Liquid Metering System Project

advertisement

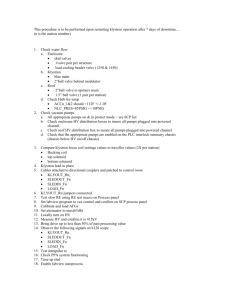

Liquid Metering System Submitted November 21st, 2013 by Kanchan Bhattacharyya Matthew Stevens Ting Zhang Xie Zheng Background Liquid Metering Systems are used all throughout the world for a variety of purposes. From manufacturing and filling of liquids to dispensing beverages in restaurants, there will always be a need for a machine to deliver specific amounts of liquids in specific amounts of time. Objective Using a budget of 100 develop a simple system capable of delivering 1000cc of water. Motivations Using a limited budget and relatively limited resources, develop a simple system capable of delivering 1000cc of water. Considering the relatively small volumes of water being dispensed, the limited budget, and sheer simplicity, we designed a system operating with a small submersible constant flow rate water pump, a solenoid valve connected to a timed DAQ input, and other simple items found at the local hardware store. Using a pump to ensure constant flow rate through a small system would allow for easy calibration of the volume flow rate of the system and subsequently would provide the necessary criteria to be able to deliver specific volumes. Basic Working Principle ∙ Constant flow rate water pump placed in a small reservoir of water connected to 12V Solenoid Valve via polyethylene tubing ∙ As implied, pump will supply a constant flow rate of water through the polyethylene tubing discharging through the valve/nozzle assembly to a container ∙ The normally closed solenoid valve will be controlled via LabVIEW programming to deliver water from the reservoir. ∙ When opened, the water will be delivered at the same flow rate allowing for calibration of the system’s discharge volume flow rate as a function of time. ∙ Having developed the relationship between the dispensed volume and elapsed time, derive a relation for time as a function of volume ∙ Use the function t(V) to control system’s valve timing to produce any desired volume of water ∙ 3D Renderings of our proposed design Theoretical Perspective and Design Considerations 𝑉𝑜𝑙𝑢𝑚𝑒 𝑄= 𝑡𝑖𝑚𝑒 ∙Utilizing a pump greatly simplifies the problem; as we know the Volume Flow Rate is given by t= ∙ If the pump displaces a finite amount of volume at a specific flow rate, we can find the required time at this flow rate to produce the volume. ∙ Because water is an incompressible fluid with a known density of 1gram/cc, we also know that any mass of water (in grams) will have a volume of equal value in cc. ρ𝐻20 𝑉𝑜𝑙𝑢𝑚𝑒 𝑄 𝑚𝑎𝑠𝑠 1.0 g = = 𝑉𝑜𝑙𝑢𝑚𝑒 cc mass g → Volume(cc) ∙ Therefore, we can also say that for water any volume flow rate in cc/sec will have an equivalent mass flow rate in grams/sec. 𝑚 g/s → Q(cc/s) Theoretical Perspective and Design Considerations ∙ Therefore, if our system were to displace a mass of water m in a time t, we can determine the volume of the displaced water in that time. ∙ Considering the results of successive flow times, we can use linear regression analysis to find the relationship that exists between the volume of water dispersed by the system And the time taken for the system to displace that water. ∙ Specifically, we can use the experimental results of volume dispensed per time to calculate a true volume flow rate for our system. 𝑚𝑎𝑠𝑠(𝑔) = 𝑣𝑜𝑙𝑢𝑚𝑒(𝑐𝑐) = 𝑄 ∗ 𝑡 𝑚 𝑡 = 𝑚0 + 𝑚 ∗ 𝑡 𝑚 g/s → Q(cc/s) 𝑉 𝑡 = 𝑉0 + 𝑄 ∗ 𝑡 ∙ By measuring the weight of water (in grams) for different valve opening times, we use the density relation to find the volume of the water. ∙ Using the V = a + Qt relationship derived from linear regression, we can determine the theoretical run time to deliver any desired volume. 𝑉 𝑡 − 𝑉0 𝑡= 𝑄 Experimental Setup & Procedure Setup 1.) Place the submersible pump in the bucket as close to the nozzle assembly as possible, submersed in at least 6 in. of water. 2.) Plug the electronic relay into the breadboard, noting the location of each pin. 3.) Plug the power supply and pump into the nearest power source, and connect the black/white wire with the red wire of the solenoid to establish a positive connection. Connect the black wire to the breadboard. 