SmartNext Wireless Monitoring and Control System

advertisement

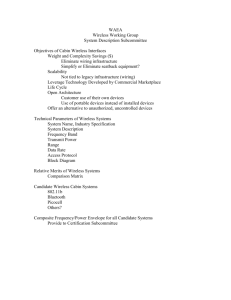

SmartNext Wireless Sensors Connectivity System S e n s i N e x t About Us 45 Years of Excellence SensiNext is a leading provider of an industrial wireless sensors connectivity systems SensiNext’s RF systems were chosen by interntional leading firms, around the globe, to provide reliable & cost-effective connectivity of multiple sensors for data acquisition, data logging and various industrial applications SensiNext is a subsidiary of Elcon-MMB, a 45 years old leading sensors manufacturer in Israel, providing sensors and complete control systems for almost all leading industries in Israel For more information, please visit our website www.sensinext.com S e n s Agenda Few Words About Wireless i N e x The SmartNext™ System SCADA & Data Acquasition t Typical Applications S Wireless Advantages e n • s i • Overcomes the difficulty to wire specific locations • Cabling works interfere with on going manufacturing procedures N e • x t Eliminating the need for expensive cabling costs Mobile / portable elements connectivity • Immediate implementation S e n s Typical Markets & Applications The Market Typical applications / measurements Industry automation Pressure, level, temperature Health & pharma Temperature & humidity of medicine & incubators Food Ingredients & refrigerators monitoring. Cooking process Universities & labs Incubators & reregiators Water & waste water Level, pipelines pressure, consumption, water quality Spinning drums & moving elements Various measurements in movment i N e x t S e n Sensing Requirements - Example Lets add 5 temperature sensors Lets add 10 various 4-20 mA sensors Lets add 3 humidity sensors s i N e x t Lets add communication cabinet With 3 I/O cards S e The Outcome We all wish it will look like this n s i N e x t Does this look familiar? S e How Does It Look In Wireless2? Wireless control panel n s Wireless Transducer And that’s it i N e x t CP CP S e n s Agenda Few Words About Wireless i N e x The SmartNext™ System SCADA & Data Acquasition t Typical Applications SensiNext A World of Wireless Connectivity S e n s Food Production Waste water Humidity N e t agriculture Pharma i x Lab’s 4-20 mA PT-100 Temperature Pressure Flow S e n s i N e x The SmartNext SmartNext™ is an industrial wireless sensors connectivity system that utilizes a state-of-art RF technology and robust communication elements, to ensure top grade, industry standards The SmartNext presents an alternative to the traditional, wire based, sensors connectivity method The SmartNext can be utilized as: • Complementary solution for wire-based systems • Comprehensive, stand-alone platform for sensors connectivity t Control Panel RS-485 / TCP/IP Wireless Sensor Repeater Wireless Sensor S e n • • • i • • N e • s x t SmartNext’s™ Main Features Frequency hopping: Robust communication technology 433 / 868 / 915 MHz frequemcy bands – Reliable industry standard True 1000 m’ (3000 ft) in open space Line-Of-Sight True 100m’ (300 ft) indoor implementation ModBus output Real plug & play installation S e SmartNext™ System Components n Basic system components s i N e • Control Panel • Transmitters (transducers) • Repeaters – Optional Optional add-ons x • Data acquisition / SCADA • Alerts SMS modem t • Data logger S SmartNext’s™ Control Panel e n The control panel is the SmartNext’s™ system hub s i N e • • • • Longer range: Up to 1km/100m open air/indoor Up to 32 transmitters (32 sensors) and up to 4 repeaters Standard Modbus output: RTU / TCP-IP System configuration and control via control panel’s built-in keyboard, or remotly, via standard modbus x t Control Panel 1 km SCADA Sensors Analog Sensors Modbus Digital Sensor 1 km S e SmartNext’s™ Transmitters - 1 n The RF Transmitters connect sensors to the control panel SmartNext’s™ transmitters are fully standard compliance and enable customer’s existing sensors connectivity, or utilizing 3rd party sensors manufacturer i • Longer range: Up to 1km/100m open air/indoor • Frequency hopping technology N • Long battery life e • Remote configuration s x t S e SmartNext’s™ Transmitters - 2 Existing SmartNext™ Roadmap n PT-100 0-10 V s 4-20 mA (active) 2 X 4-20 mA i 4-20 mA (passive) Thermocouple (beside TC-T) N e 0-2 V 2 X Dig-in x t Available Ordering Options Wall mounting box “head” connection box Temperature “Stab” S SmartNext’s™ Repeaters e n Repeaters are SmartNext’s™ range extenders. s Where sensors are located in a remote, or electronically shielded location, repeaters extends the WL range in additional 1Km / 100m (outdoor / indoor) i N e 2 km x t SCADA Repeater Control Panel Modbus Sensors 1 km Analog Sensors 1 km Digital Sensor S e n s Agenda Few Words About Wireless i N e x The SmartNext™ System SCADA & Data Acquasition t Typical Applications S e n s Data Acquisition and SCADA SW • Dedicated data acquisition software connected to your SmartNext controller, collects and logs all data from sensors • Various of graphs, bars presentation tools • Option for pre-set data acquisition SW of full SCADA application i N e x t Data Acquisition SCADA S e n s i RealWeb – Web Based SCADA • Cellular modem unit, that transmits control panel’s Modbus data to a ‘cloud’ based SCADA software • All local sensors and data are visible in the Internet via: PC, tablet or mobile devices N e Cellular x RealWeb t Cloud Based SCADA Sensors Control panel Analog Sensors Digital Sensor S e n s Agenda Few Words About Wireless i N e x The