TQM-doc - WordPress.com

advertisement

Contents

emeronTI1 viFIsa®sþénkarRKb;RKgKuNPaB

Approaches to Quality Management ............................................................................................................. 2

emeronTI2 RTwsþIénKuNPaB Quality Theory ........................... 11

emeronTI3 KuNPaBnigkarRbkYtRbECgsakl

Quality and Global Competitiveness .......................................................................................................... 22

emeronTI4 karbMeBjtRmÚvkar

nigkarEfrkSaGtifiCn Customer Satisfaction and Retention................................ 26

emeronTI5 karcUlrYm nig

karpþl;GMNacdl;nieyaCit Employee Involvement and Empowerment... 31

Chapter 6 Quality Tools .............................................................................................................................. 34

Chapter 7 Statistical Quality Control .......................................................................................................... 40

National University of Management

Year IV, Semester I

emeronTI1

viFIsa®sþénkarRKb;RKgKuNPaB

Approaches to Quality Management

bøg;emeron

1. etIKuNPaBCaGVI?

2. FatusMxan;²énKuNPaB

3. niymn½yénviFIsa®sþKuNPaBsrub

4. FatusMxan;²énKuNPaBsrub

5. TsSnaTan Six Sigma

6. RbvtþiRtÜs²énkarRKb;RKgKuNPaB

etIKuNPaBCaGVI? (What Is Quality?)

\tex©aHkarpþl;TMnij[elOn

pþl;plitpll¥

nig

manRbeyaCn_bM)at;PaBx©Hx¢ay

PaB\tpøas;bþÚreFVIRtÚv

enAelIk

dMbUgeFI

[GtifiCneBjcitþxøaMgkareBjcitþTaMgmUlGnueLamt

ameKalneya)aynignitiviFI .

KuNPaBKWCasPaBpøas;bþÚrEdlTak;TgCamY

yplitpl/ esvakmµ/ mnusS/ dMeNIrkar/ nigbriyakas

EdlbMeBj b¤ bMeBj elIskarrMBwgTuk. Quality is a dynamic

state associated with products, services, people, processes, and environments that meet or exceed

expectation.

FatusMxan;²énniymn½y³

sPaBpøas;bþÚr (dynamic state) mann½yfa manKuNPaB

Gacpøas;bþÚreTAtameBlevla nigkal³eTs³ . plitpl

(products)/ esvakmµ (services)/ mnusS (people)/ dMeNIrkar (processes)/

nig

briyakas

(environment)

mann½yfa

KuNPaBminRKan;EtGnuvtþn_cMeBaHplitpl

nigesvakmµb:ueNÑaHeT

b:uEnþEfmTaMg

Gnuvtþn_cMeBaHmnusS/

dMeNIrkar

nigbriyakaspgEdr.

FatuénKuNPaB (The Dimensions of Quality)

Management of Technology/Group30/Promotion 19

Page 2 of 48

National University of Management

Year IV, Semester I

KuNPaBenAkñúgplitkmµ³

plitplmanFatuénPaBKuNPaB

CaeRcInEdlrYmman³

1. dMeNIrkar b¤karsMEdgskmµPaB (performance)³

sMedAeTAelI smßPaBEdlplitplseRmceKal

bMNgEdlb:grbs;va.

2. lkçN³Biess (features)³

lkçN³énplitplEdlbEnßmeTAelIkarsMEdgskmµP

aBCamUldæanrbs;va.

3. PaBEdlGacTukcitþ)an (reliability)³

ninñakarrbs;plitpl

edIm,IdMeNIrkar\tpøas;bþÚrenAkñúgry³eBl

énCIviteRbIR)as;EdleKeRKagerobcM.

4. PaBGnueLamtam (conformance)³

eqøIytbeTAnwgbTdæan (specification)

b¤sþg;dar]sSahkmµ (industry standard).

5. PaBCab; b¤Fn; (duability)³ kRmitEdlplitplFn;

niwgkarFøak; b¤karb:HTgÁicxøaMgeday

mineFVI [plitpl xUc.

6. karpþl;esvakmµ (serviceability)³ karedaHRsaybBaða

nig kartva:epSg²/ PaBgayRsÜlenAkñúgkar

CYsCul.

7. esaP½NPaB (aesthetics)³

lkçN³xag\®nÞIyarmµN_Ebb Gtþenam½ti

dUcCa rsCati b:H B¤ eXIj nig kiøin .

8. KuNPaBtamsBaØakçn§ (perceived quality)³

Ep¥keTAelI TsSn³rbs;GtifiCn. GtifiCnyl;eXIj

plitpl nigesvakmµ

CamYykaryl;dwgénPaBl¥rbs;va.

KuNPaBenAkñúgesvakmµ³

FatuénKuNPaBsRmab;esvakmµrYmman³

1. eBl (time)³ etIGtifiCnRtÚvrg;caMry³eBlb:unµan?

2. PaBTan;eBl (timeliness)³

etIesvakmµRtÚv)anbMeBjtamkarsnüa?

Management of Technology/Group30/Promotion 19

Page 3 of 48

National University of Management

Year IV, Semester I

PaBeBjelj (completeness)³

etImanbBa©ÚllCeRmIsTaMgGs;?

4. karKYrsm (courtesy)³

etInieyaCitCYrmuxTTYlGtifiCnedayrak;Tak;

nigrIkray?

5. PaB\tpøas;bþÚ (consistency)³

etIesvakmµRtÚv)aneKpþl;enAkñúgrebobdUcK

ñasRmab;GtifiCnmñak;² nig RKb;

eBlsRmab;GtifiCndEdl?

6. karcUleTACit nigPaBgayRsÜl (accessibility and convenience)³

etImanPaBgayRsÜl edIm,ITTYl esvakmµ?

7. PaBRtwmRtÚv (accuracy)³

etIesvakmµRtÚv)aneKbMeBjRtÚvenAelIkdMb

Ug?

8. PaBrs;ran; (responsiveness)³

etIbuKÁlikpþl;esvakmµGaceqøIytby:agrs;revIk

nigedaHRsaybBaðaminrMBwg TukelOn?

niymn½yénviFIsa®sþKuNPaBsrub (The Total Quality

3.

Approach Defined)

manviFIBIry:agedIm,Iyl;TsSnaTanénKuNPaBsru

b (concept of total quality)

1. viFITImYyKWkareRbobRbdUceTAnwgeCIgm:

aEdlmaneCIgbI (analogy of three-legged stool)

kEnøgGgÁúyrbs;eCIgm:aKW

karykcitþTudak;GticiCn (customer focus). enHmann½yfa

CamYyKuNPaBsrub

GtifiCnenAkñúgkEnøgGgÁúyKWCaGñkvinic©½yKu

NPaB.

eCIgnImYy²

KWCaFatud¾TUlMTUlayénTsSnviC¢aKuNPaB

srub³

eCIg {measures} mann½yfa KuNPaBGac

nigRtÚvEtvas;)an.

eCIg {pepole} mann½yfa

KuNPaBminRtÚveFVIeTAplitpl nig

Management of Technology/Group30/Promotion 19

Page 4 of 48

National University of Management

2.

Year IV, Semester I

esvakmµeLIy/ vaRtÚveFVIeTAelI

mnusStamry³karpþl;GMNac

edIm,IeFVIkargarrbs;eKenAkñúgrebobRtwmRt

ÚvmYy.

eCIg {processes} mann½yfa

dMeNIrkarRtÚvEteFVI[RbesIreLIg CaRbcaM

nigKµanTIbBa©b; . GVIEdl

RtÚveKcat;Tukfal¥RbesIr

enAéf¶enHGacl¥bgÁÜrenAéf¶Es¥k. CalT§pl

{l¥lµm} KWminlµm eLIy.

viFITIBIrBnül;KuNPaBsrubCaGVI

nigseRmcvadUcemþc (what it is and how it is achieved)

vaCaGVI

(What

It

Is)³

KuNPaBsrub

KWCaviFIsa®sþénkareFVI

GaCIvkmµ

Edlb:unb:gGtibrimakar

RbkYt

RbECgrbs;GgÁPaB

tamry³kareFVI[RbesIreLIgCaRbcaMnUvKuNP

aBplitpl/ esvakmµ/ mnusS/ dMeNI kar/ nig

briyakasrbs;va.

seRmcvadUcemþc

(How

It

Is

Achieved)³

KuNPaBsrubmanlkçN³dUcteTA³

Ep¥kelIyuT§sa®sþ

(strategically

based)/

ykcitþTukdak;elIGtiCn

(customer

focus)

¬GtifiCnxagkñúg

nigxag

eRkA¦/

karKitmémCanic©dl;KuNPaB (obsession with quality)/

kareFVIesckþIseRmccitþ

Management of Technology/Group30/Promotion 19

Page 5 of 48

National University of Management

Year IV, Semester I

nigedaHRsaybBaðatam

viFIsa®sþEbbviTüasa®sþ

(scientific method to decision making

and problem solving)/

karebþCJacitþkñúgry³eBlEvg (long-term commitment) /

kareFVIkarCaRkum

(teamwork)/kareFVI

[dMeNIrkarRbesIr eLIgCaRbcaM (continual process

improvement)/ karsikSanigkarbNþúHbNþal (education and

training)/esrIPaBtamry³karRtÜtBinitü (freedom through control)/

eKalbMNg

ÉkPaB

(unity

of

purpose)/karcUlrYmnigkarpþl;GMNacdl;nieyaCit

(employee involvement and empowerment ).

