Winery Sanitation Workshops 2013

advertisement

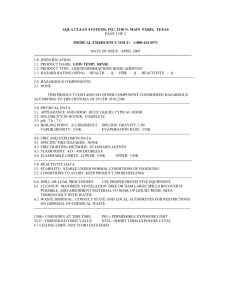

Winery Sanitation Molly Kelly Enology Extension Specialist Virginia Tech Cellar Hygiene Why? To maintain wine integrity and quality Sanitation Anything in contact with the wine is a potential vector for microbial spoilage Have appropriate sanitation protocols in place and implement them General Principles of Surface Cleaning and Sanitizing Remove loose soiling particles from surface Make bound soiling layer ‘wet’ Allow penetration of layer by solvent and cleanser Remove bound soiling layer from surface Rinse surface Sanitize surface If desired, sterilize surface Purposes of Cleaning, Sanitizing, and Sterilizing Get rid of microorganisms Get rid of nutrients and contaminating compounds Prevent entry and build-up of microorganisms and other contaminants Some Definitions Cleaning: Removing dirt, debris and stains Sanitizing: the reduction of the microbial population to a safe level (kills 99.9% of growing bugs) Sterilizing: Complete Elimination of microbial Life Definitions Cleaning: an attempt to physically and chemically remove food for microorganisms and to eliminate hospitable environments for their growth Sanitation=Disinfection Sanitation is an attempt to reduce the number of spoilage organisms on equipment surfaces Sterilization is an attempt to kill 100% of spoilage organisms QA and QC Quality Assurance (QA) focuses on attempts to improve and stabilize production practices in order to prevent defects Quality Control (QC) focuses on product testing to uncover defects HACCP: means of assuring quality, through the identification and monitoring of critical control points from vine to glass HACCP Logical system of control based on the prevention of problems Look at your process from start to finish Decide where hazards can occur Put in controls and monitor them Write it all down and keep records Ensure that it continues to work effectively All wineries would benefit from a basic outline http://www.apps.fst.vt.edu/extension/enology/EN/index.html Was process effective? Example: Cleaning Flow Chart Soiled Item Scrape, brush, shovel, squegee etc Water Temperature Dependent on Soil Type Verify Temperature Remove Soil Rinse with water until water runs clear Physical Methods Clean Verify Cleaner Concentration Chemical Methods Water Temperature Dependent on situation Water Rinse No Verify Rinse Water neutrality Was Looks, cleaning Smells, Feels Clean? effective? Look, smell, touch No Yes ATP Test Acceptable? Yes ATP swabbing test Item Ready for Sanittaion Rule of Thumb Acid cleaners dissolve alkaline soils (minerals) Alkaline cleaners dissolve acid soils and food wastes Improper use of detergents can actually “set” soils, making them more difficult to remove (e.g. acid cleaners can precipitate protein) More is better? Common misconception: “if a little is good, more is better” Using sanitizer concentrations above recommendations does not sanitize better, in fact, can be corrosive to equipment and lead to less cleanable Follow manufacturer’s label instructions Chemical and their Use Action Chemical Cleaner Alkalis, acids, detergents Sanitizer Quats, peracetic acid, SO2, hydrogen peroxide, ozone Sterilizer Hot water, steam, alcohol, UV, ozone Types of Sanitizers Heat, w/ water or steam to saturate effect Very effective anti-microbial, except some encysted forms Exposure time critical Non-corrosive, but energy intensive Chemical Effectiveness varies with exposure time, temperature, concentration, microbial load, soil load Can be corrosive Chemical Sanitizers Chlorine-containing not recommended except for out of control microbial situations Very effective anti-microbial Iodine-containing little used for wineries Effective anti-microbial, except when diluted Iodine Iodophores: broad spectrum Active against