Human Performance Improvement Presentation

advertisement

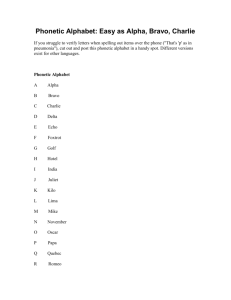

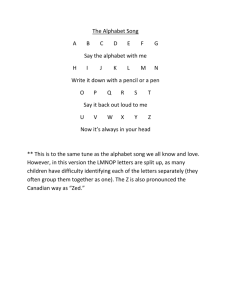

Human Performance Improvement Work Group WECC Strawman Class Based on INPO and DOE manuals 1 Objectives Objectives: Explain why human performance improvement is important to you and your Company. Describe what can influence human performance. Identify and apply Eight fundamental Human Performance Error Prevention Tools to improve safety and reduce errors. Reinforce the knowledge and usage of the HP tools so that they become commonplace in the daily work environment 2 3 Lessons Lessons: Performance Improvement Overview Human Performance Error Prevention Tools 4 What causes humans to fail At Risk Behaviors Normally, humans make about ???? errors per hour. 5 errors per hour XXX COMPANY 20,000 employees x 5/hr 100,000 errors per hour 5 What causes humans to fail At Risk Behaviors This is made worse when the person: Is in a hurry Under a high workload Doing more than one thing at a time Doing the same thing over & over 6 Traps in the Work Environment Distractions Interruptions Unplanned changes Error Precursors Those things that “set-up” a mistake to happen Task demands are greater than the worker’s abilities Confusing conditions make the job harder New techniques not used before Mental shortcuts Lack-of or unclear standards Illness / Fatigue 7 Performance Improvement Overview: Common Error Precursors Task Demands Individual Capabilities o High workload (memory requirements) o Unfamiliarity with task / First time o Time pressure (in a hurry) o Lack of knowledge (faulty mental model) o Simultaneous, multiple tasks o New technique not used before o Repetitive actions / Monotony o Imprecise communication habits o Irrecoverable actions o Lack of proficiency; Inexperience o Interpretation requirements o Unsystematic problem-solving skills o Unclear goals, roles, or responsibilities o “Can do” attitude for safety-critical task o Lack of or unclear standards o Illness or fatigue; general health Work Environment Human Nature o Distractions / Interruptions o Stress o Changes / Departure from routine o Habit patterns o Confusing procedure / Vague guidance o Assumptions o Confusing displays / controls o Complacency / Overconfidence o Work-arounds / OOS instrumentation o Mind set (intentions) o Hidden system responses o Inaccurate risk perception o Unexpected equipment conditions o Mental shortcuts or biases o Lack of alternative indication o Limited short-term memory 8 Two Kinds of Errors Active Errors Latent Conditions Performance Improvement Overview: When Safety Barriers Fail Events occur if all barriers and the frontline fail... Process Training Employees Oversight 10 Performance Improvement Overview: Common Error Precursors 11 Human Performance Error Prevention Tools 12 Human Performance Error Prevention Tools: Event Prevention • How do We Prevent Events? Anticipate, prevent, and catch errors at the job site: Work Preparation Work Performance Work Feedback Error Prevention Tools Develop and Implement Defense in Depth: Process Improvement Adequate Training Oversight Teamwork 13 • 1. 2. The Eight Human Performance Tools: Tailboards (Job Briefs) S.T.A.R. – Stop, Think, Act, Review 3. 4. 5. 6. 7. 8. Also known as “Self-Verification” Three-way communication Two-Minute Rule Stop When Unsure Questioning Attitude Phonetic Alphabet Procedure Use and Adherence 14 Tool #1 – Tailboards: A pre-job meeting of workers and/or supervision conducted before the performance of a job to discuss the tasks involved, hazards and related safety precautions. 15 Human Performance Error Prevention Tools: TAILBOARDS WHY: Helps personnel to better understand what is to be accomplished and what should be avoided. They help personnel avoid surprises in the field and reinforce the idea that there are no routine tasks. Allows an interaction between members of the crew so that there is an understanding of each members role Designated Challenger 16 TAILBOARDS WHAT should be covered: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Task Purpose Documentation Review Task Assignments Safety Hazards and Mitigation Human Performance Special Requirements or Unusual Conditions Operating Experience Stop-Work Criteria Oversight Questions 17 Human Performance Error Prevention Tools: TAILBOARDS • S.A.F.E.R 18 Contractor in work area – situational awareness 19 Contractor – Situational Awareness 20 A tailboard in action 21 How would you tailboard this situation? 22 Tool #2 - STAR: (Self Checking) WHAT: A “Self-Checking” tool where the performer pauses to focus his/her attention, reflects on the intended action and the associated outcome. Performer must have a sound knowledge of the task to know what to expect. 23 Human Performance Error Prevention Tools: STAR WHY: Helps the performer focus attention on the appropriate component, think about the intended action, understand the expected outcome before acting, and verifying the results. Boosts attention and thinking just before an action is performed. 24 Human Performance Error Prevention Tools: STAR WHEN should it be performed: 1. 2. 3. 4. 5. When operating equipment. When performing test programs. When manipulating any controls. When entering data into a computer. When revising drawings. 