ChromicTech Webinar Presentation

advertisement

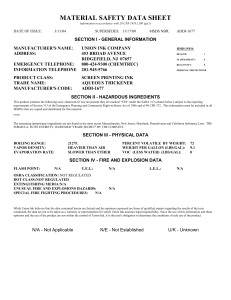

This presentation will last about 20 minutes with some time at the end for questions To raise a question, simply type into the chat window on your left and one of our presenters will answer. If you are having a technical problem, for example, you cannot see or hear the presentation, let us know by using the chat and we will address it. This presentation will be available on our blog at http://inkwithfeelings.wordpress.com/ after the webinar You may contact us by sending an email to chromictech@gmail.com with any questions or comments Feel free to contact us on Twitter using the hashtag #ChromicTech or mention us @ChromicTech Find us on Facebook: http://www.facebook.com/ChromicTech Welcome to the webinar! Presenters Brian Hui Liam Maddock Danielle Olesen The ChromicTech Team Project Manager Mathew Miller The ChromicTech Team Event & Marketing Team Brian Hui, Afm Rupal, Nara Szutu The ChromicTech Team Social Media Team Danielle Olesen, Jessica Augusto, Tiia Lahe The ChromicTech Team Communications Team Sehar Seikhe, Melissa Yung, Liam Maddock Today’s Agenda What are thermochromic inks? Who uses thermochromic inks? Working with your printer and thermochromic inks considerations What are Thermochromic Inks? …and how do they work? What are Thermochromic Inks? Thermochromic inks change colour as a result of a change in temperature. http://www.techpin.com/thermochromic/ http://www.cooljewels.com/whole sale-mood-ring.aspx http://plasticprintingny.com/thermochrom ic-ink-printing Let’s Get Scientific Credit: http://www.chromazone.co.uk/Thermochromism.htm How do they work? Thermochromic inks change colour in one of two ways: 1. 2. Thermochromatic Liquid Crystals (TLCs) Leuco Dyes Thermochromatic Liquid Crystals (TLCs) An increase in temperature will change inks with TLCs from black to any colour Advantages Extremely temperature accurate Disadvantages Expensive The effect of the liquid crystals can deteriorate over repeated exposure to UV light, water and chemicals TLCs are most commonly used in plastic thermometers http://www.cis.rit.edu/fairchild/WhyIsColor/Questions/2-5.html Leuco Dyes As the temperature increases, ink with leuco dyes change from colour to translucent. Leuco dyes can also be mixed with other colours to create a two-tone effect as the temperature changes. Advantage Disadvantage Leuco dyes are more stable than TLCs, which makes them more versatile. They are not temperature accurate. Leuco dyes can be incorporated into a multitude of products, ex. bottles, cans, clothing, plastics, etc. http://www.plastech.biz/news/article_4499_1/Ball-furtherenhances-thermochromic-ink-technology http://www.houseautomator.com/arch/kit chen-automation/ Who uses Thermochromic Inks? Companies have used thermochromic inks before for a unique marketing purpose! Companies/Products we focused on… Häagen-Dazs Ice Cream Mars Carling Beer Duracell Häagen-Dazs Ice Cream The “Dip n’ Win” Promotional Campaign Location Häagen-Dazs sells ice cream world-wide This promotion was held specifically outside Häagen-Dazs cafes in Europe Goal of the Campaign To reinforce the company’s brand image of having 100% perfect ice cream in a creative and interactive manner To help introduce trail flavours To increase traffic in cafes and stores The Product A “stick-it-in-to-win” card. An oblong shaped card with a circle on one end printed with thermochromic ink. The circle end gets pushed into cold ice cream, licked clean and reveals a % figure. The % figure determines the prize won in-store. The Promotional Campaign Employees would stand outside Häagen-Dazs cafes handing out the “Stick It In To Win” cards to anyone who walked by. Consumers then had to go into the café and buy some ice cream in order to reveal the % figure for prizes. All prizes could be seen inside the stores The largest prizes were Häagen-Dazs scooters Employees reinforced that the top prize (100%) was another large scoop of Häagen-Dazs ice cream- a clever ploy by Häagen-Dazs to emphasize that they had the best ice cream. The Results This campaign increased store traffic and created a lot of new excitement around the ice cream brand. The campaign also successfully marketed them as being 100% perfect. Ice cream sales increase 30% while the campaign