The status of this measure should be changed to Out-of

advertisement

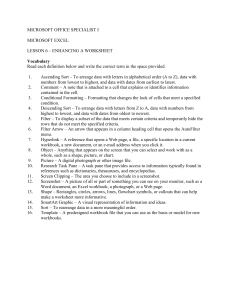

M e m o r a n d u m FROM: Michael Baker, SBW TO: RTF Staff DATE: February 11, 2013 RE: Phase I Review and Update Recommendations: Grocery Walk-in ECM This memo documents the results of DNV KEMA’s review of the UES (Unit Energy Savings) measure Grocery Walk-In ECMs. This measure has been categorized by the RTF as Proven, and therefore this memo outlines recommendations consistent with that category. This measure addresses savings that result from installing an electronically commutated motor (ECM) on a grocery walk-in case evaporator fan in place of a shaded pole (SP) motor. The measure applies to retrofits. The review focuses on the derivation of UES values. Summary Recommendation. The status of this measure should be changed to Out-of-Compliance. The following recommendations lead to a change in status to Out-of-Compliance. 1. The Average EER parameter needs to be derived transparently from publically available regional data. 2. Basis for Fan Input Power parameter should be explicitly documented The following recommendations lead to a change in status to Under Review. 1. The workbook needs to be made fully functional by adding internal links, updating cost data and running the ProCost macro. 2. Document basis for Annual Fan Runtime Hours. If documentation is not available for LT walkins, use the recommended source, and expert panel to develop documented values for MT walkins. 3. The sources noted for the Mix of Low and Medium Temperature Walk-ins and Mix of Rated Fan Power parameters should be more thoroughly documented. Limitation of Review. The Grocer Smart 3.0 model store was not available or included as part of this review. Alterations to Workbook and Documentation. 2820 Northup Way, Suite 230 Bellevue, WA 98004 Page 1 A sheet called “Summary” has been added to the workbook. This sheet describes how measures are identified, lists important constants and their sources, describes the savings estimation algorithm and the associated baseline and efficient case parameters and their sources for each measure and UES component. Since a standardized RTF measure workbook was not available, the standardized workbook ComGroceryWalkInECM_v1_0.xlsm was developed using supporting information from the RTF workbook DeemedMeasuresV26.xls. Obviously superfluous elements of that RTF workbook were ignored. All subsequent review was of this new standardized workbook. o The following worksheets were removed since they did not contain information relating to the Walk-In ECM measure SavingsData&Analysis evap fans Summary (2) ECM on Compressor Fans evap fans case ecm o Some worksheets contained additional (measure) rows which were not needed for this particular measure. These rows were removed. “MeasureTable” worksheet – Rows 9 and 10 “Measure_InputOutput” worksheet – Rows 9 and 10 “LookupTable” worksheet – Rows 4 and 5 o The measure description cells on the “LookUpTable” worksheet were filled in with values sourced from DeemedMeasureV26.xls where applicable. o Removed the remaining link to the external workbook “Deemed MeasuresV26.xls” in cell L31 on the “evap fans wi ecm” worksheet, with a value of 718 (kWh/motor). The demand savings calculations for the Refrigeration Savings UES component were erroneous. Cells I31:I37 on the “evap fans wi ecm” worksheet were changed to have their calculations reference the following equation: 𝑅𝑒𝑓𝐷𝑒𝑚𝑎𝑛𝑑𝑆𝑎𝑣𝑖𝑛𝑔𝑠 = 𝑀𝑜𝑡𝑜𝑟𝑆𝑎𝑣𝑖𝑛𝑔𝑠 × 3.413 𝐸𝐸𝑅 × 𝐷𝐹 Where, RefDemandSavings = “Refrigeration Demand Savings” in kW/motor (Cells I31:I37) MotorSavings = “Direct Demand Savings” in kW/motor (Cells H31:H37) 3.413 = Conversion ratio of 3.413 kBtu/hour = 1 kW EER = “EER – per case temp” expressed in kBtuh/kW (Cells G31:G37) DF = Degradation Factor (Cells E31:E37) The calculations for the Refrigeration Savings component previously used the refrigeration system’s compressor full load hours instead of the fan’s run time hours (Annual Fan Runtime Hours parameter). This was a mistake noted by PECI. Refrigeration Savings should use the Page 2 runtime hours of the affected equipment (i.e., the fan motor) that reduced the refrigeration load. Cells M31:M37 on the “evap fans wi ecm” worksheet were changed to have their equation reference the Annual Fan Runtime Hours in Cells D31:D36 instead of the refrigeration system full load hours in Cells F31:F37. This calculation alteration changed the measure UES value from 1,094 kWh to 1,199 kWh. The “kW base” value for the 16-23W medium temperature walk-in motor (Cell E63 on the “evap fans wi ecm” worksheet) was referencing the wrong cell and was changed to reference Cell J35. It was referencing Cell J37 (the “Combined Temp Shaded Pole to ECM Walk-in” total demand savings value) when it should have been referencing Cell J35 (the “Med