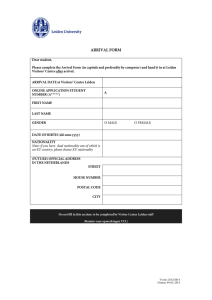

Managing Research Grant Applications

advertisement

Electrochemical Generation of Nanostructures at the Liquid-Liquid

Interface

Robert A.W. Dryfe

School of Chemistry,

Univ. of Manchester (U.K.)

robert.dryfe@manchester.ac.uk

Leiden, Nov. 2008

Liquid/Liquid Interfaces in catalysis

• Widely used: bi-phasic system, allows for

ease of separation of catalysis from reactant

mixture.

• Electrochemical investigations of phasetransfer catalysis (Schiffrin 1988 [1], Girault

1994 [2])

• Water does not have to be one of the

phases = “Fluorous biphase catalysis”

(Horvath 1994) [3]

• Stable room-temperature ionic liquids:

•

(Ballantyne 2008 [4])

Leiden, Nov. 2008

H3DA TPBF3 ethylmethylimidazolium ethylsulfate

(EMIM EtSO4) interface

Liquid/Liquid Interfaces:

electro-catalyst generation

• Reduction of solution phase

Mn+:

• Heterogeneous ET (surface

of electronic conductor)

i

ii

n+

A

A

e-

solution

Phase

electrode

Phase

solution

Phase

electrode

Phase

An+ + ne-

i

ii

An+

• Homogeneous ET

(nanoparticle preparation)

A

e-

Leiden, Nov. 2008

solution

Phase

solution

Phase

An+ + D

Dn+

D

• Heterogeneous ET

(aq/organic interface) –

with/without potential control

A

i

Dn+ + A

ii

n+

A

A

e-

D

Aq

Phase

Org

Phase

Aq

Phase

Org

Phase

Dn+

An+ + D

Dn+ + A

Liquid/Liquid Interfaces:

electro-catalytic reactions

• Questions:

•

Can the catalyst be used in situ - for catalysis of

processes at liquid-liquid phase boundaries?

• If so, could catalyst density be controlled (Langmuir

trough approach) to optimise reactivity?

• Or can catalyst be removed and immobilised on a

(conventional) electrode?

Leiden, Nov. 2008

{Liquid-liquid Electrochemistry 1:

Distribution potential}

• Each ion: distribution equilibrium at the organic/water interface

• Define standard Galvani potential of transfer:

worgi0

worgGi0

• Vary potential with common-ion

•

zi F

ratio of ion concentration in each phase (maintained by

hydrophilic/hydrophobic counter-ions) “poises” potential

RT aiorg

i

ln w

zi F

ai

w

org

w

org

0

i

• (Nernst-Donnan equilibrium )

•

- ion transfer/electron transfer – particularly for SECM @ L/L.

Leiden, Nov. 2008

{Liquid-liquid Interfaces 2:

Polarised Interfaces}

• External polarisation of L/L interface (both phases contain

electrolyte):

• Electrolytes = AX(aq) and CY(org), the following inequalities are met:

•

worg X0 0

•

worgC0 0

also:

+

and

A CV showing the transfer of Tetrapropylammonium in the

absence of a reducing agent

150

100

50

i/µA

0

-50

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

-100

-150

-200

-250

-300

worg

/V

E/V

Leiden, Nov. 2008

wor A0 0

worgY0 0

Structure of L/L interface

• Essentially sharp, even down to molecular scale – nm-scale

transition from phase 1 to phase 2.

• Interfacial fluctuations (capillary waves):

• Competition between thermal motion and interfacial tension

• Appear to extend down to molecular scale) = nm scale amplitude

• Experimental probes: X-ray scattering, non-linear optical

spectroscopy (SFG, SHG), (Schlossman, 2000 [5]), (Richmond

2001 [6]).

• => Smooth, reproducible interface.

Leiden, Nov. 2008

Modify Sharp (but fluctuating) interface?

•

Catalysis – introduction of metal

(nano-)particles

•

Result: electro-catalytic processes

at interface with only ionic

Pt C.E.

contacts.

• “In order to study the

electrochemical properties of

nanoparticle… we need to

attach them to an electrode

surface” – DJ Schiffrin, this

week.

• (1) “Synthesise, then fix them”

• (2) “in situ growth.”

Leiden, Nov. 2008

R.E.