25 Human Performance Error Prevention Tools: STAR • HOW should it be performed: 26 Human Performance Error Prevention Tools: STAR How: Halt conversation prior to performing action. Perform one action at a time. Pause and self check between actions when performing multiple actions. Recognize when uncertainties or discrepancies exist and STOP. Personnel are alert and un-fatigued. Re-perform self check after loosing visual of physical contact. 27 Human Performance Error Prevention Tools: Tool #3 Tool #3 – Three Way Communication: Fundamental Human Performance Error Prevention Tool where the communication originator (SENDER) verifies that the RECEIVER understands the message as intended. The RECEIVER ensures he/she understands what the sender is saying. 28 Human Performance Error Prevention Tools: 3-Way Communication WHAT: Fundamental Human Performance Error Prevention Tool where the communication originator (SENDER) verifies that the RECEIVER understands the message as intended. The RECEIVER ensures he/she understands what the sender is saying. 29 Human Performance Error Prevention Tools: 3-Way Communication WHY: Promotes reliable transfer of information and understanding, which ensures correct subsequent action. WHEN should it be applied: 1. 2. 3. 4. When providing critical information. When providing equipment status. When directing operation of equipment. When directing others to perform a task. 30 3 Way Communication 1. The initiator makes a statement. 2. The participator repeats the statement in confirmation. The Message 3. The initiator confirms back that the statement is correct. 31 Human Performance Error Prevention Tools: 2-Minute Rule Tool #4 – Two Minute Rule: WHAT: A fundamental HP EPT that helps the worker develop an accurate understanding of the work environment, associated hazards, equipment condition/status, and other critical work site attributes. WHY is it important?: Improves situational awareness of the job site. 32 Human Performance Error Prevention Tools: 2-Minute Rule WHEN should it be performed? 1. 2. 3. 4. 5. All work activities Upon arriving at the work location. During job walk down. After breaks, lunch, or other interruptions. Anytime conditions change. 33 Human Performance Error Prevention Tools: 2-Minute Rule HOW: 1. Explore the job site and adjacent areas. 2. Talk with co-workers 3. Mitigate hazards 34 Four Mental States of Situational Awareness Red Alert – You’re aware of an imminent hazard. You’ve already prepped safe, decisive actions and back up plans. You control the hazard safely. No surprises. Focused – You notice something, but may not know if it’s a hazard or not. You assess it, then either avoid it, or control it safely. Beware tunnel vision here. Scanning – Mental Radar is actively scanning 360° for hazards and anomalies and visualizing likely outcomes. Aim to spend most of your time in this state. Tuned out - Unaware of surroundings. Mental Radar is off. OK at home, or on brief breaks at work when resting safely outside workzone away from all hazards. 35 35 Photo by isafmedia. Used with permission. 36 36 The sniper’s mental state is Focused. The spotter’s mental state is Scanning. Both communicate effectively with each other. The result? Situational Awareness that you can bet your life on. Primarily Scanning Primarily Focusing 37 37 Photo by isafmedia. Used with permission. We spend perhaps 95%+ of each typical day in only two of these mental states – Scanning and Focusing. One “secret” to Situational Awareness is to alternate between these two mental states when you work alone, and to ensure that team members coordinate the two states effectively when working on a team. Focused – You notice something, but may not know if it’s a hazard or not. You assess it, then either avoid it, or control it safely. Beware tunnel vision here. Scanning – Mental Radar is actively scanning 360° for hazards and anomalies and visualizing likely outcomes. Aim to spend most of your time in this state. 38 Primarily Focusing Primarily Scanning 39 Neither Scanning nor Focusing 40 Human Performance Error Prevention Tools: Stop When Unsure Tool #5 – Stop When Unsure WHAT: When confronted with confusion or uncertainty, a person is in unfamiliar territory. Given that the chance for error is particularly high in such situations, the best course of action, when unsure, is to stop and get help from other people. WHY is it important? When confronted with confusion or uncertainty, a person is in unfamiliar territory. Given that the chance for error is particularly high in such situations, the best course of action, when unsure, is to stop and get help from other people. 41 Human Performance Error Prevention Tools: Stop When Unsure WHEN should it be performed? When uncertainty, doubt, confusion, or questions persist When encountering conditions inconsistent with the procedure If beyond the scope of the plan or process When feeling distrustful of another individual When unexpected results or unfamiliar situations are encountered When something expected does not happen When uncertain regarding compliance with expectations or procedures When unfamiliar with an important work situation When inexperienced or lacking knowledge with a task When someone else expresses doubt or concern 42 Human Performance Error Prevention Tools: Stop When Unsure HOW: Stop the activity. Place the equipment and the job site in a safe condition. Notify your immediate supervisor. 