Everything You Wanted to Know About Tanks But

advertisement

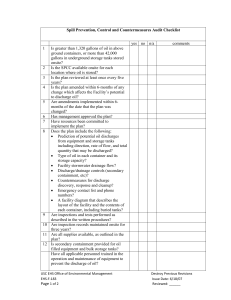

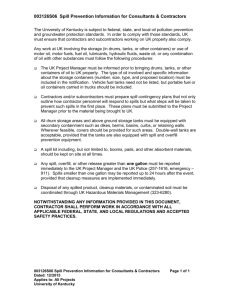

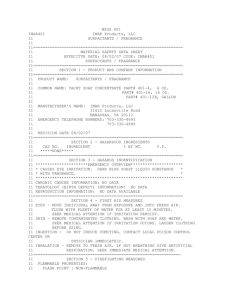

Everything You Wanted to Know About Tanks But Were Afraid to Ask Aboveground Storage Tank Systems Outline • Introduction • Spill Prevention Control and Countermeasure (SPCC) Plans • Facility Response Plans (OPA-90) • Stormwater Pollution Prevention Plans (SWP3) Oil Pollution Prevention Regulatory History • Promulgated by EPA in 1973 • Revisions proposed in 1991, 1993, 1997 • Final rule effective on August 16, 2002 • Two amendments December 12, 2005 – Streamlining – Extends Compliance Dates • One amendment effective December 26, 2006 2002 Rule Changes • • • • • • • • Exempts only completely buried storage tanks subject to all of the technical requirements of the UST regulations (40 CFR Parts 280 or 281) Exempts portions of certain facilities or any facility used exclusively for wastewater treatment Establishes a de minimis container size of 55 gallons Establishes an aboveground storage capacity threshold of greater than 1,320 gallons and removes the 660 gallon threshold Revises the trigger for submitting information on spills at SPCC regulated facilities to EPA Allows deviations from most rule provisions when equivalent environmental protection is provided Flexible plan format, but requires a cross-reference Clarifies rule applicability to the storage and operational use of oil Regulatory Overview 40 CFR 112.7 requires • Facility Diagram -- 40 CFR 112.7(a)(3) • Trajectory Analysis -- 40 CFR 112.7(b) • Secondary Containment -- 40 CFR 112.7(c) • Contingency Plans -- 40 CFR 112.7(d) • Inspection, Tests, and Records -- 40 CFR 112.7(e) • Personnel Training and Discharge Prevention Procedures -- 40 CFR 112.7(f) • Security (excluding production facilities) -40 CFR 112.7(g) • Facility Tank Car and Tank Truck Loading/Unloading Racks (excluding offshore facilities) -- 40 CFR 112.7(h) • Field-constructed Aboveground Containers - Brittle Fracture Evaluation -40 CFR 112.7(i) • • • • 40 CFR 112.8 requires spill prevention and control measures specific to the different types of oil facilities or operations, including: Onshore Facility Drainage (excluding production facilities) -- 40 CFR 112.8(b) Facility Transfer Operations, Pumping, and Facility Process (excluding production facilities) -- 40 CFR 112.8(d) Onshore Bulk Storage Containers (excluding production facilities) -- 40 CFR 112.8(e) 40 C.F.R. § 112 • Spill Prevention Requirements 40 § CFR 112.1-112.12 – Spill Prevention Control and Countermeasure (SPCC) Plans • Spill Response Requirements – Facility Response Plans (FRP or OPA-90) 40 CFR § 112.20-112.21 40 C.F.R. § 112.7-112.12 • Spill Prevention Control and Countermeasure (SPCC) Plan – Facility Diagram – Inventory – Discharge Prevention Measures – Discharge or Drainage Controls – Countermeasures – Disposal for Recovered Material – Contact Numbers 40 C.F.R. § 112.7-112.12 • SPCC Plan Continued – PE Certification – Secondary Containment – Integrity testing – Inspections – Training – Plan Updates 40CFR § 112.7-112.12 Covers SPCC Plans • Any owner/operator of a nontransportation onshore or offshore facility engaged in the following activities with oil which due to location could discharge to waters: • • • • • • Storing Processing Transferring Distributing Using Consuming oil/oil products 40CFR § 112.2 Covers • Facility: – Small as one tank – Large as a military base – Boundaries of facility depend on: Ownership Activities on site Responsibility for response 40CFR§112.1-112.3 Doesn’t Cover SPCC Plans • Facilities with USTs that contain 42,000 gallons or less of oil • Facilities with aggregate AST storage capacity of 1,320 gallons or less of oil. • Any container with a storage capacity of less than 55 gallons • Underground storage tanks (USTs) subject to part 40 CFR 280 and 281 • Any facility which is used exclusively for wastewater treatment SPCC Flow Chart Noncompliance Issues OVERALL • Plan not developed • Inspections not conducted • Spill response equipment not maintained • No training FEDERAL FACILITIES • Tenants not covered • Maintenance & housekeeping • No assigned