Alternatives & Links to Leaching Models

advertisement

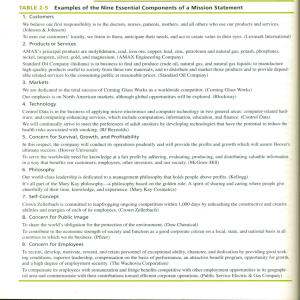

Kinetic Models Considered Jeremy Dyson Basel, Switzerland Introduction Selected core models for parent compounds & metabolites in soil and water-sediment studies Models can be applied to other studies, e.g. hydrolysis Models chosen as simple & sensible approaches to representing behaviour from pseudo-mechanistic to more pragmatic perspectives Models displayed in terms of: Integrated equations based on initial conditions Differential of above for solving new problems Differential equations without initial conditions Endpoint calculation (DT50/DT90) from parameters 2 Outline The Core Models Single First Order Biphasic Models – Gustafson & Holden – Bi-Exponential – Hockey Stick Lag Phase Models – Modified Hockey Stick – Logistic Alternatives & Links to Leaching Models Conclusion 3 Single First Order (SFO) % Remaining Single First Order 100 90 80 70 60 Fixed Shape DT90 = 3.32 x DT50 Assumes microbes not limiting Degradation % Remaining DT50 50 40 30 20 10 0 DT90 0 1 2 3 Time / DT50 4 4 5 Single First Order (SFO) Equation (integrated form) M M0 e k t Underlying differential equation dM k M dt where M = Total amount of chemical present at time t M0 = Total amount of chemical present at time t=0 k = Rate constant Parameters to be determined M0, k Endpoints 100 DTx 100 x k ln 2 DT50 k ln10 DT90 k ln 5 Biphasic Models % Remaining SFO vs. Biphasic 100 90 80 70 60 DT50 50 40 30 20 10 0 0 Generally: DT50s Shorter DT90s Longer DT90 1 2 3 Time 6 4 5 Biphasic Models Some Causes of Biphasic Behaviour Aged sorption Non-linear sorption Declining microbial activity Spatial variations in field Seasonal changes in weather 7 Gustafson & Holden (FOMC) Equation (integrated form) M M0 t 1 Differential equation (to be used only for parameter estimation) 1 dM M dt t 1 where M = Total amount of chemical present at time t M0 = Total amount of chemical applied at time t=0 = Shape parameter determined by coefficient of variation of k values = Location parameter Parameters to be determined M0, , Endpoints 1 100 DTx 1 100 x 1 DT50 2 1 1 DT90 10 1 8 Note: The proposed equation differs slightly from that in the original Gustafson and Holden (1990) reference. The parameter corresponds to 1 / in the original equation. Bi-Exponential (DFOP or FOTC) Equation (integrated form) Differential equation (to be used only for parameter estimation) M M1 e k 1 t M2 e k 2 t or M M0 g e k 1 t 1 g e k 2 t where M = M1 = M2 = M0 = g = k1 = k2 = dM k g e k 1 t k 2 1 g e k 2 t 1 M dt g e k 1 t 1 g e k 2 t Total amount of chemical present at time t Amount of chemical applied to compartment 1 at time t=0 Amount of chemical applied to compartment 2 at time t=0 M1 + M2 = Total amount of chemical applied at time t=0 fraction of M0 applied to compartment 1 Rate constant in compartment 1 Rate constant in compartment 2 Parameters to be determined M1, M2, k1, k2 or M0, g, k1, k2 Endpoints An analytical solution does not exist. DTx values can only be found by an iterative procedure 9 Hockey Stick (HS) Equation (integrated form) Underlying differential equation M M0 e k1 t for ttb dM k1 M dt for ttb M M0 e k1 tb e k 2 t tb for t>tb dM k 2M dt for t>tb where M = Total amount of chemical present at time t M0 = Total amount of chemical applied at time t=0 k1 = Rate constant until t=tb k2 = Rate constant from t=tb tb = Breakpoint (time at which rate constant changes) Parameters to be determined M0, k1, k2, tb Endpoints DTx ln 100 100 x k1 100 ln 100 x k1tb DTx tb k2 10 if DTxtb if DTx>tb Lag Phase Models SFO vs. Lag Phase % Remaining Lag Phase 100 90 80 70 60 50 40 30 20 10 0 0 1 2 3 Time 11 4 5 Modified Hockey Stick Equation (integrated form) M M0 for ttb M M0 e k t tb for t>tb Underlying differential equation dM 0 dt dM k M dt where M = Total amount of chemical present at time t M0 = Total amount of chemical applied at time t=0 k = Rate constant from t=tb tb = Breakpoint (time at which decline starts) Parameters to be determined M0, k, tb Endpoints DTx 12 ln 100 100 x k or DTx ln 100 100 x t b k for ttb for t>tb Logistic Equation (integrated form) M M0 [ amax amax a0 a0 e(r t ) Differential equation (to be used only for parameter estimation) a max ] r a where M = M0 = amax = a0 = r = a0 amax a0 (amax a0 ) e( r t ) Total amount of chemical present at time t Total amount of chemical applied at time t = 0 Maximum value of degradation constant (reflecting microbial activity) Initial value of degradation constant Microbial growth rate Note: For a0 =amax (i.e. activity of degrading microorganisms is already at its maximum at the start of the experiment) the model reduces to SFO kinetics with rate constant amax Parameters to be determined: M0, amax, a0, r Endpoints a 1 100 DTx ln [1 max (1 r a0 100 x r / amax a 1 DT50 ln [1 max (1 2r / amax )] r a0 a 1 DT90 ln [1 max (1 10r / amax )] r a0 13 )] Alternatives & Links to Leaching Models Alternatives models can be used, but: Needs to be justified, e.g. Michaelis-Menten kinetics Need to avoid, where possible: – Time-dependent endpoints – Concentration-dependent endpoints – Large number of parameters – Microbial population dynamics Avoid Timme et al. as already noted in Guideance Identify biphasic kinetics for use in leaching models Not possible, but can link to DFOP for estimation 14 Alternatives & Links to Leaching Models Equilibrium Sorption Kinetic Sorption 15 Non-Degrading Degrading Compartment Compartment Conclusion Core models able to handle most kinetics problems Hence focus on solving problems using these models 16