bacteria, viruses, yeasts, molds, fungi Bottling line (followed by hot water) Potential for TCA Quaternary Ammonium Compounds (QACs) Positively charged: mode of action is related to their attraction to negatively charged materials (bacterial proteins) Leave a residual antimicrobial film Floors Chemical Sanitizers Peroxides Hydrogen peroxide, ozone (inorganic), peroxyacetic acid, peroxyborates (organic) Very effective anti-microbials Tolerant of mineralized water Concentration dependent Not corrosive Can remove light bio-films Environmentally friendly Sanitizers percarbonates Per(oxy)carbonate Release of oxygen radicals via H2O2 Application at room temperature Effective over wide pH range (1-8) Alkaline Degradation to soda ash, water, O2 Sanitizers Soda Ash Na2CO3 Strong alkaline (pH 11.3 at 1%) Dissolves proteins, fats, oils, carbohydrates, tartrates Neutralizes acidic odors (VA) Neutral pH best for bacteria Sanitizing effect? Evaluating Cleaning Effectiveness Evaluating Cleaning Effectiveness Biofilms • • • • • A mixed group of microbial species protected by a polysaccharide/exopolymer coating. Resistant to many chemical cleaners. Usually need to be removed by physical action (scrubbing, brushing, high pressure). Many wine microbes can form or join biofilms. Commonly found at liquid boundary regions. Can be invisible to the naked eye. Winery Recommendations General Order: Stainless or plastic tanks, crusher-destemmers, presses, fittings Cold water, high pressure rinse Strong inorganic alkaline solution or paste scrub Cold water, high pressure rinse Cationic detergent, combined with peroxyacetic Cold water, high pressure rinse Hot water, high pressure rinse Ozone treatment Winery Recommendations General Order: Bottling line Cold water, high pressure rinse Mild alkaline detergent solution Cold water, high pressure rinse Cationic detergent, combined with peroxyacetic Cold water, high pressure rinse Hot water, high pressure rinse Ozone treatment Winery Recommendations General Order: Hoses and pumps Cold water, high pressure rinse w/foam ball Mild alkaline detergent solution w/foam ball Cold water, high pressure rinse w/foam ball Cationic detergent, combined with peroxyacetic, w/foam ball Cold water, high pressure rinse, w/foam ball Hot water, high pressure rinse, no ball Ozone treatment, no ball Winery Recommendations General Order: Barrels free of faulty aromas or tastes Cold water, high pressure rinse, 1-3 minutes High pressure steam rinse, 1-3 minutes Repeat cold and steam rinses twice more Either refill with clean wine or Fill with water add ozone, if available follow with water + 45 pm SO2/90 ppm citrate After 1-4 days, empty and refill with wine or empty and burn sulfur pastille, re-bung and store Winery Recommendations General Order: Barrels with faulty aromas or tastes Option 1 Remove from winery and sell for non-wine uses Option 2 Clean, sterilize, and re-use, if worth the cost Rinse cycles done as per barrel without faulty aromas or tastes Fill with water, put steam wand in water and bring water to 160180F, steam periodically to maintain temperature for 4-6 hours add ozone, if available follow with water + 45 pm SO2/90 ppm citrate After 1-4 days, empty and burn sulfur pastille, re-bung and store After 1-4 weeks, rinse and fill with clean water, after 1 week, take samples and then add 90 pm SO2/180 ppm citrate while doing microbiological assay of samples If samples are negative for spoilage microorganisms, re-use barrel, but sample periodically Winery Recommendations General Order: Floors and waterproof walls and ceilings Cold water, high pressure rinse Scrub w/mild alkaline detergent Cold water, high pressure rinse Hot water, high pressure rinse Ozone treatment Winery Recommendations General Order: Non-waterproof surfaces Dust w/ damp cloth or sponge Clean with mild household ammonia-based product Wipe