responsibility for inspections and testing • No controls on drain valves • Use of mobile/portable tanks • Lack of spill reporting procedures SPCC Violations – H&M Oil Site, 2001 The H & M Oil, Inc., Triangle site located in Pocatello, Idaho. • Three vertical above ground storage tanks (ASTs), drums, and a portable storage container containing waste oil, water, and sludge. The AST capacity ranges from 8,000 to 12,000 gallons. • Located 200 yards from Portneuf River. Feeds directly to a reservoir. • Drinking water intakes approximately 1 mile from site. • No AST maintenance and inspection. • Soil staining • Unrestricted access • No secondary containment • Spills to gravel and dirt SPCC Plan Elements Part 1 • • • • • • • Facility Diagram Inventory of Oil Types and Capacity Discharge Prevention Measures Discharge or Drainage Controls Spill Countermeasures Disposal of Recovered Material Contact Numbers Facility Diagram Inventory • Include all oil storage at facility in storage containers of 55 gallons and greater • Record the amount stored, the storage capacity, and its location • Update the inventory as changes occur and have a PE recertify the plan Discharge Prevention Measures Not a recommended spill prevention measure • Provide Employee Training! #1 • Describe spill prevention equipment (i.e., leak detection systems, secondary containment) • Describe plans for inspection and maintenance Discharge or Drainage Controls • Includes: – – – – – – Oil water separators Ditches Levies Berms Retention Ponds Curbs Spill Countermeasures • Describe the equipment at your facility such as: – – – – – Industrial absorbent Pigs Oil booms Plugs Pans • Describe the steps in the spill response procedure Disposal/Contact Numbers • Outline the plan for disposal of used absorbent material in the Plan • Identify the contractor (s) who will be disposing of material • Determine Federal, State, and local requirements for disposal (if any) • Federal, State, and Local emergency numbers (National Response Center 1- 800-424-8802) • Ambulance and hospital numbers • Spill cleanup contractors SPCC Plan Elements Part 2 • • • • • • • PE Certification Secondary Containment Integrity testing Inspections Training Security Plan Updates PE Certification • • • • • PE may use an agent PE must review the agent’s work PE Certification statement more specific PE not required for nontechnical amendments State laws may preclude a PE not registered in the state from certifying 1. Familiar with requirements of SPCC rule 2. He or his agent have visited and examined the facility. 3. The Plan has been prepared in accordance with good engineering practice including consideration of applicable industry standards. 4. Procedures for required inspections and testing have been established. 5. The Plan is adequate for the facility Secondary Containment • Secondary containment must hold contents of largest single container in containment unit plus allowance for accumulated precipitation, if applicable. • 55 gallon drums must have secondary containment. • Double walled ASTs with interstitial monitoring systems are considered acceptable secondary containment. Environmental Equivalence • Allows facilities to implement alternate measures based on site-specific considerations: – Security – Facility drainage – Corrosion protection and leak testing of completely buried metallic storage tanks – Overfill prevention – Piping – Evaluation, inspection, and testing • Measures must provide equivalent environmental protection, in accordance with good engineering practice and as determined by a Professional Engineer. Impracticability Determinations • Documentation needed • Detail on impracticability determinations for certain areas: – Piping and flowlines – Transfer areas – Oil-filled Equipment – Loading/unloading racks – Onshore bulk storage containers – Mobile/portable containers Tank Integrity Testing • ASTs require: – Integrity testing on a regular schedule – Integrity testing when material repairs are done – Visual inspection must be combined with another testing technique such as: ultrasonic, radiographic, acoustic emissions, hydrostatic, or other nondestructive testing method. – Integrity testing may include leak