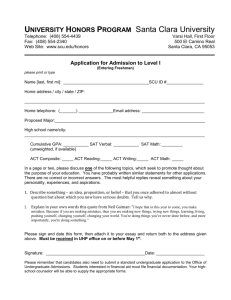

Data Center Project - Bid Package - Santa Clara County Office of

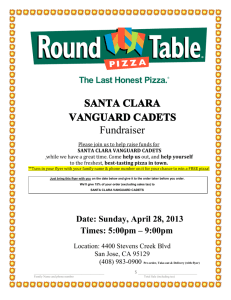

advertisement