with damp sponge or dry towel Is Sterility a Must? We don’t Need Sterility Commercial yeast out-competes wild yeasts, fungus, mold, and bacteria– especially at wine pH We don’t Want Sterility Sometimes wines may benefit from something extra… Sterilizers Hot water and steam used to sterilize bottling line 80-90F for 30 min 180F for 20 min ozone for 20-30 min Alcohol and UV: lab & for small equipment Basic Rules Clean everything BEFORE you use it. And then sanitize. Clean everything AFTER you use it. Clean the winery premises, not just the equipment, on a regular basis. Keep the winery free of clutter. Watch for pests (bacteria, mold, wild yeast, rodents, etc. Deal with pomace IMMEDIATELY. Generic Chemicals for Cleaning and Sanitation Type Dose Notes Citric Acid 3 Tbsp/gal Neutralizes alkalinity from other cleansers and helps to activate MBS Trisodium Phosphate 1 Tbsp/gal Effective against organic soils but can cause minerals to precipitate as scale Soda Ash 0.25c/gal Effective no-frills cleaning compound Sodium Metabisulfite 3 Tbsp/gal Very good must treatment; questionable product when used alone Sodium Hydroxide 1 tsp/5 gal Very effective; very caustic; very hazardous and difficult to rinse Ammonia 1.5 Tbsp/gal Difficult to rinse, but very effective on removing labels; stinks Formulated Chemicals for Cleaning and Sanitation Type Dose Notes Straight-A, B-Brite 1-2 Tbsp/gal Alkaline products containing percarbonate Iodophor 1 Tbsp/5 gal Sanitizer only; color is not as good an indicator of strength as is thought Dishwashing Detergent 1 Tbsp/gal Effective, but only use unscented versions MBS/Citric Acid 8oz/1oz/gal Very effective sanitizer with some cleaning effects; strong SO2 release may be hazardous to some people Note: B. Zoecklein et al. Wine Analysis and Production: 20 g/hL KMS and 300 g/hL citric acid at 140F Sanitizers Sanitizer Time of use Optimum (min) pH Peracetic acid 5-20 >9 Temp range Ozone 1-30 Quats 15m-24hr Sulfur dioxide 15s-20min Cold 70-120 cold 6-10 <3 70-100 Special Cases: Barrels There’s no good way to deal with old barrels that have “gone off…” Chemicals will either taint the wood or extract essence. But here are some ideas. Treat barrels right Don’t let them dry out. Store with a MBS/citric acid solution (2 oz/2 oz/5 gal water) Clean the outside as well as the inside Recover with a percarbonate based cleaner (1 Tbsp/gal), let sit 24 hours, rinse, then rinse with citric acid (0.5 tsp/gal). Cleaning and sanitation steps Debris removal without water Rinse with water Wash with cleaning agent Rinse with water Rinse with acid Rinse with water Use sanitizer & repeat rinsing if cleaner is not anti-microbial Precautions Cleaners and sanitizers are corrosive and can be harmful to skin, respiratory system and eyes Check MSDS sheets when in doubt Wear protective gear if needed Validating Winery Sanitation Perform the sanitation operation using a standard operating procedure (SOP) Validate that the SOP was effective define equipment, concentration of sanitizer, time, temperature, surface type, cleaning state, bioload, etc. Use swabbing or soak/rinse water to get sample Use microscope scans, plating, or PCR methods Changing any parameter in the SOP would indicate the need for additional validation. Verifying Concentration of Chemical Sanitizers pH pH test strips for acid sanitizers Concentration (critical to get the right range and sensitivity) Ozone test strips Iodine test strips Peracetic acid test strips Quaternary Ammonia strips Peroxide test strips Sulfite test strips Verifying Temperature Digital Thermometers Infrared thermometers Steam test strips and tape (for autoclaves) Temperature indicating labels Verifying Time Heat sanitizing time starts when the equipment reaches the desired temperature The time to get equipment up to temperature can be significant, especially with large