testing • Type of integrity testing and inspections must consider applicable industry standards. Training • Required for Oil-handling employees only • Conducted annually • Training includes: – – – – – Spill control equipment Emergency procedures Laws, rules, regulations General facility operations The plan Security/Plan Updates • Requires fencing and locks or guard entrances for unattended facilities • If fencing is impractical, explain. Provide equivalent environmental protection • Plan must be reviewed at least once every 5 years • Upon review if changes have occurred which effect plan, plan must be amended within 6 months of review Summary • Determine whether you are required to have a plan • If so, prepare one • Conduct training annually • Maintain adequate spill response materials on site • Update the Plan • Inspect equipment and your facility regularly Problems Today The Issues • Converting USTs to ASTs – Greater oil storage capacity – Greater number of ASTs – Greater annual throughput = Higher Risk of Spills • Complying with SPCC regulations – Reduces number of spills, spill volume, and amount of oil migrating offsite What’s Aboveground? Industry Standards SHOP BUILT TANKS Steel Tank Institute SP-001 Standard for Inspection of Aboveground Storage Tanks Underwriters Laboratory (UL) Standard 142 Steel Aboveground Tanks for Flammable and Combustible Liquids National Fire Protection Association (NFPA) Code 30A Automotive and Marine Service Station Code, Chapters 1 and 2 National Fire Protection Association (NFPA) Code 30 Flammable and Combustible Liquids Code, Chapter Two FIELD ERECTED TANKS American Petroleum Institute (API) Standard 620 Design and Construction of Large, Welded, Low-Pressure Storage Tanks API Standard 650 Welded Steel Tanks for Oil Storage API Recommended Practice 651 Cathodic Protection of ASTs API Recommended Practice 652 Lining AST Tank Bottoms API Standard 653 Tank Inspection, Repair, Alteration, and Reconstruction API Recommended Practice 920 Prevention of Brittle Fracture API Standard 2015 Safe Entry and Cleaning of Tank API Recommended Practice 2350 Overfill Protection for Petroleum Tanks API Standard 2610 Design, Construction, Operation and Maintenance and Inspection of Terminal and Tank Facilities Corrosion • • • • • • Uniform Localized Microbial Influenced Galvanic Erosion Environmentally Assisted Cracking Tank Testing • • • • • Hydrostatic Radiographic Ultrasonic Thickness Acoustic For Large ASTs – Robotic applications – Vacuum – Magnetic Flux Vents and Piping Good Condition Leaking Dispenser Piping Factory Built Emergency Vents Rubber Piping Valving and Level Monitoring Clock Face Gauge Secondary Containment Valves Top Causes of Overfills • • • • • • • Training Tank size restrictions Inaudible alarm Incompatible equipment Dependent alarms Lines improperly marked Multiple tanks on common fill port • Poor inventory reconciliation • Not familiar with location • Filling entire tank Operator Inattention! Key Concepts • Checking, testing and maintaining Equipment. • Doing routine preventative Actions. • Keeping good Records. • Training for proper Response. 40 C.F.R. § 112.20-112.21 • Spill Prevention Requirements – Spill Prevention Control and Countermeasure (SPCC) Plans • Spill Response Requirements – Facility Response Plans (FRP or OPA-90) C-I Attachment FRP Flow Chart Flowchart of Criteria for Substantial Harm Does the facility transfer oil over water to or from vessels and does the facility have a total oil storage capacity greater than or equal to 42,000 gallons? Yes Submit Response Plan No Does the facility have a total oil storage capacity greater than or equal to 1 million gallons? Yes Within any aboveground storage tank area, does the facility lack secondary containment that is sufficiently large to contain the capacity of the largest aboveground oil storage tank plus sufficient freeboard to all for precipitation? Yes No Is the facility located at a distance such that the discharge from the facility could cause injury to fish and wildlife and sensitive environments? Yes No No Is the facility located a distance such that a discharge from the facility would shut down a public drink ing water intak e? Yes No Has the