SmartNext™ System SCADA & Data Acquasition t Typical Applications S e n s i N e x t SmartNext – Who is it For? Low Differential Pressure Measurement in Clean Rooms S e n • The challenge: Sending a special person to measure the differential pressures and sending report in 200 points in the factory, is very inefficient. Also interference the production procedure is prohibited. Wiring is out of question. N e • Requirement: Data acquisition wireless based system that should control and alert 200 different points in the factory and must be integrated with the main SCADA of the factory. x • Solution: Based on our SmartNext™, Special pressure transmitters (for low differential pressure) were connected to 4-20mA wireless transducers. Some were connected to the Control Panels directly and some via Repeaters (due to lot of electrical noises). The Control Panels transmit the information to the SCADA system. s i t Temperature Measurement in Wagons in Motion S e n • The challenge: Any frozen food manufacturer that uses industrial motion freezer for the production process, has the problem of efficient control the required temperature. • Requirement: To have a current control of the temperature of the food (dough) in the motion freezer, in order to move it to a permanent freezer (when reach the required temperature). • Solution: A special probe of Pt100 is inserted into the freezer. This sensor was connected also the a wireless transducer. When it reaches the temperature, the wireless sensor (Wireless RTD transducer with Pt100) transmits the info, via the Control Panel, to the SCADA. s i N e x t Measuring Temperature in Grains / Food Piles S e n • The challenge : Keeping a permanent temperature in compost / grain piles is very difficult, as it is very danger to send a person to measure it. • Requirement: Wireless reporting of temperature in Compost / Pet food / Grains piles. • Solution: SmartNext™ is the perfect solution for this application. The information is transmitted to the data acquisition system and the customer has a full reliable control. A special probe was produces to fulfill the requirements of the area (comes with Pt100 that is connected to the wireless transducer). These wireless probes are inserted into the piles and report to the Data Acquisition software via the Control Panel. s i N e x t Millivolts Measurement for Cathode Protection S e n • The challenge : In all seawater desalination plants, there is similar problem: cathode digesting in the metal pipes. • Requirement: Since there are many sensors, there is a need to protect the sensors and continue to use them. Wiring the plants is forbidden. • Solution: Based on SmartNext™: with special modification, the wireless transducer acts as “voltmeter” in the range of 0-2V. As a results, a new wireless transducer had been added in order to protect against the cathode digesting and still using the existing sensors in the plant. s i N e x t The system was installed in one of the largest sea water desalinations in the world. Temperature & Humidity Measurements in Pharma Warehouses S e n • The challenge : There are many large Pharmaceutical warehouses that are not wired. Since current monitoring of temperature and humidity is required, it is not efficient to do it manual. i • Requirement: To have efficient and cost effective current temperature & humidity monitoring and report it to the main HMI. N e • Solution: With SmartNext™ system, we reduced dramatically the infrastructure cost and saved lot of installation time. We installed Temperature & Humidity transmitters to the 4-20mA Wireless Transducers that transmit the information via the control panel, to the main HMI. In these cases, each installation took about on working day. s x t We installed the systems at Teva and some other pharmaceutical manufacturers. Temp. & Humidity Measurements In Food Storage / Warehouses S e n s • The challenge : In food Logistic warehouses it is required to keep the goods in a range of specific temperature and humidity. In many places there is no wiring infrastructure. • Requirement: The demand is for fast installation and reliable sensors that will transmit the temp. & humidity status to a central data logging software. • Solution: We based on the SmartNext™ System, that includes the Control Panel, 4-20mA wireless transducers and the Temp. & Humidity transmitters. i N e x t S Temperature & Humidity Measurements in Clean Rooms e n s i N e x t • The challenge : Wiring clean rooms are forbidden whilst measuring the temperature and humidity are important. • Requirement: To measure the temperature and the relative humidity in the clean rooms without wires. • Solution: We based on the SmartNext™ System, with Control Panel, wireless transducers for temperature Pt100 temperature sensor and wireless transducer for with humidity transmitter (4-20mA). High Temperature Measurement in Furnaces in Motion S e n • The challenge : Measuring temperature with current report, is impossible. People are not allowed doing this. • Requirement: To know a specific threshold. Upon it, material should be taken out and continue with another process. • Solution: Based on the SmartNext™ system. A temperature sensor with long cable is connected to the wireless transducer. The probe is inserted into the furnace and reports via the control panel, to the SCADA / HMI software. s i N e x t S Level Measurement in Tanks e n • The challenge : Measuring diesel / oil level in tanks is needed without interfering by people. Wiring is