MarsHomestead

advertisement

“Bulk Gas Generation and

Storage Systems of the Mars

Homestead Project”

Damon Ellender

MHP Programming Team

DamonE@marshome.org

Design Goals

• Design a Bulk Gas Plant and associated

processes, located on Mars, to meet

settlement and manufacturing needs for O2,

H2, CH4, N2/Ar2 production and storage.

Design Assumptions

• Gas Composition as specified by NASA

• Ready source of water available

• Where possible, known and proven

techologies are used

• CH4 stored and used for fuel

• Initial Storage vessels imported from Earth

Process Assumptions

• Electrolysis:

– 2H20=> 2H2 + O2

• Sabatier Reactor:

– 4H2 + CO2 => 2H2O + CH4

• Compression and Cooling:

– Atmosphere => CO2 (l or s) + N2 (g) +Ar2 (g)

• O2 Liquefaction and Storage:

• CH4 Liquefaction and Storage:

• N2/Ar Liquefaction and Storage:

Process Details

• Electrolysis:

– 2H20=> 2H2 + O2

– Gibbs Free Energy: DG=-237.13 kJ/mol

– 1 Bar , 298K

• Sabatier Reactor:

– 4H2 + CO2 => 2H2O + CH4

– Exothermic after startup

– 1 Bar, 873K

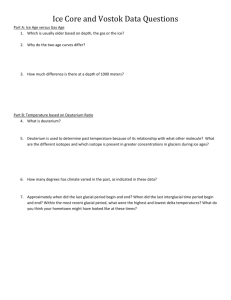

Electrolysis-Sabatier Process

• Basic Electrolysis

assumed

• Hydrogen the

limiting factor

• All water from

Sabatier Process

recycled

Electrical

Power Supply

1 Bar CO2 Supply

0.7 kW

CO2 (5.5 kg)

Redundant Electrolysis Cells

1 bar and 298K

DG=-237.13 kJ/mol

H2O (9 kg)

Sabatier Reactor

1 Bar and 873K

H2 (1kg)

O2 (8 kg)

CH4 (2 kg)

Water Storage Tank

1 bar and 298K

H2O (4.5 kg)

O2 Compression and Storage

50 Bar and 183K

CH4 Compression and Storage

50 Bar and 183K

Gas Liquefaction and Storage

CO2(lr)

CO2(l )

CO2(ll)

Atmosphere

Air

Primary

Compression

20 Bar

Air

Cooling

N2/Ar2

Secondary

Compression

50 Bar

N2/Ar2

1st Stage

Cooling

N2

2nd Stage

Cooling

(Optional0

N2(l)

1

2

3

4

LIN Storage

N2

5

Ar2(l)

CO2(l or s)

Ar Storage

CO2 Storage

Ar

S

c

N2

r N2

Usage

u

b

S

c

Ar2

r Ar

Usage

u

b

CO2

Storage

Sabatier

Processes

Process Flow Diagram-Mars Air Separation and Compression

Wednesday, January 19, 2005

CO2 Basic Separation

• Compression chosen to 20 Bar to keep CO2 in

liquid phase for piping and storage

Specific

Work (kJ/kg)

Compression and Cooling

450

400

350

300

250

200

150

100

50

0

InterCooling

Isentropic

Isothermal

Intercooled

0

•

•

•

•

•

10

Bar (Differential)

20

Compress Mars Atmosphere from .07 to 20 Bar. Provides CO2 Liquid phase

Worst Case Specific Work(Isentropic): -421 kJ/kg

Best Case Specific Work(Isothermal): -199 kJ/kg

Isentropic Dt=~500K requires Inter-cooling: -747 kJ/kg

Additional Compression Cooling to liquefy Ar/N2 gas: -120 kJ/kg

Storage Vessel Design

2500

Volume (m3)

2000

1500

10 Bar

40 Bar

1000

500

0

O2

CH4

Ar2/N2

• Storage for 4 Months full usage

• Higher Pressures Selected to minimize imported

pressure vessel mass

Storage Vessel Design

35

Mass (tonne)

30

25

Steel

Aluminum

Titanium

20

15

10

5

0

O2

CH4

Ar2/N2

• Spherical Vessels

• Maximum Allowable Working Pressure (MAWP)= ~42 Bar

• Composite Vessels are expected to reduce Titanium Mass by 1/2

Summary Power Matrix

Phase One-(2 Years) Gas Production to Storage

Assume full production to storage. Fill 1 Month Emergency Storage in 1 Year.

Gas

Instantaneous Demand

Long Term Storage

Daily Use (kg)

Capacity* (kg/day)

Power (kw)

Emergency Storage

Requirement(kg)

Power (kw)

O2

0

0

157.775

57587

14

H2*

0

0

20.1

-

-

N2/Ar

0

0

4

1461

-

CO2

0

0

156

**16377

-

CH4

0

0

39.56

14439

***

CO2/Ar/N

C&L

3

O2 C&L

2

CH4 C&L

1

Totals:

0

*100% Required for CH4 production

**110kg/day used in CH4 production, excess can be used for cooling.

***Requires some power at start-up, then process self sustaining.

20

Phase Two-(2 Years)All Gas Production to Manufacturing

Gas

Instantaneous

Demand

Refining Needs

Daily Use (kg)

Metals Usage (kg/day)

Plastics Usage(kg)

Power (kw)

O2

70

414

0

110

H2**

2.6

0

60.75

-

N2/Ar

48

0

0

-

CO2

21.8

1515

583.75

-

CH4

5.3

187

0

-

CO2/Ar/N

C&L

30

O2 C&L

8

CH4 C&L

3

Totals:

**Includes H2 used for making CH4, not shown

151

Import Staging

Phase 1 Import Listing Weight and Size

Item

Floor space

m2

Volume

m3

Mass

kg

Assume 50%

reduction using

Composites

CH4 Storage Sphere(r=2.5)*

25

125

4500

(2250**)

O2 Storage Sphere(r=3)*

36

216

8000

(4000**)

Ar/N2 Storage Sphere(r=1.1)*

5

11

500

(250**)

CH4 HX

.25

.125

100

CH4 Sabatier Column

1

2

200

Electrolysis Cells

1

2

200

CO2

N+1 redundancy (est 2 small scroll

units)

4

4

250

O2/CH4/N2/Ar2 Compressors

N+1 redundancy

3

5

600

O2/CH4/N2/Ar2 Heat Exchangers

N+1 redundancy

3

5

400

Total Mass(kg)

14750

(8250**)

Import Staging

Phase 2 Import Listing Weight and Size

Item

Floor space

m2

Volume

m3

Mass

kg

C2H4 Column 1

1

2

200

C2H4 Column 2

1

2

200

m{C2H4} Reactor and catalyst 5

10

200

Electrolysis Cells

4

6

400

Inspection Equipment

1

2

200

Total Mass(kg)

1200