+e-

-e-

-e-

+e-

Approaches 1 vs. 2 at L/L interface

i

ii

n+

A

• Source of particles?

A

e-

– (i) Assembled at

interface (particles =

surfactants)

– (ii) Grown at interface

(either (a)

spontaneous

deposition or (b)

electrodeposition).

solution

Phase

solution

Phase

An+ + D

n+

D

D

Dn+ + A

Then spontaneous assembly

(adsorption) at interface

i

ii

n+

A

A

e-

D

Leiden, Nov. 2008

Aq

Phase

Org

Phase

Aq

Phase

Org

Phase

Dn+

An+ + D

Dn+ + A

(i) Assembly of (pre-formed) particles at L/L

interfaces

• Method: form hydrosol (organo-sol), particles

adsorb interface on introduction of organic

(aqueous) phase.

• Particles are surfactants, if favourable

contact angle,q.

• Desorption energy given by:

E r 2 o / w (1 cos q ) 2

• Particles of given type, will be displaced by

those with larger radius (r):

• Size segregation effect demonstrated for

CdSe (Russell, 2003 [7]).

Leiden, Nov. 2008

(i) Assembly of (pre-formed) particles at L/L

interfaces - continued

• Other terms in equation:

•

E r 2 o / w (1 cos q ) 2

q can be varied by changing surface

chemistry (Vanmaekelbergh, 2003 [8]) –

induce assembly of Au NPs by addition

of ethanol – contact angle tends 90o.

• Residual surface charge, Au NPs

attracted to/from polarised L/L interface

– see Figure, from (Fermin, 2004 [9])

• Lippmann equation, interfacial tension

is function of applied potential

o / w

Q w

o

w

Leiden, Nov. 2008

T , p

Ordering of insulating particles at L/L

interfaces

• System

– 1.6mm SiO2 particles (Duke

Sci. Corp., USA).

• Hydrophobic coating dichlorodimethylsilane.

– Non-aqueous phase

• Octane (e = 2.0) or

Octanone (e = 10.3).

• Suspend at water/org interface

Dried: close packing

• (Campbell/Dryfe 2007, but

after Nikolaides, 2002 [10])

Leiden, Nov. 2008

Spontaneous ordering of SiO2

Use image analysis to identify

Field of view: 190 microns x individual particle positions:

radial distribution function

143 microns:

found.

- metallic particles, more polar

phases?

Leiden, Nov. 2008

(ii – a) In situ growth of particles at L/L

interfaces: spontaneous chemical reduction

• Faraday (1857 [11]): formation of colloidal Au

at L/L (water/CS2) interface

• “dark flocculent deposits”, metal in “a fine

state of division”.

• General problem of particle formation at L/L

interface is prevention of aggregation:

•

e.g. Au deposition @ water/1,2dichloroethane interface, fractal structures

form: image statistics, growth laws for

aggregation process (scale bar = 10 microns)

Leiden, Nov. 2008

Control deposit aggregation

• (a) Template diameter <

“intrinsic” particle diameter

(TEM: Pt deposition in zeolite

Y)

– Electrodeposition

• (b) Presence of ligands in

interfacial system (TEM: Au

deposition in presence of

phosphines)

• - Spontaneous deposition

Leiden, Nov. 2008

Stabilisation: surface chemistry

• Ideal case: modify surfaces to prevent

aggregation, but retain catalytic activity.

• Brust/Schiffrin (1994, [12]) (+ Faraday?): thiol

stabilisation of Au formed by two-phase

reduction

• Hutchison (2000 [13]), Rao (2003 [14]) (+

Faraday?) : phosphine ligands for stabilisation

of Au formed at L/L interface.

•

• Question: for Au deposition, can process (i) =

assembly of particles at L/L be related to

process (ii) = in situ L/L formation?

Leiden, Nov. 2008

Au formation at L/L interface

•

Au NPs formed at interface,

• TEM suggests particle size

regular, density increases with

time.

1.5 hrs

24 hrs

Leiden, Nov. 2008

Comparison of (i) assembly vs. (ii) formation

• Works – i.e. electron microscopy,

xrd

i

A

and xps suggest can get similar

(ca 2A

nm) Au NP from routes (i) and (ii) eif wesolution

Phase

use the same reducing agent.

ii

i

n+

-

solution

Phase

An+ + D

Dn+

D

i

Dn+ + A

ii

n+

A

A

e-

D

Leiden, Nov. 2008

Aq

Phase

Org

Phase

Aq

Phase

Org

Phase

Dn+

An+ + D

Dn+ + A

The characterisation problem

• Deposit characterisation:

ex situ, and (normally)

vacuum based methods

• TEM, SEM, XPS –

particle distribution lost.