43 44 Human Performance Error Prevention Tools: Questioning Attitude Tool #6 – Questioning Attitude WHAT: Attitude is a state of mind or a feeling toward a subject or object of interest. A questioning attitude promotes a preference for facts over assumptions and opinion. Questions such as “What if…,” or “Why is this acceptable?” 45 Human Performance Error Prevention Tools: Tool #6 Tool #6 – Questioning Attitude WHY is it important?: A questioning attitude fosters situational awareness, promotes a preference for facts over submission and opinion, and encourages thought about safety BEFORE action is taken. Without sufficient facts or verification, the performer stops the activity to address unexpected work situations that could lead to either a serious mistake or a significant event. 46 Human Performance Error Prevention Tools: Questioning Attitude WHEN should it be performed? During self-checking (Think step of STAR) Before performing an important step or phase of an activity When making a decision about an important activity When experiencing uncertainty, confusion, or doubt When experiencing a “gut feeling” that “something is not right” When encountering unanticipated changes in conditions When conflicts or inconsistencies exist between plans, procedures and actual conditions After encountering unexpected results After discovering missing information or resources Upon hearing danger words: “I assume,” “probably,” “I think,” “maybe,” “should be,” 47 Human Performance Error Prevention Tools: Questioning Attitude HOW: Stop, Look, and Listen – Ask questions – Gather relevant information. Proceed if sure – Continue the activity if the uncertainty has been resolved with facts. Otherwise, do not proceed in the face of uncertainty! 48 Human Performance Error Prevention Tools: Questioning Attitude Perception, Comprehension, and Projection. SCAN FOCUS ACT. 49 Situational awareness 50 51 52 Human Performance Error Prevention Tools: Phonetic Alphabet Tool #7 – Phonetic Alphabet WHAT: Several letters in the English language sound alike and can be confused in stressful or noisy situations. The Phonetic alphabet specifies a word for each letter of the alphabet reducing the likelihood that the letters will be confused. 53 Human Performance Error Prevention Tools: Phonetic Alphabet 54 Human Performance Error Prevention Tools: Phonetic Alphabet WHY is it important?: The phonetic alphabet can reduce the effects of noise, weak telephone or radio signals, or even a person’s accent WHEN should it be performed? When communicating alpha numeric information When specifying phase or channel designations When a sender or receiver may misunderstand the designations of an order 55 Human Performance Error Prevention Tools: Phonetic Alphabet HOW to use the Phonetic Alphabet?: Speak distinctly and slowly Use terms like “Stop” , “Correct”, “Wrong” Do Not use Slang Terms 56 Human Performance Error Prevention Tools: Tool #8 Tool #8 – Procedure Use and Adherence WHAT: Understanding the overall purpose and strategy of approved procedures, promotes a safe reliable outcome. Adhering to approved procedures helps to dispel doubt and provides clarification regarding questions in the execution of various tasks and duties 57 Human Performance Error Prevention Tools: Procedure Use and Adherence WHY is it important?: Procedure quality is paramount to safety and reliability. The completeness, accuracy, and internal consistency of the instructions, and its usability (easy to understand and follow) all impact the user. Procedures have been written over the years based on experience and proven uses of equipment. Procedures MUST be followed. Short cuts are often precursors of error 58 Human Performance Error Prevention Tools: Procedure Use and Adherence WHEN should it be performed? When manipulating, altering, monitoring, or analyzing equipment When a procedure exists for a work activity When required 59 Human Performance Error Prevention Tools: Procedure Use and Adherence HOW: Make sure you have the correct procedure or SW log and it has been checked Review the procedure or SW log before starting work, confirming understanding of the procedure’s overall purpose and expected outcome. Make any changes/revisions before you start switching. Follow the procedure as written without deviation being aware of the potential impact the action can have on equipment. 60 Human Performance Error Prevention Tools: The Four Tools • 1. 2. The Eight Human Performance Tools: Tailboards (Job Briefs) S.T.A.R. – Stop, Think, Act, Review 3. 4. 5. 6. 7. 8. Also known as “Self-Verification” Three-way communication Two-Minute Rule Stop When Unsure Questioning Attitude Phonetic Alphabet Procedure Use and Adherence 61 Human Performance Error Prevention Tools: The Working Connection Each employee has a role and a responsibility in error prevention, at all levels in an organization. Individuals Leaders Organization 62 Human Performance Error Prevention Tools: Individuals Role of the Individual: Apply and use Error Prevention Tools. Coach and reinforce use of EPTs with others. 63 Human Performance Error Prevention Tools: Visibility Role of Visibility between Peers and Leaders: Observations Role modeling Reinforcing expectations Coaching Recognition Brother’s Keeper 64 65 Human Performance Make it a Habit 66