impossible. • Requirement: To measure oil / diesel during the process, to ensure a proper quantity of the liquid. • Solution: Based on SmartNext™ system. A level transmitter (4-20mA) was connected to the wireless transducer (one wireless sensor in each tank). That way, there was a full control on all the oil containers in the plant. s i N e x t S Level Measurement in Silos e n • The challenge : Wire Infrastructure in food factories, bakeries, Compound Institutes / Feed Mills, etc., is difficult and very expansive. • Requirement: Measuring the current level of the materials in the silo (various types of grains) and report to the SCADA software. • Solution: With our SmartNext™ wireless system Ultrasonic device were connected to a wireless transduces (0-2V) in each silo. The info was reported via the Control Panel to the local SCADA. There is an option to be connected to the web. s i N e x t S e n s Measuring Pressure & Temperature in Energy Station • The challenge : Reliable and accurate measuring accurate pressure and temperature in organization’s energy rooms / power stations is very difficult (wires are many times prohibited). • Requirement: To control the pressure and temperature in wireless methods. • Solution: With our SmartNext™ system using pressure transmitters that were connected to 4-20mA wireless transducers and temperature sensors (Pt100) that were connected to the RTD wireless transducers. Via the control panel, the information was sent to the main SCADA. i N e x t S Level Measurement in Environmental plant e n s i N e x t • The challenge : Keeping a specific level of water might be very complicated. • Requirement: To allow keeping a specific level of the water in the wastewater ponds, by sending the information to the Control Room without any wiring in the plant. • Solution: Based on SmartNext™, we installed level transmitter (connected to 4-20 mA Wireless transducer) to measure the continues level of the water and float level (connected to digital wireless transducer) switches (for on-off operation). The information of the level was transmitted to the main PLC of the plant from the control panel. S Temp. & Humidity Measuring in Agriculture e n s • The challenge : Reporting information (temperature & humidity) to the control rooms (located far away from a Green House) is problematic, due the long distance between the GH and the control room. • Requirement: To keep a required temperature and humidity in Greenhouses and report the info to the HMI / PLC without wire infrastructure. • Solution: Based on SmartNext™ system with Humidity & Temperature transmitters that are connected to the 4-20mA wireless transducers and transmit the information to the HMI or PLC via the control panel. i N e x t S e Level Measurement in Water Treatment Plants n s • The challenge : The distance between Control Rooms and the Water Ponds in Water Treatment plants is usually very far. Information of water level, level of PH & Conductivity is essential and wiring is not an option due to rats & mice. • Requirement: To report the level of water, PH and Conductivity to the SCADA / HMI without wires. • Solution: Using the SmartNext™ system: Control Panel is located in the control room and in the water ponds the Wireless Sensors are installed. The wireless sensors can measure the level of the water (with 4-20 transducer), the conductivity /PH (with 0-2V Passive) and also Analytical measurements. i N e x t S Energy – Vibrations Measurement in Engines e n s i N e x t • The challenge : The mass of vibrations in engines (in energy plants), cause problems to the engines. • Requirement: To protect the engine without Wiring (in these areas manual measuring is quite difficult and wireless is the preferred). • Solution: Based on our SmartNext™, we installed in each engine a vibration transmitter that is connected to a 2w 4-20mA wireless transducer and via the control panel the information is sent to a PLC or to the SCADA / HMI software. Pressure Measurement in Pump and Pipes S e n • The challenge : Controlling the pressure on pumps and pipes in the fields, is sometimes critical. Using wiring infrastructure is not a reliable options, due to rats, snakes and other rodent pests. Also, usually, power source is not available. N e • Requirement: To control pressure on pumps, by sending the information wireless to the HMI / PLC in a control room or the Web. x • Solution: Using SmartNext™ system with pressure transmitters that are connected to a 4-20mA or 0-2V wireless transducers and transmit the information to the HMI / PLC or to the web. s i t Level Measurement of Water in Remote River S e n • The challenge : Whenever there is a need to measure the level of the water in remote river and transmit information a control room, wire infrastructure is impossible (crossing public area, when wiring infrastructure is impossible). N e • Requirement: To measure the level of the water in a river and sends the information to a control room that is located about 1km far and a public road was in between. x • Solution: Based on SmartNext™ with level & pressure sensors (transmitters) that are connected to the wireless 4-20mA transducers and transmit the information to the control panel that is located in the control room. s i t S e n s i N e x t Summary • Plug & play wireless sensors connectivity system • Longer range – 1000m` \ 100m` (out\in door) • Designed to work in an harsh encironment • Connectivity to any standard sensors • Standard compliance with any SCADA \ data acquisition SW