, I. Romera ramirez

A. Marin

R. Nunes

J. F. Bel, B. Ivens

A. Gonzalez Puertas

J. Shade, M. Da Costa

R. Chery

R. Chery

R. Denz, M. Zerlauth, K. Dahlerup-Petersen

R. Mompo

A. Masi

A. Masi

V. Montabonnet, C. Coupat

V. Montabonnet, C. Coupat

V. Montabonnet, C. Coupat

V. Montabonnet, C. Coupat

V. Montabonnet, C. Coupat

V. Montabonnet, C. Coupat

V. Montabonnet, C. Coupat

V. Montabonnet, C. Coupat

V. Montabonnet, C. Coupat

V. Montabonnet, C. Coupat

BPM

PIC

BIC/ FMCM

Survey

Access/ Safety

Cryogenics

Fibres

Ethernet

Timing

Remote reset

QPS

Current leads heaters

Collimation

Collimation

power converters

power converters

power converters

power converters

power converters calibration system

power converters

power converters

power converters hot spare

power converters spare

power converters spare

(*) equipment to be removed / dismounted.

LHC Project Document No.

LHC-LJ-ECPage 14 of 20

1.3 CIVIL ENGINEERING ACTIVITIES

To minimise cables length and to provide passageways for new cables and pipe work

into UL557 bypass, several ducts will have to be drilled (see Figures 8):

- through the UJ56 separating wall between machine (LHC tunnel) and services area:

5 ducts 2 m long with 350 mm diameter;

- between UL557 and UL558 (‘mur tympan’): 4 ducts 350 mm diameter for cables and

4 ducts 350 mm diameter for cooling pipes (2 for the ‘mini’ safe room);

- between the UJ56 cavern (services area) and the UL557 bypass tunnel: 4 ducts 14

m long with 400 mm diameter.

Before the start of these works surrounding equipment (especially those located in

UJ56 levels 0 and 1 including the ‘safe room’) will have to be protected. The protection

will need to be water-proof as the drilling method will use water. The removal of the

excavated material will be via PM56 lift. The base of the UL557 vault will be cut on the

external wall (opposite to ‘mur tympan’) along 30 m. Three to five centimeters of

concrete will be removed. In order to carry out the drilling activities the Civil

Engineering contractor will require a free space of 2 m clearance from the tunnel wall

and 1 m additional diameter around each duct to be drilled.

The overall time of the drilling/excavation activities is estimated to 15 weeks:

- 5 ducts through the UJ56 separating wall: 2 weeks;

- 4 ducts between UJ56 and UL557 bypass: 10 weeks;

- 8 ducts through the UL557/UL558 separating wall: 2 weeks;

- cut the base of the UL557 vault: 1 week.

3D models showing the ducts to be performed are stored in SmarTeam under the

reference ST0307981_01 for UJ56, ST0307980_01 for UL557 and ST0057895_01 for

UP56.

The mini safe room structure construction and fire resistant doors installation will be,

respectively, performed under the GS/SE and EN/HE responsibilities. These 2 tasks

are estimated to be, respectively, 3 and 2 weeks.

Figure 8a: 4 ducts 14 m long to be drilled between UJ56 and UL557 bypass

LHC Project Document No.

LHC-LJ-ECPage 15 of 20

Figure 8b: 5 ducts to be drilled through UJ56 wall

Figure 8c: 8 ducts to be drilled through the UL557/UL558 separating wall (‘mur tympan’).

1.4 SAFETY CONSIDERATIONS IN UJ561 BYPASS

Sealing: following the CMS, Safety and Radioprotection requests all openings for

cables and pipes performed between UL557 and UL558 will be properly sealed such

that they are leak tight, withstand a fire for at least 90 minutes and a blast of 120

mbar overpressure. In order to preserve the current fire and ventilation compartmentalisations,

both extremities of each hole will be sealed with 80 mm thick plates made of mineral wool and

with external faces covered by a layer of fire-resistant paint. In addition, the cables will be painted

with the fire-resistant paint at the position where they exit of the plates.

Relocation of ‘tablotins’: the relocation of equipment in the UL557 bypass will

interfere with two ‘tablotins- safety organs’ today installed in the bypass (see Figure

2). The ‘tablotin T1’ consists of AUG push button, siren, emergency lightning and fire

extinguisher. The ‘tablotin T2’ consists of AUG push button, siren (with ‘bris de

glace’), emergency lightning and fire extinguisher. For T2 the siren will not have to be

moved as it will not interfere with equipment. The Safety (DGS/SEE) agreed to

relocate the 2 ‘tablotins’ T1 and T2. These relocations are technically feasible (studies

performed by GS/ASE and EN/EL). T1 will be relocated on the other side of the bypass

while T2 will be translated 2 meters away from its current position (see Figure 5).

