ANALISIS PEKERJA (WORKER ANALYSIS)

advertisement

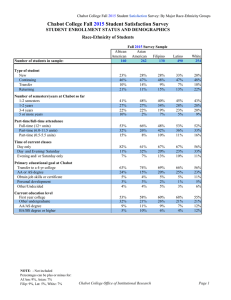

VIII. SUMBERDAYA MANUSIA DALAM MANAJEMEN OPERASI A. PERKEMBANGAN MANAJEMEN SUMBERDAYA MANUSIA MANAJEMEN ILMIAH PENDEKATAN PERILAKU • Perluasan pekerjaan secara horizontal • Perluasan pekerjaan secara vertikal • Rotasi Pekerjaan KECENDERUNGAN KONTEMPORER • Fleksibilitas pekerjaan • Pertanggungjawaban dan pemberdayaan • Peningkatan keahlian dan kemampuan • Pelibatan pekerja • Kompensasi pekerja • Teknologi dan otomatisasi • Pekerja-pekerja temporer • Kepuasan kerja B. ELEMEN-ELEMEN DISAIN PEKERJAAN ANALISIS TUGAS (TASK ANALYSIS) ANALISIS PEKERJA (WORKER ANALYSIS) ANALISIS LINGKUNGAN PEKERJAAN C. ANALISIS PEKERJAAN PROCESS FLOWCHART WORKER-MACHINE CHART ANALISIS TUGAS (TASK ANALYSIS) • Description of task to be performed • Task sequence • Function of tasks • Frequency of tasks • Criticality of tasks • Relationship with order jobs/tasks • Performance requirement • Information requirement • Control requirement • Error possibilities • Task durations • Equipment requirement ANALISIS PEKERJA (WORKER ANALYSIS) • capability requirement • Performance requirement • Evaluation • Skill level • Job training • Physical requirement • Mental stress • Boredom • Motivation • Number of workers • Level of responsibility • Monitoring level • Quality responsibility • Empowerment level ANALISIS LINGKUNGAN PEKERJAAN ( Environmental Analysis ) • Workplace location • Process location • Temperature humidity • Lighting • Ventilation • safety • Logistics • Space requirement • Noise • Vibration PROCESS FLOWCHART Simbol-simbol Flow-Chart Contoh : Process Flowchart Contoh : Process Flowchart Contoh : Process Flowchart WORKER-MACHINE CHART D. PENGUKURAN PEKERJAAN STOPWACH TIME STUDI NUMBER OF CYCLE ELEMENTAL TIME FILES PREDETERMINED MOTION TIME WORK SAMPLING LEARNING CURVE ELEMENTAL TIME FILES Elemental standard time files are predetermine job element time PREDETERMINED MOTION TIME Predetermined Motion Time are predetermined times for basic micromotions STOPWACH TIME STUDY Langkah-langkah Stopwatch Time Study 1. Establish the standard job method 2. Break down the job into element 3. Study the job 4. Rate the workers performance 5. Compute the average time 6. Compute the normal time Normal time = (elemental average time)(Rating Factor) Nt = (t)(RF) Normal Cycle Time = Summing the elemental mormal times NT Nt 7. Compute the standard time Standard time = (Normal Cycle Time)(1+Allowance Factor) ST = (NT) (1+AF) NUMBER OF CYCLE zs n eT 2 n the number standard deviation from the mean in a normal distributi on s x i x sample standard deviation from the sample time study n 1 T Average job cycle time from the sample time study e the degree of error from the true mean of the distributi on WORK SAMPLING Langkah-langkah Work Sampling 1. Define the job activities 2. Determine the number of observations in the work sample 2 z n p1 p e n the sample size (number of sample observatio n) z The number of standard deviation from the mean for the desire level of confidence e the degree of allowable error in the sample estimate p the proportion of the time spent on the work activity estimated prior to calculating the work sample 3. Determine the length of sampling period 4. Conduct the work sampling study and record the observations 5. Periodically recompute the number of observations LEARNING CURVE Processing time per unit Unit produced t n t1n b t n the time required for the nth unit produced t1 the time requared for the first unit produced n the cumulative number of unit produced b ln/ln 2, where r is the learning curve percentage ( decimal coefficient)