• Reactive systems: ebeam/x ray damage?

• Dryfe/Campbell 2008

Leiden, Nov. 2008

gives……..

In situ deposit characterisation: gel or freeze

interface

• Deposit Au at gel/organic

interface: thickness (600 nm)

• Approach (ii), deposit Au at

L/L interface (org = acrylate

and photo-initiator) = photocure interface.

• (after Benkoski 2007,

approach (i) [15])

• Aim: “freeze” structure of

deposit – aggregate of ca 200

nm particles. Dryfe/Ho 2008

Leiden, Nov. 2008

In situ deposit characterisation: alternative

techniques (1)

• Structure of “neat” L/L

interface: x-ray scattering, nonlinear spectroscopy.

• Both recently applied to NP

assembly/formation at L/L

interface.

• Former: e- density profile

attributed to cluster (d = 18

nm) of 1.2 nm NPs.

• Approach (ii)

From Sanyal (2008 [16])

Leiden, Nov. 2008

In situ deposit characterisation: alternative

techniques (2)

• Second-harmonic generation

from polarised water/octanone

interface, for Au NPs

assembled at interface (ie

approach (i)),

• Short time-scales, reversible

particle assembly

• Longer time-scales,

irregularities in SHG response

attributed to NP aggregation.

Leiden, Nov. 2008

From Galletto

(2007 [17]).

(ii – b) In situ growth of particles at L/L

interfaces: electrochemical reduction

• Motivation: apply variable potential difference (4-electrode

methodology):

RT aRw1aOorg2

w

0

0

org E2 E1

ln w org

F aO1aR 2

• Study electrochemical growth in absence of solid substrate:

– M. Guainazzi (1975 [18]) – Cu, Ag

– Schiffrin/Kontturi, (1996 [19]) (Au, Pd)

i

ii

n+

A

e-

– Unwin, (2003, [20]) - (Ag)

– Cunnane, (1998,.[21]) (polymers)

– Dryfe, (2006, [22]) (review).

A

D

Aq

Phase

Org

Phase

Aq

Phase

Org

Phase

Dn+

An+ + D

Dn+ + A

• Advantage: Analysis of current response - information on growth.

Leiden, Nov. 2008

What is known at present?

• Deposit “units” nm scale, adsorb,

tend to aggregate.

• (TEM of Pd, scale bar = 100 nm)

• Replace single interface with

array of micron scale (or smaller)

interfaces = template.

•

-alumina as template, 200 nm

diameter pores (SEM of Pd,

scale bar = 100 nm)

Leiden, Nov. 2008

Nucleation/Growth: Voltammetry

Electrolytic cell:

Mn+(1) + nR(2) → M(s) + nO+(?)

Cell 1

x mM (NH4)2 PdCl4

Where Mn+ = PdCl42−,

R = n-BuFeCp2.

Ag AgCl

y mM BuFc

x mM TPACl

20 mM

50x mM LiCl

1 mM BTPPACl

10 mM LiCl

AgCl

BTPPATPBF 20

A CV showing the transfer of Tetrapropylammonium + in the

presence of a reducing agent

E0 ≈ 0.3 V

120

100

80

60

40

i/µA

Insufficient for spontaneous

reaction: extra η ≈ 0.2 V

needed.

N.B. Irreversible deposition

20

0

-0.1

-20 0

0.1

0.2

0.3

0.4

-40

-60

-80

w

E/V

org / V

Leiden, Nov. 2008

0.5

0.6

0.7

0.8

Ag

Chronoamperometry

• Interfacial Pd depn. Step

potential, increasing h.

All L/L

500

450

400

•

350

i/μA

• Approximate treatment, use of

excess (40-fold) of electron

donor (org): metal precursor

(aq).

200

0.6 V

0.65 V

150

100

50

0

0

5

10

15

Leiden, Nov. 2008

25

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

0

0.5

1

1.5

t/tmax

• t > tmax does not follow Cottrell

20

t/s

Apply “classical” models to Pd

deposition @ L/L.

