Define Phase Palm Harvester

advertisement

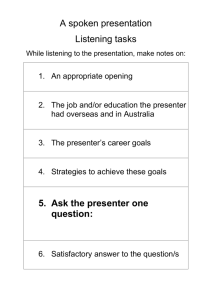

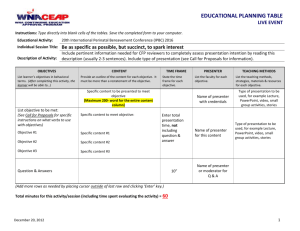

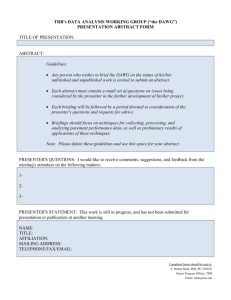

MEASURE PHASE PALM HARVESTER Sponsor: Dr. Okoli Advisors: Dr. Chuy Dr. Frank Team: Talya Levin Thomas Baker Shaneatha Gates Maurice Derius Amber Smith Christopher Chiros 1 PRESENTATION AGENDA Introduction Background Research Recap of the Define Phase Process Improvement Mechanical Systems Overview Budget SWOT Analysis Design Improvement Conclusion Presenter: Maurice Derius 2 INTRODUCTION Improve working conditions at palm plantations Improve last year’s mechanism Define Phase: Gave the areas of improvement Measure Phase: Tests current mechanism in those areas of improvement Presentation Agenda Introduction Presenter: Maurice Derius Background Research 3 BACKGROUND RESEARCH Palm oil is the 2 nd most consumed oil in the world after soybean oil Malaysia is the 2 nd largest producer of palm oil after Indonesia Malaysia has less strict laws on palm oil plantations than Indonesia Introduction Background Research Presenter: Chris Chiros Recap of the Define Phase 4 BACKGROUND RESEARCH Produces 4.08 tons of palm oil and palm kernel oil per hectare per year [2] Introduction Background Research Presenter: Chris Chiros Recap of the Define Phase 5 RECAP OF THE DEFINE PHASE Objective: Create a safe, reliable, inexpensive and competitive device to retrieve palm fruit. Budget: $2,500.00 Improvements: Pulley System Materials Mobility Automation Background Research Recap of the Define Phase Presenter: Chris Chiros Process Improvement 6 PROCESS IMPROVEMENT 0:00- 0:39 0:39- 1:15 1:15-2:15 Disassembling Cart Assembly time: 3:50 2:15-2:25 2:25-3:10 3:10-3:50 1:15-2:15 Disassembling time: 0:00- 0:40 0:40- 1:12 Define Phase Recap 1:12-1:22 1:22-1:50 Process Improvement Presenter: Chris Chiros 1:22-1:50 2:20 1:50-2:05 2:05-2:20 Mechanical Systems Overview 7 MECHANICAL SYSTEMS OVERVIEW Telescoping Pole Cart Pulley System Automation Process Improvement Mechanical Systems Overview Presenter: Talya Levin Telescoping Pole 8 TELESCOPING POLE Mechanical Systems Overview Telescoping Pole Presenter: Talya Levin Shape and Material Stress Deflection Shape and Material 9 CROSS-SECTIONAL SHAPE AND MATERIAL Switched from circular to square cross section Pole rotation is avoided Changed from PVC/Steel to Aluminum Improved ductility Telescoping Pole Shape and Material Presenter: Talya Levin Forces on the Pole 10 FORCES ON THE POLE Shape and Material Forces on the Pole Presenter: Talya Levin Stress 11 STRESS Forces on the Poles Stress Presenter: Talya Levin Deflection 12 DEFLECTION Stress Deflection Presenter: Talya Levin Cart 13 Lowering the Center of Gravity CART Wheels Locking Mechanism Deflection Cart Presenter: Thomas Baker Lowering Center of Gravity 14 LOWERING CENTER OF GRAVITY Pole will rest on the bottom level of the cart Height of pole above cart will decrease Stability of the mechanism will increase Cart Lowering Center of Gravity Presenter: Thomas Baker Wheels 15 WHEELS Pneumatic Swivel Caster Wheels No-Flat Replacement Turf Tire [3] Lowering Center of Gravity Wheels Presenter: Thomas Baker [4] Locking Mechanism 16 LOCKING MECHANISM Old Pivot Model Threaded Tightening Bolt New Pivot Model Circular Alignment Block Pressure Plate Circular Alignment Block Wheels Locking Mechanism Presenter: Thomas Baker Pulley System 17 PULLEY SYSTEM Locking Mechanism Pulley System Presenter: Thomas Baker Inner Pulley System Internal