Operations Management Class 2 - Supply Chain Research Institute

advertisement

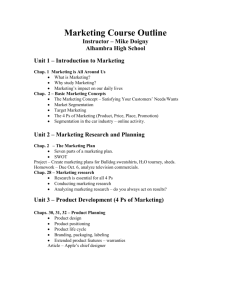

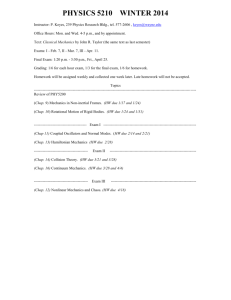

Class 2 Chapter 5 Chapter 6 Syllabus • • • • • • • • • • • • Class 1 (May 21): chap 1; chap 2, case study Class 2: (May 28) Chap 5; chap 6 ( thru 243) Jun 4 – no class Jun 11 – tour of Cabela’s – meet at Cabela’s at 5:45 Class 3: (Jun 11) chap 7; chap 9 (Take home exam) Jun 18 No Class Class 4: (Jun 25) chap 10, chap 11 Summer Break – Jun 29 – Jul 10 Class 5: (Jul 16) chap 6 (243-250); chap 12, The Beer Game Class 6: (Jul 23) Reverse Logistics – need “The Forklifts Have Nothing To Do!” Available in the Lewis and Clark Bookstore; chap 14; chap 16; Supply Chain Security Class 7: (Jul 30) Chap 13; Chap 3 (take home exam) Other requirements: →visit Harley-Davidson Plant in Kansas City to see operations management in practice and write a 3-5 page paper comparing the class slides and readings to the Harley operations → Paper comparing Harley to Cabela’s → Home Work and Quizzes Chapter 5 Products and Services Product Design Specifies materials Determines dimensions & tolerances Defines appearance Sets performance standards Service Design Specifies what the customer is to experience Physical items Sensual benefits Psychological benefits An Effective Design Process Matches product/service characteristics with customer needs Meets customer requirements in simplest, most cost-effective manner Reduces time to market - haste vs. speed to market Minimizes revisions - quality designed into the product Stages in the Design Process Idea Generation — Product Concept - can you create your own market? What role does the voice of the customer play in idea generation? Feasibility Study — Performance Specifications Preliminary Design — Prototype - testing and redesign Final Design — Final Design Specifications Process Planning — Manufacturing Specifications - make to order/stock – assembly line? The Design Process Idea generation Suppliers Product or service concept Feasibility study Performance specifications Form design Customers R&D Marketing Competitors Revising and testing prototypes Production design Functional design New product or service launch Final design & process plans Design specifications Pilot run and final tests Manufacturing or delivery specifications Idea Generation Suppliers, distributors, salespersons Trade journals and other published material Warranty claims, customer complaints, failures Customer surveys, focus groups, interviews Field testing, trial users Research and development More Idea Generators Perceptual Maps Visual comparison of customer perceptions Benchmarking Comparing product/service against best-in-class Reverse engineering Dismantling competitor’s product to improve your own product Perceptual Map of Breakfast Cereals GOOD TASTE LOW NUTRITION HIGH NUTRITION BAD TASTE Perceptual Map of Breakfast Cereals GOOD TASTE Cocoa Puffs LOW NUTRITION HIGH NUTRITION Rice Krispies Cheerios Wheaties Shredded Wheat BAD TASTE Feasibility Study Market Analysis Market Segmentation Economic Analysis Technical / Strategic Analysis Performance Specifications Not unlike mission analysis or Intelligence Preparation of the Battlefield Risk Analysis 1. Identify the Hazards 2.Assess hazards to determine risks. 3.Develop controls and make risk decisions. 4.Implement controls. 5.Supervise and evaluate. From FM 100-14 Preliminary Design How will it look? Create form & functional design Build prototype Test prototype Revise prototype Retest Functional Design (How the Product Performs) Reliability Probability product performs intended function for specified length of time Maintainability Ease and/or cost or maintaining/repairing product Computing Reliability Components in series 0.90 0.90 0.90 x 0.90 = 0.81 Computing Reliability Components in series 0.90 0.90 0.90 x 0.90 = 0.81 Components in parallel 0.90 R2 0.95 + 0.90(1-0.95) = 0.995 0.95 R1 System Availability MTBF System Availability, SA = MTBF + MTTR System Availability MTBF System Availability, SA = MTBF + MTTR PROVIDER MTBF (HR) MTTR (HR) A B C 60 36 24 4.0 2.0 1.0 System Availability MTBF System Availability, SA = MTBF + MTTR PROVIDER MTBF (HR) MTTR (HR) A B C 60 36 24 4.0 2.0 1.0 SAA = 60 / (60 + 4) = .9375 or 93.75% SAB = 36 / (36 + 2) = .9473 or 94.73% SAC = 24 / (24 + 1) = .96 or 96% Production Design Part of the preliminary design phase Simplification Standardization Modularity Final Design & Process Plans Produce detailed drawings & specifications Create workable instructions for manufacture Select tooling & equipment Prepare job descriptions Determine operation & assembly order Program automated machines Improving the Design Process Design teams Concurrent design Design for manufacture & assembly Design to prevent failures and ensure value Design for environment Measure design quality Utilize quality function deployment Design for robustness Engage in collaborative design Breaking Down Barriers to Effective Design Design Teams Preferred solution = cross functional teams Marketing, manufacturing, engineering Suppliers, dealers, customers Lawyers, accountants, insurance companies Concurrent Design Improves quality of early design decisions Decentralized - suppliers complete detailed design Incorporates production process Scheduling and