Marcet Boiler Thermodynamics Lab Report - Pressure & Temperature

advertisement

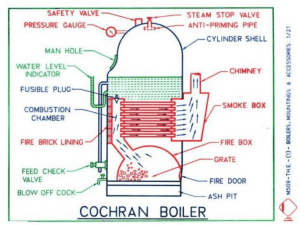

DUBLIN INSTITUTE OF TECHNOLOGY Marcet Boiler Thermodynamics Lab Name: Shiyas Basheer No: D10119909 Date: 3/19/2012 Course: DT022/2 Table of Contents Aim: ....................................................................................................................................................... 2 Apparatus:........................................................................................................................................... 2 Procedure:........................................................................................................................................... 2 Results: ................................................................................................................................................. 3 Conclusion: ......................................................................................................................................... 4 Page | 1 Marcet Boiler Aim: To show the connection between pressure and temperature of saturated steam. Apparatus: A marcet boiler was used. It was provided with a pressure gauge, Digital thermometer and a safety valve. The main elements of the WL 204 unit were: The stainless steel steam boiler with a mineral wool insulating jacket. The filler opening to pour water into the boiler. The overflow valve to ensure the vessel was filled to the correct level. The drain valve to drain the vessel. An electric heater bolted on to the floor of the boiler. A manometer fitted on the lid of the boiler to provide a direct indication of the boiler pressure. A temperature sensor A safety valve, a digital display, a master switch and a heater switch to switch the heater on and off. Schematic: Page | 2 Procedure: Before starting the experiment a quick inspection was performed to ensure the unit is in proper operating condition. The boiler was filled before the unit was run for the first time. The water was heated and brought to the boiling point with the overflow valve opened. When the steam was seen coming from the overflow valve it was closed. This was to ensure that there was no air in the boiler. With the valve shut the boiler was further heated and the pressure was raised. Temperature corresponding to the various pressures was recorded at 0.5 bar intervals up to 15-bar pressure. Results: Pressure, P (bar) Temperature, T Saturated temperature, T Gauge Absolute 0C K 0C K 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 102 106.8 115.2 123.1 129.4 134.4 139.6 143.9 147.6 151.7 155 158.2 160.9 164 166.5 169.1 171.3 173.8 175.7 177.8 179.8 182.1 183.8 185.5 187.3 188.8 375.15 379.95 388.35 396.25 402.55 407.55 412.75 417.05 420.75 424.85 428.15 431.35 434.05 437.15 439.65 442.25 444.45 446.95 448.85 450.95 452.95 455.25 456.95 458.65 460.45 461.95 99.6 111.4 120.2 127.4 133.5 138.9 143.6 147.9 151.8 155.5 158.8 372.75 384.55 393.35 400.55 406.65 412.05 416.75 421.05 424.95 428.65 431.95 Average Temp. K 237.375 245.675 254.275 261.825 268.025 273.225 278.175 282.475 286.275 290.175 293.475 165 438.15 299.525 170.4 443.55 305.025 175.4 448.55 309.925 179.9 453.05 314.375 184.1 457.25 318.525 188 461.15 322.475 191.6 464.75 326.025 Page | 3 13 13.5 14 14 14.5 15 190.5 192.2 193.7 463.65 465.35 466.85 195 468.15 329.325 198.3 471.45 332.575 Conclusion: In this experiment, the relationship between pressure and temperature is found to be directly proportional. When compared to the theoretical result, the experimental result shows a small deviation between them because of certain errors. The percentage of error ranged from 0.3% to 44% which can validate this experiment. Pressure Gauge Thermometer Vent valve Insulation Bunsen burner Page | 4