equipment such as filler bowls Time/Temperature strips may be available that meet specific needs Bottling and Packaging One of the most critical steps in wine production Many opportunities for problems People with different responsibilities Multiple wines to bottle Operation and maintenance of multiple equipment stations Sterile bottling rooms? Not an absolute necessity Bottling area should be screened-off from fermentation areas and excessive air movement Easily sanitized floors, walls and ceilings Sources of contamination at bottling Filter pad drip trays: drain often during runs Fill bowls: Mist filler spouts with 70% ethanol to inhibit microbial growth Corker: likely to have spilled wine. Ethanol misting of corker jaws during bottling Activity: Limit number of people around filling/corking area Spoilage Microorganisms on Grapes Non-Saccharomyces yeasts Kloeckera apiculata Acetic acid bacteria Lactic acid bacteria Lysozyme Brettanomyces • Most serious of spoilage yeasts • Red wine in barrels • Bottled wines • Transmitted by fruit flies • Grows on cellobiose, toasted barrels • Tolerance to sulfur dioxide Brettanomyces growing in culture Brettanomyces.wordpress.com B. bruxellensis on WL agar Brettanomyces Practical winery and vineyard Wikipedia.com Smells like: Brett Barnyard Horse (blanket, sweat, saddle) Wet dog Tar Tobacco Creosote Plastic Leather Pharmaceutical (band aid) Yeast prevention/control Grapes Minimize damage to skins Pick when cool Sorting Add SO2 to picking bins Minimize transport distance Adequate hygiene Winery equipment Regular cellar hygiene Wines Adequate SO2 Absence of air/oxygen Filtration Microorganisms on Grapes Non-Saccharomyces yeasts Kloeckera apiculata Acetic acid bacteria Lactic acid bacteria Lysozyme Acetobacter angeladouglaslab.com, Cornell University •Gram negative rods or cocci •Strictly aerobic •0.6 to 0.9 microns by 1 to 3 microns •Formation of acetic acid from ethanol AAB control •Low pH (acid) •Minimize oxygen incorporation •Maintain cool temperatures (<50F) •Free sulfur dioxide levels according to pH •High VA wines can be blended with unaffected wine or treated by RO Microbes during fermentation Non-Saccharomyces yeasts Lactic acid bacteria (LAB) What to watch for: Ethyl acetate Spontaneous or sluggish fermentation Spontaneous MLF VA Off odors Lactic acid bacteria spoilage Typical spoilage times: During “stuck” fermentations Finished wines with low SO2, residual malic acid or sugar Lactobacillus spp. Enologyaccess.org Fermentacionvegetales.wikispaces.com Lactobacillus fermentum Lactobacillus brevis LAB Volatile acidity-metabolism of citric acid and glucose to acetic acid Mousiness Geranium taint-metabolism of sorbic acid Ropiness –production of extracellular polysaccharides Pediococcus Practicalwinery.com Pediococcus spp. and one Lactobacillus chain Mousey taint Aftertaste: not volatile at wine pH;mix with neutral pH of saliva become apparent Mouse urine Rancid nuts Can also smell like acetaldehyde, corn chips (when rub in palms) Comes from Brett (rarely) and LAB (usually) Stuck Ferments Lactobacillus Pediococcus Brettanomyces Acetobacter Film yeasts (Candida and Pichia) Watch for: VA increase Film yeast Spontaneous MLF CO2 production Microbes during MLF Acetobacter Lactobacillus Pediococcus Brettanomyces Film yeasts Oenococcus Watch for: VA increase >0.15 g/L (from citric acid) Film Off-odors and flavors VA post fermentation sources Headspace in barrels Oxidation of wine “acetic aroma” not exclusively a result of acetic acid Also due to ethyl acetate (ester) Esters are volatile compounds formed by combination of an alcohol and an acid Bacteria prevention/control Grapes Minimize damage to skins Pick when cool Sorting Add SO2 to picking bins Minimize transport distance Adequate hygiene Bacteria prevention/control Winery equipment Regular cellar hygiene Wines