management can be complex as tasks are done in parallel include the customer in the process!! Design for Manufacture and Assembly Design a product for easy & economical production Incorporate production design early in the design phase Improves quality and reduces costs Shortens time to design and manufacture also known as Design for Six Sigma Design for Six Sigma • Define – the goals of the design activity • Measure – customer input to determine what is critical to quality from the customers’ perspective – what are customer delighters? What aspects are critical to quality? • Analyze – innovative concepts for products and services to create value for the customer • Design – new processes, products, and services to deliver customer value • Verify – new systems perform as expected DFM Guidelines ü Minimize the number of parts, tools, fasteners, and assemblies ü Use standard parts and repeatable processes ü Modular design ü Design for ease of assembly, minimal handling ü Allow for efficient testing and parts replacement Design for Assembly (DFA) Procedure for reducing number of parts Evaluate methods for assembly Determine assembly sequence Design Review Failure Mode and Effects Analysis (FMEA) A systematic approach for analyzing causes & effects of failures Prioritizes failures Attempts to eliminate causes Value Analysis (Value Engineering) Is there value added? Ratio of value / cost Assessment of value : 1. Can we do without it? 2. Does it do more than is required? 3. Does it cost more than it is worth? 4. Can something else do a better job 5. Can it be made by less costly method, tools, material? 6. Can it be made cheaper, better or faster by someone else? Should we contract it out? Design for Environment Design from recycled material Use materials which can be recycled Design for ease of repair Minimize packaging Minimize material & energy used during manufacture, consumption & disposal green laws in Europe - Examples • Recycling of oil • carpets in land fills - 4 billion pounds in land fills annually • Xerox and Hewlett-Packard - pay for return of printer cartridges on larger printers Metrics for Design Quality ü Percent of revenue from new products or services ü Percent of products capturing 50% or more of the market ü Percent of process initiatives yielding a 50% or more improvement in effectiveness ü Percent of suppliers engaged in collaborative design Metrics for Design Quality ü Percent of parts that can be recycled ü Percent of parts used in multiple products ü Average number of components per product ü Percent of parts with no engineering change orders (ULLS/SAMS/SARSS) ü Things gone wrong - should be identified by the returns process Quality Function Deployment (QFD) Translates the “voice of the customer” into technical design requirements Displays requirements in matrix diagrams First matrix called “house of quality” Series of connected houses Design for Robustness Product can fail due to poor design quality Products subjected to many conditions Robust design studies Controllable factors - under designer’s control Uncontrollable factors - from user or environment Designs products for consistent performance Consistency is Important Consistent errors are easier to correct than random errors Parts within tolerances may yield assemblies which aren’t Consumers prefer product characteristics near their ideal values Characteristics of Services • • • • • • • • • Services are intangible Service output is variable Service have higher customer contact Services are perishable Service inseparable from delivery Tend to be decentralized and dispersed Consumed more often than products Services can be easily emulated Call girl principle – value diminishes after service is rendered A Well-Designed Service System is Consistent with firm’s strategic focus Customer friendly Easy to sustain Effectively linked between front & back office Cost effective Visible to customer Chapter 6 Processes and Technologies Process Strategy Overall approach to producing goods and services Defines: Capital intensity Process flexibility Vertical integration Customer involvement Types of Processes Projects Batch production Mass production Continuous production Process Selection with Break-Even Analysis Total cost = fixed cost + total variable cost TC = cf + vcv Total revenue = volume x price TR = vp Profit = total revenue - total cost Z = TR - TC = vp - (cf + vcv) Break-Even Analysis Fixed cost = cf = $2,000 Variable cost = cv = $5 per raft Price = p = $10 per raft Break-Even Analysis Fixed cost = cf = $2,000 Variable cost = cv = $5 per boogie board Price = p = $10 per board The break-even point is cf 2000 v= p-c = = 400 boards v 10 - 5 Process Planning Make-or-buy decisions Process selection Specific equipment selection Process plans Process analysis Make-or-Buy Decisions 1. 2. 3. 4. 5. 