was running. Mars Bars Chilled Mars Campaign Goals: To encourage sales of chocolate bars in New Zealand during the Summer months. Implementation: 6 different designs were released. Each one had an area of print that used of theromchromic ink. When these bars were chilled bellow 4 degrees the Mars name would change from white to blue. During this campaign they also handed out tickets at events and promos that were printed with thermochromic ink. When the tickets were chilled a message appeared with over a 50% chance of it declaring you a winner of free talk time. Billboards and print ads were focused near to the beaches and in corner stores in New Zealand to increase buzz in areas where chilled treats are most desired. Carling Beer: Cold Lion/Taste Lock Carling Campaign Goals: To Increase interactivity with customers. An added value asset for the product that assists both customers and retailers. “With thermochromic, we are rewriting the rules of cold. No longer are the measurements of cold touch and taste alone: we’re absolutely thrilled to be introducing the technology that allows you to tell when your Carling is perfectly cold to drink, on sight alone.” Carling Campaign Implementation: A small image of a can, lion or knot (depending on which version of the can you are dealing with) turns white to blue when cold Carling’s cans are steel unlike the Coor’s can. When printing on these cans you do not require a varnish in order to reduce damage to the print. 86% of customers say it is important to drink a cold beer. 62% of consumers say they would pay for this product. In having a visual cue on when a product is cold or not it can assist with last minute purchases. If the customer is aware that the beer they are thinking about purchasing is cold by a visual aid and not simply just touch, they may be more inclined to buy. 80% of shoppers consume their alcohol on the date of purchase. Results from a Survey... After collecting data from a Survey of individuals (Male and Female) aged 18 to 32, all of whom were priory enrolled in a post secondary institution or currently are, the following conclusions were drawn: Price sensitivity is high when purchasing alcoholic beverages ( Approximately 60% of the purchase is based off of this alone). Followed by brand knowledge and appearance Consumers are willing to purchase a newly packaged product out of interest if it is placed at the same price point however when a price increase of 5% is added the likelihood of sales drops to around 20%. When consumers are presented with a potential new product approximately 40% of the sale is made on image alone. When purchasing a luxury brand product approximately 75% of consumers will be more inclined to go for the same product if presented in a new package. However this number decreases to 23% when the newly packaged product requires a travel time of +15 minutes. Duracell Battery with POWERCHECK “Smart Power you can see – no more throwing away batteries with power left in them!” History 1996 began selling AA size batteries with testers Ultra Advanced with Powercheck became available near the end of 2009 The ink Uses 2 types of inks 1. 2. Conductive Ink Thermochromic Ink http://cdn.coolest-gadgets.com/wp-content/uploads/duracell-powercheck.jpg The ink Conductive Ink Printed on a flexible plastic that is placed on the side of the battery Connects the electronic current and allows it to flow Generates heat for the thermochromic ink The ink Thermochromic Ink Uses leuco dyes Printed on the other side of the plastic. The Product Printed with thermochromic ink Plastic material Side printed with conductive ink Battery modified from http://www.freepatentsonline.com/5557208.pdf The Product The Product Marketing “Ultra Advanced with POWERCHECK is power that you can see, and it demonstrates Duracell’s commitment to develop products that build on the brand’s strong heritage of reliability and trusted performance. With POWERCHECK, the days of guessing whether a battery has enough power are in the past” - Rick June, Duracell VP and general manager (http://news.duracell.com/press-release/duracell-product-news/duracell-unveils-new-battery-gauge-showingpower-levels) Marketing Retail price is about $8.99 for a pack of 6 AA/AAA batteries Selling points Designed for high-drain/frequently used devices Ex. MP3, digital