FatusMxan;²énKuNPaBsrub (Key Elements of Total Quality)

Ep¥kelIyuT§sa®sþ

(strategically

based)³

GgÁPaBeq<aHeTArkKuNPaBsrub (total quality

organizations)

manEpnkaryuT§sa®sþd¾TUlMTUlaymYy

(a

comprehensive

strategic

plan)

Edly:agehacNas;rYmman

FatudUcteTA³ ckçúvis½y (vision)/ ebskkmµ (mission)/

eKalbMNgTUlay (broad objectives)/ nigskmµPaB (activities)

EdlRtÚveFVIedIm,IseRmceKalbMNgTUlayen

H.

EpnkaryuT§sa®sþ

enHRtÚv)aneKeRKagerobcMeLIgedIm,Ipþl;[G

gÁPaB

nUv]tþmÖPaBénkarRbkYtRbECgsßitesßrmYy

(a

sustainable

competitive

enAkñúgTIpSar . ]tþmÖPaBénkarRbkYt

RbECg

enHsRmúkeTArk

karseRmc)annUvKuNPaBnaMmuxlMdab;BiPB

elak

(world-leading

quality)

nigeFVI[vaRbesIreLIgCaRbcaM

nigCaerogrhUt.

ykcitþTukdak;elIGtifiCn

(customer

focus)³

enAkñúgbriyakasKuNPaBsrub

GtifiCnKWCaGñkkac;cgáÚt

(driver)

cMnucenHGnuvtþn_

TaMgGtifiCnxagkñúg

advantage)

Management of Technology/Group30/Promotion 19

Page 6 of 48

National University of Management

Year IV, Semester I

nigGtifiCnxageRkA. GtifiCnxagkñúg (internal customers)

kMNt;KuNPaBplitpl

b¤esvakmµ.

GtifiCnxageRkA

(external

customers)

CYykMNt;KuNPaBmnusS/ dMeNIrkar/ nig

briyakasEdlTak;TgCamYyplitpl b¤ esvakmµ .

karKitmémCanic©dl;KuNPaB (obsession with quality)³

buKÁlikenARKb;kRmitTaMgGs;énGgÁPaBTa

k;Tg

CamYyRKb;TidæPaBTaMgGs;énkargaredayQ

anecjBITsSn³

{etIeyIgGaceFVI[RbesIrCagenHdUcemþc?}

(how can we do this better?) .

kareFVIesckþIseRmccitþ

nigedaHRsaybBaðatamviFIsa®sþEbbviTüasa

®sþ (scientific method to decision making and problem solving)³

Tinñn½yRtÚv)aneKeRbIedIm,IkMNt;sþg;dar

tamdandMeNIrkar nigkareFVI [RbesIreLIg .

karebþCJacitþkñúgry³eBlEvg (long-term commitment)³

karebþCJacitþ

ry³eBlEvgedIm,IeFVIkarpøas;bþÚr

Edl

mansar³sMxan;sRmab;eCaKC½y .

kareFVIkarCaRkum

(teamwork)³

lubbM)at;karRbkYtRbECg

nigPaBminTukcitþKña .

kareFVI[dMeNIrkarRbesIreLIgCaRbcaM (continual

process

improvement)³

plitplRtÚv)anplit

nig

esvakmµRtÚv)anpþl;edaymnusSedayeRbIdM

eNIrkarenAkñúgbriyakas¬RbB½n§¦

.

edIm,IeFVI[KuNPaBplitpl

nig

esvakmµRbesIreLIgCaRbcaM

vaRtÚvkarcaM)ac;eFVI[RbB½n§RbesIreLIgCa

RbcaM .

karsikSa nigkarbNþúHbNþal (education and training)³

karsikSanigkarbNþúHbNþal KWCamUldæan

énKuNPaBsrub

Management of Technology/Group30/Promotion 19

Page 7 of 48

National University of Management

Year IV, Semester I

BIeRBaHvatMNag[viFIRbesIrbMputedIm,IeFVI

[mnusSRbesIreLIgCaRbcaM

.

KWtamry³karsikSa

nigkarbNþúHbNþalenHehIyEdleFVI[mnusSdw

gBIrebobeFVIkargar

nigeFVIkargarRbkbedayPaBv½yqøat .

esrIPaBtamry³karRtÜtBinitü

(freedom through control)³

karcUlrYm nigkarpþl;GMNac dl;buKÁlik KW

CaRKwHénKuNPaBsrub

BIeRBaHvaKWCameFüa)aymYyedIm,I[mnus

SmanKMnit nig dwgBIrebobénkareFVIesckþI

seRmccitþ .

eKalbMNgÉkPaB

(unity

of

purpose)³

edIm,IGnuvtþn_viFIsa®sþ

KuNPaBsrub

GgÁPaBRtÚvmaneKalbMNg ÉkPaBKña .

karcUlrYm nigkarpþl;GMNacdl;nieyaCit (employee

involvement

and

empowerment

)³

GnuBaØat

[nieyaCitGacbeBa©jsMelgBitR)akdmYy

.

enHGaceFVIeTA)anedaykarerobcMrcnasm<n

§kargarmYy

Edl

GnuBaØat[nieyaCiteFVIesckþIseRmccitþEdlT

ak;TgCamYykareFVI[RbesIreLIgéndMeNIrkar

kargar .

TsSnaTan Six Sigma (Six Sigma Concepts)

TsSnaTan Six Sigma

RtÚv)anbegáIteLIgedayRkumh‘un Motorola

enABak;kNþalTsSvtSr_qñaM1980 .

eKalbMNgrbs; Six Sigma

KWeFVI[RbesIreLIgnUvkarsMEdgskmµPaBén

dMeNIrkar (performance of the process)

eTAdl;cMnucmYyEdlkRmitGnibuNPaB (defect rate)

esµI 3.4 b¤ticCagkñúgmYylan .

RbvtþiRtÜs²énkarRKb;RKgKuNPaB (Historical Review)

qñaM1911³ Frederick W. Taylor e)aHBumÖesovePA The

Principles of Scientific Management

Management of Technology/Group30/Promotion 19

Page 8 of 48

National University of Management

Year IV, Semester I

Edlpþl;kMeNIteTA[viFIsa®sþmYycMnYndUcC

a time and motion studies.

qñaM1931³ Walter A. Shewhart ]eTÞsnam statistical

quality control enAkñúgesovePArbs;Kat; Economic Control of

Quality of Manufactured Products.

qñaM1940³ W. Edwards Deming CYy U.S. Bureau of the Census

enAkñúgkarGnuvtþ statistical sampling techniques.

qñaM1941³ W. Edwards Deming eTAbeRmIkargarenA U.S.

War Department edIm,IbeRgón quality control techniques.

qñaM1950³ W. Edwards Deming

EføgsunÞrkfaeTAkan;Gñk viTüasa®sþ (scientists) /

visVkr (engineers)/ nignaykRbtibtþi Rkumh‘un (corporate

executives)RbeTsCb:un

sþIGMBIeKalbMNgénKuNPaB .

qñaM1951³ Joseph M. Juran e)aHBumÖesovePA Quality

Control Handbook.

qñaM1961³ Martin Company (later Martin-Marietta) plitkaMRCÚc

Pershing Edlman GnibuNPaBsUnü (zero defects).

qñaM1970³ Philip

Crosby ]eTÞsnamTsSnaTanGnibuNPaBsUnü

(concept of zero defects).

qñaM1979³ Philip Crosby e)aHBumÖesovePA Quality Is

Free.

qñaM1980³ kmµviFITUrTsSn_pSay If Japan Can...Why

Can’t We EdleFVI[ W. Edwards Deming

TTYlsÁal;CafµImþgeTotenAkñúgshrdæGaemr

ik .

qñaM1981³ Rkumh‘un Ford )anGeBa©Ij W. Edwards

Deming eTAEføgsunÞrkfaenAcMeBaHmuxnayk

Rbtibtþi (top executives).

qñaM1982³ W. Edwards Deming e)aHBumÖesovePA

Quality, Productivity, and Competitive Position.

qñaM1984³ Philip Crosby e)aHBumÖesovePA Quality

without Tears: The Art of Hassel-Free Management.

qñaM1987³ sPaGaemrikbegáIt Malcom Baldrige National

Quality Awards/ Rkumh‘un Motorola ]eTÞsnam “Six Sigma” Method.