• Behaviour intermediate (prog blue vs. instantaneous models

- pink),

0.5 V

0.55 V

250

i/imax

•

0.4 V

0.45 V

300

2

2.5

3

Analysis of chronoamperometry

• Heerman/Tarallo ≈ Mirkin/Nilov

models [23, 24]:

j zFDc

1

e At

At

1/ 2

Applied

overpotential/

V

1

Dt

1/ 2

At1 / 2

e d

0

1 exp qN Dt

1/ 2 1/ 2

0

2MDc

q 2

1/ 2

t

1 e At

1

At

Nucleation

Rate constant/

s-1

Nucleation

saturation

density /cm-2

Diffusion

Coefficient/

cm2 s-1

[BuFc] /

mM

0.47

0.29

10063

7.6×10-6

20

0.52

0.64

11589

9.8 × 10-6

20

0.57

0.76

8349

2.5 × 10-5

20

0.62

0.54

11526

4.1 × 10-5

20

Leiden, Nov. 2008

Extending model: 4th parameter

-4

1.6x10

-4

•

1.4x10

Cell: Cell 1

-4

1.2x10

x mM TPACl

50x mM LiCl

1 mM BTPPACl

20 mM

10 mM LiCl

BTPPATPBF 20

AgCl

-4

-2

Ag AgCl

y mM BuFc

Ag1.0x10

J/ A cm

x mM (NH4)2 PdCl4

-5

8.0x10

-5

6.0x10

•

Co-evolution of hydrogen

•

Palladium surface grows, acts as

catalyst.

•

Deposition (almost) insensitive to

applied potential: implies zero

critical cluster!

Leiden, Nov. 2008

5

10

15

20

time/ s

-4

2.5x10

-4

2.0x10

-2

Proton reduction rate included as

4th parameter (after Palomar, 2005

[25]): improved fit, but no direct

evidence for hydrogen evolution.

0

J/ A cm

•

-5

4.0x10

-4

1.5x10

-4

1.0x10

-5

5.0x10

0

10

20

30

time/ s

40

Competitive reactions

• pH dependence of metal

deposition?

• However, ferrocene oxidation

is coupled to H+ transfer (H2O2

generation)

• Nernst-Donnan equilibrium

dictates interfacial potential,

hence extent of H+ transfer.

(from Su, Angew. Chem, 2008

[26])

Leiden, Nov. 2008

Potential dependence of particle size

• High resolution TEM of Pd, deposition for 20 s at L/L.

= 0.5 V

Relative number of particles

30

(upper), down

to 0.4 V (lower)

– higher h:

higher mean

particle size.

25

20

15

10

5

0

3.5-4

4-4.5

4.5-5

5-5.5

5.5-6

6-6.5

5.5

particle size (nm)

5

30

Particle size (nm)

Relative number of particles

35

25

20

15

10

5

0

2-2.5

2.5-3

3-3.5

3.5-4

4-4.5

4.5-5

5-5.5

4.5

4

3.5

particle siz e (nm)

0.4

Leiden, Nov. 2008

0.425

0.45

0.475

Overpotential (V)

0.5

In situ electrocatalysis at L/L

• Photo-catalytic interfacial

electron transfer,

mediated by Pd

deposited in situ.

• (from Lahtinen,

Electrochem Comm,

2000 [27])

• Complex system: flow

based approach ?

Leiden, Nov. 2008

Ex situ Electrocatalysis

• Au-phosphine stabilised

NPs formed at L/L

interface, transferred by

adsorption on to glassy

carbon surface:

• Response of GC to

formaldehyde oxidation

(before/after Au NP

adsorption) is shown:

• Electrocatalytic activity of

materials. (Luo/Dryfe,

2008)

Leiden, Nov. 2008

Conclusions

•

L/L interface offers a ready “contact-less” route to the:

•

(i) assembly of (catalytically active) particles and

•

(ii) to the growth of (catalytically active) particles, the latter either by

spontaneous or electrochemical approaches.

•

Issues -

Deposit geometry conditions

– Applicability of “classical” deposition models

•

- difficulty/lack of applicability of “standard” nano-scale characterisation

techniques

•

Nano-scale morphology not dictated by strong substrate-deposit attraction

but strong substrate(1)-substrate(2) repulsion.

•

Regularity of particle structure (before aggregation) – uniform flux to each

particles?

Leiden, Nov. 2008

Suggestions for Future Work

• Catalytic production of H2O2 at the L/L interface

• Photo-catalytic reduction (H2, CO2??) at this

interface

• Does one of the phases have to be H2O?