facility experienced a reportable oil spill in an amount greater than or equal to 10,000 gallons within the last 5 years? No No Submittal of Response Plan Except at RA Discretion Yes 40 CFR § 112.20 Covers FRP (OPA-90) • Conduct over water transfers of oil and have a capacity of 42,000 gallons or greater OR • Total oil storage capacity of one million gallons or more AND • Inadequate secondary containment • Could impact fish, wildlife or sensitive environments • Could shut down drinking water intakes • Reportable spill greater than 10,000 gallons within the past 5 years Regulatory Requirements at a Complex What is a Complex? • Some facilities must meet the requirements of two or more federal agencies, because they engage in activities that fall under the jurisdiction of those agencies. Case Study on Multiple Agency Responsibility OPS jurisdiction extends to pressure influencing device which affects operating pressure of the main pipeline. Product Tank2 Pump Valve (Storage) & (Breakout) MARINE LOADING DOCK 1 2 The tank depicted is used for storage associated with the MTR facility and is under EPA jurisdiction. If tank is also usedas a breakout tank it is subject to both OPS and EPA jurisdiction. Marine Transportation—Related Facility (MTR) is defined in 33 CFR 154.1020. This segment of a complex is under CG jurisdiction for the purposes of CWA Section 311(j). CG Jurisdiction DOT/OPS Jurisdiction3 3 EPA Jurisdiction Joint EPA-OPS Jurisdiction3 Who is Responsible for Regulating? • EPA is responsible for nontransportation- related facilities located landward of the • The Minerals Management Service of the Department of the Interior handles offshore nontransportation-related facilities located seaward of the coastline, including certain pipelines. • The USCG under DOT is responsible for deepwater ports and transportation-related facilities located landward of the coastline. 40 C.F.R. § 112.20 • Facility Response Plan (FRP) – Emergency Response Action Plan – Facility name, type, location, owner – Emergency notification information – Potential Discharges – Discharge detection procedures 40 C.F.R. § 112.20 • Facility Response Plan (FRP) – Plans for containment and disposal – Facility Inspection Plan – Training – Facility Diagrams of facility – Security Measures Critical Regulatory Aspects • Emergency Response Action Plan – Hazard identification – Vulnerability analysis – Planning distance calculation – Worst case discharge scenario – Equipment deployment and – NOAA environmentally sensitive environment maps http://response.restoration.noaa.gov/esi/esiintro.html FRP Requirements • Maintain copy of plan at facility and revisions • Log response training drills and exercises 40 CFR § 112.21 • Record inspections • Review annually • Make changes, submit revisions within 60 days to EPA Things To Know • SPCC plans and FRP are federal programs. • Additional federal oil spill plans are Vessel Response Plans and Shipboard Oil Pollution Emergency Plans . • States may have their own versions of these regulations and plans but do not enforce the federal programs. • State and federal plans can be combined as an Integrated Contingency Plan (ICP). 40 CFR 110.6 Spill Reporting Requirements • Any person in charge of a vessel or of an onshore facility shall as soon as he or she has knowledge of any discharge of oil … IMMEDIATELY notify the National Response Center (40 CFR 110.6) 800-424-8802 EPA Information and Hotlines 800-424-8802 National Response Center (NRC): 800-424-8802 NCP Product Schedule Information: 202-260-2342 www.epa. gov/oilspill For SPCC, FRP, & OPA Information: 800-424-9346 www.epa.gov/oilspill oilinfo@epamail.epa.gov Region 2 and 9 EPA Contacts Region 2 For questions or clarifications on the SPCC or FRP Rules, call or email: Christopher Jimenez, SPCC Coordinator 732-906-6847 Jimenez.christopher@epa.gov Arlene Anderson, FRP Coordinator 732-906-6803 Anderson.arlene@epa.gov Region 9 For questions or clarifications on the SPCC Rule, call or email: Pete Reich 415-972-3052 Reich.peter@epa.gov Or Mark Calhoon 415-972-3090 Calhoon.mark@epa.gov Or Elizabeth M Cox 415-972-3044 Cox.elizabethm@epa.gov Storm StormWater WaterPollution Pollution Prevention PreventionPlans