Management of Technology/Group30/Promotion 19

Page 9 of 48

National University of Management

Year IV, Semester I

qñaM1988³ rdæelxaFikarRksYgkarBarCati Frank

Carlucci dwknaM U.S. Department of Defense

Gnuvtþn_KuNPaBsrub.

qñaM1989³ Florida Power and Light TTYlrgVan; Deming Prize

rbs;RbeTsCb:un.

qñaM1993³ viFIsa®sþKuNPaBsrub (total quality

approach) RtÚv)an eKbeRgóny:agTUlMTUlay

enAtam mhaviTüal½y

nigsaklviTüal½yGaemrik .

qñaM2000³ ISO standard

RtÚv)antak;EtgeLIgvijedIm,IbBa©Úl

TsSnaTanKuNPaBsrub.

qñaM2001³ E-Commerce nig masscustomization

KWCaktþaEdlRtÚvbBaÚ©lkñúgkareFVIvinicä

½yd¾sMxan; .

sMnYr (Review Questions)

1. cUrniymn½yKuNPaB.

2. cUrerobrab;FatusMxan;²énKuNPaB ¬plitpl

nigesvakmµ¦.

3. etIKuNPaBsrubCaGVI?

4. cUrerobrab;

nigBnül;FatusMxan;²énKuNPaBsrub.

5. etI Six Sigma CaGVI?

6. cUrerobrab;RtÜs²GMBIRbvtiþénkarRKb;RK

gKuNPaB.

Management of Technology/Group30/Promotion 19

Page 10 of 48

National University of Management

Year IV, Semester I

emeronTI2

RTwsþIénKuNPaB

Quality Theory

bøg;emeron

•

•

•

•

•

•

W. Edwards Deming

Joseph M. Juran

Philip B. Crosby

Armand V. Feigenbaum

Kaoru Ishikawa

Genichi Taguchi

W. Edwards Deming

• Deming’s Contribution

• Deming Chain Reaction

•

•

•

•

kareFVI[KuNPaBRbesIreLIg

naMeTAdl;cMNayTab

BIeRBaHvabegáIt[mankareFVIkargareLIgvijtick

MhuskarBnüaeBl nig

bBaðaticnigkareRbIeBlnigsmÖar³RbesIr.

cMNayticeFVI[plitPaBRbesIreLIg.

KuNPaBl¥ nig éføTab

Rkúmh‘unGacTTYl)annUvGRtaTIpSarFM

dUecñH bnþenAkñúgGaCIvkmµ/

pþl;kargarkan;Et eRcIneLIg.

Deming Cycle

Management of Technology/Group30/Promotion 19

Page 11 of 48

National University of Management

1.

2.

3.

4.

5.

•

Year IV, Semester I

RsavRCavGñkeRbIR)as; nig

eRbIvaenAkñúgkareFVIEpnkarplitpl (plan)

plitplitpl (do).

RtÜtBinitüplitpl

edIm,IeFVI[R)akdfavaRtÚv)aneKplitRsbCam

Yy Epnkar (check).

lk;plitpl (act).

viPaKetIplitplRtÚv)anTIpSarTTYlykdUcemþc

edayeyaleTA elIKuNPaB/ éføedIm/ nig

lkçN³vinic©½y déTeTot (analyze).

Deming’s Fourteen Points

1.

2.

begáIteKalbMNg\tpøas;bþÚrmYy

eKalbMNg\tpøas;bþÚreq<aHeTArk

kareFVI[plitplRbesIreLIgCaRbcaM.

Gnuvtþn_TsSnviC¢afµI

GñkRKb;RKgfñak;x<s;nigRKb;KñaRtÚveronn

UvTsSnviC¢afµI²

.

GgÁPaBRtÚvEsVgrkkareFVI[RbesIreLIg

KµanTIbBa©b;

(never-ending

improvement)

nigQb;TTYlyknUvPaBminGnueLamtam

(nonconformance).

3.

yl;BIeKalbMNgénkarBinitüemIl

GñkRKb;RKgRtÚvyl;faeKal

bMNgénkarBinitüemIlKWedIm,IeFVI

[dMeNIrkar RbesIreLIg nig bnßycMNayrbs;va .

karBinitüemIlenAkñúgRTg;RTayFM (mass inspection)

PaKeRcIn

cMNayluykak;eRcIn

nigminGaceCO)an.

vaKYrRtÚv)anCMnYs

edaykareFVI[RbesIreLIgKµanTIbBa©b; (never-ending

Management of Technology/Group30/Promotion 19

Page 12 of 48

National University of Management

Year IV, Semester I

edayeRbIviFIsa®sþsßiti

.

PsþútagsßititRmÚv[mansRmab;Rkumh‘un nig

GñkpÁt;pÁg;.

4. Qb;GnuvtþkareRCIserIsGñkpÁt;pÁg;Ep¥keTA

elIéfø GgÁPaBRtÚvQb;GnuvtþkaredjéføTab

BIeRBaHéføTab

BMumann½y

eLIyRbsinebIKµanKuNPaB

.

RtÚvmanGñkpÁt;pÁg;EtmYyKt;

ehIybegáItTMnak;TMngry³eBlEvg Rbkbeday

PaBesµaHRtg;

nigTukcitþ

.

dUecñHeKnwgpþl;nUvplitplnigesvakmµkan;Et

RbesIreLIg .

5. FVI[RbB½n§RbesIreLIgCaRbcaM

nigCaerogrhUt

eFVI[RbB½n§plit

kmµRbesIreLIgCaRbcaM

nigKµanTIbBa©b;

edIm,I eFVI[KuNPaB nig plitPaBRbesIreLIg

dUecñHcMNayFøak;cuHCabnþbnÞab;.

6. bNþúHbNþal

(Institute

Training).

bNþúHbNþalnieyaCitGMBIkar

karBarbBaðaKuNPaB

nigkareRbIR)as;

statistical quality techniques.

7. beRgon

nigbNþúHPaBCaGñkdwknaM

beRgon nigbNþúHPaBCaGñkdwknaMdl;supervisor

edIm,I[eKCYynieyaCit eFVIkargar)anl¥RbesIr.

8. bM)at;karP½yxøac

begáItesckþITukcitþ

nigbegáItbriyakassRmab;rbkKMehIjfµI

.

CMrujkarR)aRs½yTak;Tg

edaycMhrmanRbsiT§iPaB

nig

kareFVIkarCaRkúm.

9. lubbM)at;]bsKÁrvagEpñkepSg²

lubbM)at;]bsKÁrvagEpñkepSg²

edIm,I[nieyaCitGaceFVIkarCaRkúm .

10. Qb;sMu[begáInplitPaB

edayminpþl;nUvviFIsa®sþedIm,IseRmcva

improvement)

Management of Technology/Group30/Promotion 19

Page 13 of 48

National University of Management

Year IV, Semester I

lubbM)at;Baküesøak kardas;etOn nigeKal

edAsRmab;kmµkr.

11. lubbM)at;cMnYnkRmit

nigkarRKb;RKgtameKalbMNg

karykcitþTukdak;eTAelIcMnYnkRmitCRmuj

nigelIkTwk

citþmnusS[eq<aHeTArkbrimaNCaCagKuNPa

B.

12.

lubbM)at;]bsKÁEdlbøn;nUvemaTnPaBénbMNi

nrbs;mnusS ]bsKÁcm,gcMeBaHemaTnPaBén

bMNin

KWRbB½n§én

karvaytémøkargarEp¥keTAelIeKaledAcMnYnk

Rmit niglkçN³mYycMnYneTot .

13. CMrujkarsikSa

nigkarGPivDÆn_xøÜnsRmab;niyaCitmñak;²

14cMnucrbs; Deming nig ebskkmµrbs;GgÁPaB

KYreFVICamUldæanénkmµviFIsikSa

.

RKb;²KñaKYrRtÚvbNþúHbNþaleLIgvijenAeBlt

RmÚvkarrbs;GgÁPaBpøas;bþÚr

edIm,I

eqøIytbnwgbmøas;bþÚrbriyakas.

14. begáIeLIgnUvrcnasm<½n§

enAkñúgGñkRKb;RKgfñak;x<s;Edlsgát;eTAelI

13cMnucxagelI GñkRKb;RKgRtÚvTTYlyknUv

karTTYlxusRtÚvsRmab;

kareFVI[dMeNIrkarRbesIreLIgKµanTIbBa©ab;

.

RtÚvbegáItrcnasm<½n§Rkumh‘unedIm,IGnu

vtþn_TsSnviC¢aenH

.