• Catalysis as fn(, ) ?

Leiden, Nov. 2008

References (1/2)

•

•

•

•

•

•

•

•

•

•

•

•

1.

V.J. Cunnane, D.J. Schiffrin, C. Beltran and G. Geblewicz, J. Electroanal. Chem. 247, 203

(1988).

2.

S.N. Tan, R.A.W. Dryfe and H.H. Girault, Helv. Chim. Acta, 77, 231 (1994)

3.

I.T. Horvath and J. Rabai, Science, 266, 72 (1994)

4.

A.D. Ballantyne, A.K. Brisdon and R.A.W. Dryfe, Chem. Comm., 4980.

5.

D.M. Mitrinovic, A.M. Tikhonov, M. Li, Z.Q. Huang and M.L. Schlossman, Phys. Rev.

Lett. 85, 582 (2000).

6.

L.F. Scatena, M.G. Brown and G.L. Richmond, Science 292, 908 (2001).

7.

Y. Lin, H. Skaff, T. Emrick, A.D. Dinsmore and T.P. Russell, Science, 299, 226 (2003).

8.

F. Reincke, S.G. Hickey, W.K. Kegel, and D. Vanmaekelbergh, Angew Chem. Int. Ed., 43,

458 (2004).

9.

B. Su, J.P. Abid, D.J. Fermín, H.H. Girault, H. Hoffmannova, P. Krtil, Z. Samec, J. Amer.

Chem. Soc. 126, 915 (2004).

10.

M.G. Nikolaides, A.R. Bausch, M.F. Hsu, A.D. Dinsmore, M.P. Brenner, C. Gay and D.A.

Weitz, Nature 420, 299 (2002).

11.

M. Faraday, Philos. Trans. I, 147, 145 (1857).

12.

M. Brust, M. Walker, D.J. Schiffrin and R. Whyman, J. Chem. Soc. Chem. Comm., 801

(1994).

13.

W.W. Weare, S.M. Reed, M.G. Warner and J.E. Hutchison, J. Amer. Chem. Soc., 122,

12890 (2000).

Leiden, Nov. 2008

References (2/2)

•

•

•

•

•

•

•

•

•

•

•

•

•

•

14.

C.N.R. Rao, G.U. Kulkarni, P.J. Thomas, V.V. Agrawal and P. Saravanan, J. Phys. Chem.

B, 107, 7391 (2003).

15.

J.J. Benkoski, R.L. Jones, J.F. Douglas and A. Karim, Langmuir, 23, 3530 (2007).

16.

M.J. Sanyal, V.V. Agrawal, M.K. Bera, K.P. Kalyanikutty, J. Daillant, C. Blot, S. Kubowicz,

O. Komovalov and C.N.R. Rao, J. Phys. Chem. C, 112, 1739 (2008).

17.

P. Galletto, H.H. Girault, C. Gomis-Bas, D.J. Schiffrin, R. Antoine, M. Broyer and P.F.

Brevet, J. Phys. Cond. Matt. 19, 375108 (2007).

18

M. Guainazzi, G. Silvestri and G. Serravalle, J. Chem. Soc. Chem. Commun., 200 (1975).

19

Y. Cheng and D.J. Schiffrin, J. Chem. Soc. Farad. Trans., 92, 3865 (1996).

20.

J.D. Guo, T. Tokimoto, R. Othman and P.R. Unwin, Electrochem. Comm., 5, 1005 (2003).

21

V.J. Cunnane and U Evans, Chem. Comm., 2163 (1998).

22.

R.A.W. Dryfe, Phys. Chem. Chem. Phys. 8, 1869, (2006).

23.

L. Heermann and M. Tarallo, J. Electroanal. Chem., 470, 70 (1999).

24.

M.V. Mirkin and E. Nilov, J. Electroanal. Chem., 283, 35 (1990).

25.

M. Palomar-Pardave, B.R. Scharifker, E.M. Arce and M. Romero-Romo, Electrochim. Acta,

50, 4736 (2005).

26.

B. Su, R. Partovi Nia, F. Li, M. Hojeij, M. Prudent, C. Corminboeuf, Z. Samec and H.H.

Girault, Angew. Chem. Int. Ed., 47, 4675 (2008).

27.

R.M. Lahtinen, D.J. Fermín, H. Jensen, K. Kontturi and H.H. Girault, Electrochem. Comm.

2, 230 (2000).

Leiden, Nov. 2008