LHC Project Document No.

LHC-LJ-ECPage 16 of 20

UL557 – bypass framework load resistance: it is proposed to install on the UL557

framework the cooling pipes and part of the cables for the equipment to be relocated

in the UL557 bypass (see Photo 1 and Figure 9). They correspond to an additional

weight on the framework of 1t/m. GS/SE studied the impact of this additional load on

the framework and concluded that the framework will support it [7].

Mini ‘safe room’: Racks today located in the UJ56 ‘safe room’ will be relocated in

UL557. After discussion with Safety colleagues, the equipment owners decided for

safety reasons to relocate part of these racks in a 2 hours fire resistant structure

called ‘mini safe room’ (see Tables 6). A dedicated ‘mini safe room’ will thus be built

in UL557 (see Figure 6). The height of the racks to be installed inside the ‘mini safe

room’ will be limited to 1.80m (instead of the usual 2.20m) due to the presence of

cable trays already installed along the UL557/UL558 separating wall.

Fire detection: see paragraph 1.2.6.

Photo 1. Framework along UL557 bypass- present situation

Figure 9. Cross section of UL557 bypass after equipement relocation

LHC Project Document No.

LHC-LJ-ECPage 17 of 20

Sector door: to minimize the length of the water cooled cables, the power converters

will be relocated at the present location of the YCPS01=UJ561 sector door. As a

consequence this door will be displaced 10 m away into UL56 behind the

ventilation/blast door. In its new location the sector door will allow the full aperture of

the blast door and will be compatible with the passage of the TIM. GS/ASE and the

machine DSO agreed with this displacement taking into account that R2E will ensure

the arrival of the cables to the new sector door location.

Transport volume: in their new location in UL557, the power converters calibration

racks (RYCA01/02) will interfere with the transport volume by 30 cm. It is agreed

between EN/HE and TE/EPC colleagues that EN/HE will inform TE/EPC about each

heavy transport requiring the 2 racks to be pivoted to free the transport volume. The

rotation of the calibration racks will be performed by TE/EPC. It will take half a day.

If heavy transport convoy breaks down in UL557 (between the mini safe room and the

power converters areas), EN/HE foresees a non standard recovery method with a

mechanical jack with cradle (device called ‘recovery’) [8]. Once all equipment will be

relocated in UL557, a transport test (with a wooden mock-up) will be carried out by

EN/HE in the UL557 bypass.

1.5 INSTALLATION PHASES

The equipment relocation is scheduled for LS1. The activities sequences with the coactivities are today defined. The overall implementation to be carried-out during LS1 is

estimated to 57 weeks (14 months) [9]. Table 7 gives a summary of the teams

involved with their estimations of the duration of their respective activities.

During the 2011-2012 winter shutdown, UPS and PIC were relocated. Preparatory

work for BIC relocation and part of the civil engineering activities were also

anticipated. All remaining preparatory work than can be anticipated will be performed

during the 2012 technical stops (e.g., cables trays installation).

The integration layouts changes linked to the R2E relocations were discussed within

the ICL. They are today approved throughout the ICL by the equipment owners and

the services (see Table 8). All the installation drawings will be verified by the

corresponding CERN services, in particular by EN/CV, EN/EL and GS/SE to ensure their

conformity with the 3D LHC integration models. They will be circulated amongst the

services teams and the LHC integration team (EN/MEF-INT). During LS1, survey scans

of the areas will be performed at the end of each major service

installation/intervention. A follow-up of the installation non-conformities will be

performed by the EN/MEF-INT team. In case of a critical non conformity, the

equipment not installed in its nominal location will be removed and then reinstalled

following the installation drawings.

LHC Project Document No.

LHC-LJ-ECPage 18 of 20

Table 7: Teams involved into the R2E relocations activities in Point 5 with the

estimated duration of their respective activities (as provided by the responsible

groups).

Group

BE/ABP

BE/CO

EN/CV

EN/EL

EN/HE

EN/STI

GS/ASE

GS/SE-CE

IT/CS

TE/CRG

TE/EPC

TE/MPE

Equipment / activity

survey equipment

timing & remote reset

WorldFip

pipes/ducts

UTAs

equipment relocation,

cabling & optical fibers

equipment transport

collimator control equipment

fire/ODH detection

access

drill/dig activities

mini safe room

Ethernet

cryogenics equipment

power converters

QPS*

PIC*

current leads heaters

BIS

Duration

[weeks]

3

<1

1

19

6

27

(2 shifts/day)

2

5

5

6

9 (2 shifts/day)

4

3

4

7

1

<1

3

<1

*activities performed outside the LHC hardware commissioning

Table 8: EDMS references of the LHC integration models taking into account the

relocations to be carried out within the R2E Mitigation Project.

