Pressure Transmitters Usage in Hydraulic Fracturing

advertisement

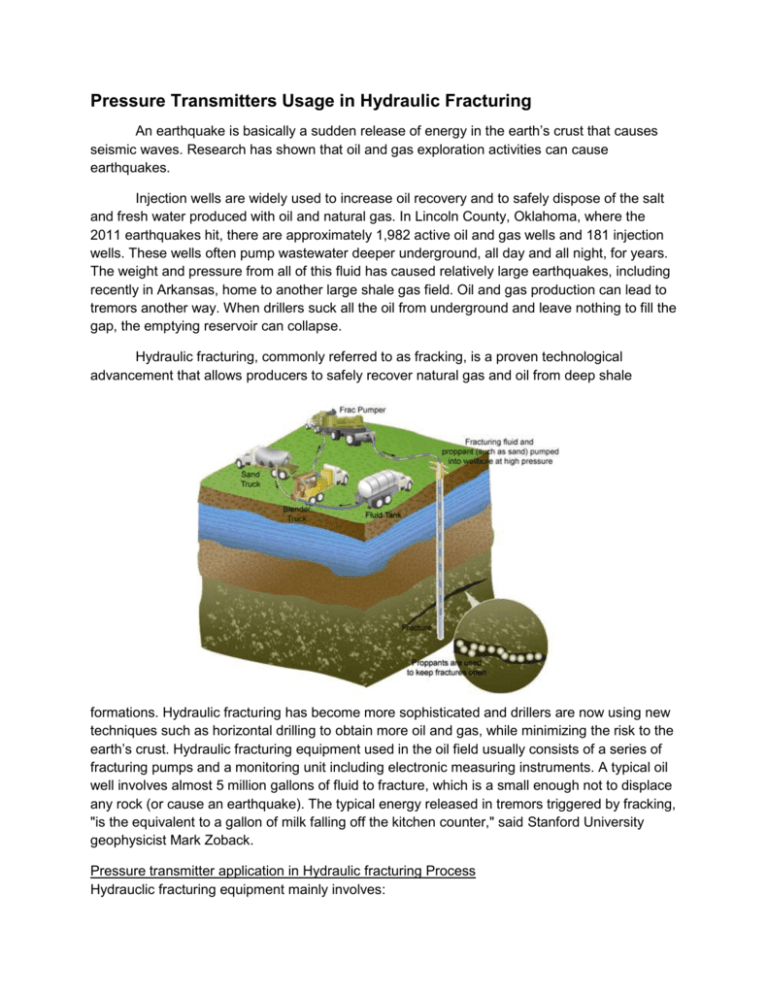

Pressure Transmitters Usage in Hydraulic Fracturing An earthquake is basically a sudden release of energy in the earth’s crust that causes seismic waves. Research has shown that oil and gas exploration activities can cause earthquakes. Injection wells are widely used to increase oil recovery and to safely dispose of the salt and fresh water produced with oil and natural gas. In Lincoln County, Oklahoma, where the 2011 earthquakes hit, there are approximately 1,982 active oil and gas wells and 181 injection wells. These wells often pump wastewater deeper underground, all day and all night, for years. The weight and pressure from all of this fluid has caused relatively large earthquakes, including recently in Arkansas, home to another large shale gas field. Oil and gas production can lead to tremors another way. When drillers suck all the oil from underground and leave nothing to fill the gap, the emptying reservoir can collapse. Hydraulic fracturing, commonly referred to as fracking, is a proven technological advancement that allows producers to safely recover natural gas and oil from deep shale formations. Hydraulic fracturing has become more sophisticated and drillers are now using new techniques such as horizontal drilling to obtain more oil and gas, while minimizing the risk to the earth’s crust. Hydraulic fracturing equipment used in the oil field usually consists of a series of fracturing pumps and a monitoring unit including electronic measuring instruments. A typical oil well involves almost 5 million gallons of fluid to fracture, which is a small enough not to displace any rock (or cause an earthquake). The typical energy released in tremors triggered by fracking, "is the equivalent to a gallon of milk falling off the kitchen counter," said Stanford University geophysicist Mark Zoback. Pressure transmitter application in Hydraulic fracturing Process Hydrauclic fracturing equipment mainly involves: -Fracturing pumps -Chemical storage tanks -Fracturing tanks Pressure at different stages of hydraulic fracturing process is monitored by a data monitoring van. Pressure transmitters are a critical part of the whole system. WIKA S-10 and S-11 pressure transmitters are precision engineered to fit most hydraulic fracturing pressure measurement applications. The compact and rugged design pressure transmitter can be used in the hydraulic fracturing process for the purpose of pump protection and numerous other processing and control operations. The WIKA S-11 transmitter features a flush diaphragm process connection. The S-11 is specifically designed for the measurement of viscous fluids and can be used to measure the pressure when fluid is pumped down the well bore. Pressure Transmitters selection consideration Protected against mechanical shock, vibration and moisture Wide pressure range Special external and internal material An accuracy of < 0.25% full scale