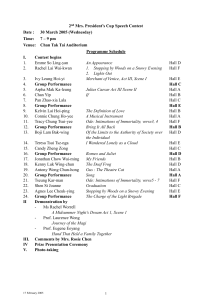

resume2_47461453002891

advertisement

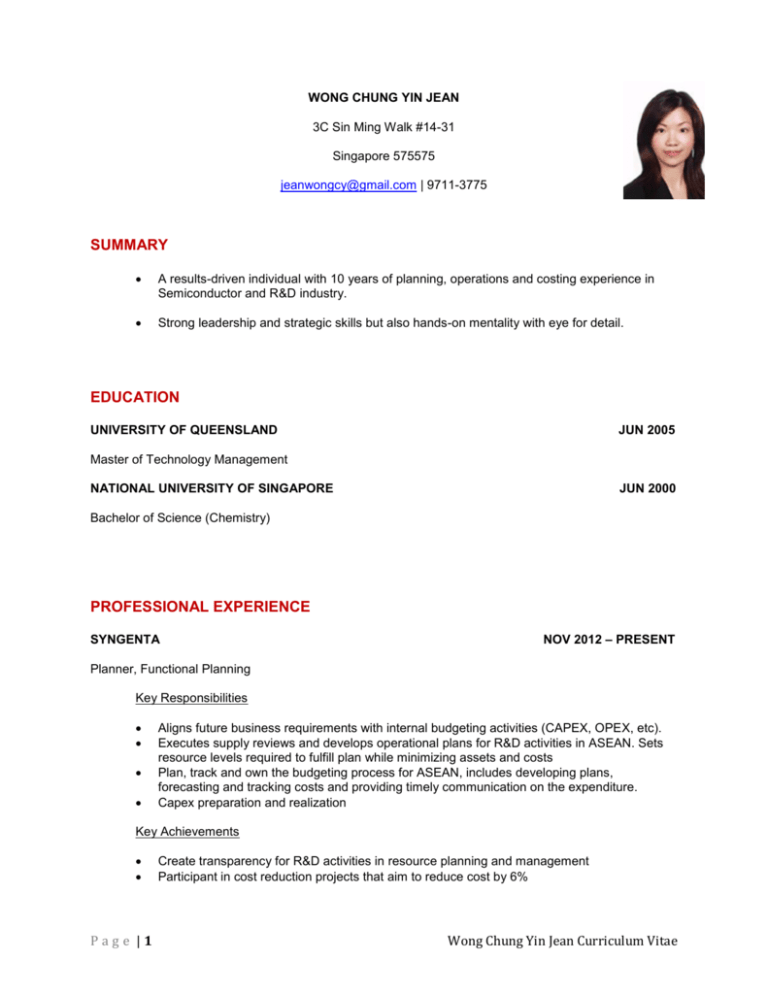

WONG CHUNG YIN JEAN 3C Sin Ming Walk #14-31 Singapore 575575 jeanwongcy@gmail.com | 9711-3775 SUMMARY A results-driven individual with 10 years of planning, operations and costing experience in Semiconductor and R&D industry. Strong leadership and strategic skills but also hands-on mentality with eye for detail. EDUCATION UNIVERSITY OF QUEENSLAND JUN 2005 Master of Technology Management NATIONAL UNIVERSITY OF SINGAPORE JUN 2000 Bachelor of Science (Chemistry) PROFESSIONAL EXPERIENCE SYNGENTA NOV 2012 – PRESENT Planner, Functional Planning Key Responsibilities Aligns future business requirements with internal budgeting activities (CAPEX, OPEX, etc). Executes supply reviews and develops operational plans for R&D activities in ASEAN. Sets resource levels required to fulfill plan while minimizing assets and costs Plan, track and own the budgeting process for ASEAN, includes developing plans, forecasting and tracking costs and providing timely communication on the expenditure. Capex preparation and realization Key Achievements Page |1 Create transparency for R&D activities in resource planning and management Participant in cost reduction projects that aim to reduce cost by 6% Wong Chung Yin Jean Curriculum Vitae OCT 2010 – OCT 2012 ST MICROELECTRONICS Engineer, Central Planning Key Responsibilities Handle Capacity planning and production control for worldwide Packaging and Test subcontracting activities Monitor and contribute to the improvement of KPI (JIT, CT, Service, Delivery) Interface between Divisions Planning and Sub-con Factories on demand and supply planning. Key Achievements Participate in the setup of EWS capacity modelling. Service adherence project with APAC EWS operations PHILIPS LUMILEDS JAN 2007 – JUN 2010 Capacity Planner, World Wide Supply Chain 2008/11 – 2010/06 Production Manager, Manufacturing 2007/01 – 2008/11 World Wide Supply Chain Capacity Planner Key Responsibilities Based in San Jose, CA for 11 months (Oct 2008 – Aug 2009) Drive CT reduction activities, review CT targets and support implementation within manufacturing Organization Support Supply Chain Program Manager with New Program (Apple) Ramps Validate overall build plan and shipment schedules with Supply Planner and make any necessary changes Review order demand and work with the Demand Planners to create an achievable weekly Master Build plan. Perform other duties and projects as required. Review Capacity plan and prepare Capex during S&OP short term plan/ mid-term plan Key Achievements Created a Master Capacity Plan, taking into account available capacity and production constraints Drive CT Reduction from 52 days to 40 days Manufacturing Production Manager Key Responsibilities Page |2 Being the Pioneer in the startup team Lead the Manufacturing team and Planning team in the start-up and production operation for new start-up fab Wong Chung Yin Jean Curriculum Vitae Helped in hiring of Fab Assistants, Production Planner, Material Planner and Fab Supervisors to prepare for start-up and ramp-up in Singapore. Manage production material, machine capacity and manpower allocation of the