4.) Connect the DAQ Unit to the Breadboard in the ports corresponding to the middle pins of the relay, then to the Laptop PC via USB. 5.) Connect the pump with the solenoid valve/nozzle assembly via polyethylene tubing and fittings. Experimental Setup & Procedure Experimental Procedure 1.) Open the LabVIEW program 2.) Place beaker underneath the solenoid valve nozzle output, and use the timer in the LabVIEW Program and allow the water to flow into the beaker. 3.) When the valve closes, measure the weight of the water (in grams) using the scale. 4.) Empty the measure water back into the bucket, and use paper towels to carefully dry any water left in or on the beaker 5.) Repeat 6,7, & 8 for various times. LabVIEW Programming Front Panel •Sub-VI for calibration & Sub-VI for Volume Dispensing Combined LabVIEW Programming Block Diagram •Logic ensures no I/O errors if the user accidentally puts input for calibration & volume dispensing – either the one intended occurs or the program stops. •One branch for calibration, another for volume dispensing – argument passing, formula expression from calibration, timing for self-check; both use flat structures enclosed in case structures. LabVIEW Programming Logic •First boolean from each input connected by ‘AND’, T/F trigger top Volume Dispensing Branch •Second boolean from each input connected by ‘AND’ trigger bottom Calibration Branch. •Desired operation requires > 0 value in front panel for that operation and <= 0 for the other operation. •If both >0, both branches false, program ends. LabVIEW Programming Volume Dispensing & Calibration Branches Volume Dispensing Sub-VI Formula “t” (output) = (Volume – 0.318)/(9.7745) Calibration Sub-VI Material Cost/Assembly Analysis Description Price 12V/500 mA Power Supply $19.99 12V Solenoid Valve $15.99 Electronic Relay $2.00 Ecoplus 185 Submersible Pump $15.50 Socket Breadboard $9.99 (3) 1/4" NPT Polytube Fittings $9.72 Lead Connector Accessory for Power Supply $4.99 Wood Base Board $4.31 2 Gallon Bucket $3.58 1/4" Brass Female Pipe Coupling $1.99 1/4" NPT Brass Hex Pipe Nipple $1.19 1/4" OD Polyethylene Tubing $0.28 Wood/Screws for Nozzle Holder Assembly $0.00 TOTAL $89.53 The Nozzle Holder Assembly was fabricated in the following Process: ∙Desired holes were marked for the screw locations on vertical/horizontal beams as well as the location for the solenoid valve. ∙Holes were drilled using a vertical milling press in the Machine Shop ∙ Locations along width of baseboard for vertical supports of the nozzle holder assembly were marked using a depth gage before fastening. ∙A Simple Project Contact Cement was applied to the regions making face contact with the baseboard ∙ The screws were drilled into the vertical supports/base board and horizontal beam/vertical beams to create nozzle holder assembly. ∙ The output port of the solenoid valve was fitted with a ¼” Hex Pipe Nipple, which fits in the hole drilled in the horizontal beam ∙ The length of the nipple extends through the beam, and is fastened along with the solenoid via a ¼” Brass Female Pipe Coupling ∙ Finally, a spout was created with a small length of ¼” OD Polyethylene tubing and fittings. Results mass (grams) 4 9 14 19 24 28 38 48 52 57 67 97 117 147 166 196 215 245 274 294 313 342 362 392 421 440 489 539 587 636 685 732 782 830 879 927 976 1024 Mass vs. Time 1200 m = 9.7745t - 0.318 1000 Mass (grams) t (s) 0.5 1.0 1.5 2.0 2.5 3.0 4.0 5.0 5.5 6.0 7.0 10.0 12.0 15.0 17.0 20.0 22.0 25.0 28.0 30.0 32.0 35.0 37.0 40.0 43.0 45.0 50 55 60 65 70 75 80 85 90 95 100 105 800 600 Mass vs. Time 9.7745t-0.318 400 200 0 0.0 20.0 40.0 60.0 80.0 100.0 120.0 Time (seconds) Graph plotting the dispensed mass of water for allotted trial time (the time in seconds the solenoid valve was opened for). As expected, a linear relationship was found between the mass dispensed and the trial time. Linear Regression rendered the equation y = 9.7745x – 0.3198. Using known dimensions for the variables involved, m = (9.7745grams/second)t – 0.3198 grams. The slope of this line is the mass flow rate of the system, 9.7745 grams/second. Considering the relationship between mass, density, and volume as well as a density of 1.00g/cc, we find the desired volume flow of 9.7756 cc/sec. Linear Regression mass (grams) 4 9 14 19 24 28 38 48 52 57 67 97 117 147 166 196 215 245 274 294 313 342 362 392 421 440 489 539 587 636 685 732 782 