Location

EDMS reference

UJ53

UJ56

UJ57

UP56/UL557/UL558

UL54

UL56

USC55 (machine side)

RR53

RR57

1143900

1102744 / 1145767

1143908

1143676

1143902

1143904

1143911

1143898

1143910

LHC Project Document No.

LHC-LJ-ECPage 19 of 20

2. REASONS FOR CHANGE

by AL Perrot

Reduce the risk of misbehaviour due to SEE of the equipment located in UJ56 that

may lead to stop of the LHC machine or jeopardize its correct operation.

3. IMPACT ON COST, SCHEDULE & PERFORMANCE

by AL Perrot

The total cost for the relocation activities is estimated to 3175 KCHF (see Table 9).

These relocations are discussed with the LHC integration team (EN/MEF-LE), the

services and the equipment owners. The new integration layouts are approved

through LHC Integration Committee (ICL). The relocation activities are scheduled by

the LHC planning officers (EN/MEF-OSS).

The present estimate of the hadron flux in UJ56 indicates that SEE may be a limitation

for LHC operation. The modifications proposed would allow for a safer operation and a

decrease of the machine down-time.

Table 9: Cost estimate corresponding to the R2E relocation activities in Point 5 (as

provided by the responsible group, rounded up to 5 KCHF).

Equipment /service

EL

Cooling / Ventilation

Civil engineering

Fire detection

Sector doors YCPS01=UJ561

Access rack

Transport

Network

Survey

Activity

control cabling for electrical distribution

low voltage

optical fibers

DC and control cables installation

UTAs, cooling pipes installation

drilling activities

safe room

UJ56/RR53/RR57 smoke detectors relocation

UJ561 new smoke detectors

displacement

displacement

relocation of equipment

structure cabling, wifi

1 rack

VDSL cabling

GGPSO installation

reference marks

Cryogenics

Collimation control

QPS

False floor on the bypass framework

Metallic structure for UPS

Power converters ('gerbeur')

Group

Contact

Total cost [KCHF]

EN/EL

EN/EL

EN/EL

EN/EL

EN/CV

GS/SE

J C Guillaume

N. dos Santos

A. Gonzalez Puertas

J C Guillaume, N. dos Santos

P Valente

J Osborne

GS/ASE

S Grau

75

410

100

1420

420

265

85

100

10

45

50

20

40

5

GS/ASE, EN/HE

GS/ASE

EN/HE

IT/CS

R Nunes, A. Foreste

R Nunes

C. Bertone

M. Da Costa

EN/EL

BE/ABP

J. C. Guillaume

A. Marin

TE/CRG

EN/STI

TE/MPE

GS/SE

B.Ivens, J. F. Bel

A. Massi, J. Lendaro

R. Denz

D. Parchet

TE/EPC

C. Coupat

5

5

50

35

10

15

5

5

TOTAL [KCHF]

4. IMPACT ON OTHER ITEMS

3175

by A L Perrot

See paragraph 1.2.

5. CHANGE CLASS

by Project Engineer

6. COMMENTS (COMPULSORY)

by Project Engineer

7. COMMENTS (IF REQUIRED)

by other Project Engineers

LHC Project Document No.

LHC-LJ-ECPage 20 of 20

8. COMMENTS (IF ANY)

by PLO appropriate Committees

9. REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

‘R2E FLUKA studies for Point 1 and Point 5’, R. Versaci & al, ATS/Note/2010-046,

October 2010;

‘Residual dose maps, air activation and prompt dose in the adjacent tunnel at IR5’, M.

Fuerstner &al, CERN-DG-2009-057-RP-TN, edms: 1006918;

‘Strategy against SEE for Fire and Oxygen deficiency detection systems’, S. Grau & A. L.

Perrot, Feb. 2011, edms: 1126688, LHC-LJ-EC-0023 v.0.1;

https://edms.cern.ch/nav/P:CERN-0000083951:V0/P:CERN-0000091190:V0/TAB3

www.cern.ch/h4irrad

‘Proposition d'implantation et distribution des équipements EN-EL en UL55 et TZ76,

dans le cadre des déplacements des équipements liés au projet R2E’, N. Dos Santos,

April 2012, edms: 1210200 v.1, ELG-LVNET-EN-0179 v.1;

Private discussions and calculations performed by D. Parchet (GS/SE), January 2011.

Discussion in ICL no. 2011-324, 9th March 2011.

Work by M. Barberan and K. Foraz (EN/MEF-OSS), November 2011:

https://espace.cern.ch/MEFactivitiesforR2E/Planning_Documents/Forms/AllItems.aspx