GñkRKb;RKgRtÚvebþCJacitþ/

cUlrYmenAkñúgkarGnuvtþn_TsSnviC¢afµIen

H.

•

Deming’s Seven Deadly Diseases

Management of Technology/Group30/Promotion 19

Page 14 of 48

National University of Management

1.

2.

3.

4.

5.

6.

7.

Year IV, Semester I

karxVHnUveKalbMNgPaB\tpøas;bþÚr

Rkumh‘unEdlBMumaneKalbMNg\tpøas;bþÚrB

MumanEpnkarry³eBlEvgsRmab;

bnþenAkñúgGaCIvkmµ .

karsgát;F¶n;elIR)ak;cMeNjry³eBlxøI

.

karRkeLkemIleTAelIkar

begáInR)ak;cMeNjRbcaMRtImas

eFVI[Gnþ

raydl;KuNPaBnigplitPaB.

karvaytémøedaykarsEmþgskmµPaB/

cMNat;fñak;KuNsm,tþi/

b¤

BinitüemIlkarsEmþg skmµPaBRbcaMqñaM .

\T§iBlBlrbs;va

eFVI[exÞcxÞIGs;

kareFVIkarCaRkumRtÚv)anbMpøaj/

begáItnUvkarRbECg/ cMNat;fñak;kar sEmþg

skmµPaB

begáItkarP½yxøac

nigeFVI[mnusSmankarQWcab;/

xUccitþ/

nigehvht; .

clPaBénGñkRKb;RKg

GñkRKb;RKgEdlpøas;bþÚrkargarjwkjab;

minEdleCOeTAelIRkumh‘unEdleKeFVIkar[ nig

minEdlenAyUredIm,IedIrtambmøas;bþÚrry³eBl

EvgEdlRtÚvkarcaM)ac;sRmab;KuNPaB

nigplitPaBeLIy .

karerobcMRkumh‘unEp¥kEteTAelIB½t’manCa

tYelxEdlemIleXIj

.

B½t’manCatYelxsMxan;²PaKeRcInminRtÚv)a

ndwg b¤ minGacdwg)an .

cMNayeTAelIEpñkevC¢sa®sþeRcInhYsehtu .

sRmab;Rkumh‘unmYycMnYn

cMNayenHCacMNayd¾eRcInbMputmYy .

cMNayeRcInhYsehtueTAelIesvakmµc,ab;

EdlbeBaäHedayemFavI

EdleFVIkaredIm,IkéRm .

Joseph M. Juran

Juran’s Contribution

Management of Technology/Group30/Promotion 19

Page 15 of 48

National University of Management

Year IV, Semester I

Juran’s Three Basic Steps to Progress

Juran’s Ten Steps to Quality Improvement

The Pareto Principle

The Juan’s Trilogy

Three Basic Steps to Progress

1.

2.

3.

begáIteLIgnUvrcnasm<½n

sRmab;kareFVI[RbesIreLIgCaRbcaM.

begáItkmµviFIbNþúHbNþald¾TUlMTUlay .

begáItkarebþCJacitþ nigPaBCaGñkdwknaM

enAelIEpñkénGñkRKb;RKgfñak;x<s; .

Ten Steps to Quality Improvement

begáIt[mankaryl;dwgGMBItRmÚvkar

nigkalanuvtþPaB sRmab;kareFVI[RbesIreLIg .

2. kMNt;eKalbMNgsRmab;kareFVI[RbesIreLIg

3. erobcMedIm,IeqøIytbeKalbMNgEdl)ankMNt;

4. pþl;karbNþúHbNþal

5. Gnuvtþn_KeRmagedayeq<aHeTArkkaredaHR

saybBaða

6. raykarN_karrIkceRmIn

7. TTYlsÁal;

8. bgðajlT§pl

9. rkSalT§pl

10. rkSakarrIkceRmIn

edayeFVI[karRbesIreLIgcUleTAkñúgRbB½n§r

bs;Rkumh‘un

1.

The Pareto Principle

CYnkaleKehAfa 80/bBaða 80% bNþalmkBI

mUlehtu

20%.GgÁPaBRtÚvykcitþTukdak;eTAelIkarlubbM)at; vital

few

sources

EdleFVI[ekItbBaðaPaKeRcIn.RbB½n§EdlGñkRKb;

RKgRtÜtRta

KWCaRbB½n§EdlbBaðaPaKeRcInekIteLIg .

The Juan’s Trilogy

Management of Technology/Group30/Promotion 19

Page 16 of 48

National University of Management

•

•

•

Year IV, Semester I

kareFVIEpnkarKuNPaB

³

kareFVIEpnkarKuNPaBTak;TgCamYykar

begáItplitpl RbB½n§ nig dMeNIrkarEdlRtÚv

karcaM)ac;edIm,IbMeBj

b¤bMeBjelIskarrMBwgTukrbs;GtifiCn .

karRtÜtBintüKuNPaB

³

karRtÜtBinitüKuNPaBTak;TgCamYykarvay

témøkarsMEdgskmµPaBKuNPaBBitR)akdeRbo

b eFobkarsMEdg skmµPaBCamYyeKalbMNg

eFVIskmµPaBelIPaBxusKña

rvagkarsMEdgskmµPaB nigeKalbMNg.

kareFVI[KuNPaBRbesIreLIg³

kareFVI[KuNPaBRbesIreLIg

KYreFVIeLIg

CaRbcaM nig mindac;.

Philip B. Crosby

• Crosby’s Contributions

• Absolutes of Quality Management

• Crosby’s Quality Vaccine

• Crosby’s Fourteen Steps to Quality Improvement

Absolutes of Quality Management

1.

2.

3.

4.

KuNPaB mann½yfaGnueLamtambTdæan/

minEmnPaBl¥eT.

RbB½n§ sRmab;karseRmcnUvKuNPaB

KWkarkarBar/ minEmnkarvay témøeT.

sþg;darénkarvaytémøKuNPaBKW zero defects

minEmn close enough eT.

rgVas;énKuNPaBKWcMNayeTAelIPaBminGn

ueLam.

Crosby’s Quality Vaccine

Management of Technology/Group30/Promotion 19

Page 17 of 48

National University of Management

1.

2.

3.

Year IV, Semester I

karebþCJacitþ³

GñkRKb;RKgfñak;x<s;RtÚvykcitþTukdak;xøa

MgeTAelI kareFVI[KuNPaBRbesIreLIg.

karsikSa³

RKb;Kña²RtÚvyl;dwgnUvmUldæanRKwHénka

rRKb;RKgKuNPaBEdlGacseRmc)anEttamry³k

arsikSab:ueNÑaH.

karGnuvtþ³ smaCikmñak;²énRkumRKb;RKg

RtÚvyl;dwgnUvdMeNIrénkarGnuvtþ .

Fourteen Steps to Quality Improvement

eFVI[R)akdfaGñkRKb;RKgmankarebþCJacitþ

cMeBaHKuNPaBenAkñúgry³eBlEvg.

2. begáItRkumKuNPaBcMruHEpñk.

3. kMNt;kEnøg EdlbBaðabc©úb,nñ

nigskþanuBlekIteLIg.

4. RbmaNkarcMNayeTAelIKuNPaB.

5. begáInkaryl;dwgelIKuNPaB

nigkarebþCJacitþpÞal;rbs;nieyaCitTaMgGs;.

6. eFVIskmµPaBCabnÞan;

edIm,IEktRmÚvbBaðaEdl)ankMNt;.

7. begáItkmµviFI a zero defects.

8. bNþúHbNþal supervisor

edIm,IGnuvtþn_karTTYlxusRtÚvrbs;eK

enAkñúgkmµviFIKuNPaB.

9. begáIt Zero Defects Day edIm,IeFVI[R)akdfa

nieyaCitTaMgGs; dwgfeKmanTisedAfµI .

10. CMrujbuKÁl nigRkum

edIm,IbegáIteKalbMNgénkareFVI[RbesIreLIgT

aMgbuKÁlnigRkum .

11. CMrujnieyaCit

[R)ab;GñkRKb;RKgGMBI]bsKÁEdleKCYb

enAkñúgkar

RbwgERbgedIm,IeqøIytbeKalbMNgKuNPaB.

12. TTYlsÁal;nieyaCitEdlcUlrYm.

1.

Management of Technology/Group30/Promotion 19

Page 18 of 48

National University of Management

Year IV, Semester I

begáItRkumRbwkSaEpñkKuNPaB

edIm,ICMrujkarR)aRs½yTak;TgCaRbcaM.

14. eFVIGVI²mþgeTot

edIm,IbgðajkareFVI[KuNPaBRbesIreLIg

KWCadMeNIrKµanTIbBa©b;.

13.

Armand V. Feigenbaum

Feigenbaum’s Contributions

Three Steps to Quality

1.

2.

3.