Short or no skin contact Adequate SO2 Exclusion of air Filtration Acid addition Validating Winery Sanitation Perform the sanitation operation using a standard operating procedure (SOP) Validate that the SOP was effective define equipment, concentration of sanitizer, time, temperature, surface type, cleaning state, bioload, etc. Use swabbing or soak/rinse water to get sample Use microscope scans, plating, or PCR methods Scorpions™ testing can provide fast results and target specific wine spoilage organisms. Changing any parameter in the SOP would indicate the need for additional validation. Swab or Soak Sampling Specify the details of the sampling technique in the SOP Swabbing area and location Use good sterile technique Rub hard to break up biofilms Place swab in labeled container of sterile saline Sterile water soak/rinse sampling may be appropriate for some situations. A concentration step may be helpful if low cell numbers are anticipated. A negative result (no cells found) does NOT indicate sterility. Ongoing testing and historical trends important in developing and implementing effective programs. Membrane Filter Method Sartorius stedim biotech •Isolate small number of microbes from liquid sample •Demonstrate their presence as colonies on culture medium •Cellulose nitrate membrane: 0.45 micron for bacteria, 0.65-8.0 microns for yeasts and molds Surface Testing Sartorius stedim biotech •For smooth surfaces •Place membrane on surface to be tested and place on agar plate •Use sterile technique Swab Test Method Sartorius stedim biotech Sartorius stedim biotech •Semi-quantitative analysis •Moist sterile cotton swabs for dry areas (sterile physiological saline) •Dry sterile cotton swabs for moist areas Airborne Microorganisms Sartorius stedim biotech •Sedimentation plates •Leave plates open for 30 min-2 hrs •Incubate Yeasts and molds Wort Culture Media Malt Extract Wallerstein Lysine (wild yeasts) Addition of Actidione will allow only Brettanomyces and some Kloeckera to grow Bacteria Orange Serum (AAB, LAB) Tomato Juice (O. oeni) Sartorius stedim biotech Cellar Hygiene Why? To maintain wine integrity and quality Poor wine quality is usually due to poor sanitation practices! Sources/areas of build up Vineyard Diluted pools of juice Second-hand barrels Imported bulk wine Areas of winery that are difficult to reach General guidelines Proactive and not reactive Constant and immediate attention Clean up immediately Save time at end of day Conclusions Prevent and control microbial contamination Reducing population during winemaking So2 Temp Filtration Quality control plan SOPs based on cGMPs HACCP Sample wines/taste for faults Contact Information Molly Kelly Enology Extension Specialist Food Science Dept., Virginia Tech Email: mkkelly@vt.edu Cell phone: 540-315-6920 References Lansing, R. May 2011. Managing Bottling Operations. Wine Business Monthly. Neradt, F. 1982. Sources of reinfections during cold-sterile bottling of wine. Am. J. Enol. Vitic. Vol. 33. no. 3. Pregler, B. Dec 2009. What’s Cool: Accurate Membrane Filter Integrity Testing. Wine Business Monthly. Tracy, R. and Skaalen, B. Jan/Feb 2009. Bottling-last line of microbial defense. Practical Winery and Vineyard. Ritchie, G., Napa Valley College, VWT 280, Cellar Hygiene, 2007. Menke, S., Cleansers and Sanitizers, Penn State Enology Extension, 2007. Butzke, C., Barrel Maintenance, Dept. of Food Science, Purdue University, 2007. Howe, P., ETS Laboratories, SOWI “Current Issues” Workshops March 2011. Crowe, A. Avoiding Stuck Ferments, Wine Business Monthly, August 2007. Zoecklein, B. et al, Wine Analysis and Production, Aspen Publishers, 1999. Van de Water, L., Practical Winery and Vineyard Journal, Sept/Oct 2009. Just, E. and H. Regnery. Microbiology and Wine Preventive care and monitoring in the wine industry. Sartorius Stedim Biotech. 2008.