6. Cost Capacity Quality Speed Reliability Expertise What about Proprietary Information? Barrier to Make-or-Buy? Rationale for Off Shore to Low Country Source 100.00% 94.00% 90.00% 80.00% 70.00% 60.00% 50.00% 37.00% 40.00% 27.00% 30.00% 23.00% 22.00% 21.00% 20.00% 20.00% 10.00% 0.00% $ Savings procured goods Penetration to new market inventory redux inc customer service access new technology Source: Aberdeen Research, “Low-Cost Country Sourcing Success Strategies: Maximizing and Sustaining the Next Big Supply Savings Opportunity,” Jun 2005 reduced cycle time log cost reductions Specific Equipment Selection 1. Purchase cost 2. Operating cost 3. Annual savings 4. Revenue enhancement 5. Replacement analysis 6. Risk and uncertainty 7. Piecemeal analysis – “one piece at a time” Process Plans Blueprints Bill of material Flat or multiple layers - part or assembly Assembly chart / product structure diagram Operations process chart - list of operations involved in assembly Routing sheet - sequence of events Operations Process Chart Part name Crevice Tool Part No. 52074 Usage Hand-Vac Assembly No. 520 Oper. No. Description Dept. Machine/Tools Time 10 Pour in plastic bits 041 Injection molding 2 min 20 Insert mold 041 #076 2 min 30 Check settings & start machine 041 113, 67, 650 20 min 40 Collect parts & lay flat 051 Plastics finishing 10 min 50 Remove & clean mold 042 Parts washer 15 min 60 Break off rough edges 051 Plastics finishing 10 min Process Analysis The systematic examination of all aspects of a process to improve its operation Faster More efficient Less costly More responsive Basic tools Process flowchart Process diagrams Process maps Process Flowchart Symbols Operations Inspection Transportation Delay Storage Process Flowchart Description of process 1 Unload apples from truck 2 Move to inspection station 3 Weigh, inspect, sort 4 Move to storage 5 Wait until needed 6 Move to peeler 7 Apples peeled and cored 15 8 Soak in water until needed 20 9 Place in conveyor 5 10 Move to mixing area 11 Weigh, inspect, sort Page 1 0f 3 Total Distance (feet) Location: Graves Mountain Process: Apple Sauce Time (min) Operation Transport Inspect Delay Storage Step Date: 9-30-02 Analyst: TLR 20 100 ft 30 50 ft 360 20 ft 20 ft 30 480 190 ft Process Diagram UPS Active Bins Receiving Reserve Storage Picking Packing Monogramming Embroidering Quality Assurance Back to Vendor Hemming Gift Boxing Shipping Parcel Post Next-Day UPS Process Map Customer Waiter Place order Is order complete? Salad Chef Dinner Chef N Y Give soup or salad order to chef Prepare soup or salad order Prepare dinner order Give dinner order to chef Drink Get drinks for customer Eat salad or soup Deliver salad or soup order to customer Eat dinner Deliver dinner to customer Receives check Deliver check to customer Gives payment to waiter Receive payment for meal Cash or Credit? Credit Cash Collect change, leave tip Bring change to customer Run credit card through Fill in tip amount Return credit slip to customer Collect tip Give order to waiter Give order to waiter Principles for Redesigning Processes • • • • Remove waste, simplify, consolidate Link processes to create value Let the swiftest and most capable execute Capture information digitally and propagate Principles for Redesigning Processes • • • • • Provide visibility through information about process status Fit the process with sensors and feedback loops Add analytic capabilities Connect, collect and create knowledge around the process Personalize the process Other ways to redesign the process • Define • Measure • Improve Velocity Management Methodology • • • • • Define Measure Analyze Improve Control General Electric’s Six Sigma Methodology Techniques for Generating Innovative Ideas Vary entry point to a problem Draw analogies Change your perspective Use attribute brainstorming Information Technology Management Information Systems (MIS) Move large amounts of data Decision Support Systems (DSS) Add decision making support Expert System Recommend decision based on expert knowledge Artificial Intelligence Neural networks Emulate interconnections in brain Genetic algorithms Based on adaptive capabilities in nature Fuzzy logic Simulate human ability to deal with ambiguity Enterprise Software Collect, analyze, and make decisions based on data ERP - Enterprise Resource Planning Managing wide range of processes Human resources, materials management, supply chains, accounting, finance, manufacturing, sales force automation, customer service, customer order entry Finding hidden patterns through data mining ERP • SAP – 42% of market; forecast to 43% in 2006 • Oracle – 20%; forecast to 23% 2006 • Sage Group – 6% • Microsoft – 4% • Horror Stories – Hershey’s, Dell Advanced Communications Electronic data interchange (EDI) Internet, extranets Wireless communications Teleconferencing & telecommuting Bar coding, Radio Frequency Identification Virtual reality Distance Learning? RFID • • • • Active Tags Always on Battery powered Can be read from up to 300 ft • US Army • Savi Tags • • • • • • • Passive Tags Small Must be activated May be turned off England California Rolex Automated Material Handling Conveyors Automated guided vehicle (AGV) Automated storage & retrieval system (ASRS) Grainger/Defense Distribution Center, San Joaquin Flexible Manufacturing Systems (FMS) Programmable machine tools Controlled by common computer network Combines flexibility with efficiency Reduces setup & queue times cellular layout - more on design next week Robotics Programmable manipulators Follow specified path Better than humans with respect to Hostile environments Long hours Consistency Adoption has been slowed by ineffective integration and adaptation of systems Welding at Harley Davidson Plant Next Week • No Class • 11 Jun Cabela’s • 18 Jun: Chapter 7, 9; Handout Mid Term