Temp Shaded Pole to ECM in walk-in – 16-23 Watt Output” total demand savings value). There were several cells on the “evap fans wi ecm” worksheet that had hard-entered values for the average weighted values of the 1/20 HP, 1/15 HP, and 16-23W motor demand savings. These cells needed to be updated in order for changes in the previous bullets to be reflected throughout the workbook. Cells E70, E71, F71, and F72 had their hard-entered values replaced with corresponding equations to calculate the cell’s value. The average demand of all cases for 16-23W motors was also added in Cell B66 in order for the aforementioned cells to reference that value without being hard-entered. Recommendations for Updates. The RTF should implement the following recommendations: 1) Workbook Structure and Formulas a) The measure workbook (ComGroceryWalkinECM_v1_0.xlsm) was developed using supporting information from the RTF workbook DeemedMeasuresV26.xls; however, the measure workbook still needs the ProCost macro to be run and the ‘MeasureTable’ worksheet populated in order to be fully functional. i. The “Input Data” section of the “Measure_InputOutput” worksheet is pointing to the correct workbook UES value. The remaining row items (Life (years), Capital Cost, Annual O&M, etc.) need to be updated. ii. The named range “OutputRange” needs to be updated to reference the ProCost output results that will be listed on the “Measure_InputOutput” worksheet. The named range is currently referencing Cell G58 on the “ProCost 6th Plan Inputs” worksheet. These deficiencies cause a change of status to Under Review. 2) Documentation a) No changes recommended 3) Measure Definition a) No changes recommended 4) UES Savings Estimation Method Page 3 a) No changes recommended 5) Input Parameters a) The Average EER parameter is based on proprietary DOE 2.2-R simulations of Northwest grocery environments. The Degradation Factor will need to be removed as a parameter from the UES Savings Estimation Method and spreadsheet calculations and incorporated into the Average EER value to include this degradation impact. This parameter needs to be derived transparently from publically available data. This deficiency causes a change of status to Out-of-Compliance. b) Further documentation support is needed for the Annual Fan Runtime Hours. No source is currently cited for this parameter, which is listed as 8,760 for both medium and low temperature cases. Units found in low temperature areas typically have defrost cycles, which should be accounted for in the Annual Fan Runtime Hours parameter. If supported documentation is not available, use the suggested value of 8,322 sourced from Pacific Gas and Electric (PGE) and Southern California Edison (SCE) work papers, which assume a daily defrost period lasting 72 minutes for evaporator fans located in low temperature areas1. This equates to an Annual Fan Runtime Hours value of 8,322 hours for low temperature areas. Evaporator fans found in medium temperature areas can be assumed to operate continuously (8,760 hours); however, an expert panel should determine the Annual Fan Runtime Hours value for medium-temperature areas. This deficiency causes a change of status to Under Review. c) The sources noted for the baseline and efficient case Fan Input Power parameter should be explicitly documented with a full source document citation, if available. These sources are noted in Cells B100:B102 on the “evap fans wi ecm” worksheet as “Heatcraft/Bohn Evap Coil Data” and “ESG Invoice Data”. If the sources were not published, provide a summary of the analyses performed on the raw data to obtain the referenced values. This deficiency causes a change of status to Out-of-Compliance. d) The sources noted for the Mix of Rated Fan Power and Mix of Low and Medium Temperature Walk-ins parameters should be more thoroughly documented with a summary of analyses performed on the study’s raw data. The sources are referenced as “BPA Invoice Data HP vs. Watt Motor Breakdown” in Cell A117 and “Case Temp Market Potential from Audit Data” in Cell A118 on the “evap fans wi ecm” worksheet. PECI has indicated that more thorough explanations and summaries can be provided as part of their update effort. This deficiency causes a change of status to Under Review Additional Considerations. 1) An alternative to using motor size weightings and case type weightings would be to separate the measures by motor size and case type. This would alleviate the need to have weightings data. 1 PGECOREF109.1 – Efficient Evaporator Fan Motor – Electronically Commutated Motor (ECM) and WPSCNRRN0011.1 – Evaporator Fan Motors Page 4 2) Since this measure does not rely on external codes, standards, or efficiency specifications, the measure sunset criteria should be set to 5 years after the RTF decision to move the measure to “Active” status. Page 5