830 879 927 976 1024 xixi 0.25 1 2.25 4 6.25 9 16 25 30.25 36 49 100 144 225 289 400 484 625 784 900 1024 1225 1369 1600 1849 2025 2500 3025 3600 4225 4900 5625 6400 7225 8100 9025 10000 11025 xiyi 2 9 21 38 60 84 152 240 286 342 469 970 1404 2205 2822 3920 4730 6125 7672 8820 10016 11970 13394 15680 18103 19800 24450 29645 35220 41340 47950 54900 62560 70550 79110 88065 97600 107520 y = a + bxi 4.569238 9.456506 14.34377 19.23104 24.11831 29.00558 38.78011 48.55465 53.44192 58.32919 68.10372 97.42733 116.9764 146.3 165.8491 195.1727 214.7218 244.0454 273.369 292.918 312.4671 341.7907 361.3398 390.6634 419.987 439.5361 488.4088 537.2814 586.1541 635.0268 683.8995 732.7722 781.6449 830.5175 879.3902 928.2629 977.1356 1026.008 [y 0.324031652 0.20839753 0.118180415 0.053380307 0.013997206 1.01118669 0.608577529 0.307636396 2.079126934 1.766734887 1.218201816 0.182610768 0.000556874 0.489986242 0.022776293 0.684442096 0.077416468 0.911318706 0.398188931 1.170616073 0.28395909 0.043793979 0.435861535 1.786473078 1.026132702 0.21521256 0.349552986 2.95341426 0.715496108 0.947098804 1.211122256 0.596246536 0.126131499 0.267837352 0.152263895 1.594891357 1.289519445 4.033068515 k 38 Sx 1379.0 Sy 13467.0 Sxx 88872 Sxy 868244 a -0.31803 b 9.774536 theta 29.67544 ua 0.2228235 ub 0.0046076 𝑏= 𝑘𝑆𝑥𝑦 − 𝑆𝑥𝑆𝑦 𝑘𝑆𝑥𝑥 − 𝑆𝑥 𝑆𝑥 1/2 𝑆𝑥𝑆𝑥 θ 𝑢𝑎 = [ (1 + )] 𝑘 𝑘−2 𝑘𝑆𝑥𝑥 − 𝑆𝑥 𝑆𝑥 1/2 𝑘 𝜃 𝑢𝑏 = [ (1 + )] 𝑘−2 𝑘𝑆𝑥𝑥 − 𝑆𝑥 𝑆𝑥 Mass vs. Time 1200 1000 Mass (grams) t (s) 0.5 1.0 1.5 2.0 2.5 3.0 4.0 5.0 5.5 6.0 7.0 10.0 12.0 15.0 17.0 20.0 22.0 25.0 28.0 30.0 32.0 35.0 37.0 40.0 43.0 45.0 50 55 60 65 70 75 80 85 90 95 100 105 (a+bxi)]2 𝑆𝑦 − 𝑏𝑆𝑥 𝑎= 𝑘 m = 9.7745t - 0.318 800 Mass vs. Time 600 9.7745t-0.318 400 200 0 0.0 20.0 40.0 60.0 Time (seconds) 80.0 100.0 120.0 Discussion An expected linear relationship between delivered mass/volume and time elapsed Effect of Initial Height of Water in Reservoir ∙ The height of the surface of the water does affect the velocity of the flow ∙ We noticed through various observations that increasing the height of water in the tank/above the pump resulted in an increase in dispensed mass I.E. the volume/mass flow rate increased ∙ To maintain a constant flow rate throughout the course of the experiment an initial height of water was chosen, and any water dispensed by the system was poured back into the reservoir. Length of Tubing delivering water ∙ A specific length of tubing was used, such that a direct connection between the solenoid input and pump output was established with minimal transfer height and kinks. ∙ As the length of the tubing through which the water was delivered was increased, there was an increased tendency for formation of air bubbles. ∙ When the valve was closed these bubbles would be forced through the system from the pressure provided by the pump, eventually leaking through valve ports. ∙ This effect was eliminated by a direct line with as little lift as possible. Accuracy of Final Results ∙ Using relationships between mass, time, and volume we developed the relationship for time as a function of volume ∙ Using this function to calculate the required valve open time for a user specific value, we were able to achieve results within the 2cc accuracy limit for volumes of 10, 50, 100, 500, 750, and 1000cc. Conclusion Using a constant flow rate water pump greatly simplified the problem The height of the water in the reservoir was an important factor ∙ The pump requires at least 6 inches of water to operate ∙ The greater the height of water, the greater the volume flow rate through the system Effects of Reservoir Geometry ∙ The larger the overall volume of the reservoir, the greater the accuracy of the calibration Effects of Tubing Length/Diameter ∙ Minimizing kink and overall tubing length ensured constant flow and minimized air bubbles/pressure bursts ∙ A relatively small tubing diameter was chosen and maintained throughout the system to ensure flow consistency and considerable rate for timing considerations PC-DAQ-Valve Response Lag? ∙ While seemingly insignificant, a slight lag was present in timing ∙ Of fractional order, these effects can be neglected when considering accuracy of final results Successful Problem Solving Approach ∙ Calibration Technique rendered extremely accurate results Thank You