Pulley System 18 INTERNAL PULLEY SYSTEM Current Pulley System Internal Pulley System [5] Pulley System Internal Pulley System Presenter: Thomas Baker Automation 19 AUTOMATION Internal Pulley System Automation Presenter: Shaneatha Gates DC Gear Motor DC Gear Motor 20 DC GEAR MOTOR Compact Light weight 36V needed to power Built-in worm gear Torque Needed: 38.1 N*m [6] Max Torque: 44.8 N*m Automation DC Gear Motor Presenter: Shaneatha Gates Expenses 21 EXPENSES DC Gear Motor Expenses Presenter: Shaneatha Gates Budget 22 BUDGET Part Quantity Price Aluminum Square Tubes Pulleys 4 $787.07 7 $34.46 Wheels 4 $119.96 Motor 1 $500.00 Miscellaneous (nuts, bolts, etc.) Total - $30.00 Expenses $1,471.49 Budget Presenter: Shaneatha Gates Voice of Customer Analysis 23 VOICE OF CUSTOMER ANALYSIS Budget Voice of Customer Analysis Presenter: Amber Smith SWOT Analysis Improved Designs SWOT Analysis 24 SWOT ANALYSIS Strengths Weaknesses • Stronger and more wind resistant material • Automation will simplify controls • Easier to use over manual method • Easy to operate • Large apparatus • Cutting tool at top is not easily controlled • Total process may take longer than traditional method so plantation owners may not see a need for it Opportunities Threats • Rising demand for palm oil • Lack of competition • Reduce labor issues on plantations • Commercial manufacturing • Future designs that may be more efficient • No safe fall method for the fruit Voice of Customer Analysis SWOT Analysis Presenter: Amber Smith Improved Designs 25 IMPROVED DESIGNS Automated Telescoping Pole Square Cross-Section Aluminum Telescoping Pole Lowering Center of Gravity Internal Pulley System Polyurethane Wheels SWOT Analysis Improved Designs Presenter: Amber Smith Gantt Chart 26 GANTT CHART Improved Designs Gantt Chart Presenter: Amber Smith Conclusion 27 CONCLUSION Objective: Create a safe, reliable, inexpensive and competitive device to retrieve palm fruit. Measure Phase Goals: Make measureable improvements to last year’s mechanism Demonstrate difference between last year’s mechanism and current design Create small scale model Next Steps: Order parts & assemble mechanism Gantt Chart Conclusion Presenter: Amber Smith Questions? 28 QUESTIONS 29 REFERENCES [ 1 ] (C o v e r Pic tu re )h ttp ://w w w.s oap q u ee n .co m /b usi n e ss/o n -p al m -o i l/ [ 2 ] " Of fi c i al P al m O i l I n f o rm atio n S o u r c e ." W e l c o m e t o t h e Mal ay s i an P al m O i l B o ar d / / Mal ay si an P al m O i l I n d u st ry / / W as h i ng to n, D C / / 1 202-572-9768. Web. 2 Dec. 2014. < h t t p ://ww w .p al m oi l w orl d.org /ab o ut_m al aysi an -i n dus try.ht ml > . [ 3 ] " 1 0 I n. P n e u m at i c S w i v e l C as t e r ." Har b o r F r e i g ht T o o l s . W e b . 2 D e c . 2 0 1 4 . < h t t p ://ww w .h arb o rf rei g ht .c o m /1 0 -i n ch -p n eu m ati c - swi v el -c aste r 3 8 9 4 4 .h t m l > . [ 4 ] " F ar m & R an c h F R 1 0 3 0 1 0 - I nc h No - F l at R e p l ac e m e n t T u r f T i r e f o r Han d T r u c k s an d U t i l ity C ar t s ." Am az o n . c o m : : W h e e l s F o r C ar t : P at i o, L awn & G ar d e n . W e b . 2 D e c . 2 0 1 4 . < h t t p ://ww w .am az o n.c o m /FR1 0 3 0 1 0 - I n c h-No -Fl atR ep l ace m e n t -U ti li ty/dp/B 0 0 3 OANJ MY > . [ 5 ] Web. 2 Dec. 2014. <http://www.l owes .com/pd_348562 -273 - T7550502_ 0__ ?productI d=3594202 > . [6]"Kinetek Companies ." Kinetek Companies . Web. 2 Dec. 2014. <http://eucl i duniv ersal .com/compani es/i ndex.asp> . 30