PaBCaGñkdwknaMKuNPaB³karsgát;F¶n;eTA

elIkarRKb;RKgCaRbcaMEp¥kelImUldæanénk

areFVIEpnkard¾l¥CaCagmanRbtikmµeTAnw

gbraC½y

.

GñkRKb;RKgRtÚvEtykcitþTukdak;CaRbcaM

nigdwknaMkarRbwgERbgKuNPaB .

bec©kviTüaKuNPaBTMenIb

³

EpñkKuNPaBEbbburaN

minGacedaHRsay80eTA90PaKryénbBaðaKu

NPaB

.

kargarenH

tRmÚv[mansmahrNkmµénbuKÁlikkariyal½y

visVkr nig kmµkreragcRk EdlCaGñkvaytémø

nig

Gnuvtþn_CaRbcaMnUvbec©keTsfµI²

edIm,IbMeBjtRmÚvkarGtifiCn.

karebþCJacitþrbs;GgÁPaB

³

karbNþúHbNþalCaRbcaM nigkarelIkTwkcitþ

kMlaMgBlkmµTaMgGs;rYmTaMgsmah

rNkmµénKuNPaBeTAkñúgkareFVIEpnkarGaC

Ivkmµ bgðajnUvsar³sMxan;énKuNPaB nig

pþl;nUvmeFüa)aysRmab;

karbBa©ÚlKuNPaBeTAkñúgTidæPaBTaMgG

s;énskmµPaBrbs;Rkumh‘un .

Kaoru Ishikawa

1.

2.

KuNPaBcab;epþImCamYykarsikSa

nigbBa©b;CamYykarsikSa .

CMhandMbUgenAkñúgKuNPaB

KWRtÚvdwgtRmÚvkarGtifiCn .

Management of Technology/Group30/Promotion 19

Page 19 of 48

National University of Management

Year IV, Semester I

sPaBl¥Nas; énkarRtÜtBinitüKuNPaB

ekIteLIgenAeBl inspection Elgmansar³sMxan; .

4. lubbM)at;mUlehtub¤sKul/

minEmneraKsBaØaeLIy .

5. karRtÜtBinitüKuNPaB

KWCakarTTYlxusRtÚvénkmµkrTaMgGs;

nigEpñkTaMgGs; .

6. kMuRcLMmeFüa)ayCamYyeKaledA .

7. dak;KuNPaBmunGVI²TaMgGs;

nigsMLwgeTArkR)ak;cMeNjry³eBlEvg .

8. m:arXItFIg KWCapøÚvcUl nigecjénKuNPaB .

9. GñkRKb;RKgfñak;x<s; minRtÚvbgðajkMhwg

enAeBlB½t’manBit RtÚv)an

bgðajedayGñkenAeRkambgÁab; .

10. bBaðaenAkñúgRkumh‘un 95%

GacRtÚv)anedaHRsayeday]bkrN_ samBaØ

sRmab;karviPaK nigkaredaH RsaybBaða .

3.

11.

Tinñn½yEdlBMumanB½t’manbERmbRmÜlKW

CaTinñn½yxus .

Genichi Taguchi

Quality Loss Function

kMNt;nUvcMNayTaMgGs;EdlTak;TgCamYyKuN

PaBGn;

nigbgðajfa

cMNayTaMgenHekIneLIgdUcemþcenAeBlKuN

PaBplitplXøatBIGVIEdlGtifiCncg;)an

.

cMNayTaMgenH

rYmmanminRtwmEtkarmineBjcitþrbs;GtifiCn

b:ueNÑaHeT b:uEnþ EfmTaMgcMNayelIkarFana

nig esvakmµ cMNayeTAelIkarBinitüplitpl karCYsCul

Management of Technology/Group30/Promotion 19

Page 20 of 48

National University of Management

nigxUc

nigcMNay

RtÚveKBiBN’naCacMNaycMeBaHsgÁm .

Year IV, Semester I

EdlGac

sMnYr (Review Questions)

1. cUrBiBN’naeKalKMnit³

a. Deming Chain Reaction

b. The Deming Cycle

c. Deming’s Fourteen Points

d. The Seven Deadly Disease

2.

3.

4.

cUrBnül; Juran’s Quality Trilogy.

etIkareRbI Pareto chart sRmab;bBaðaNamYy

maneKalbMNgGVI?

cUrsegçbviPaKTansMxan;én Crosby, Feigenbaum, Ishikawa,

nig Taguchi cMeBaHeKalKMnitKuN PaBTMenIb.

Management of Technology/Group30/Promotion 19

Page 21 of 48

National University of Management

Year IV, Semester I

emeronTI3

KuNPaBnigkarRbkYtRbECgsakl

Quality and Global Competitiveness

bøg;emeron

The Relationship between Quality and Competitiveness

Cost of Poor Quality

Impact of Competitiveness on Quality of Life

Factors Inhibiting Competitiveness

Human Resources and Competitiveness

The Relationship between Quality and Competitiveness

TMnak;TMngrvagKuNPaBnigkarRbkYtRbECg

mandUcteTA³enAkñúgTIpSarsaklTMenIb/KuN

PaBKWCaKnøwHénkarRbkYtRbECg

sBVéf¶enH

karRbkYtRbECg)anpøas;BIkRmitenAkñúgRsuk

/

tMbn;b¤Cati

eTAkRmitGnþrCati

EdlmansPaBkan;Et

xøaMgkøaeLIg²BImYyéf¶eTAmYyéf¶.

manEtRkumh‘unEdlGacplitplitplEdlmanKuNPa

BlMdab;BiPBelakeT

eTIbGacRbkYtRbECgenAkñúgkRmit

Gnþr

Cati)an .

vamansar³sMxan;xøaMgNas;sRmab;Rkumh‘un

enAkñúgRbeTsmYy

edIm,IGacRbkYtRbECgCalkçN³sakl

.

enAeBleK

minGac

kargarRtÚv)at;bg;

ehIyKuNPaBénCIvitenAkñúgRbeTsenaHFøak;

cuHeTAtamenaHEdr .

etIKuNPaBCYy[GgÁPaBRbkYtRbECgdUcemþ

c?

Costs of Poor Quality

etIeKRtÚvcMNayluyeTAKuNPaB?

etIeKKYrkat;bnßyKuNPaB

edIm,I[RsbCamYybBaðaEpñkhirBaØvtßú?

]TahrN_³

Rkumh‘unBIr

ABC

nig

Rkumh‘unTaMgBIrRbkYt

RbECgenAkñúgTIpSarsakledIm,Irs;ran .

Management of Technology/Group30/Promotion 19

XYZ

Page 22 of 48

National University of Management

GñkRKb;RKgRkumh‘un

ABC

cab;epþImkat;bnßycMNaysMxan;²

dUcCalubbM)at; quality audits eRCIserIs low-bid suppliers

kat;bnßycMNayeTAelI R&D. l.

GñkRKb;RKgRkumh‘un

XYZ

RbwgERbglubbM)at;cMNayepSg²

dUcCacMNayEdlTak;TgCamYy late deliveries to customers,

billing

Year IV, Semester I

errors,

scrap

and

rework.

edaymineFVI[b:HBal;eTAdl;KuNPaB .

etIRkumh‘unNamYynwgrs;ranenAkñúgry³eBlEv

g?

cMNayeTAelIKuNPaBGn;manRbEhlBI 15% eTA

30% éncMNaysrubrbs;Rkumh‘un .

karkat;bnßycMNayEdlTak;TgCamYyKuNPaBG

n;RtÚvEteFVIcaM)ac;sRmab;Rkumh‘unEdlRbk

YtRbECgenAkñúgTIpSarsakl

ktþaEdlRtÚvBicarNarenAeBlkMNt;cMNayeTAel

IKuNPaBGn;³

Impact of Competitiveness on Quality of Life

smßPaBrbs;CatimYyedIm,IRbkYtRbECgenAkñ

úgTIpSarsaklman\T§iBledaypÞal;eTAelIKuNPa

BénCIviténRbCaBlrdærbs;xøÜn.

smßPaBedIm,IRbkYtRbECgBwgEp¥keTAelIsm

ßPaBedIm,IeFVIkargar)anRbesIrenAkñúgkarpli

tTMnij.

edIm,IeFVIkargar)anRbesIrenAkñúgkarplitTMni

j/

RbeTsCati

nig

Management of Technology/Group30/Promotion 19

Page 23 of 48

National University of Management

Year IV, Semester I

GgÁPaBRtÚvykcitþTukdak;eTAelI policies, systems nig

resources

enAkñúg

coordinated

way

edIm,IeFVI[RbesIreLIgCaRbcaM .

bNþaRbeTs]sSahkmµCaeRcIn)anP¢ab;vaeTA

nwgkarsikSaesdækic©

nigeKalneya)ayTIpSarBlkmµ

edIm,ICMrujkar

RbkYtRbECg.