Plans(SWP3) (SWP3) Clean Water Act Regulatory History • Amended 1987 • National Pollution Discharge System (NPDES) established November 6, 1990. • NPDES consists of Phase I and II regulations NPDES Storm Water Program • Phase I – Medium and Large municipal separate storm water – Sewer systems (MS4s) in communities with populations greater then 100,000 – Construction activities disturbing greater then 5 acres – Certain SIC codes • Phase II – – Certain small municipal separate storm sewer systems (MS4s) Construction activity disturbing between 1 and 5 acres Federal Facilities Vehicle Maintenance Facilities!!! Fueling Loading/Unloading to USTs or ASTs Vehicle/Equipment Washing Handling fuels, oils or chemicals Demonstration SWP3 Elements •Descriptions of Oil Storage •Maps •Stormwater BMPs •Employee Training •Inspections •Certifications /Amendments •Monitoring Requirements •Annual Compliance Report •Spill Response/ Procedures P2 Team/Training • Pollution Prevention Team – Environmental Manager – Maintenance Technicians/ Operators • Employee Training Demonstration Stormwater BMPs • Structural BMPs • Non Structural BMPs • Procedural BMPs http://www.bmpdatabase.org/ Inspections • Exteriors of ASTs and oil storage containers • Spill response equipment • Secondary containment • Transfer areas Comprehensive Site Compliance Evaluation • Annual Compliance Inspection – Inspection results – Changes to facility’s operations/activities – Data comparison – New BMPs/corrective measures – Previous year’s information Spill Response • Identify source • Take Action! Stop the spill • Immediately secure the spill area • If the material is flammable, remove all sources of ignition • Collect used spill material in a covered DOT approved container • Date, label, and staged in a secure area • Determine appropriate disposal method and contact waste hauler Spill Notification • Name, location, organization, and telephone number • Name and address of responsible party • Date and time of incident • Location of the incident • Source/cause of release • What was spilled and the quantity? • Danger or toxicity posed by the release/spill? • Any injuries? How many? • Weather conditions • Other information Spill Notification Contact the National Response Center (NRC), at 1-800-424-8802 24 hours a day See SWP3 for state and local contacts SWP3 Summary • • Applies to federal facility vehicle maintenance facilities Major components of the SWPPP are: – Pollution prevention team; – Site map; – Description of potential pollutant sources; – Measures and controls for stormwater management; and – Comprehensive site compliance evaluation. • Must be updated when facility operations/activities change • Best Judgment Required! Key Concepts • • • • • Develop SWP3 Conduct inspections Implement BMPs Train annually Update annually Other Federal AST Regulations Other Federal AST Regulations • New Source Performance Standards (NSPS) • Resource Conservation and Recovery Act (RCRA), Subpart J • RCRA Subparts AA, BB, CC • Clean Air Act – Highway Rule NSPS Tank Capacity Vapor Pressure Requirements Floating Roof > 40, 00 gallons 68 mm Hg – 570 mm Hg >570 mm Hg Vapor Recovery System 10.3 kPA – 76.7 kPA External Floating Roof OR Fixed Roof With Internal Floating Type Cover OR Vapor Recovery System - Keep records only 10,566 – 19,813 gallons RCRA 264/265, Subpart J • Hazardous Waste Tanks – Proper installation, operation and inspection – Integrity of primary containment system – Monitoring for leaks – Response to releases – Proper closure and post-closure Subpart J Additional Elements • Corrosion Protection • Vaults • Secondary containment for ancillary equipment • Spill control equipment (e.g., check valves, freeboard) • Inspections • Waste analysis and trial tests RCRA, Subparts AA, BB, CC • AA, BB – Emissions from Process Vents Associated with Hazardous Waste • CC – Organic Air Emission from Large Quantity Generators and Treatment, Storage and Disposal Facilities Diesel Fuel Content • 15 ppm sulfur required – June 2006 • 2007 Heavy Duty Diesel exhaust standards Summary • Limit VOLs emissions from ASTs • Specific Regulations for Hazardous Waste Tanks and Their Emissions • Diesel Fuel Sulfur Content Reduced