fab in order to meet production targets and meet delivery deadlines Plan and schedule required production quantities. Monitor inventory, review PO backlog and generate reports Review and resolve production and operational problems related to output, quality, yields, delivery and cost Improve production indices performances, productivity and delivery. Purchase ordering, price gating and follow-up on schedule update. To plan, execute, analyze materials requirements and reschedule plans Co-ordinate with Logistics on sales order status; arrange shipment and ensure timely delivery Key Achievements Contribute to new product transfer by planning and preparing production resources and logistics. Start-up, qualify for 3 products in Singapore and meet production targets within 7 months Volume increased to 5k wafers/month with < 1 year ST MICROELECTRONICS SEP 2000 – DEC 2006 Production Section Head, Manufacturing 2005/04 – 2006/12 Cycle Time Engineer, Manufacturing 2004/07 – 2005/04 Process Engineer, Diffusion Engineering 2000/09 – 2004/07 Manufacturing Production Section Head Key Responsibilities Manage production area to meet production targets for output, cycle time and yield. Lead and motivate a highly-trained and skilled team of Wafer Fab Manufacturing Supervisors and Specialists. Responsible for output, quality, productivity and yield improvement. Key Achievements Design and maintain company’s system, to monitor input and output based on cycle time. Develop central documentation control application to efficiently manage company’s intellectual property. Develop online production database, providing real-time production result for speedy management and corrective decision. Manufacturing Cycle Time Engineer Key Responsibilities Page |3 Wong Chung Yin Jean Curriculum Vitae Streamline process in order to improve machine capacity and throughput Perform daily monitoring of output versus cycle time (day/ mask level) with in-depth analysis and recovery plan. Develop and explore machine capacity by cross-qualification to cater for different products. Key Achievements Involved in numerous capacity improvement projects Acts as a decision-maker in the allocation overall capacity to meet the customers’ demand. Improved Cycle time by 6% with increased output and same amount of equipment. Award Extraordinary Employee in year 2005. Diffusion Process Engineer Key Responsibilities Define, set-up and sustain current and new processes. Conduct product/ failure analysis to support the engineering processes. Device characterisation, electrical parameters, evaluation and correlation of yield factor between device and process variation. Carry out equipment maintenance and trouble-shooting to ensure performance consistency according to process specifications. Carry out process improvement and failure analysis using statistical software such as DOE, 8D, SPC and FMEA. JUN 2000 – SEP 2000 LAPORTE Laboratory Analyst 2000/06 – 2000/09 Key Responsibilities Responsible for analysis of ultrapure chemicals using ICP-MS, AAS and IC Maintenance and calibration of equipment; optimisation of analytical methods and assisting in daily lab activities REFERENCES Available upon request Page |4 Wong Chung Yin Jean Curriculum Vitae