Factors Inhibiting Competitiveness

Business and Government

Family

Education

Factors Inhibiting Competitiveness

Business/Government-Related Factors

sgát;F¶n;eTAelIR)ak;cMeNjry³eBxøI.

cMNayeRcIhYsehtueTAelIEpñkevC¢sa®sþ.

cMNayeRcIhYsehtueTAelIesvakmµEpñkc,ab;.

edIm,IlubbM)at;]bsKÁTaMgenH/

vaTamTa[

business

nig

government

eFVIkarCamYyKñaedIm,IbegáItnUveKal

neya)ay

Edlkat;bnßycMNay\tRbeyaCn_eTAdl;kRmitTab

bMput.

Family-Related Factors

• RKÜsarKWCaPñak;garGPivDÆn_FnFanmnusS

d¾sMxan;bMputrbs; RbeTsCati.

• RKÜsaredIrtYnaTIsMxan;enAkñúgkarsikSaCam

Uldæanrbs;kUnekµg .

RbeTsEdlmantémøRKÜsarxøaMgRtÚv)aneKem

IleXIjfa karGb;rM kUnrbs;eKmanPaBRbesIr

dUecñHbegáItnUvmnusSEdlmancMeNHdwg

nigPaBv½yqøat .

• KuNPaBénRbB½n§sikSarbs;RbeTs

KWCaktþasMxan;énKuNPaB kmøaMgBlkmµ .

Management of Technology/Group30/Promotion 19

Page 24 of 48

National University of Management

Year IV, Semester I

• RbB½n§énkarsikSamanKuNPaBx<s;KWCaFatu

d¾sMxan;énsmßPaBrbs;CatiedIm,IRbkYtRbEC

gsakl .

Human Resources and Competitiveness

• FnFanmantémøbMputsRmab;CMrujkarRbkYtRb

ECg[xøaMgkøabMputKWFnFanmnusS.

• RbeTsGaløWmg; nigCb:un

KWCa]TahrN_RbesIrbMputénkareRbI

R)as;FnFanmnusSd¾manRbsiT§PaB.

Strategies for human resources competitiveness in Japan and Germany

Review Questions

1.

2.

3.

4.

5.

6.

7.

cUrBnül;TMnak;TMngrvagKuNPaB

nigkarRbkYtRbECg.

cUrBnül;cMNayeTAelIKuNPaBGn;

Gacb:HBal;dl;karRbkYt RbECgdUcemþc.

etIsmßPaBrbs;CatimYyedIm,IRbkYtRbECg

man\T§iBleTAelI

KuNPaBénCIvitrbs;RbCaBlrdærbs;xøÜndUem

þc?

cUrBiB½N’na business/government factors GacraraMgkar

RbkYtRbECgdUcemþc.

cUrBiB½N’na family-related factors

GacraraMgkarRbkYtRbECg dUcemþc.

cUrBiB½N’na education-related factors

GacraraMgkarRbkYt RbECgdUcemþc.

cUrerobrab; nigBnül;edaysegçb basic philosophical

constructs

Management of Technology/Group30/Promotion 19

Page 25 of 48

National University of Management

Year IV, Semester I

Ep¥kelITidæPaBFnFanmnusSénkarRbkYt

RbECgrbs;Cb:un nigGaløWmg;.

emeronTI4

karbMeBjtRmÚvkar nigkarEfrkSaGtifiCn

Customer Satisfaction and Retention

bøg;emeron

•

•

•

•

•

Customer Satisfaction

Who Is the Customer?

Customer Perception of Quality

Feedback

Customer Retention

Management of Technology/Group30/Promotion 19

Page 26 of 48

National University of Management

Year IV, Semester I

Customer Satisfaction

•

•

•

•

•

•

RTBüsm,tþisMxan;bMputrbs;GgÁPaBKWGtifiCn

rbs;eK .

eCaKC½yrbs;GgÁPaBBwgEp¥keTAelIcMnYnGt

ifiCnEdleKman brimaN nwgPaBjwkjab;EdleKTij .

bc©úb,nñenH

Rkúmh‘uneRbIkarbMeBjtRmÚvkarGtifiCn

KWCargVas;énKuNPaB.

sar³sMxan;énkarbMeBjtRmÚvkarGtifiCn

minRtwmEtkarRbkYt

RbECgenAkñúgRbeTsb:ueNÑaHeT

b:uEnþEfmTaMgkarRbkYt RbECgsaklpgEdr .

enAkñúgbriyakasKuNPaBsrub

GtifiCnkMNt;nUvKuNPaB

.

dUecñH

karbMeBjtRmÚvkarGtifiCnRtÚvEtman GaTiPaB

x<s;bMput.

karbMeBjtRmÚvkarGtifiCn

seRmc)anedaykarpþl;plitpl

manKuNPaBx<s;EdleqøIytb

b¤eqøIytbelIskar

rMBwgTuk.

Who Is the Customer?

•

•

n½yFmµta/

GtifiCn

KWCaGñkEdlTij

nigeRbIplitplrbs;Rkumh‘un

ehIyGñkpÁt;pÁg;

KWCaGñkEdlpþl;vtßúFatu

dl;Rkumh‘un

edIm,Iplitplitpl.

n½yTsSn³TMenIb/

GgÁPaBnImYy²manGtifiCnxagkñúg

nig

GtifiCnxageRkA .

External Customer

•

•

GtifiCnxageRkA

KWCaGñkEdlTijplitpl

b¤esvakmµ/ GñkEdleRbIplitplplitpl b¤esvakmµ/

GñkEdl man\T§iBl dl;karTijplitpl b¤esvakmµ .

GtifiCnxageRkAmanCabIRbePT³

GtifiCnEdl)at;bg;/

GtifiCnbc©úb,nñ

nigGtiCnskþanuBl .

Management of Technology/Group30/Promotion 19

Page 27 of 48

National University of Management

•

•

Year IV, Semester I

nieyaCitmñak;²RtÚvyl;dwgBIrebobeFVIkargarrb

s;eKedIm,IeFIV[ GtifiCnxageRkAeBjcitþTaMgRs

ug .

dMeNIrkareFVIkargarRtÚvEteFVI[RbesIreLIgCa

RbcaMedIm,IEfrkSa

Gtifinbc©úb,nñ

nigbegáItGtifiCnfµI .

Internal Customer

•

•

•

GtifiCnxagkñúgKWCanieyaCitEdlkargarrbs;eKB

wgEp¥kelI nieyaCitEdleFVIkargarmunKat;.

eKalbMNgénkmµkrmñak;²

KWeFVI[R)akdfaKuNPaBeqøIytbeTA

nwgkarrMBwgTukénkmµkrbnÞab;.

enAeBlvaekIteLIgTUTaMgEpñkplitkmµ

karlk;

nigRckEbgEck

enaHkarbMeBjtRmÚvkarGtiCnxageRkARtÚv)an

Fana.

Traditional View of Suppliers and Customers

Customer Perception of Quality

• American Society for Quality

(ASQ)

)aneFVIkarsÞg;mtieTAelIsBaØakçn§GñkeR

Management of Technology/Group30/Promotion 19

Page 28 of 48

National University of Management

Year IV, Semester I

bIR)as;cugeRkayGMBIktþasMxan;²

EdlCH\T§iBldl;karTij³

(1) Performance

(2) Feature

(3) Service

(4) Warranty

(5) Price

(6) Reputation

CYy[GgÁPaB³

rkeXIjkarbMeBjtRmÚvkarrbs;GtifiCn.

rkeXIjGaTiPaBeFobénKuNPaB.

eRbobeFobdMeNIrkarplitplCamYyKUrRbkYtRb

ECg.

kMNt;tRmÚvkarGtifiCn.

kMNt;»kassRmab;kareFVI[RbesIreLIg.

Feedback

•

•

•

•

•

Comment Card

•

eKalbMNgrbs; card

enHKWedIm,IRbmUlB½t’mansamBaز dUcCa

eQµaH Gasydæan Gayu muxrbr

nigGVIEdlman\T§iBleTAelIkar

eFVIesckþIseRmccitþTijtbs;GtifiCn.

Customer Questionnaire

•

enAkñúgTRmg;én questionnaire

GtifiCnRtÚv)aneKsaksYr

edIm,I[eqøIysMnYrEdlTak;TgeTAnwgKuNPaBpl

itpl b¤ esvakmµ.

Focus Group

• Focus group

KWCaviFIsa®sþénkarRsavRCavedIm,Irk[eXIj

nUvGVIEdlGtifiCnkMBugKit.

Toll-Free Telephone Numbers

•

KWCaviFIsa®sþedIm,ITTYlkartva:rbs;GtifiCnd¾

manRbsiT§PaB.

Customer Visits

•

•

GgÁPaBGactamdannUvkarsMEdgskmµrbs;plitpl.