camera, video game control, etc. To use up the battery until it is empty Lasts 30% longer Marketing Promotion In 2011 between April 19-25, customers are able to partake in an event where they test their own power, which was hitting the Duracell “High Striker” Marketing “This is an ideal platform for consumers to experience the superior power of Duracell Ultra with POWERCHECK™. These batteries are ideal for high-drain devices such as toys and digital devices. No other alkaline lasts longer and with Duracell POWERCHECK™ you can literally see how much power you have left,”- Jason Frichol, head of marketing at the Fore Good Group http://www.bizcommunity.com/PressOffice/PressRelease.aspx?i=142332&ai=58872 Advantages and Disadvantages Advantages Provides consumers information about how much power the battery has when they need it Gives the user the maximum usage of the battery Disadvantages It does not give an exact amount, such as determine the voltage. Thermochromic Ink Considerations Working with Your Print Company Uses Ink can be adjusted to change at different temperatures for its intended use Thermochromic pigment is often used in dyes and paints Recycling Thermochromic Inks Not hazardous or dangerous Treated the same as standard ink for most converters Leuco Dyes Easy to work with Greater range of applications Used by CTI – largest manufacturer of the ink Environmentally sound Don’t interfere with recycling Contents Thermochromic inks contain Gel vehicle, freeflow vehicle, drying agent, lithographic varnish, ink wax, polyester vehicle, polyglycol solvent, colloidal dispersion resin, water and a defoamer Cost More costly than traditional inks Placed in small areas to minimize costs Printing Processes Can be applied to most printing processes Lithographic printing Flexographic printing Rotogravure printing Considerations when printing Certain solvents can ruin the dyes Aldehydes, ketones, diols and many aromatic compounds should not be used with thermochromic inks Can substitute these solvents with a solvent that is not as reactive Considerations when printing Ink must be kept pH neutral Ideally kept between 6.5 and 7.5 pH Ideally kept with low acidity Considerations when printing Printed as a spot colour Requires no mixing with solvents, alcohols or other inks Negative effect on colour and printability Mixing with alcohol results in a permanent colour change Print Quality Considerations Adhesion Best used with absorbent paper and boards Used on a variety of substrates Rub Resistance Low resistance to pressure so it requires a varnish Recommended that it is printed on wax free inks Ink activated at cold temperatures Less than 20°C/68°F Use of a matte laminate Ink activated at hot temperatures Greater than 20°C/68°F Use of a gloss laminate Colour Strength Colour strength of reversible thermochromic ink is weaker than conventional ink Light and translucent inks Light Fastness Recommended for use with little exposure to UV light A protective UV varnish could be used to help protect the ink Ink Film Thickness Requires a thicker ink film thickness due to the light colour Results in more dot gain Reversible thermochromic ink can be printed on other inks for a more vibrant colour Dilution Supplied at an appropriate print viscosity Only water should be used to thin the ink No more than 15% Adding other thinners could alter the effectiveness of the ink Drying Dried with hot air dryers or IR lamps at a maximum of 70°C/158°F If printed product is being stacked make sure there is not too much pressure being applied if the ink is not coated in a varnish Handling 2 part ink system that is to be mixed prior to use Water based ink containers must be kept shut Minimizes evaporation Minimizes skinning Storage Stored in dark, temperature controlled environment (above 25°C/77°F) Make sure it doesn’t freeze Water based screen inks should be stored away from solvents, UV light and high temperatures If ink is unmixed the ink can be stored for 12 months If ink is mixed the ink can be stored for 24 hours Question period Thanks for attending! These presentation slides are now available on our blog at http://inkwithfeelings.wordpress.com You may contact us with questions or comments at: • Email: chromictech@gmail.com • Twitter: @ChromicTech • Facebook: http://www.facebook.com/ChromicTech