UNIT-II - E

advertisement

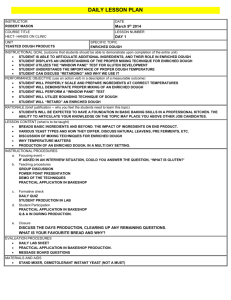

DEPARTMENT : HOTEL MANAGEMENT & CATERING SCIENCE YEAR : II SEMESTER : THREE SUBJECT : BAKERY AND CONFECTIONERY - I UNIT : TWO SYLLABUS YEAST DOUGH, TYPES OF DOUGH, STEPS IN YEAST DO UGH PRODUCTION, TYPES OF DOUGH MAKING PROCESS, CONTROLLING FERMENTATION, BREAD FAULTS AND THEIR CAUSES. &&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&& YEAST DOUGH: Bread is nothing more than a yeast dough made of flour , water and leavened by yeast. These are the basic building blocks of all breads. Eg French bread.Other breads contain sugar, fat, milk, egg, & flavourings. Types of dough products:There are 3 type of dough products they are lean dough product, Rich dough product, and Rolled in yeast dough products. Lean dough products:- A Lean dough is one that is low in fat and sugar.Eg:- Hard crusted bread, Hard rolls, French and Italian bread etc. Rich dough products:- There is no exact dividing line between rich and lean doughs but in general , rich doughs are those that contains higher proportions of fat and sugar sometimes eggs. Rolled in Yeast dough products:- Rolled in doughs are those in which a fat is incorporated into the dough in many layers by using a rolling and folding procedure. The alternating layers of fat and dough give the baked product a flaky texture. Eg: Danish pastry & Croissants. Steps in yeast dough production:There are 12 steps in the production of yeast breads. These steps are generally applied to all yeast products with variations depending on the particular product. 1. 2. 3. 4. Scaling ingredients Mixing Fermentation Punching 5. 6. 7. 8. 9. 10. 11. 12. Scaling Rounding Benching Makeup and panning Proofing Baking Cooling Storing Scaling ingredients:- All ingredients must be weighed accurately. Water , milk and eggs may be accurately measured by volume, while measuring spices and other ingredients used in very small quantities. This is particularly important with salt which affects the rate of fermentation. Mixing:- Mixing yeast doughs has three main purposes i)To combine all ingredients into a uniform , smooth dough. ii) To distribute the yeast evenly throughout the dough. iii) To develop the gluten. There are 3 principal mixing methods they are straight dough method, modified straight dough method, and sponge dough method. Straight dough method:- It consists of only one step combine all ingredients in the mixing bowl and mix. Many bakers make good quality products by using this procedure. The yeast may not be evenly distributed in the dough. It is therefore safer to mix the yeast separately with a little of water. Modified straight dough method:- for rich sweet doughs, the straight dough method is modified to ensure even distribution of the fat and sugar. Sponge method:- sponge doughs are prepared in two stages, first stage is called sponge, a yeast starter or a yeast preferment. The second stage there are two possible ways to express percentages when using a sponge. 1.Consider the sponge or preferment as a separate formula. Express the flour in the sponge as 100%.Then in the main formula express the total weight of the sponge as a percentage of the flour weight in the main formula. 2. Consider the sponge as part of the main formula, express the flour in the sponge as a percentage of the total flour in the complete formulas. 3. mixing times and speeds:-The first two puroses of mixing , combining the ingredients into a dough and distributing the yeast are accomblished during the first part of this step. The remaining time is necessary to develop the gluten. Overmixed and undermixed doughs have poor volume and texture. Fermentation:- Fermentation is the process by which yeast acts on the sugars and starches to the dough to produce co2 (carbondioxide) gas and alcohol . Gluten becomes smoother and more elastic during fermentation, so it stretches further and holds more gas. An underfermented dough will not develop proper volume, and the texture of the product will be coarse and if it ferments too long or at too high temperature becomes sticky, hard to work and slightly sour. An underfermented dough is called young dough and overfermented dough is called an old dough. Punching:- Punching is not hitting the dough with your finger. It is a method of deflating the dough that expels co2, redistributes the yeast for further growth, relaxes glutten , equalizes the temperature throughout the dough. Additional fermentation and punching may or may not be necessary depending on the dough. Scaling:- During scaling , allowance is made for weight loss due to evaporation of moisture in the oven. This weight loss is approximately 10 to 13% of the weight of the dough. Scaling should be done rapidly and efficiently to avoid overfermenting the dough. Rounding;- After scaling, the pieces of dough are shaped into smooth , round balls. This procedure forms a kind of skin by stretching the gluten on the outside of the dough into a smooth layer. Rounding simplifies the later shaping of the dough and also helps retain gases produced by the yeast. Benching, Bench proofing or intermediate proofing:- Rounded portions of dough are allowed to rest for 10 to 20 minutes. This relaxes the gluten to make shaping the dough easier. Makeup and panning:- The dough is shaped into loaves or rolls and the placed in pans or on baking sheets. Proofing;- Proofing is a continuation of the process of yeast fermentation that increases the volume of the shaped dough. Baking :- Many changes takes place in the dough during baking. The important changes are 1. Oven spring :- Yeast is very active at first it is killed when the temperature inside the dough reaches 140*F (60*C). 2. The product becomes firm and holds its shape, because of coagulation of proteins & starch. 3. Formation & browning of the crust. 4. Oven temperature & baking time:- It should be adjusted for each product being baked. 5. Washes;- yeast products are brushed with a liquid called a wash. Eg: water, starch paste, eggwash. Cooling :- After baking bread must be removed from pans and cooled on racks to allow to escape the excess moisture and alcohol created during fermentation. Storing:- wrapping & freezing maintains quality for longer periods. For longer storage wrap cooled breads in moisture proof bags to retard staling. Types of dough making process:Straight dough:- All ingredients are mixed by the straight dough method. The dough is then given a bulk ferment Bulk fermentation time (until molding & proofing) of 1 to 2 1/2hrs. This is called a short fermentation straight dough. “no time” dough is made with a large quantitiy of yeast , taken from the mixer at a higher temperature upto 32*C and given only a few minutes rest before scaled & make up. Long fermentation dougs are fermented for 5 to 6hrs sometimes overnight at a temperature of 75* F (24*C) . This enhance the flavor of the product. Sponge process:- Sponge is made of water, Flour and yeast are allowed to ferment. Then the doug is made by mixing in the remaining ingredients. The finished dough may be given a short fermentation or if the sponge has had a long fermentation, it may be scaled immediately like a no time dough. Controlling fermentation:Fermentation requires a balance of time, temperature and yeast quantity. Time:- Fermentation time varies , so the time to punch the dough is indicated not by clock but by the appearance and feel of the dough. Fermentation time must control the doug temperature and the amount of yeast. Temperature :- Usually it is fermented at room temperature but in large bakery units there will be a special room for fermenting will be there for controlling fermentation and humidity. Water temperature:- Dough must be at the proper temperature usually 78* to 80*F. The dough is affected by several factors – Shop temperature, flour temperature, water temperature to control these we should bring the water to room temperature while weighing and use it to avoid overfermenting or underfermenting. Bread faults & their causes :- Refer professional Bakery.