GñkRKb;RKgfñak;x<s;RtÚvcUlrYmenAkñúgskm

µPaBenH ehIyminRtÚv

RbKl;va[eTAnrNamñak;eToteLIy. k¾b:uEnþ

Cakarl¥RtÚvnaMCamYy

Management of Technology/Group30/Promotion 19

Page 29 of 48

National University of Management

Year IV, Semester I

nUvbuKÁlikEpñkRbtibtþikaredIm,I[eKemIleXIjCa

mun etIplitpl dMeNIrkarya:gdUcemþc.

Report Card

•

•

enAkñúgTRmg; Report Card/

Rkumh‘un[GticiCncat;fñak; plitplrbs;eK.

cMNat;fñak;mandUcteTA³

A = Excellence, B = Very Good, C = Average, D = Poor, F = Failing

Report Card

I. Product Quality

II. On-Time Delivery

III. Service

IV. Overall

Signed

Title

Grade

Comment

Grade

Comment

Grade

Comment

Grade

Comment

Date

Organization

Employees

•

•

nieyaCitGacpþl;KMnitGMBIplit

b¤esvakmµenAkñúgGgÁPaB.

RkuménnieyaCitGacbMpusKMnitGMBIdMeNaH

RsayénbBaðaEdl GtifiCn)ankMNt;.

Customer Retention

•

•

•

karbMeBjtRmÚvkarGtifiCnminRKb;RKan;eLIy.

GgÁPaBKYreTA hYsBIkareBjcitþGtifiCn

edaypþl;GtßRbeyaCn_RbesIrbMputdl;

GtifiCnedIm,I[eKmanPaBesµaHRtg;nwgRkumh‘

un.

karEfrkSaGtifiCnCMrujkareBjcitþGtifiCneTAdl;k

RmitbnÞab;

edaykMNt;GVIEdlBitCamansar³sMxan;cMeBaH

GtifiCn.

karEfrkSanieyaCitman\T§iBly:agxøaMgeTAelIka

rEfrkSaGtifiCn.

meFüa)aymYyEdlGgÁPaBGacRKb;RKgkarEfrk

SaGtifiCnKWRtÚv

ykcitþTukdak;[)anxøaMgcMeBaHnieyaCitbc©úb

,nñ nignieyaCitEdl Rkumh‘unnwgRtÚvCYl.

Review Questions

Management of Technology/Group30/Promotion 19

Page 30 of 48

National University of Management

1.

2.

3.

4.

Year IV, Semester I

cUrBnül;GMBIsar³sMxan;rbs;GtifiCnenAkñúgbri

yakasKuNPaB srub.

cUr[niymn½yGtifiCn GtifiCnxagkñúg

nigGtifCnxageRkA.

cUrerobrab;nwgBnül;ktþasMxan;TaMgR)aMmY

yEdlCH\T§iBldl;kar Tijrbs;GñkeRbIR)as;.

etIviFIsa®sþsMxan;²edIm,IRbmUlB½t’manGMBI

GtifiCnmanGVIxøH?

emeronTI5

karcUlrYm nig karpþl;GMNacdl;nieyaCit

Employee Involvement and Empowerment

bøg;emeron

• Involvement

• Motivation

• Benefits of Employee Involvement

• Empowerment

• Teams

• High Performance Work Systems

Employee Involvement

• Any activity by which employees participate in work-related decisions and improvement

activities.

Motivation

• Maslow’s Hierarchy of Needs

• Herzberg’s Two-Factor Theory

• Employee Wants

Maslow’s Hierarchy of Needs

• Level 1 (survival): food, clothing, and shelter, which is usually provided by job. In workplace,

Level 1 needs include proper lighting, heating/air conditioning, ventilation, phone system,

data/voice access, and computer information system.

• Level 2 (security): a safe place to work and job security, which are important to employees

• Level 3 (social): our needs to belonging.

• Level 4 (esteem): pride and self-worth.

Management of Technology/Group30/Promotion 19

Page 31 of 48

National University of Management

Year IV, Semester I

• Level 5 (self-actualization): individuals must be given the opportunities to go as far as their

abilities will take them.

Herzberg’s Two-Factor Theory

• Motivators: people were motivated by recognition, responsibility, achievement, advancement,

and the work itself.

• Dissatisfiers: bad feelings were associated low salary, minimal fringe benefit, poor working

condition, ill-define organizational policies, and mediocre technical supervision.

Employee Wants

• While management thinks that good pay is number one of the employee, survey results show

that this factor is usually in the middle of the ranking.

• Employee wants tend to follow the theories of Maslow and Herzberg.

• Managers’ perception are much different.

• Interesting work

Employee rating: 1

Manager rating: 5

• Appreciation

Employee rating: 2

Manager rating: 8

• Involvement

Employee rating: 3

Manager rating: 10

• Job security

Employee rating: 4

Manager rating: 2

• Good pay

Employee rating: 5

Manager rating: 1

• Promotion/growth

Employee rating: 6

Manager rating: 3

• Good working conditions

Employee rating: 7

Manager rating: 4

• Loyalty to employees

Employee rating: 8

Manager rating: 7

• Help with personal problems

Employee rating: 9

Manager rating: 9

• Tactful discipline

Employee rating: 10

Manager rating: 6

• By involving employees through the use of teams in meaningful work and by providing the

proper reward and recognition, managers can reap the advantages of greater quality and

productivity along with employee satisfaction.

Achieving a Motivated Work Force

1. Know thyself: Managers must understand their own motivations, strengths, and weaknesses.

2. Know your employees: Most people like to talk about themselves, therefore, the motivating

manager will ask questions and listen to answers.

3. Establish a positive attitude: A positive action-oriented attitude permeates the work unit.

Managers are responsible for generating attitudes that lead to positive actions.

4. Share the goals: A motivated work force needs well-defined goals that address both individual

and organizational needs

Management of Technology/Group30/Promotion 19

Page 32 of 48

National University of Management

Year IV, Semester I

5. Monitor progress: The process of goal-setting should include a road map detailing the journey

with periodic milestones and individual assignments. Managers should periodically review

performance.

6. Develop interesting work: Managers should consider altering the employees’ assignments by job

rotation, job enlargement, and job enrichment.

7. Communicate effectively: Effective communication provides employees with knowledge about

their work unit and the organization.

8. Celebrate success: Recognizing employee achievements is the most powerful tool.

Benefits of Employee Involvement

• Employees make better decisions using their expert knowledge of the process.

• Employees are more likely to implement and support decisions they had a part in making decision.

• Employees are better to spot and pinpoint areas for improvement.

• Employees are better able to take immediate corrective action.

• Employee involvement reduces labor/management friction by encouraging more effective

communication and cooperation.

• Employees are better able to accept change because they control the work environment

• Employees have an increased commitment to unit goals because they are involved

Empowerment

• Employee Empowerment

The controlled transfer of authority to make decisions and take action.

• Empowerment and Motivation

Empowerment is the key to motivation and productivity.

An employee who feels he or she is valued and can contribute is ready to help and grow in the job.

Empowerment enables a person to develop personally and professionally so that he or her

contributions in the workplace are maximized.

Teams

• Team

Team is defined as a group of people working together to achieve common objectives or goals.

• Teamwork

Teamwork is the cumulative actions of the team during which each member of the team

subordinates his individual interests and opinions to fulfill the objectives or goals of the group.

•

•

Why Teams Work

Teams work because many heads are more knowledgeable than one.

Many processes are so complex that one person cannot be knowledgeable concerning the

entire process.

The whole is greater than the sum of its members

The interaction within team produces results that exceed the contribution of each member.

Team members develop a rapport with each other that allow them to do a better job.

Teams provide a vehicle for improved communication, thereby increasing the likelihood

of a successful solution.

Common Barriers to Team Progress

o Insufficient training

o Incompatible reward and compensation

o First-line supervisor resistance

o Lack of planning

o Lack of management support

o Lack of union support

o Project scope too large

o Project objectives are not significant

o No clear measure of success

o No time to do improvement work

o Team is too large

o Trapped in groupthink

Management of Technology/Group30/Promotion 19

Page 33 of 48

National University of Management

Year IV, Semester I

Review Questions

1. Define the following:

(a) Involvement

(b) Motivation

(c) Empowerment

(d) Team

(e) Teamwork

2. List the five levels in the Maslow’s hierarchy of needs and describe each level.

3. Describe Herzberg’s dissatisfies and motivators.

4. List five common barriers to team progress.

5. Why do team work?

6. Evaluate an organization’s high performance work systems.

Chapter 6

Quality Tools

The Seven Basic Quality Tools.

1. Flowcharts

A flowchart is a visual representation of a process.

As a problem-solving tool, a flowchart can help investigators in identifying possible points

in a process where problems occur.

Management of Technology/Group30/Promotion 19

Page 34 of 48

National University of Management

Year IV, Semester I

T

he

diamon

d

shapes

in the

flowcha

rt

represe

nt

decisio

n points

in the

process.

R

ectangu

lar

shapes

2.

represent procedures.

The arrows show the direction of "flow" of the steps in e process.

To construct a simple flowchart

Begin by listing the steps in a process.

Then classify each step as either a procedure or a decision (or check) point.

Check Sheets

A check sheet is a simple tool frequently used for problem identification.

Check sheets provide a format that enables users to record and organize data in a way that

facilitates collection and analysis.

This format might be one of simple checkmarks.

Check sheets designed on the basis of what the users are attempting to learn by collecting

data.

Management of Technology/Group30/Promotion 19

Page 35 of 48

National University of Management

Year IV, Semester I

3. Histograms

A histogram can be useful in getting a sense of the distribution of observed values.

Among other things, one can see if the distribution is symmetrical, what the range of

values is, and if there are any unusual values

4. Pareto Analysis

Pareto analysis is a technique for focusing attention on the most important problem areas.

The Pareto concept, named after the nineteenth-century Italian economist Vilfredo Pareto,

is that a relatively few factors generally account for a large percentage of the total cases

(e.g., complaints, defects, problems).

The idea is to classify the cases according to degree of importance, and focus on resolving

the most important, leaving the less important.

Often referred to as the 80-20 rule, the Pareto concept states that approximately 80 percent

of the problems come from 20 percent of the items.

For instance, 80 percent of machine breakdowns come from 20 percent of the machines,

and 80 percent of the product defects come from 20 percent of the causes of defects.

Often, it is useful to prepare a chart that shows the number of occurrences by category,

arranged in order of frequency.

Presumably, the manager and employees would focus on trying to resolve this problem.

Once they accomplished that, they could address the remaining defects in similar fashion.

Management of Technology/Group30/Promotion 19

Page 36 of 48

National University of Management

Year IV, Semester I

5. Scatter Diagrams

A scatter diagram can be useful in deciding if there is a correlation between the values of

two variables.

A correlation may point to a cause of a problem.

6. Control Charts

Charts A control chart can be used to monitor a process to see if the process output is

random.

It can help detect the presence of correctable causes of variation.

Management of Technology/Group30/Promotion 19

Page 37 of 48

National University of Management

Year IV, Semester I

7. Cause-and-Effect Diagrams

A cause-and-effect diagram offers a structured approach to the arch for the possible

cause(s) of a problem.

It is also known as a fishbone diagram because fits shape, or an Ishikawa diagram, after

the Japanese professor who developed the approach aid workers overwhelmed by the

number of possible sources of problems when problem solving

This tool helps to organize problem-solving efforts by identifying categories of factors that

might be causing problems.

Often this tool is used after brainstorming sessions to organize the ideas generated.

Management of Technology/Group30/Promotion 19

Page 38 of 48

National University of Management

Year IV, Semester I

The Use of Graphical Tools

Management of Technology/Group30/Promotion 19

Page 39 of 48

National University of Management

Year IV, Semester I

Chapter 7

Statistical Quality Control

Quality Control Approaches

o Statistical process control (SPC)

Monitors the production process to prevent poor quality

Statistical Process Control

o Take periodic samples from a process

o Plot the sample points on a control chart

o Determine if the process is within limits

o Correct the process before defects occur

Types Of Data

Attribute data

Product characteristic evaluated with a discrete choice

– Good/bad, yes/no

Variable data

Product characteristic that can be measured

– Length, size, weight, height, time, velocity

SPC Applied To Services

Nature of defect is different in services

Service defect is a failure to meet customer requirements

Monitor times, customer satisfaction

Service Quality Examples

Hospitals timeliness, responsiveness, accuracy

Grocery Stores

Check-out time, stocking, cleanliness

Airlines

luggage handling, waiting times, courtesy

Fast food restaurants

waiting times, food quality, cleanliness

Constructing a Control Chart

Decide what to measure or count

Collect the sample data

Plot the samples on a control chart

Calculate and plot the control limits on the control chart

Determine if the data is in-control

If non-random variation is present, discard the data (fix the problem) and recalculate the control

limits

Management of Technology/Group30/Promotion 19

Page 40 of 48

National University of Management

Year IV, Semester I

A Process Is In Control If

No sample points are outside control limits

Most points are near the process average

About an equal # points are above & below the centerline

Points appear randomly distributed

Types Of Data

Attribute data (p-charts, c-charts)

Product characteristics evaluated with a discrete choice (Good/bad, yes/no, count)

Variable data (X-bar and R charts)

Product characteristics that can be measured (Length, size, weight, height, time, velocity)

Control Charts For Attributes

p Charts

Calculate percent defectives in a sample;an item is either good or bad

c Charts

Count number of defects in an item

p-Chart Example

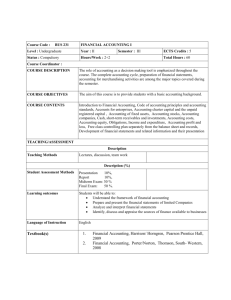

The Western Jean Company produced denim jean. The company wants to establish a p-chart to

monitor the production process and main high quality. Western beliefs that approximately 99.74 percent

Management of Technology/Group30/Promotion 19

Page 41 of 48

National University of Management

Year IV, Semester I

of the variability in the production process (corresponding to 3-sigma limits, or z = 3.00) is random and

thus should be within control limits, whereas 0.26 percent of the process variability is not random and

suggest that the process is out of control.

The company has taken 20 sample (one per day for 20 days), each containing 100 pairs of

jeans (n = 100), and inspected them for defects, the results of which are as follow.

Sample

1

2

3

4

5

6

7

8

9

10

# Defects

6

0

4

10

6

4

12

10

8

10

Management of Technology/Group30/Promotion 19

Sample

11

12

13

14

15

16

17

18

19

20

# Defects

12

10

14

8

6

16

12

14

20

18

Page 42 of 48

National University of Management

Year IV, Semester I

c-Chart Example

The Ritz Hotel has 240 rooms. The hotel’s housekeeping department is responsible for

maintaining the quality of the room’s appearance and cleanliness. Each individual housekeeper is

responsible for an area encompassing 20 rooms. Every room in use is thoroughly clean and its supplies,

toiletries, and so on are restocked each day. Any defects that the housekeeping staff notice that are not

part the normal housekeeping service are supposed to be reported hotel maintenance.

Every room is briefly inspected each day by a housekeeping supervisor. However, hotel management also

conducts inspection for quality-control purposes. The management inspector not only check for normal

housekeeping defects like clean sheets, dust, room supplies, room literature, or towels, but also for

defects like an inoperative or missing TV remote, poor TV picture quality or reception, defective lamps, a

malfunctioning clock, tears or stains in bedcovers or curtain, or a malfunctioning curtain pull.

An inspection sample include 12 rooms, i.e., one room selected at random from each of the twelve 20room blocks served by a housekeeper. Following are the results from 15 inspection samples conducted at

random during a 1-month period.

Sample

# Defects

Sample

# Defects

1

2

3

4

5

6

7

8

9

10

12

8

16

14

10

11

9

14

13

15

11

12

13

14

15

12

10

14

17

15

Management of Technology/Group30/Promotion 19

Page 43 of 48

National University of Management

Management of Technology/Group30/Promotion 19

Year IV, Semester I

Page 44 of 48

National University of Management

Year IV, Semester I

Control Charts For Variables

Mean chart (X-Bar Chart)

Measures central tendency of a sample

Range chart (R-Chart)

Measures amount of dispersion in a sample

Each chart measures the process differently. Both the process average and process variability

must be in control for the process to be in control.

Example: Control harts for Variable Data

The Goliath Tool Company produces slip-ring bearings, which look like flat doughnut or washer, they fit

around shafts or rods, such as drive shaft in machinery or motor. In the production process for a particular

slip-ring bearing the employees has taken 10 samples (during a 10 day period) of 5 slip-ring bearing (i.e.,

n = 5). The individual observation from each sample are shown as followed:

Example: Control Charts for Variable Data

Management of Technology/Group30/Promotion 19

Page 45 of 48

National University of Management

Management of Technology/Group30/Promotion 19

Year IV, Semester I

Page 46 of 48

National University of Management

Management of Technology/Group30/Promotion 19

Year IV, Semester I

Page 47 of 48

National University of Management

Year IV, Semester I

Variation

Common Causes

Variation inherent in a process

Can be eliminated only through improvements in the system

Special Causes

Variation due to identifiable factors

Can be modified through operator or management action

Sample Size Determination

Attribute control charts

50 to 100 parts in a sample

Variable control charts

2 to 10 parts in a sample

The End!

Management of Technology/Group30/Promotion 19

Page 48 of 48